Patents

Literature

78results about How to "Avoid overstretching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

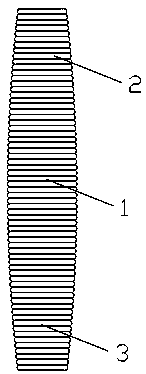

Tire crown for an airplane

ActiveCN102076507AExtend your lifeIncrease wear areaPneumatic tyre reinforcementsTyre tread bands/patternsEngineeringTread

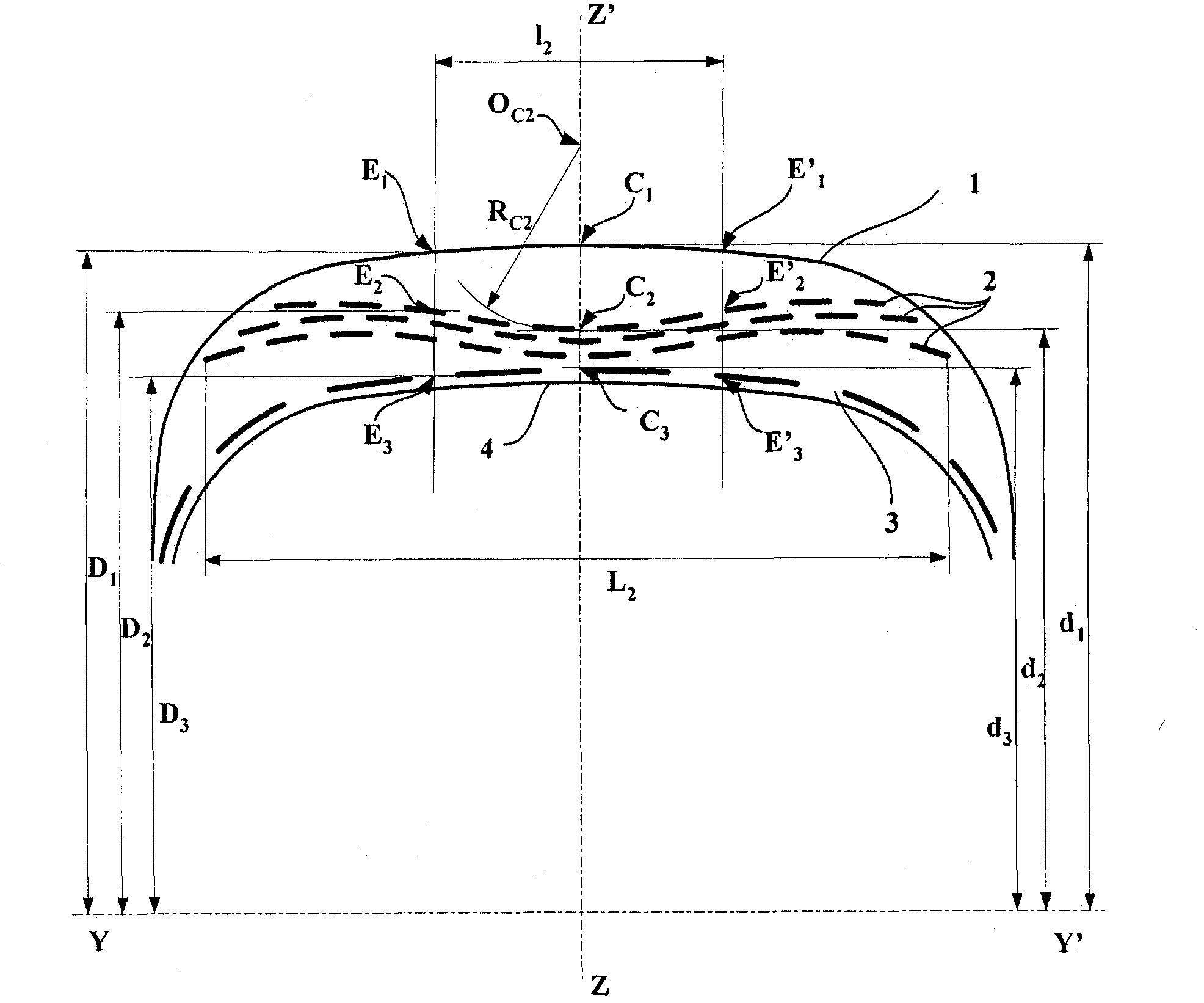

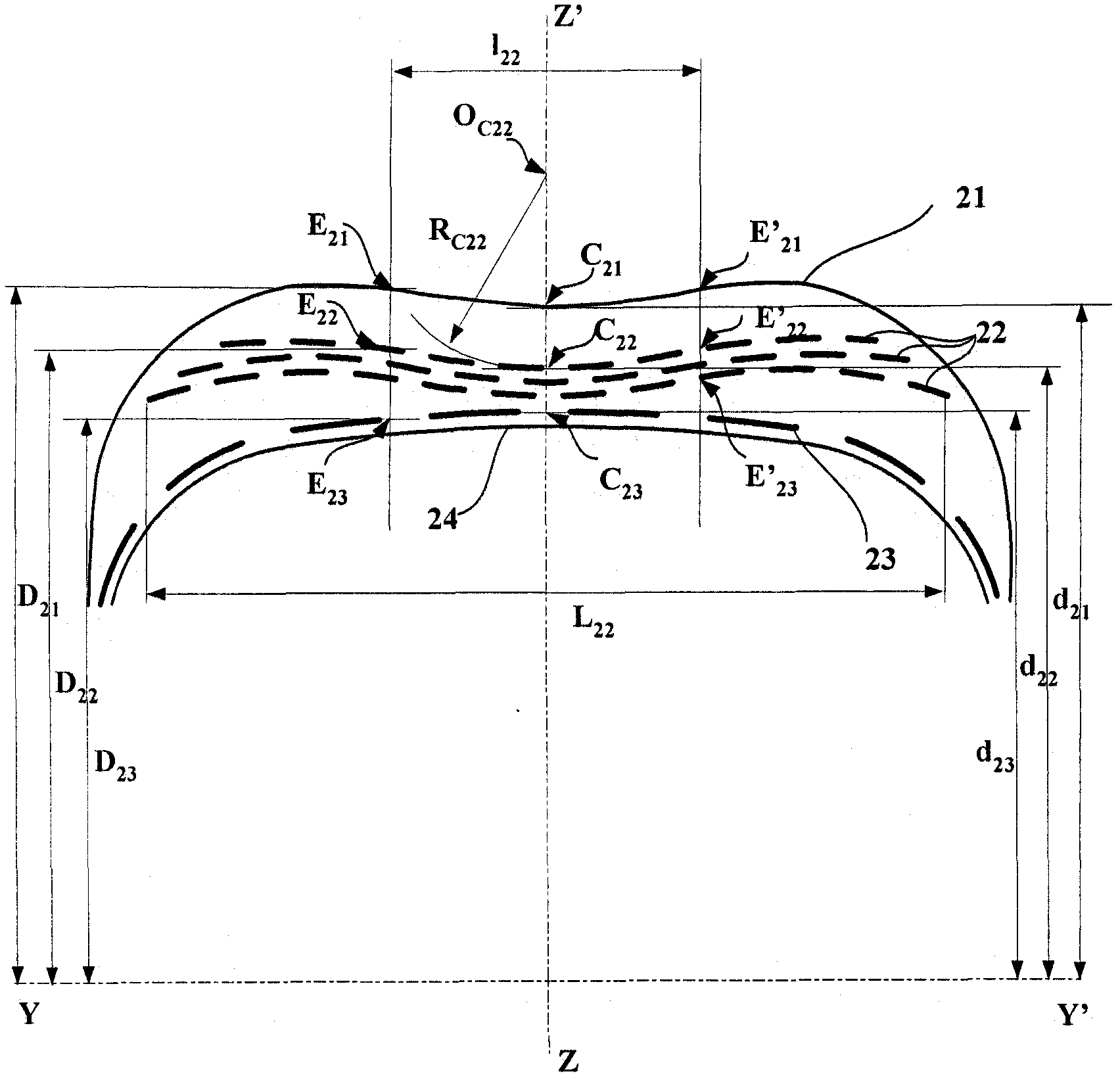

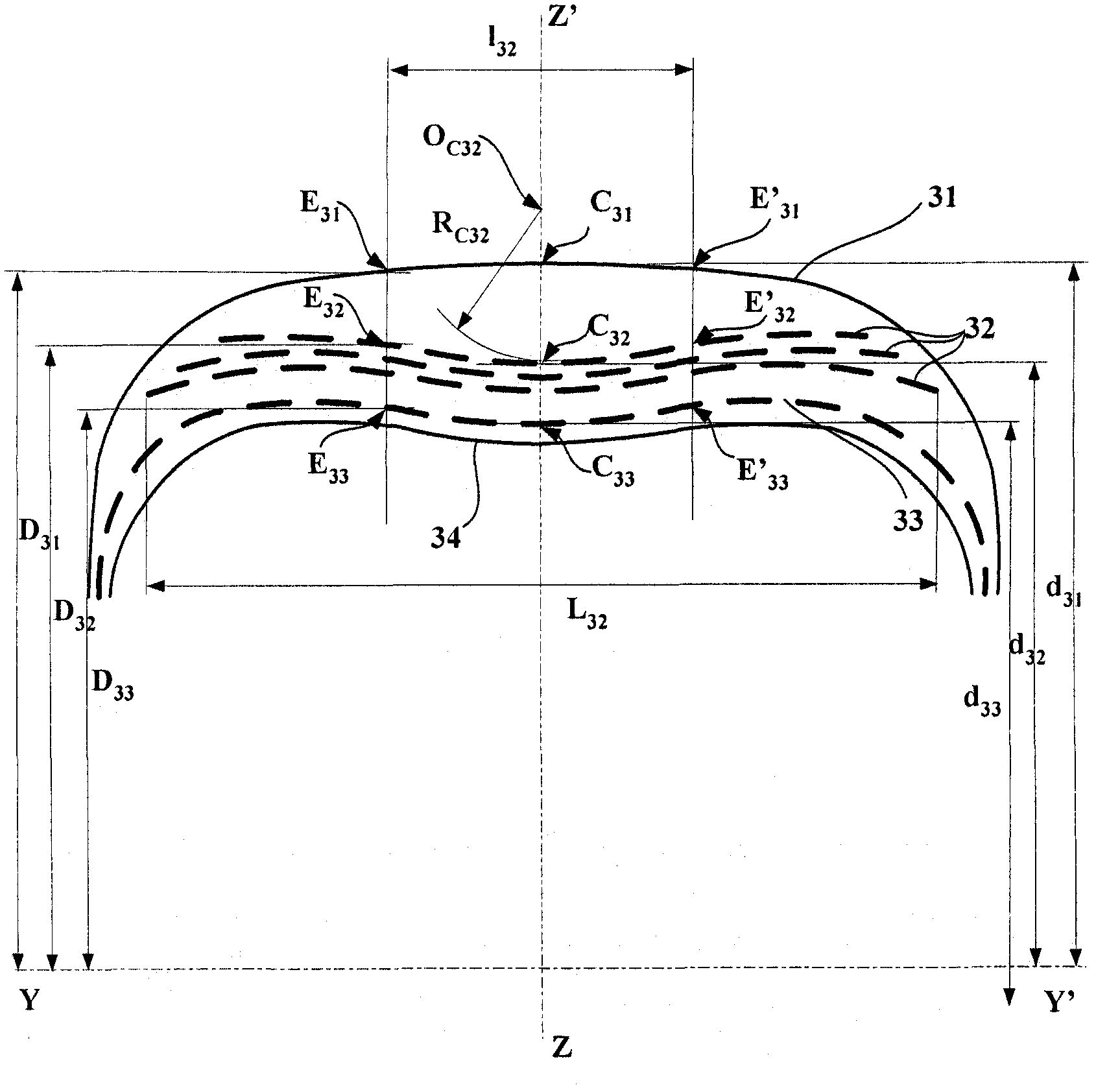

The invention relates to an airplane tire, the nominal pressure of which is greater than 9 bars and the sag of which, under a nominal load, is greater than 30%, including a tread having: a rolling surface (41); a crown reinforcement (42), including at least one layer of reinforcing elements; and a carcass reinforcement (43) including at least one layer of reinforcing elements, said rolling surface (41), crown reinforcement (42), and carcass reinforcement (43) being geometrically defined, respectively, by initial meridian profiles. According to the invention, the initial meridian profile of the crown reinforcement (42) is locally concave on a medial portion having an axial width I42 at least equal to 0.25 times the axial width L42 of the crown reinforcement.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

