Structure of connecting shear walls and coupling beam by U-shaped steel bars and connecting pieces, and assembling method

A technology of connectors and shear walls, applied in the direction of walls, building components, building structures, etc., can solve the problems of inapplicability and high technical requirements for grouting, and achieve the effects of high assembly rate, shortened construction period, and improved assembly degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0050] like Figure 1 to Figure 19 As shown, the prefabricated concrete U-shaped steel bar-connector of the present invention connects the shear wall coupling beam structure and assembly method, including two specific implementation modes, specifically as follows:

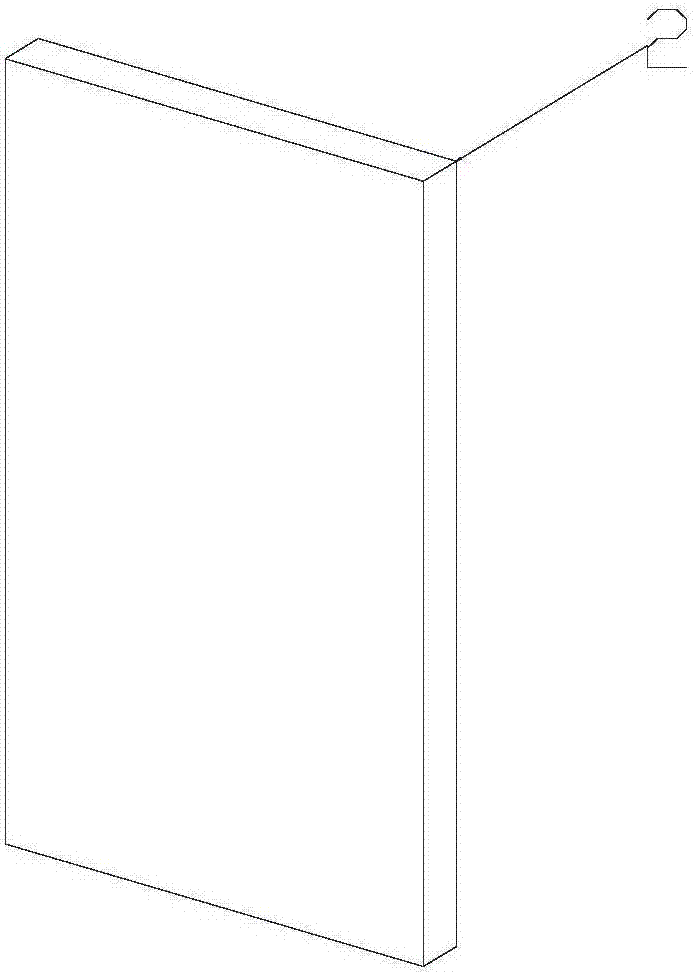

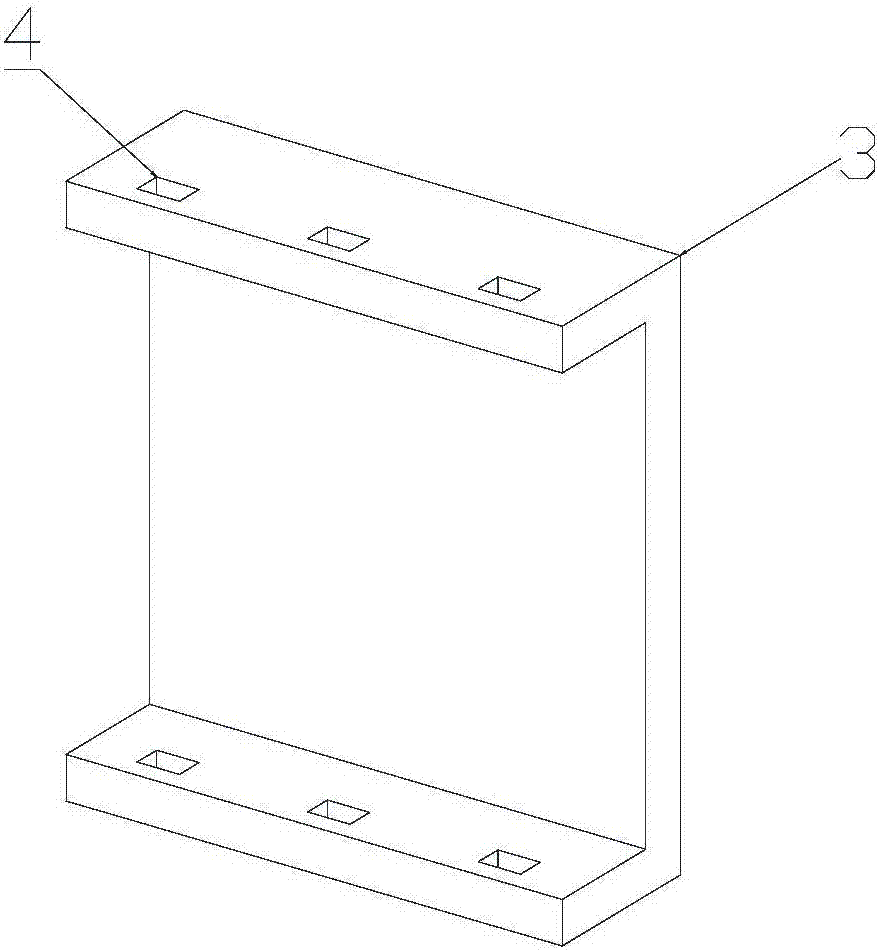

[0051] (one) Figure 1-Figure 16 As shown, when the length of the connecting beam of the shear wall in the prefabricated concrete frame-shear structure is greater than 3m or the project has clear requirements, the two ends of the connecting beam and the connection position of the shear wall are split to form two prefabricated walls 11 and A prefabricated coupling beam 15 constitutes a structural disassembly and assembly system.

[0052] (1) In order to realize the connection between the prefabricated wall 11 and the prefabricated connecting beam 15 , the embedded connecting piece 5 is arranged in the prefabricated wall 11 and the prefabricated connecting beam 15 .

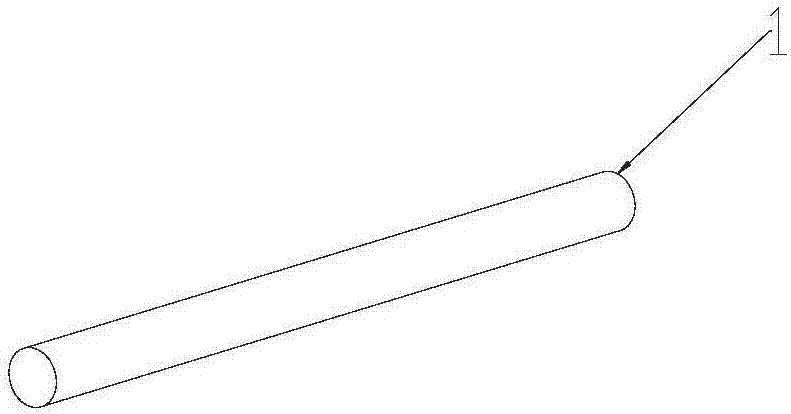

[0053] like Figure 1-Figure 4 As shown, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com