Splitting and assembling structure and assembling connecting method of assembled type concrete frame-shear wall

A shear wall and concrete technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of inconvenient construction, long lap length, too many roots, etc., and achieve high assembly rate, less sleeves, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

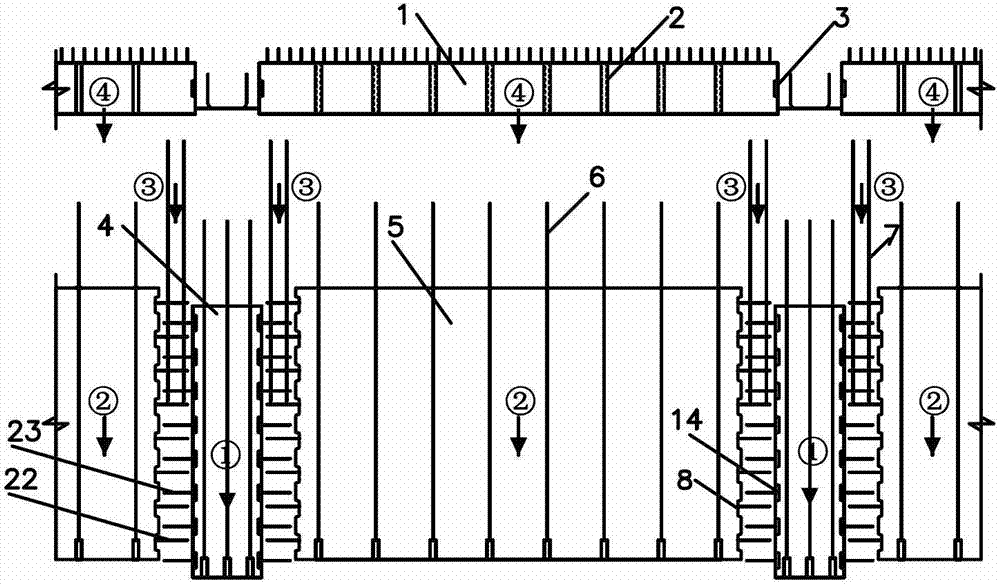

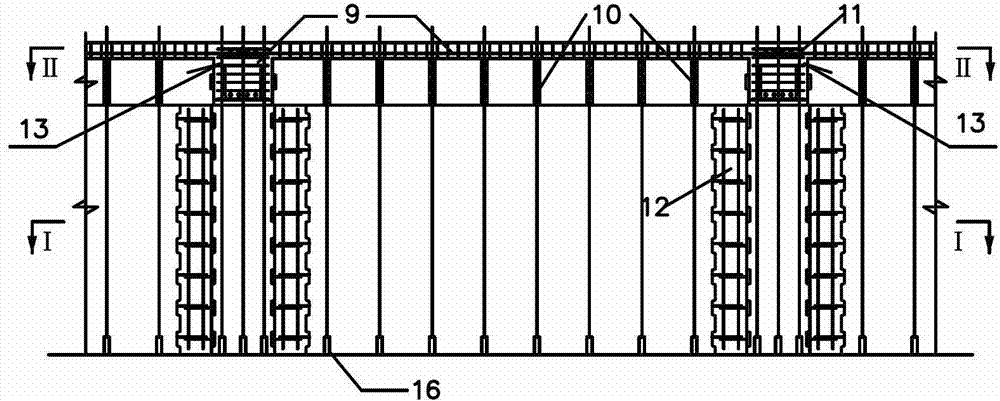

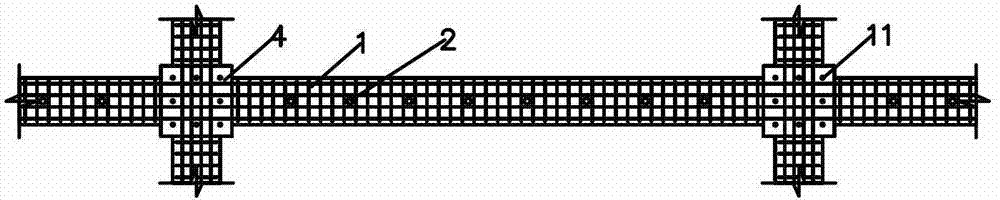

[0069] (1) The implementation scheme shown in Figure 1-3 is a composite beam method, and the prefabricated beam can also adopt a fully prefabricated method.

[0070] (2) The overlap between the beam end of the prefabricated beam and the column should not be less than 20mm, and the beam end face should be provided with a grooved shear key. The anchorage of the longitudinal reinforcement of the prefabricated beam in the core area of the node can be in the form of a hook, or it can be paired with the beam on the other side of the node by a mechanical connection such as sleeve butt joint.

[0071] (3) In addition to the sleeve grouting butt joint method, the connection of the vertical reinforcement (core reinforcement) of the prefabricated shear wall can also adopt the reinforcement grout anchor lap joint with reserved holes.

[0072] (4) In the connection mode of the U-shaped connecting bars between the shear wall and adjacent columns, concealed columns can be formed as require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com