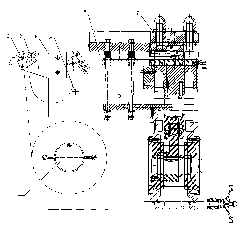

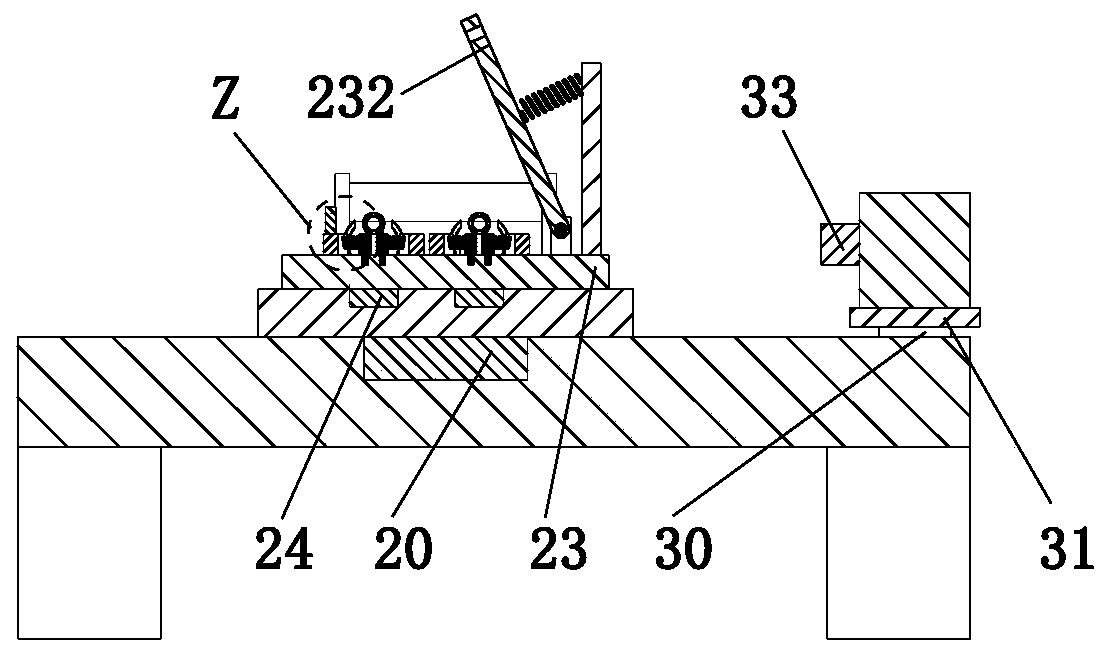

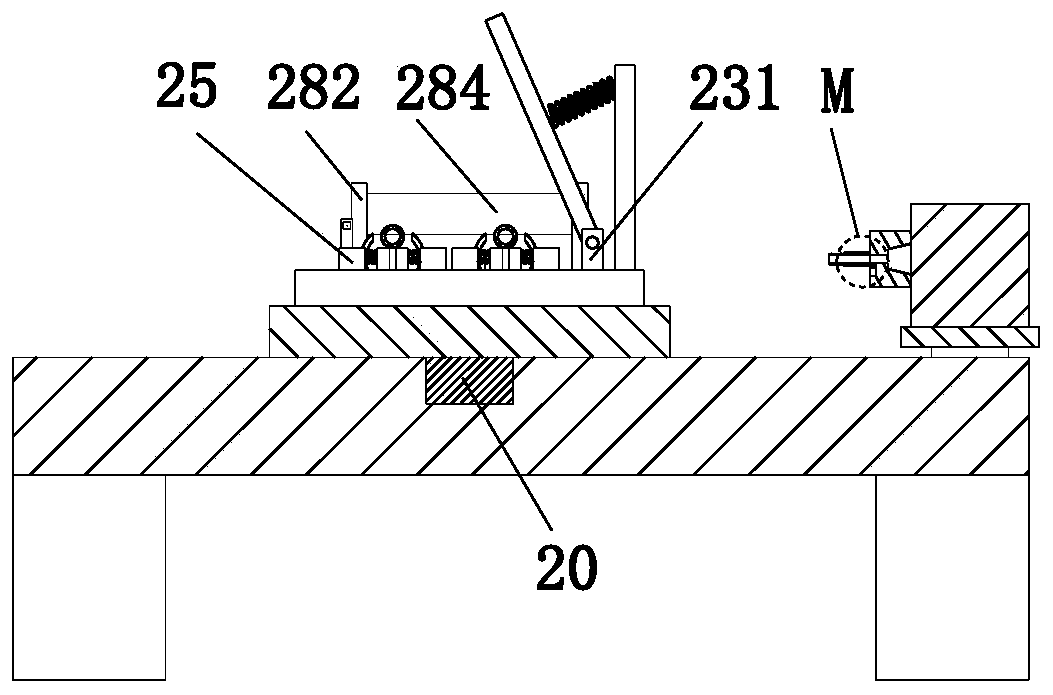

Plastic film pre-feeding device for flat-plate aluminum plastic blister packaging machine

InactiveCN101823578AAvoid overstretchingQuality assuranceWrapping material feeding apparatusPackaging automatic controlPlastic filmBlister pack

The invention discloses a plastic film pre-feeding device for a flat-plate aluminum plastic blister package machine, which is arranged between a plastic film emptying roller and a heating plate for blister shaping. The plastic film pre-feeding device is characterized by comprising a pair of feed rollers which are arranged in a parallel manner and close with each other, wherein, a main feed roller is driven by a motor; an inductive probe is arranged on a plastic film delivery pathway between the feeder rollers and the heating plate for blisters shaping; and the inductive probe is electrically connected with the motor. The plastic film pre-feeding device can prevent the plastic films to be excessively stretched before blister shaping, thereby ensuring the quality of aluminum plastic blister package.

Owner:RUIAN ANTAI PHARMA MACHINERY

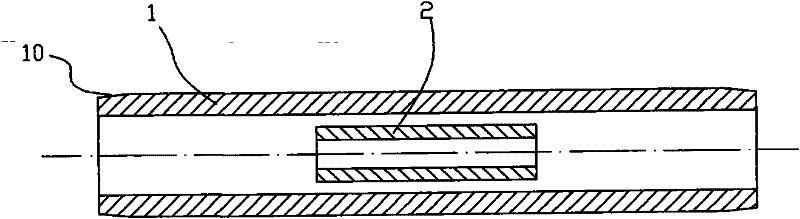

Lead crimping tube

InactiveCN102447169AAvoid corona phenomenonAvoid overstretchingConnections effected by permanent deformationMulticonductor cable end piecesEngineeringElectric power

The invention provides a lead crimping tube and relates to a lead link fitting. The lead crimping tube has advantages of high connection reliability and good effect. The lead crimping tube is characterized in that: tapering is formed respectively at outer surfaces of orifices of two ends of the tube; the internal diameter of the tube is larger than 1 to 5% of the external diameter of the lead; and a ratio of the internal diameter of the tube to the length of the tube is 1 to 5-20. According to the invention, in order to avoid an occurrence of a corona phenomenon at a step between a crimping tube and a lead after the crimping, outer surfaces of orifices of the crimping tube are arranged in a tapering mode; and an optimally selected mode is as follows: the mode of transition to an inner bore edge of the tube is arranged into a curved one. In addition, with regard to an occurrence of a steel-cored aluminium strand product, a connecting tube is added; crimping and connection are carried out on the steel core and then crimping is carried out on the aluminium stranded wire; therefore, a main stretching load is exerted on the steel core and it is avoided the aluminium stranded wire for power transmission is stretched too much. Moreover, the lead crimping tube has high connection reliability and a good conducting effect is realized after the connection.

