Modular assembly type composite wall and connecting mode thereof

A technology of composite walls and connection methods, applied in the direction of walls, building components, buildings, etc., can solve the problems that the degree of assembly stays at the component level, the overall construction cost increases, and the processing labor costs a lot, etc., to improve the level of shear resistance. capacity, reduce overall cost, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] Production of modular prefabricated composite walls:

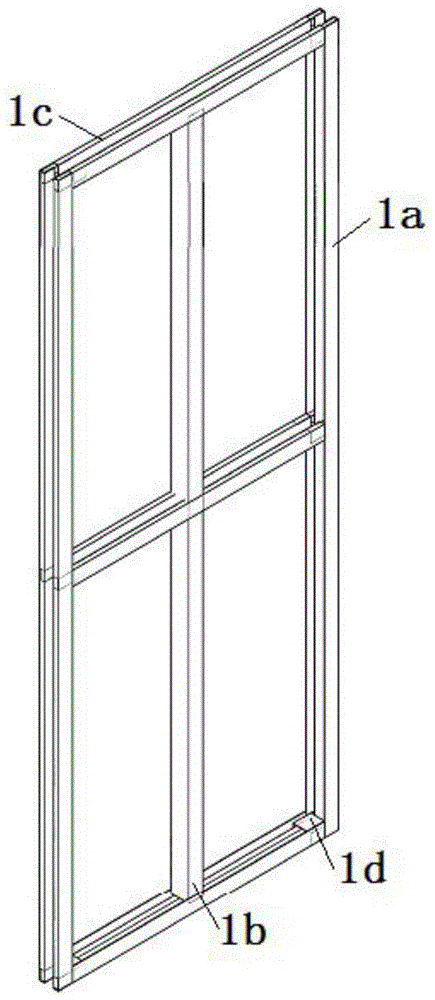

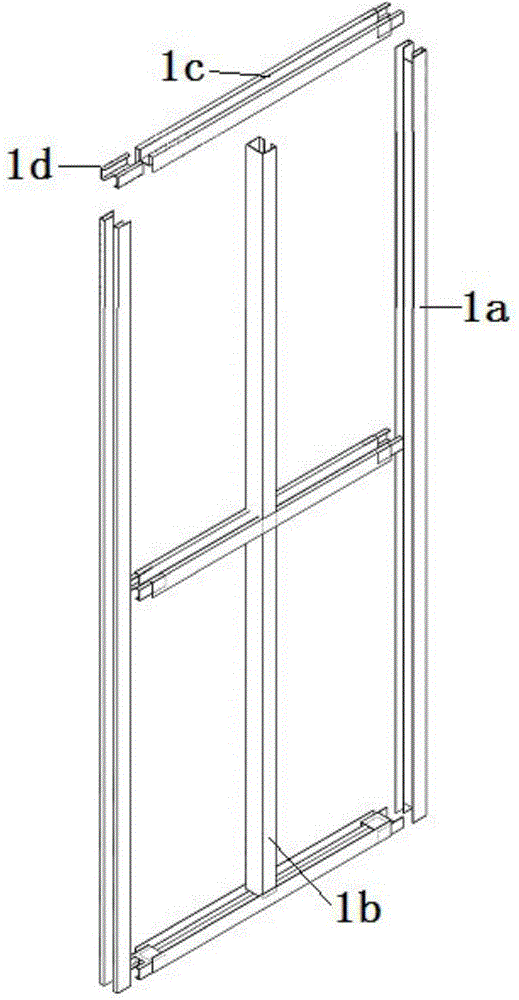

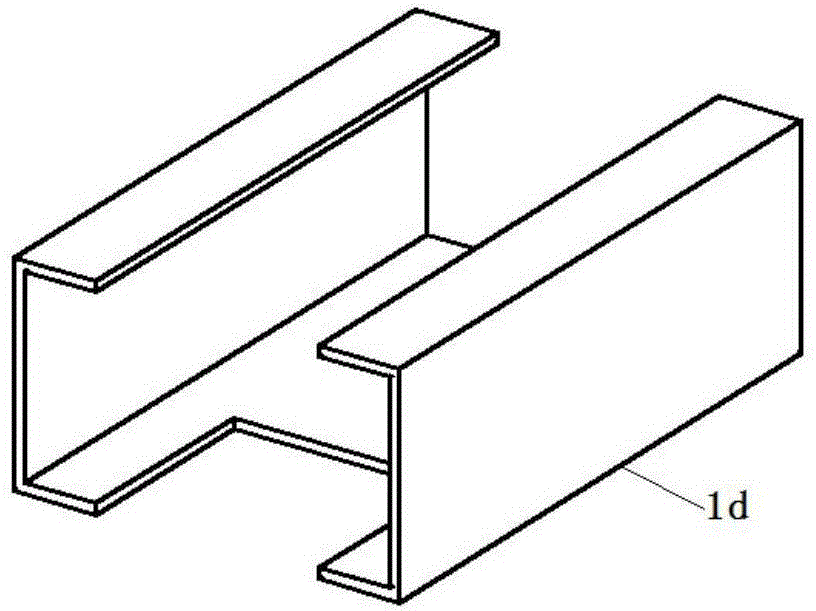

[0038]During the specific implementation, firstly, the vertical M-shaped steel (1a), the vertical C-shaped steel (1b), the horizontal M-shaped steel (1c), and the U-shaped connector are cut according to the modulus size of the modular assembly type composite wall that is actually required. (1d), the above four components according to the attached figure 1 , 2 The form is pre-connected on the factory assembly line, and then according to the attached Figure 4 The connection method is connected with self-tapping screws to form a cold-formed thin-walled steel frame (1);

[0039] The above cold-formed thin-walled steel frame (1) is attached Figure 5 Punch out reserved holes for self-tapping screws and high-strength bolts (7) on the assembly line of intelligent digital stamping equipment in the factory;

[0040] Attached Figure 5 Screw the self-tapping screws into the self-tapping screw reserved holes in the cold-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com