Tree ring type high-strength concrete filled square steel tube column equipped with multiple spiral stirrups

A technology of high-strength concrete and spiral stirrups, applied in the directions of columns, piers, pillars, etc., can solve the problems of unfavorable building space layout and complex joints, and achieve the effects of favorable building space layout, saving building materials, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, but it is not intended to limit the protection scope of the present invention.

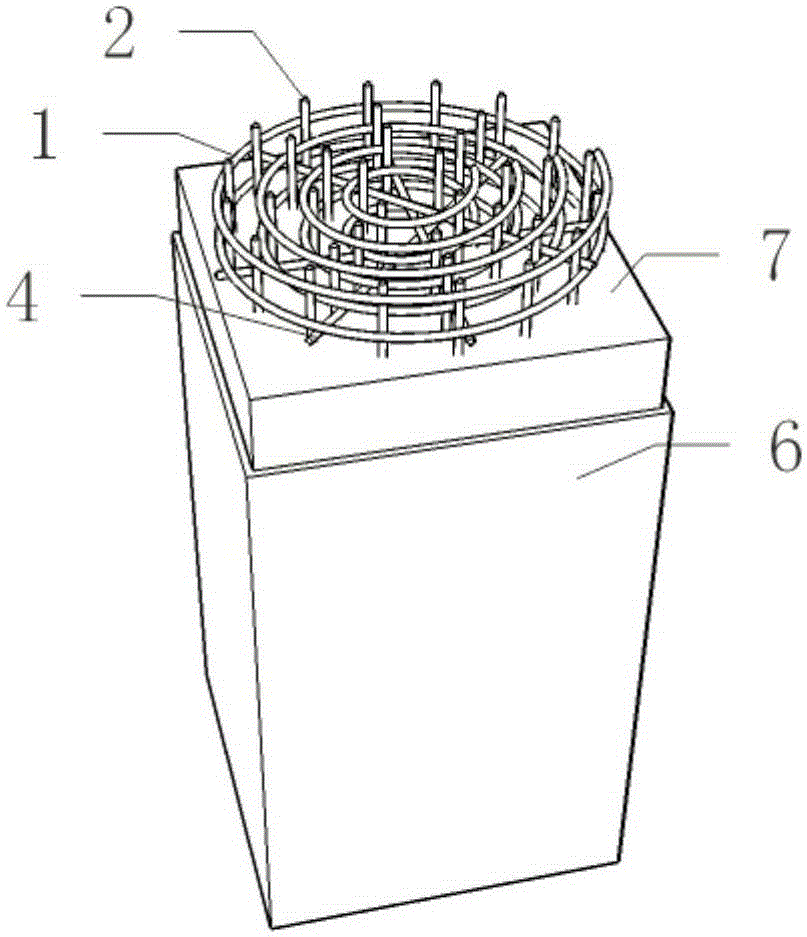

[0026] like figure 1 As shown, the annual ring type high-strength concrete column with square steel tubes with multiple spiral stirrups includes square steel tubes 6, spiral stirrups 1, longitudinal bars 2, transverse radial steel bars 4 and high-strength concrete 7.

[0027] The 6 side lengths of square steel pipes are 2000mm, welded and formed by steel plates with a wall thickness of 40mm, and the steel strength is Q390. The spiral stirrup 1 adopts a steel bar with a diameter of 12 mm, and the longitudinal bar 2 and the transverse radial steel bar 4 both use a steel bar with a diameter of 20 mm. The strength grades of the above steel bars are all HRB400. The pitch of the spiral stirrup 1 is 100mm. The strength grade of high-strength concrete 7 is C80....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com