Owner:江苏华厦电力成套设备有限公司

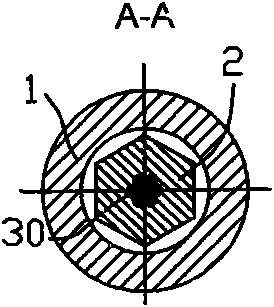

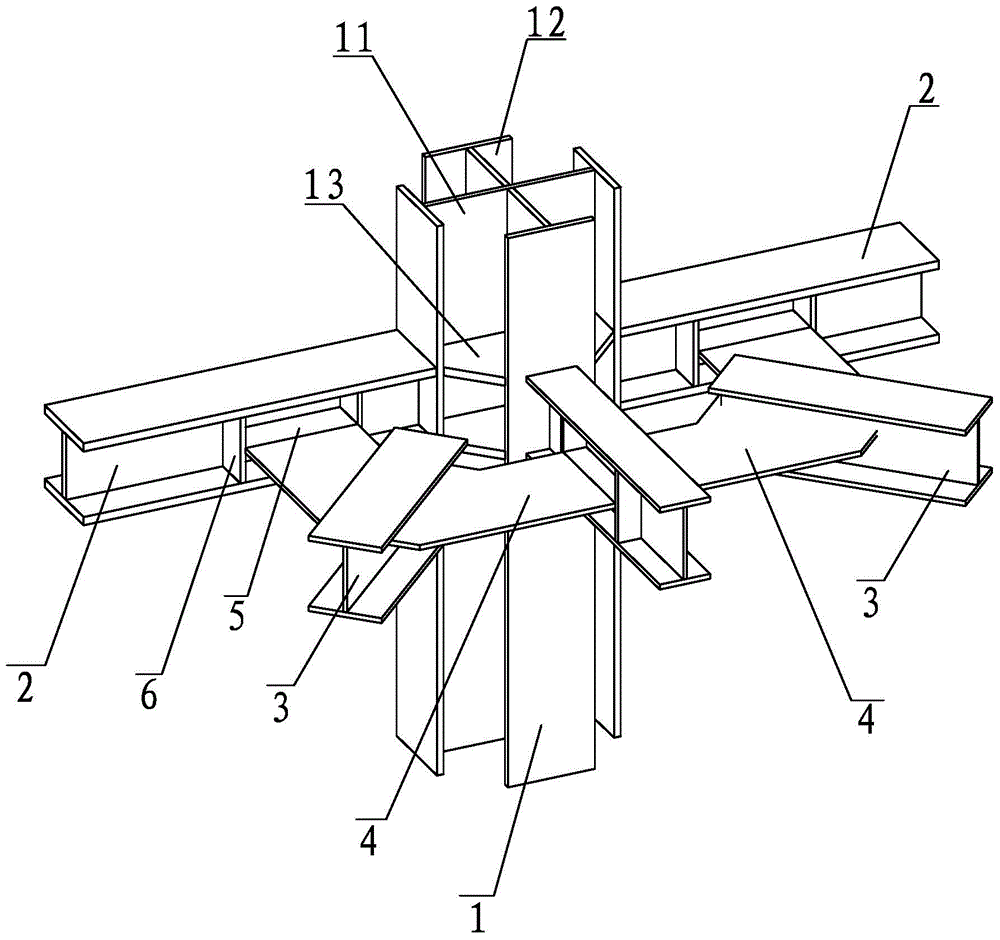

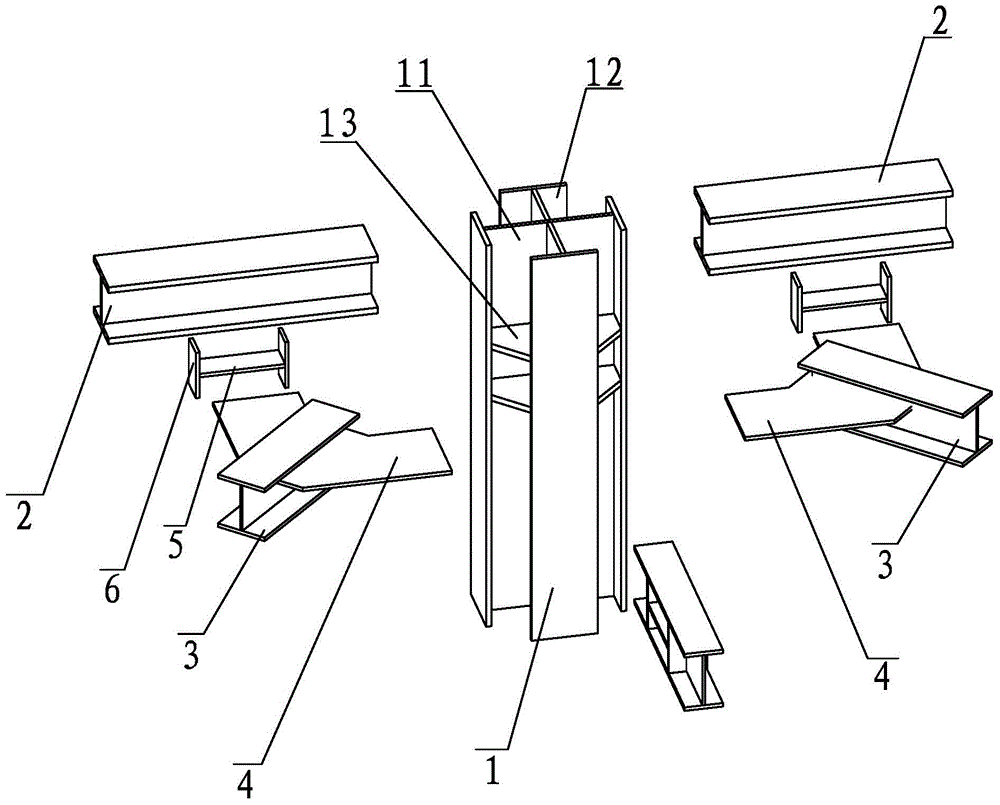

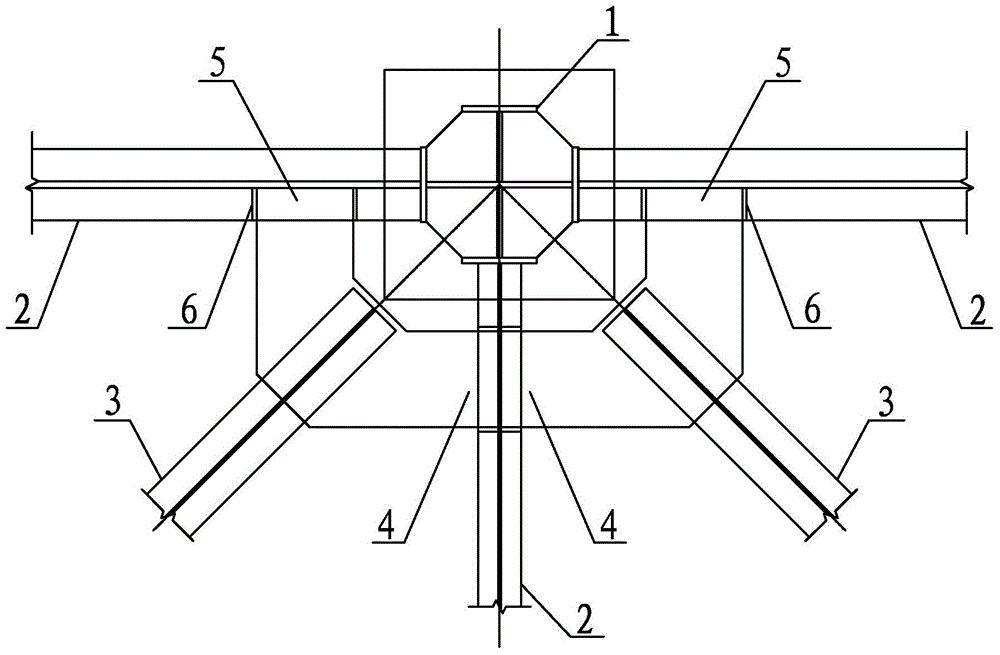

Connecting joint non-orthogonal to cross column and construction method

InactiveCN105220767AReduce the number of weldsReduce welding difficultyBuilding constructionsRebarNon orthogonal

The invention belongs to the field of steel structures, and particularly relates to a connecting joint non-orthogonal to a cross column and a construction method. The connecting joint non-orthogonal to the cross column comprises the cross column and steel brackets, wherein the steel brackets are welded to a peripheral surface of the cross column in an orthogonal mode; an annular connecting plate is fixedly welded between the adjacent steel brackets; and a horizontal component is fixedly welded on the annular connecting plate. Problems that connecting plates and stiffening ribs which correspond to a non-orthogonal component in a cross column are welded difficultly, weld joints are overlapped, rebars penetrate in steel plates, field construction positioning precision is difficult to control and the like are solved, after certain modification, various stress requirements can be met, a large amount of costs can be saved, and manufacturing and mounting efficiency is improved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

