Connecting joint non-orthogonal to cross column and construction method

A technology for connecting nodes and cross-columns, applied in the direction of buildings, building structures, etc., can solve the problems of overlapping welding seams, difficult to control the positioning accuracy of on-site construction, and difficult welding of non-orthogonal nodes of cross-columns, etc. Small angle and small space welding seam, the effect of welding seam quality is easy to ensure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

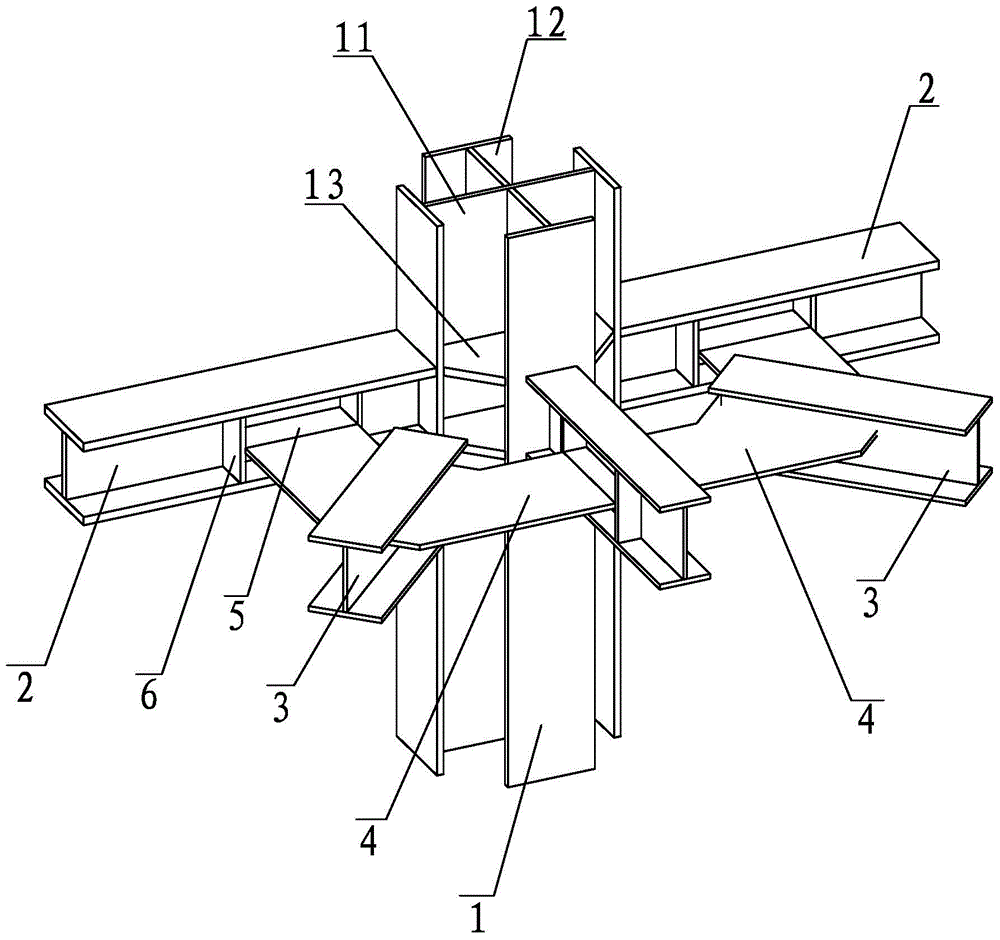

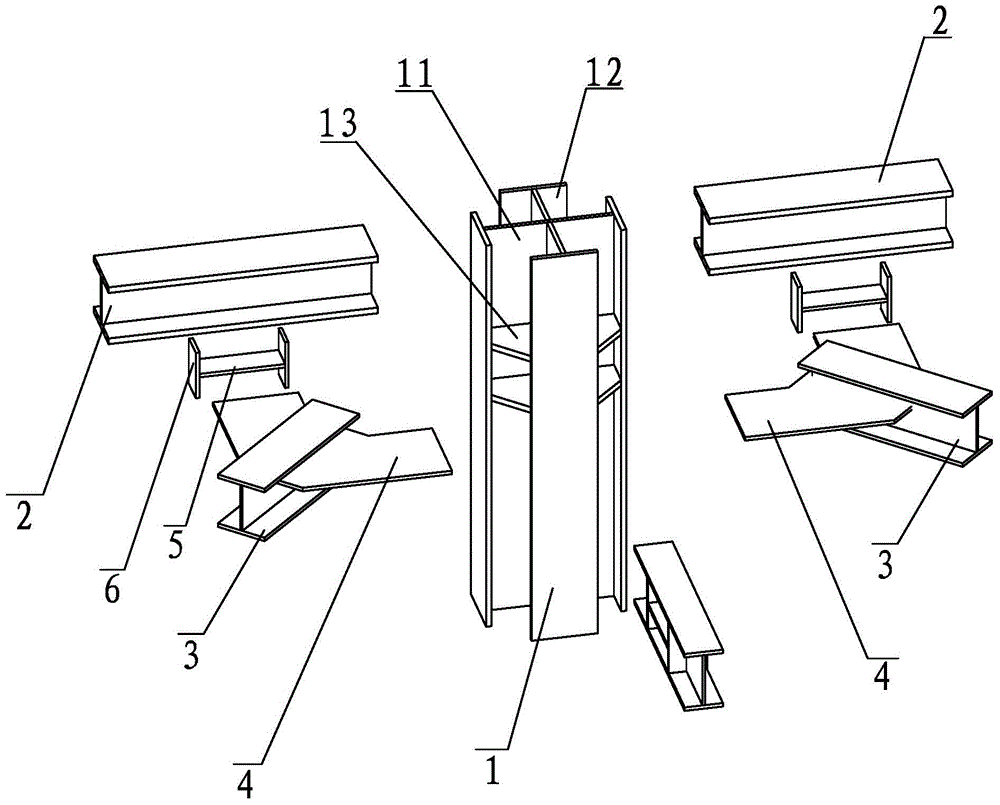

[0023] Such as Figure 1-3 As shown, a connection node that is non-orthogonal to the cross column, the related components include cross column 1, orthogonal steel beam corbel 2, non-orthogonal horizontal member 3, annular connecting plate 4, butt plate 5, stiffening plate 6.

[0024] Orthogonal steel beam corbel 2 and cross column 1 are conventionally welded, butt plate 5 is welded to the web of orthogonal steel beam corbel 2, both sides are reinforced with stiffening plates 6, and non-orthogonal horizontal members 3 are welded to annular connecting plate 4 , The annular connecting plate 4 is welded with the butt plate 5 at the construction site.