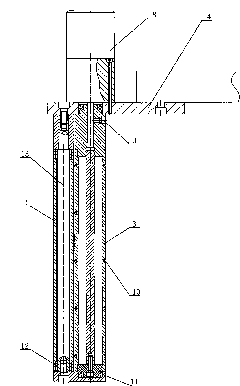

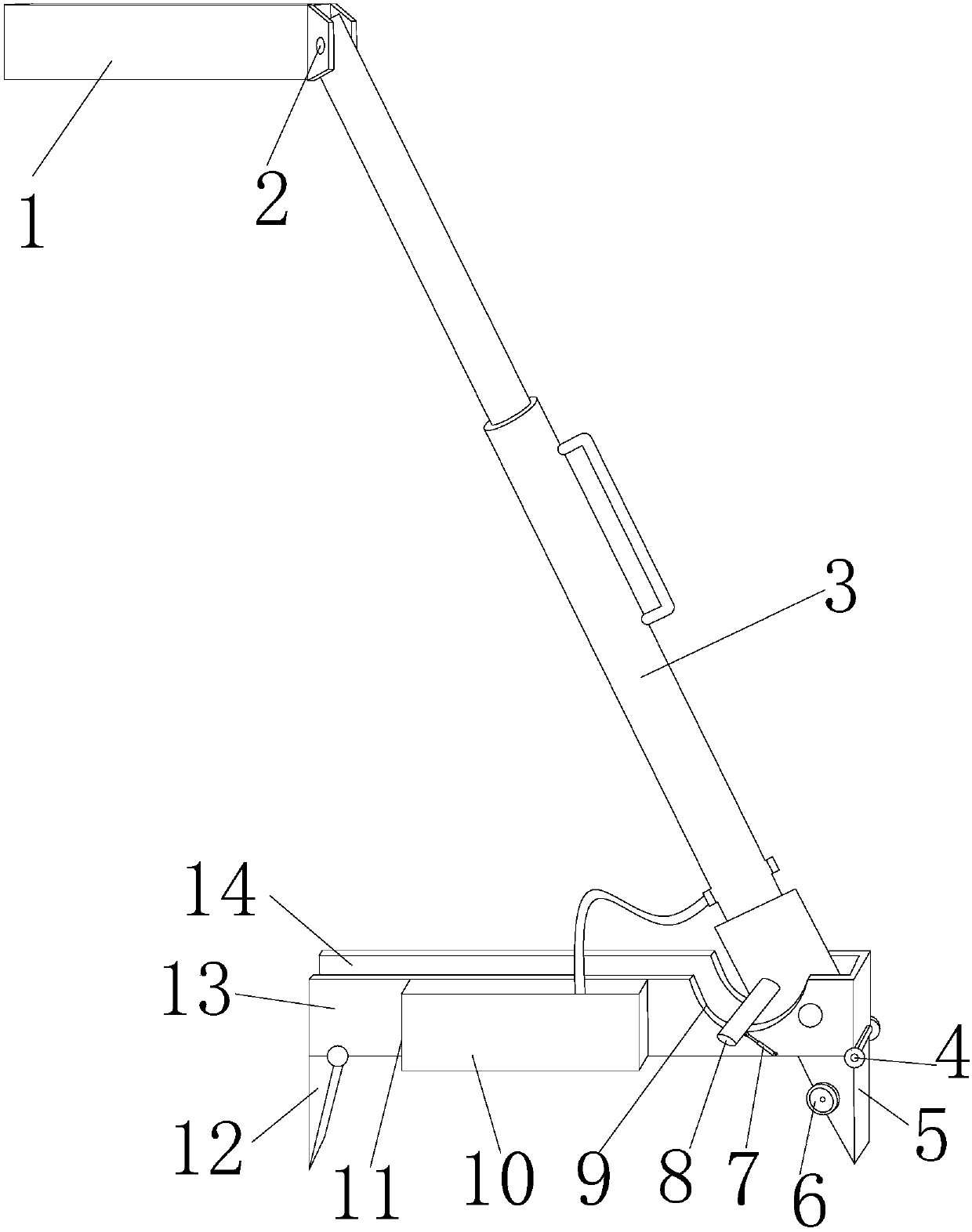

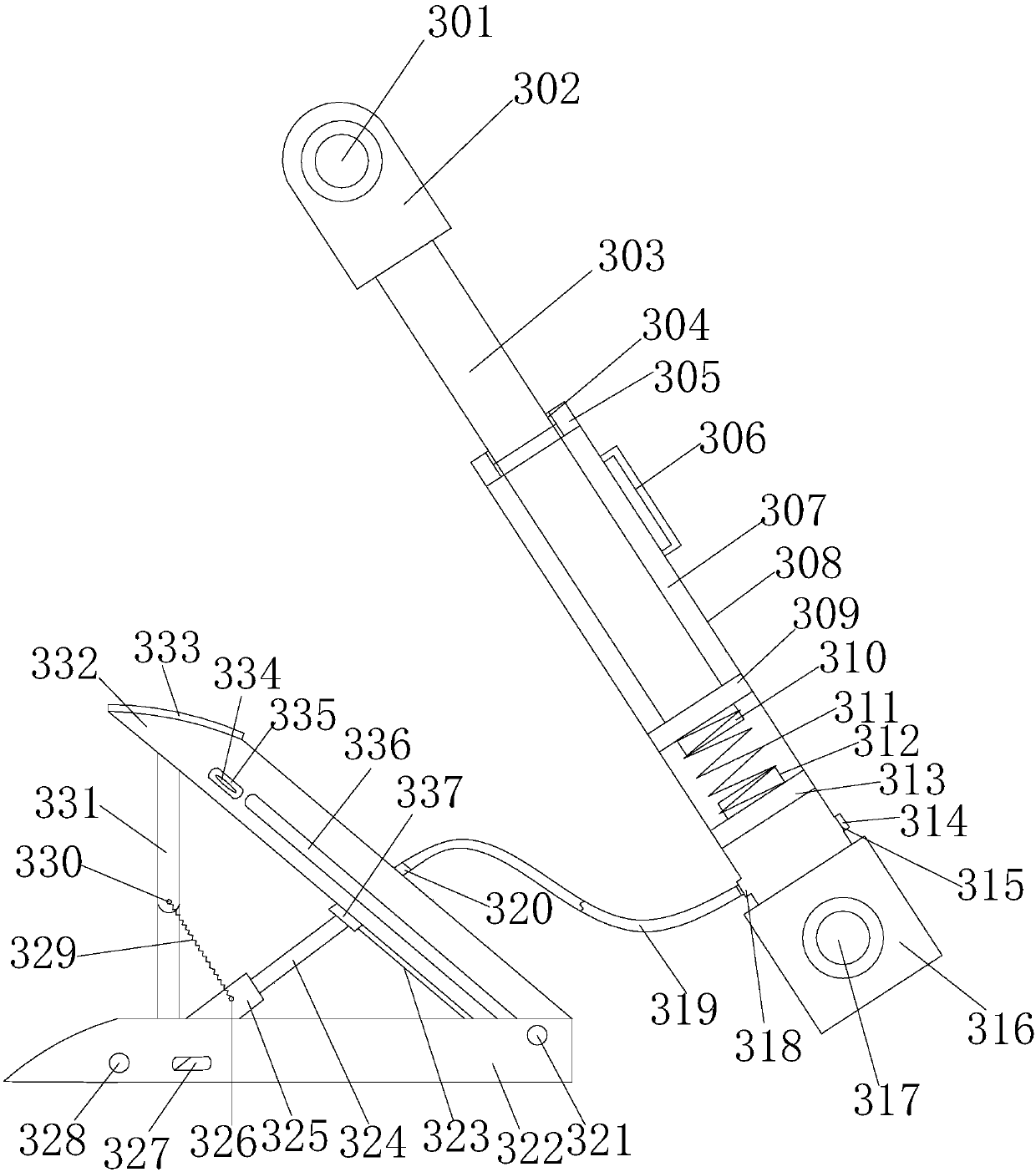

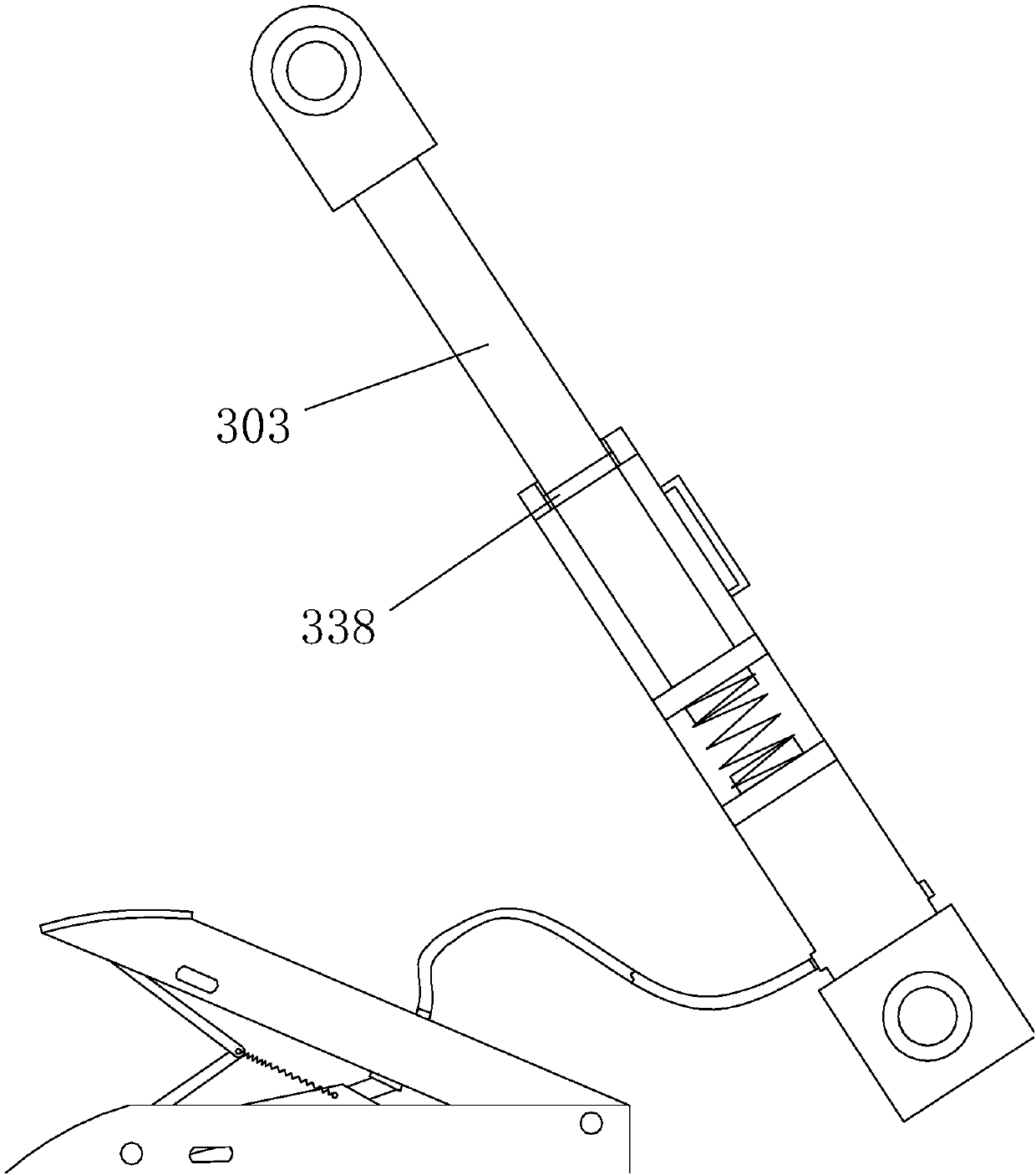

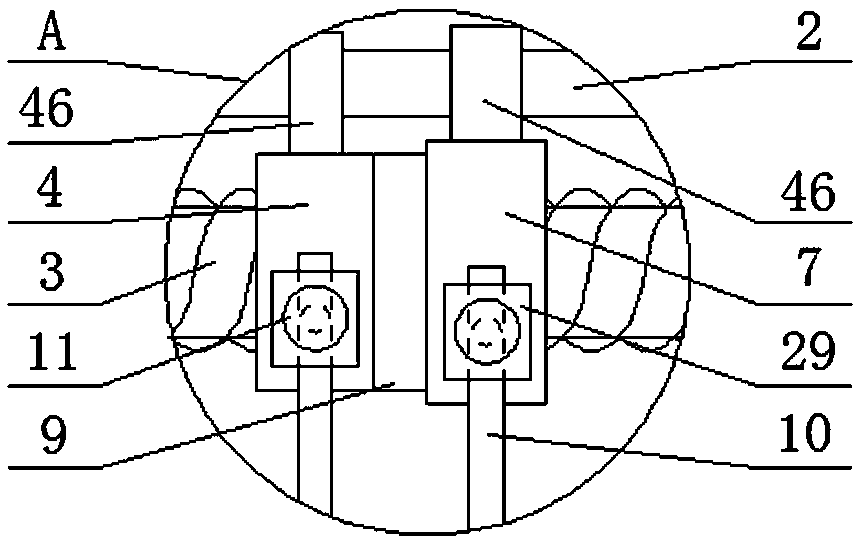

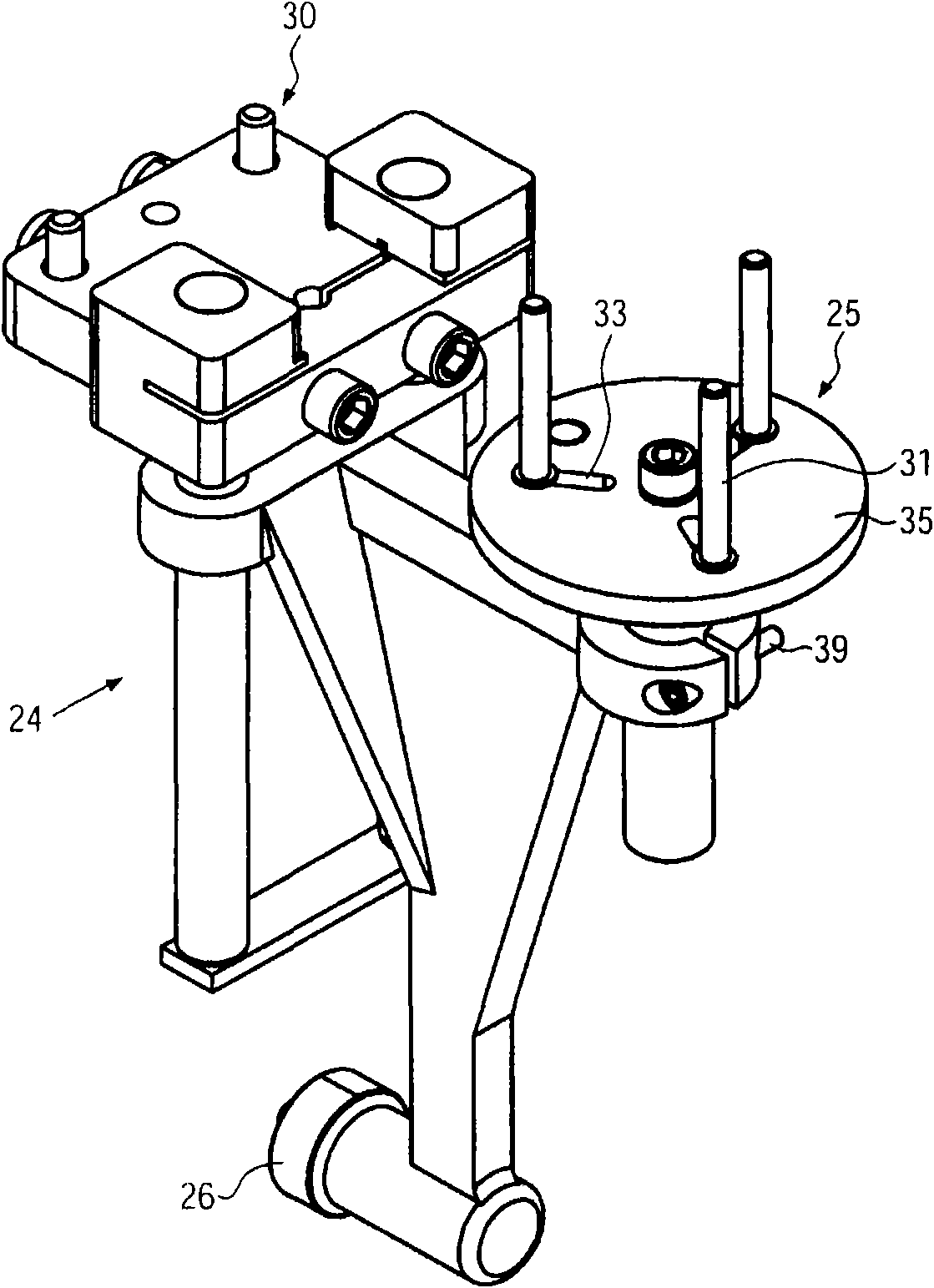

Pole centralizer special for electric power overhaul of rural area electricity and being used by single person

ActiveCN107762251AAvoid overstretchingSave manpower and material resourcesTowersElectricityHydraulic cylinder

The invention discloses a pole centralizer special for electric power overhaul of rural area electricity and being used by single person. The pole centralizer structurally comprises an adjustable clamping hoop, hinge columns, a telescopic device, a hinge shaft, a rear inserting plate, universal wheels, a hydraulic cylinder, lifting and pulling handles, notches, a storing box, a storing opening, afront inserting plate, a base and a groove; the top of the telescopic device is in hinged connection with one end face of the adjustable clamping hoop through the hinge columns, and the telescopic device can also be movably connected with the two inner sides of one end of the base through the hinge columns; two hinge columns are mounted; lifting and pulling handles which are parallel and symmetrical are fixed to the two sides of the bottom of the telescopic device. According to the single pole centralizer special for electric power overhaul of the rural area electricity, the telescopic devicewhich can be pressed by foot stepping is arranged, so that operator conducts operations such as sleeving, hoop clamping and the like by hands, and operations can also be conducted by feet, that is tosay, centralizing and overhauling work of a pole can be conducted only by one person, manpower and material resources are saved, and the working efficiency is improved.

Owner:安徽众力农业装备科技有限公司

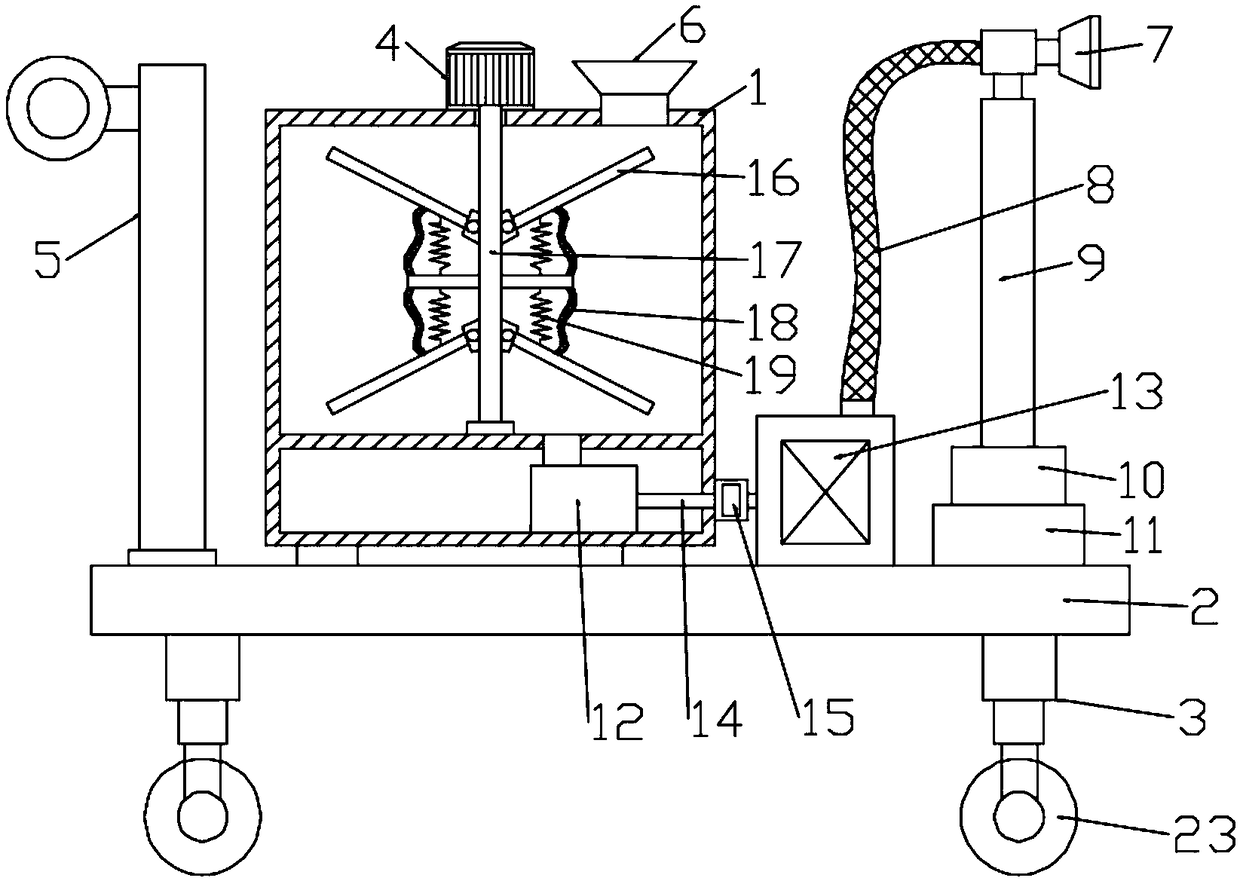

Agricultural planting bactericide spraying device

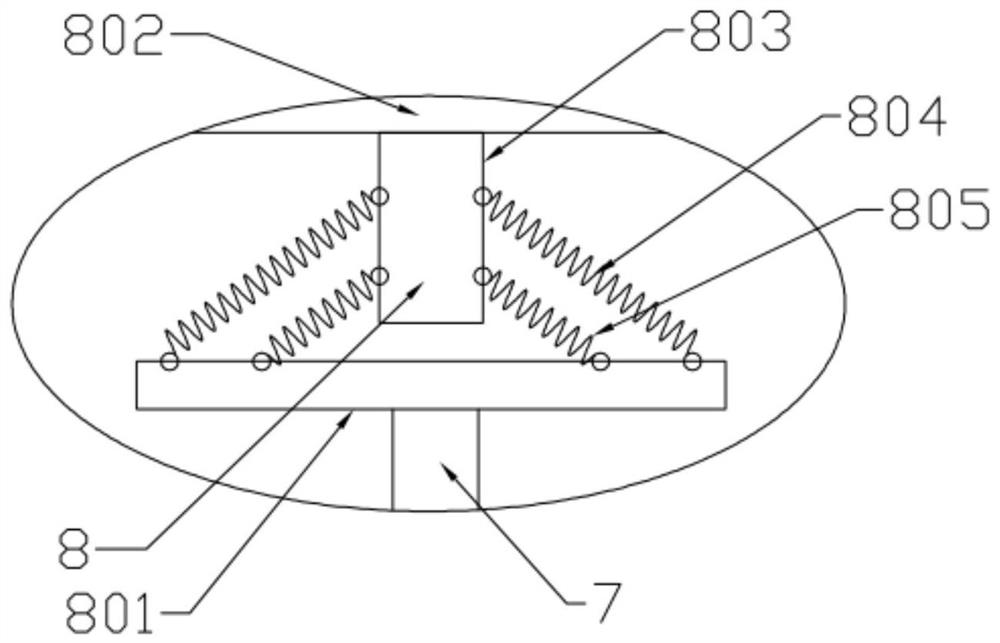

InactiveCN108902096APrevent precipitationAvoid overstretchingTransportation and packagingRotary stirring mixersAgricultural engineeringPrecipitation

The invention discloses an agricultural planting bactericide spraying device. The device comprises a pesticide box, a base plate, damping supporting legs, a spray head, a water pump, an atomizer, trundles and a stirring mechanism. According to the invention, a sterilizing agent in the inner cavity of the pesticide box is pumped into the atomizer through the water pump, the sterilizing agent atomized by the atomizer is sprayed out through the spray head, and the spraying angle can be adjusted under the action of an angle adjusting motor, so that the spraying range is wide. A rotating rod is driven to rotate at a variable speed through the utilization of a stirring motor, and continuous change of the included angle between each of stirring rods and the rotating rod is realized in a variable-speed rotating process of the rotating rod, so that the stirring range is increased, the sterilizing agent in the pesticide box is prevented from precipitation, and the pesticide effect is guaranteed.Arranged safety ropes exert a safety protection function, so that excessive stretching of elastic connecting pieces is avoided, and the safety is high.

Owner:合肥久多农业科技有限公司

Splits exercise device

Owner:合浦县文化体育和广播电视局

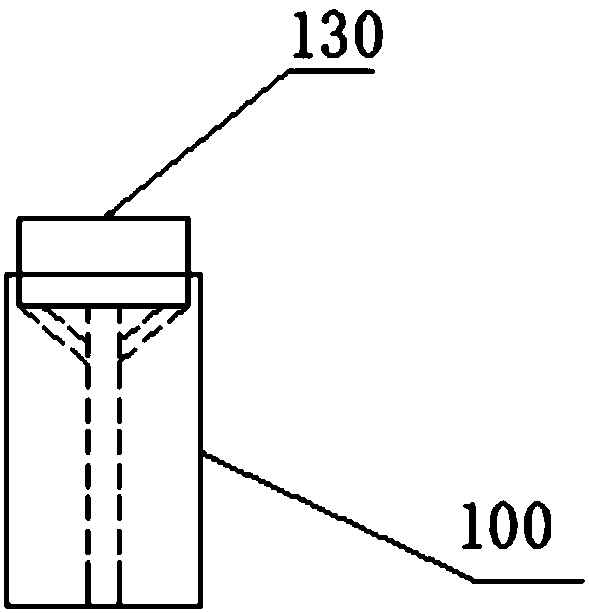

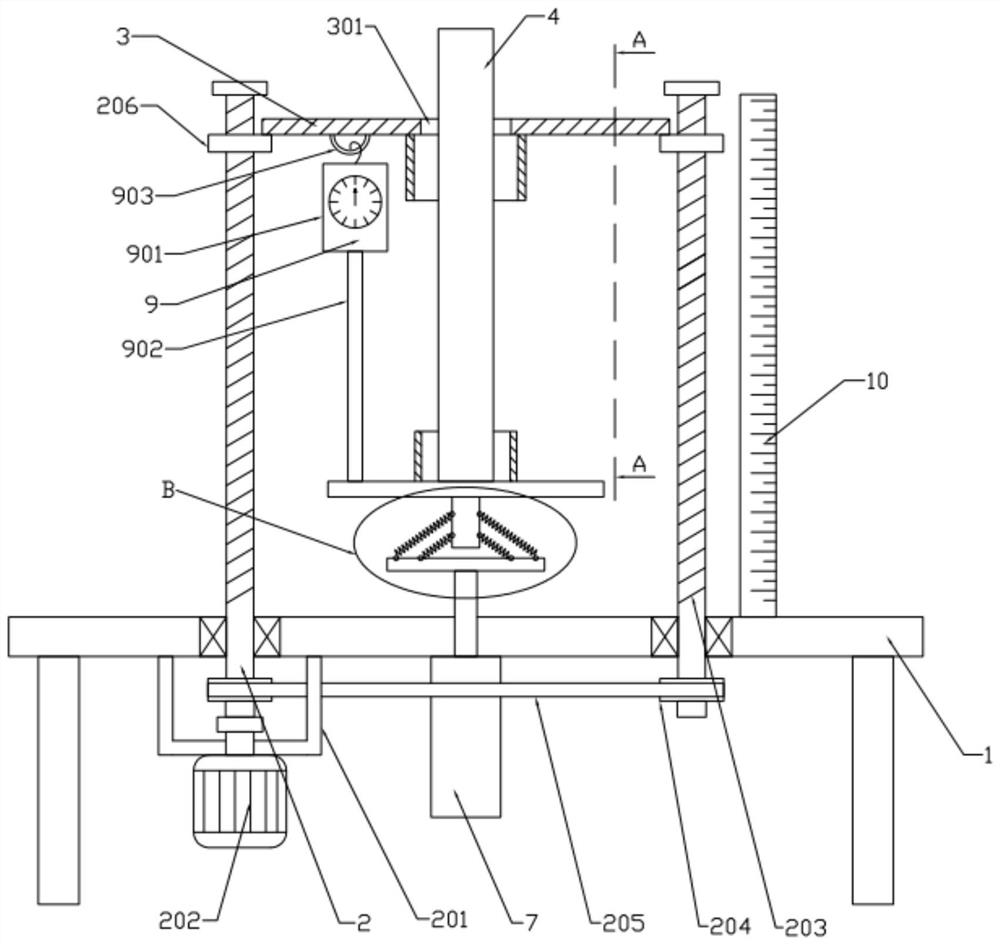

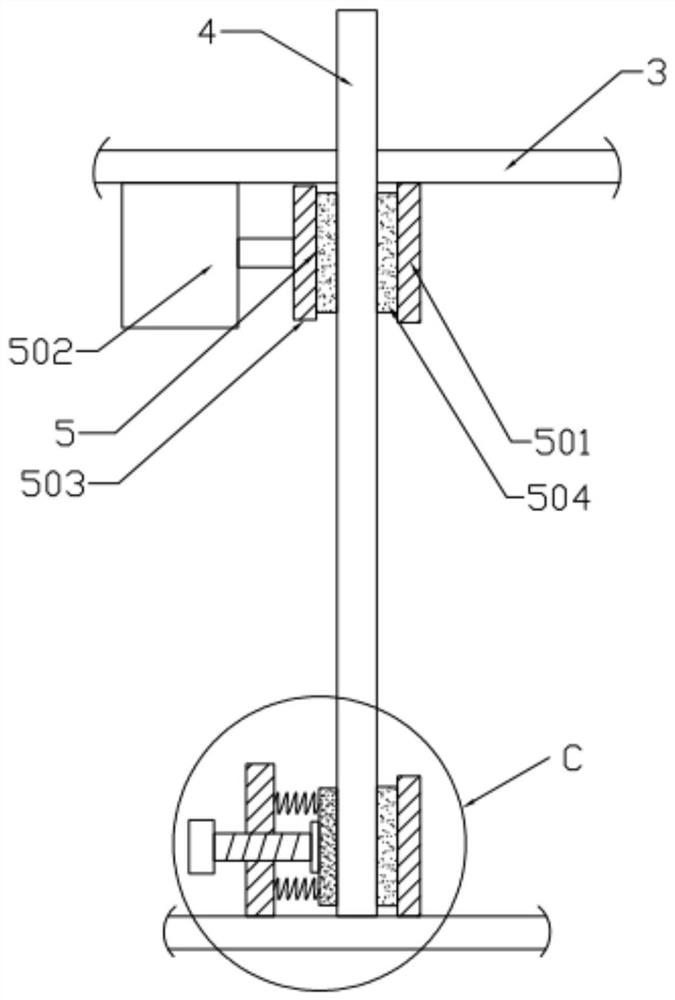

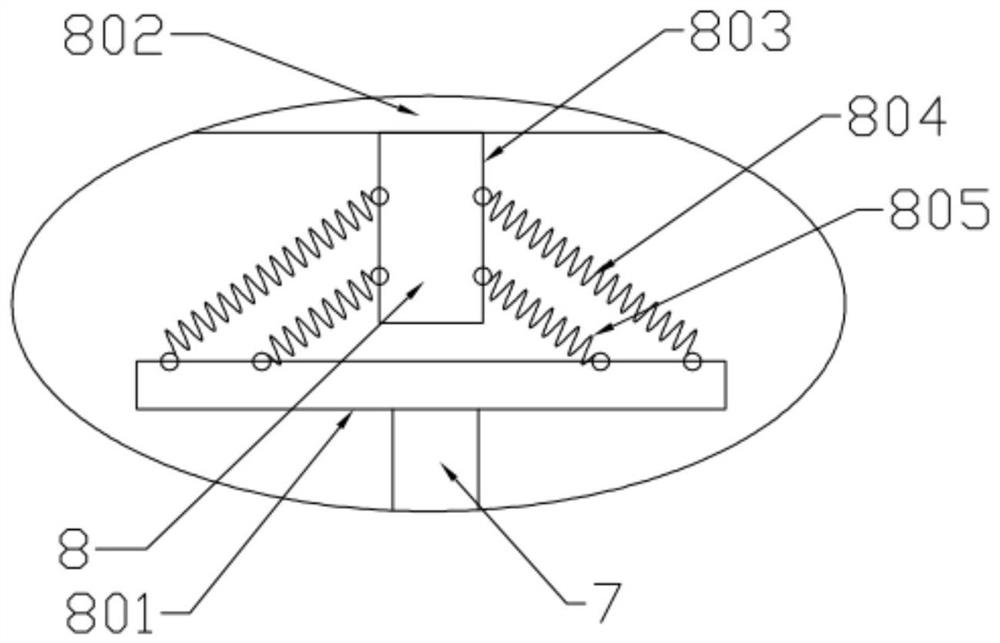