[0025] In this embodiment, the cross column 1 is usually a cross column inside a steel reinforced concrete column, which is generally manufactured in a factory.

[0026] Orthogonal steel beam corbel 2 is welded H-shaped steel, the length is generally the same as the height of the orthogonal steel beam web, and then rigidly connected to t...

Embodiment 2

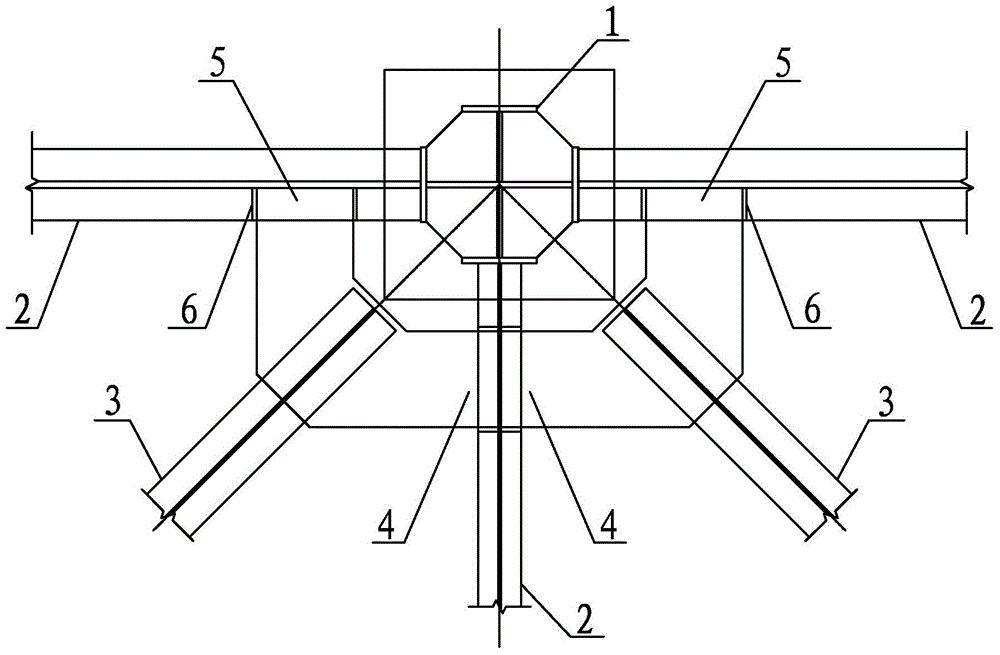

[0030] If the non-orthogonal horizontal member is a steel beam on the floor, the butt plate 5 can be turned into a vertical steel plate, connecting the upper and lower annular connecting plates, and other preferred embodiments of the present invention can be derived. See details Figure 4 .

[0031] The stiffening plates 6 are on both sides of the butting plate 5 to ensure the stability of the butting plate 5, strengthen the bearing capacity of the nodes, and share the force of the webs of the orthogonal steel beam corbels 2.

[0032] The annular connecting plate 4 is welded with the butt plate 5 on the steel beam to realize the connection with the corbel 2 of the orthogonal steel beam, which can avoid the complicated connection between the non-orthogonal member 3 and the cross column 1.

[0033] The ring-shaped connecting plate 4 avoids the outer skin of the steel-concrete column, which can prevent the non-orthogonal member 3 and the cross column 1 from being directly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com