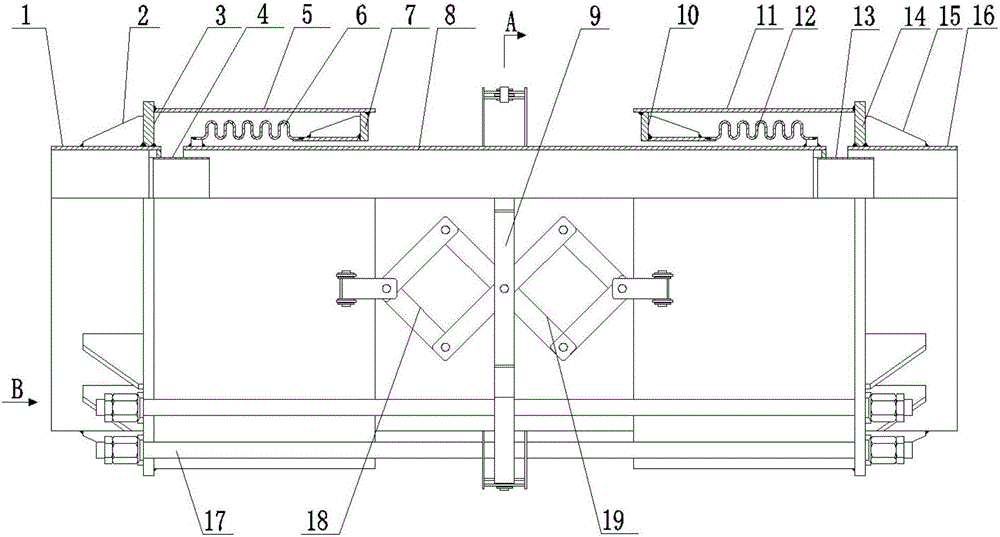

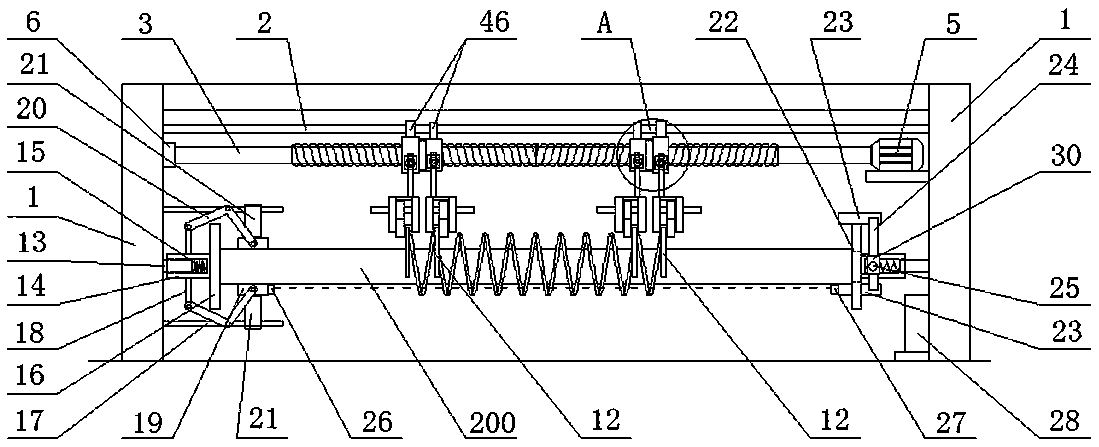

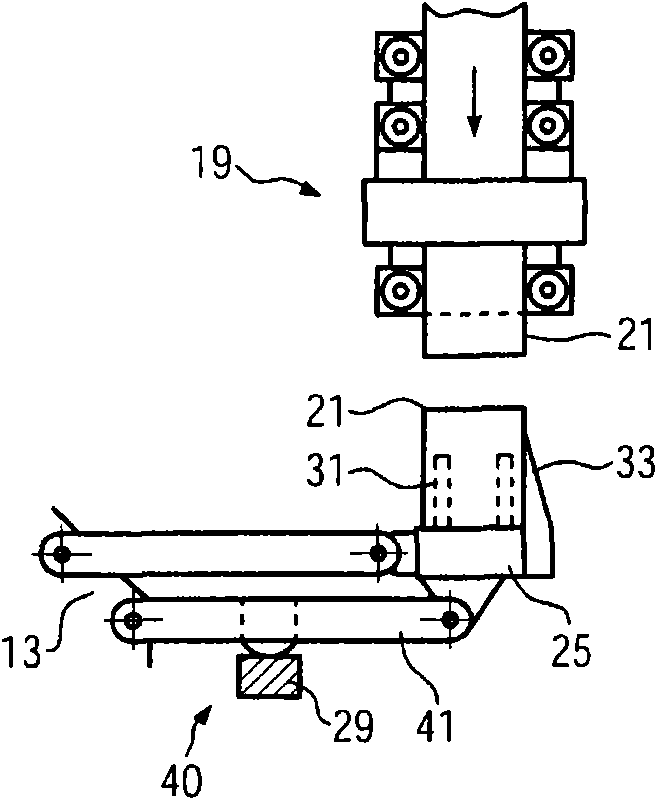

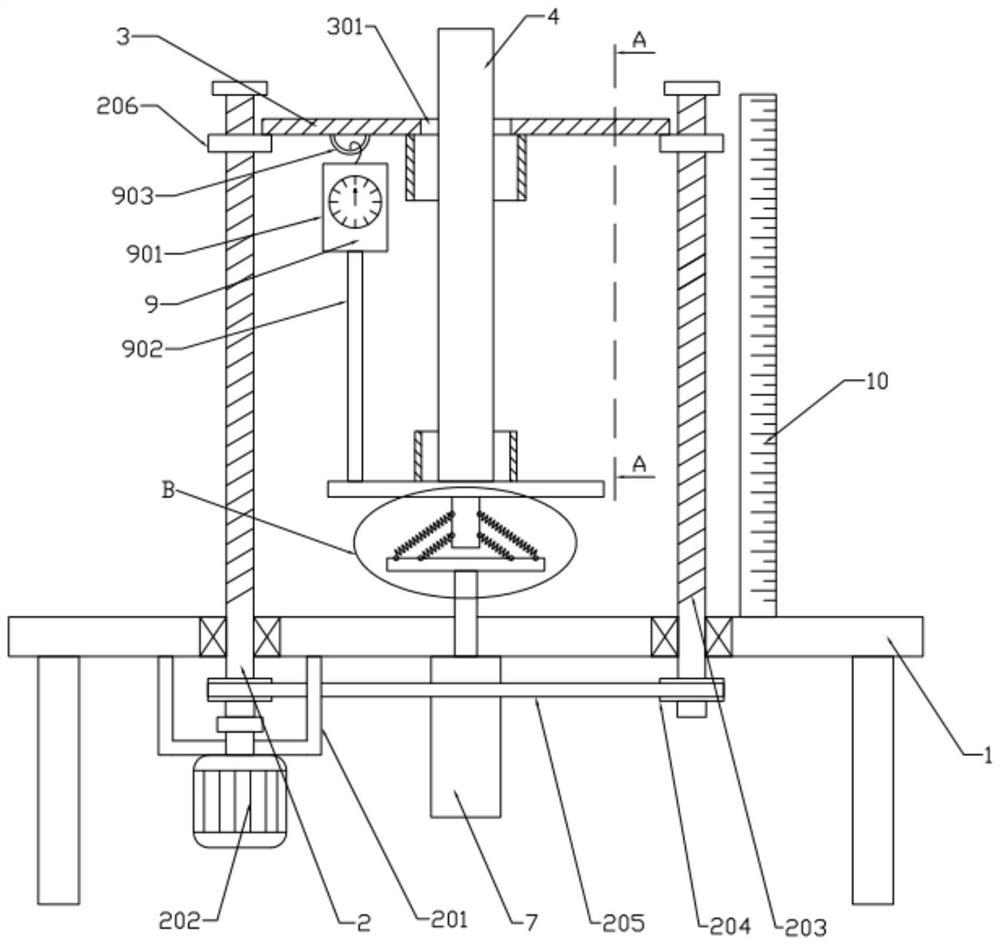

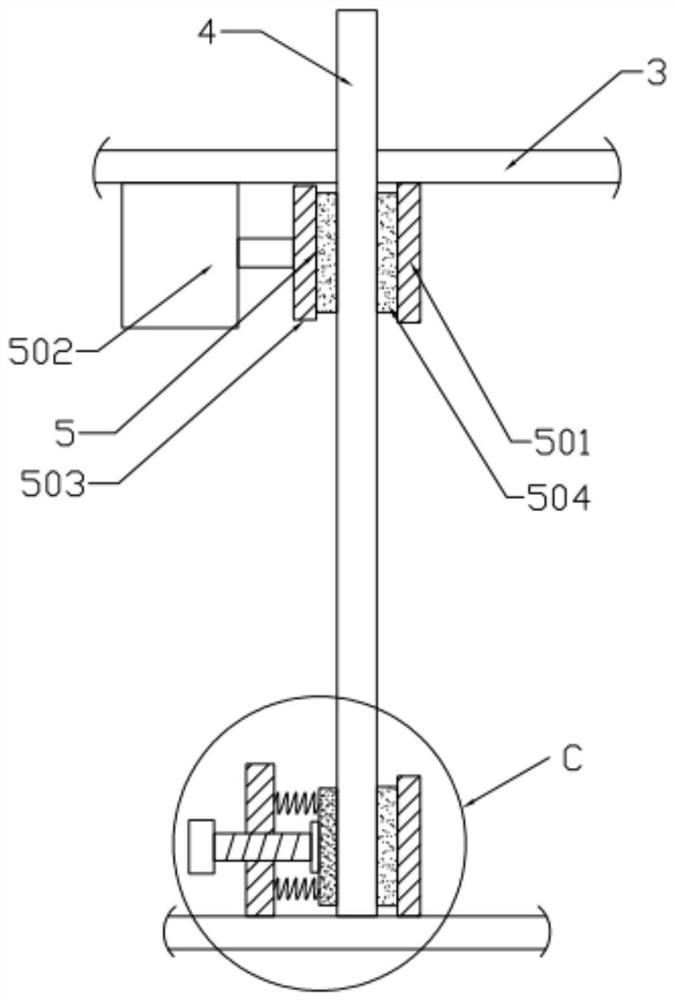

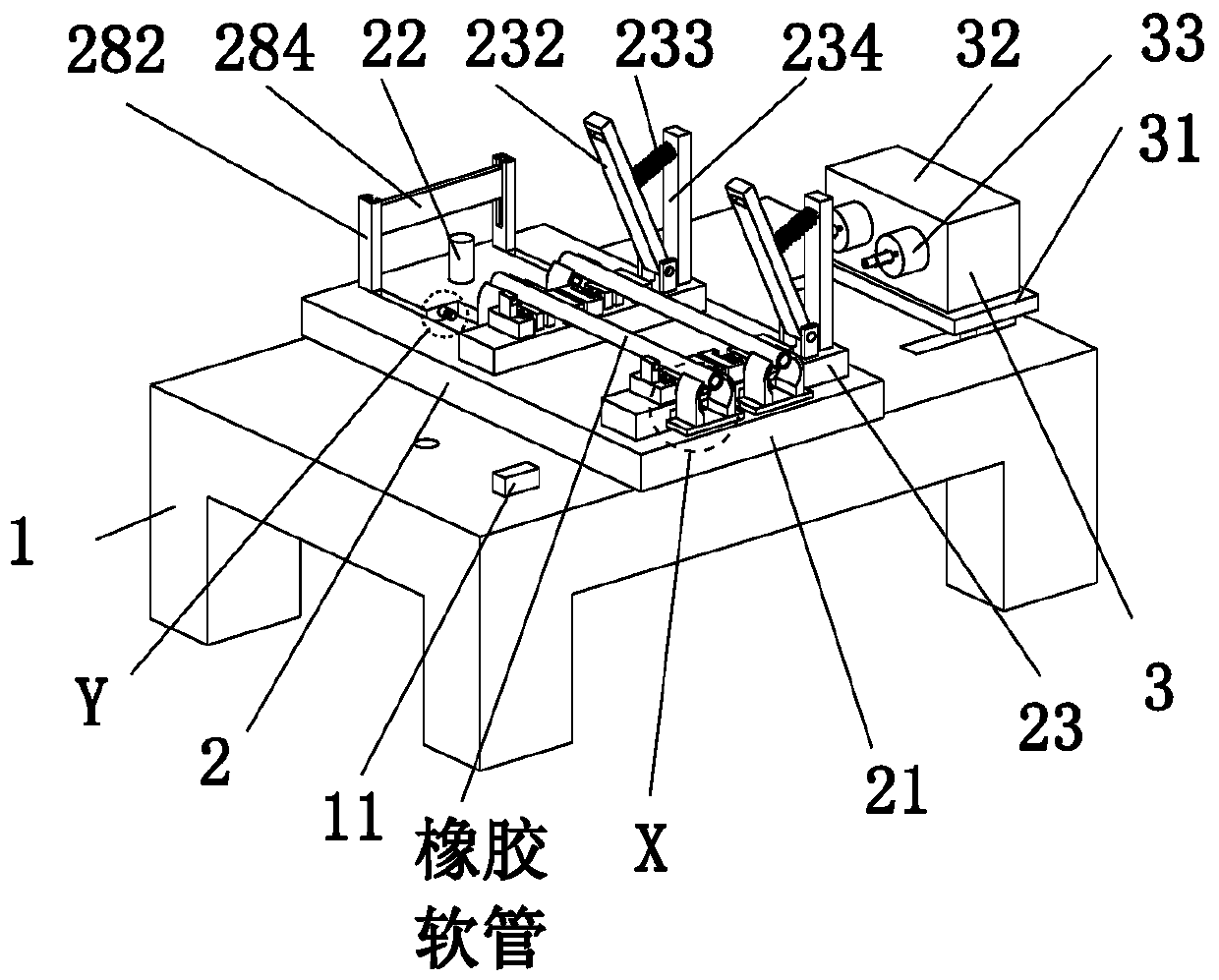

Rubber plastic strip tensile capacity detection device

ActiveCN111650042AStretch PreciselyEasy to stretchMaterial strength using tensile/compressive forcesHydraulic cylinderStructural engineering

The invention discloses a rubber plastic strip tensile capacity detection device comprising a workbench; and a height adjusting device is installed on the workbench. A lifting plate is mounted on theheight adjusting device; a rubber plastic strip is mounted on the lifting plate; an automatic clamping mechanism is installed on the lower side of the lifting plate, a hydraulic cylinder is installedon the workbench and located below the lifting plate, the hydraulic cylinder is connected with a buffer mechanism, a manual clamping device is installed at the top of the buffer mechanism, the bottomof the rubber plastic strip is fixed in the manual clamping device, and a tension measuring device is connected between the lifting plate and the buffer mechanism. According to the invention, the rubber plastic strip is convenient to fix, and the tensile property of the rubber plastic strip is accurately measured.

Owner:SUZHOU CANGMIN EIECTRONIC TECH CO LTD

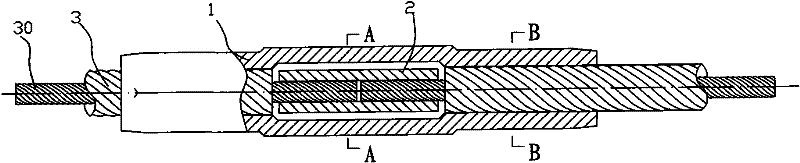

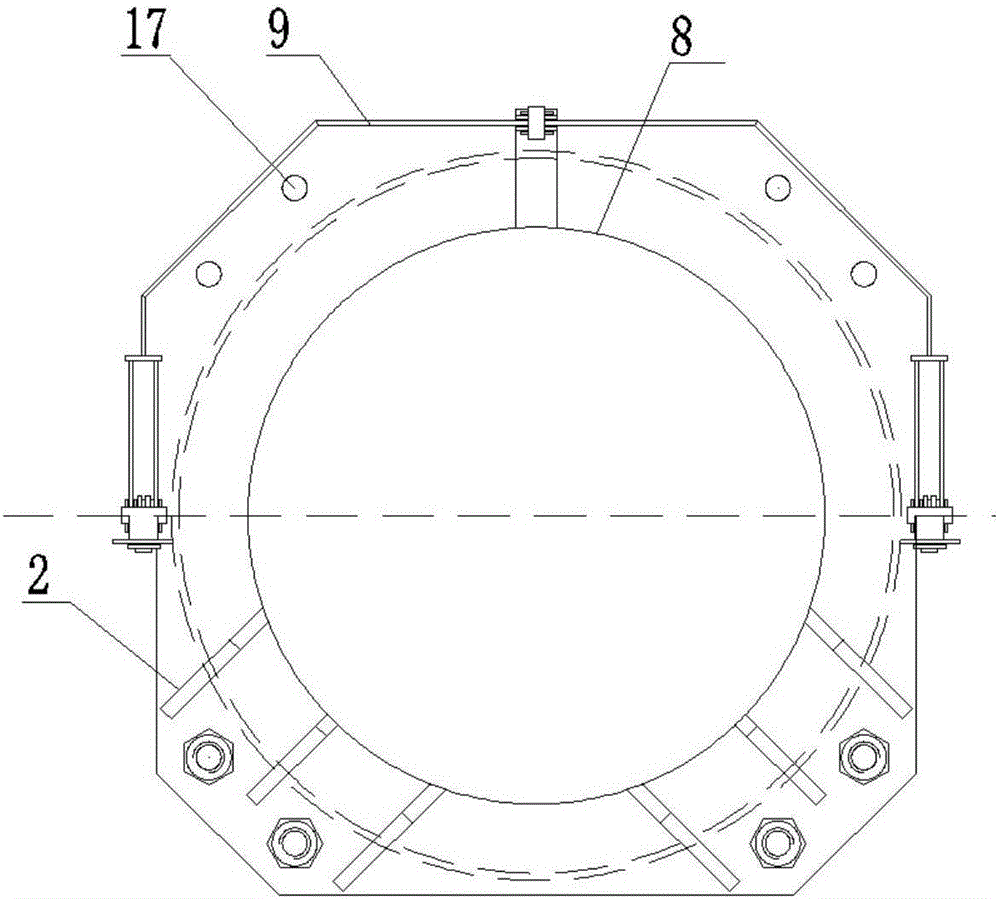

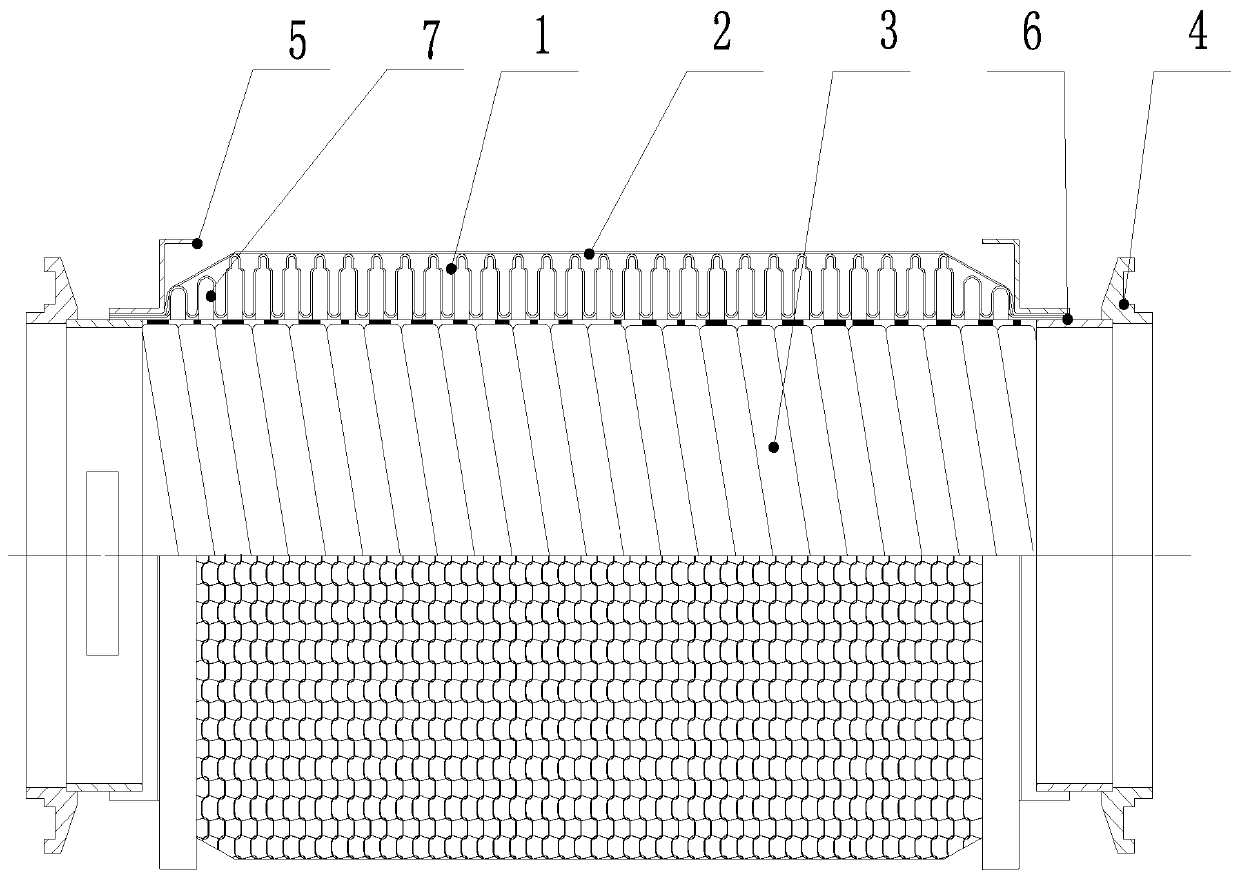

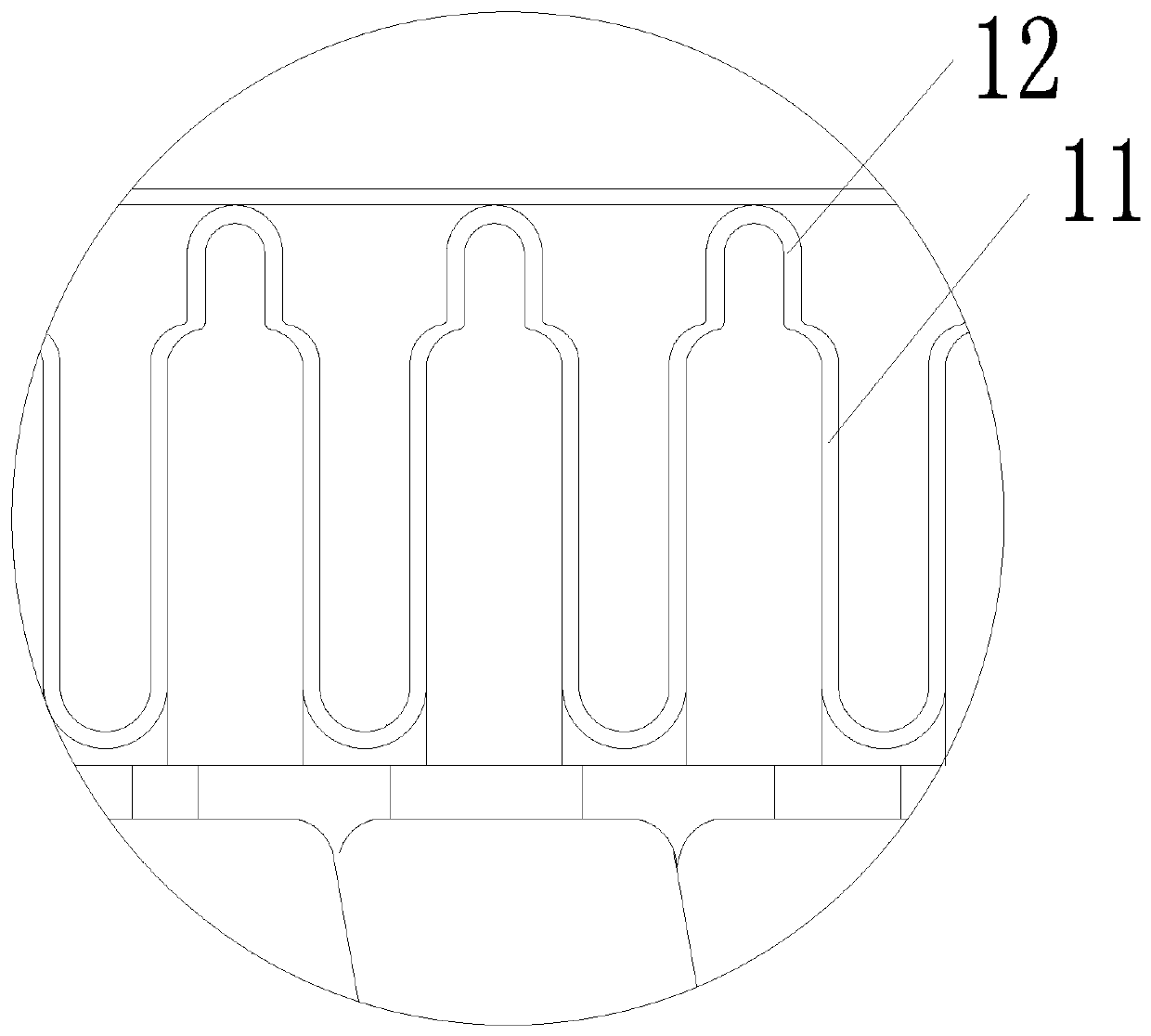

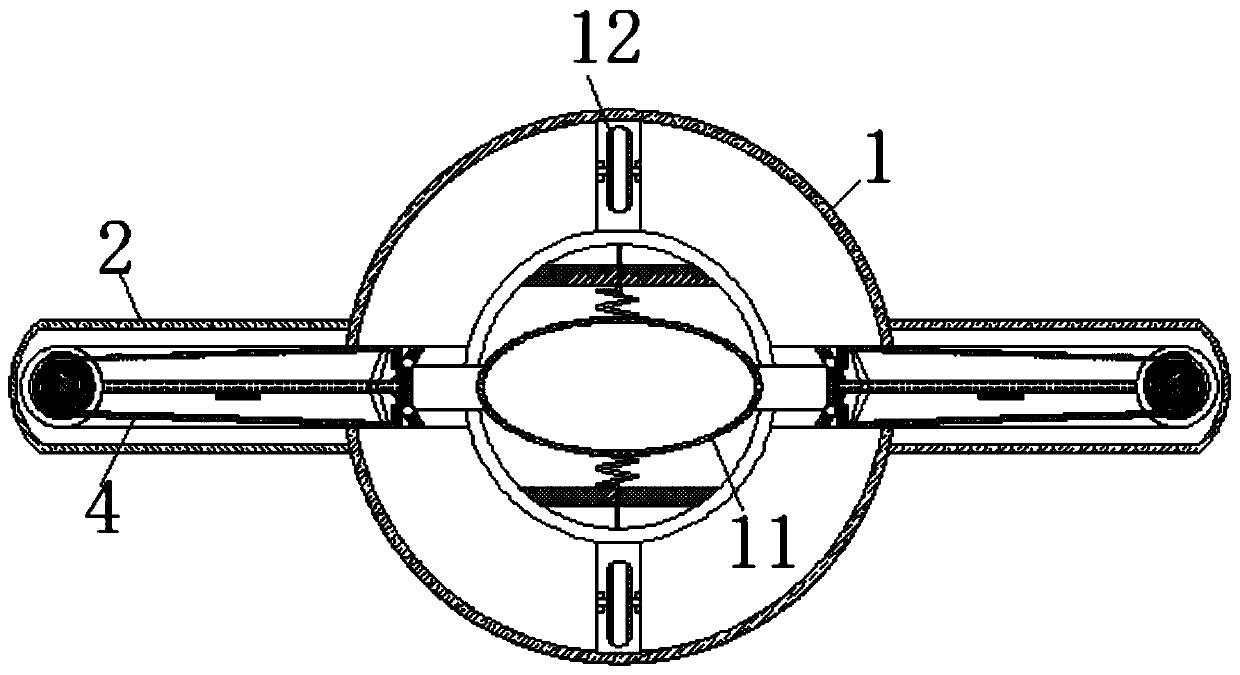

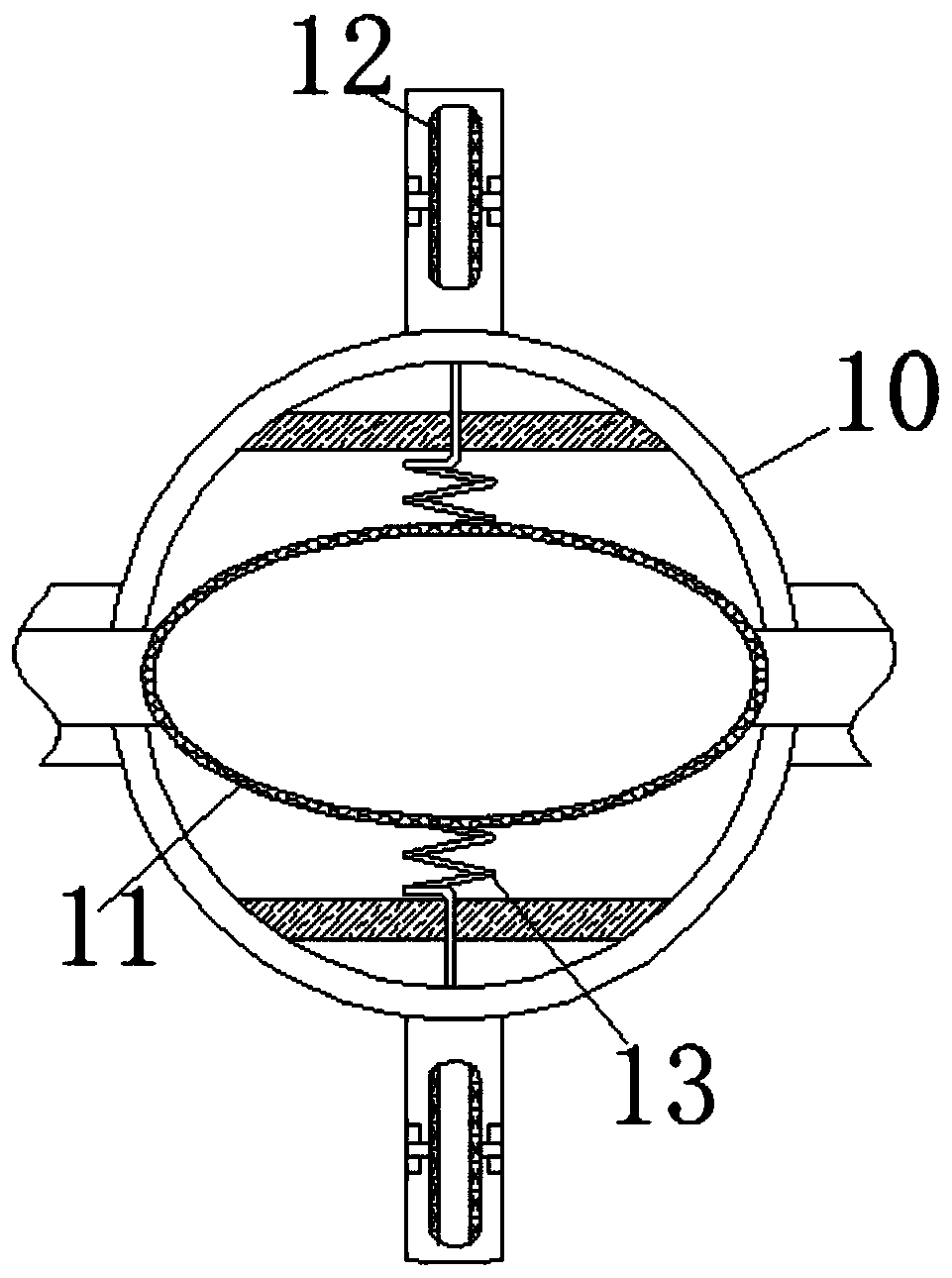

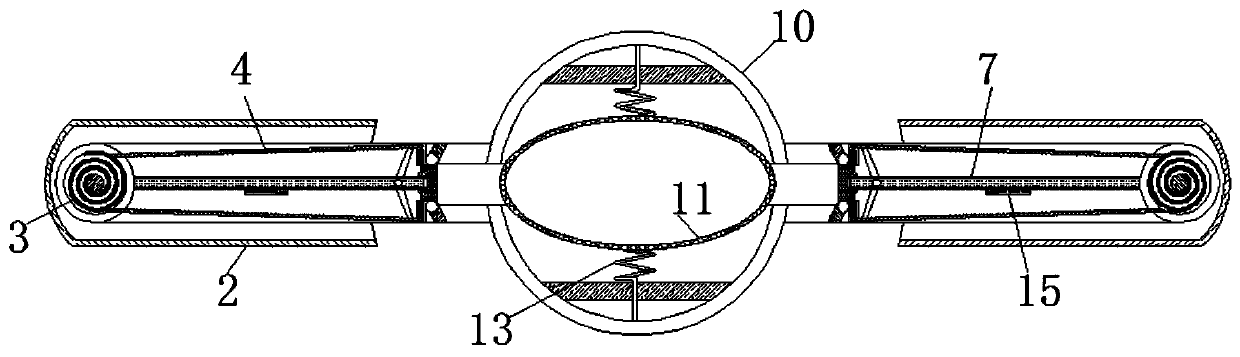

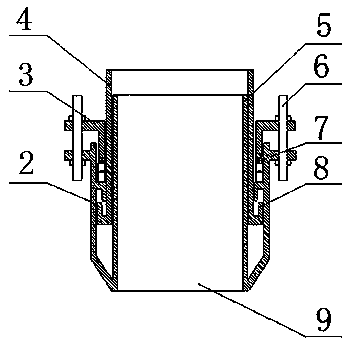

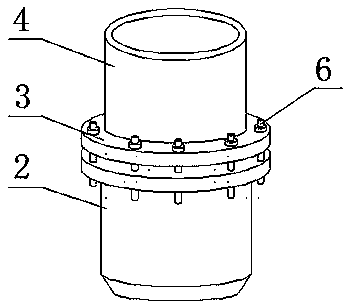

External pressure universal expansion joint

ActiveCN106151759ASolve instabilityLarge lateral compensation capabilityPipeline expansion-compensationInstabilityEngineering

The invention discloses an external pressure universal expansion joint. The external pressure universal expansion joint comprises a left connecting pipe and a right connecting pipe, wherein the left connecting pipe is connected with a left outer sleeve, a left corrugated pipe is arranged in the left outer sleeve, and the left outer sleeve and the left corrugated pipe are connected through a left pressure bearing annular plate at one end of the left outer sleeve and the corresponding end of the left corrugated pipe; and the right connecting pipe is connected with a right outer sleeve, a right corrugated pipe is arranged in the right outer sleeve, and the right connecting pipe and the right corrugated pipe are connected through a right pressure bearing annular plate at one end of the right connecting pipe and the corresponding end of the right corrugated pipe. The external pressure universal expansion joint further comprises a middle connecting pipe arranged in the left corrugated pipe and the right corrugated pipe, wherein one end of the middle connecting pipe is connected with the other end of the left corrugated pipe, the other end of the middle connecting pipe is connected with the other end of the right corrugated pipe, a left lining tube is arranged in the left outer sleeve, the free end of the left lining tube is arranged inside the left corrugated pipe, a right lining tube is arranged inside the end, located on the right corrugated pipe, of the middle connecting pipe, and the free end of the right lining tube is arranged in the right connecting pipe. According to the external pressure universal expansion joint, the structure that two groups of external pressure type multi-layer U-shaped corrugated pipes are combined is adopted, the problem of column instability is avoided, and therefore, the external pressure universal expansion joint has the high horizontal compensation capacity under the working conditions of high pressure and high temperature, and can meet the requirement on the compensation capacity of an on-site long-range pipeline.

Owner:CHENGUANGDONGLUO BELLOWS CO LTD NANJING

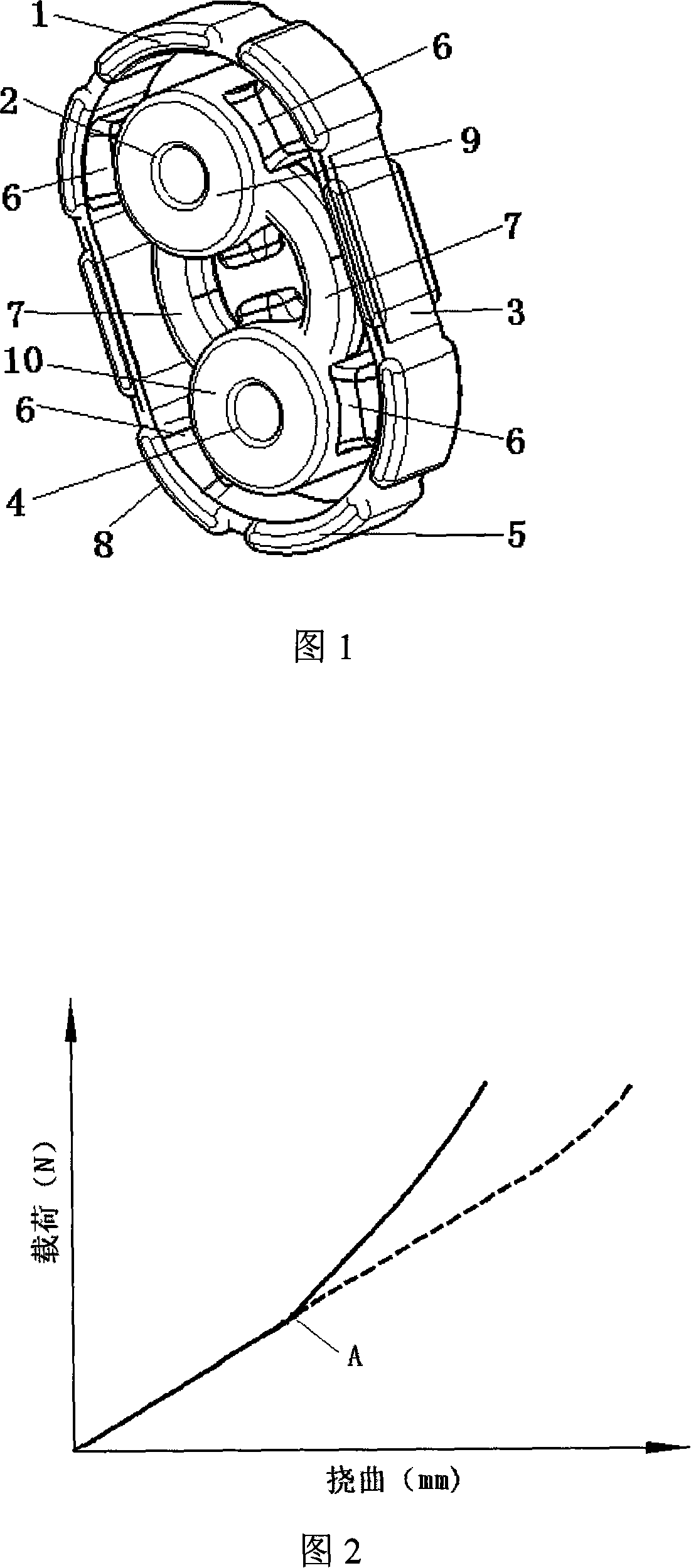

Automobile exhaust system mounting hanger

ActiveCN101088792APrevent rubber from overstretchingExtended service lifePropulsion unit gas exhaustAutomotive engineeringFatigue resistance

The present invention discloses one kind of automobile exhaust system mounting hanger. One metal frame is set around the hanger, the automobile body installation unit and the exhaust pipe installation unit; and the automobile body installation unit and the exhaust pipe installation unit are fixed through supporting and connecting parts of rubber onto the metal frame. Compared with available technology, the present invention has the advantages of long service life, good vibration reducing performance, high fatigue resistance, etc.

Owner:安庆福莱克斯动力科技有限公司

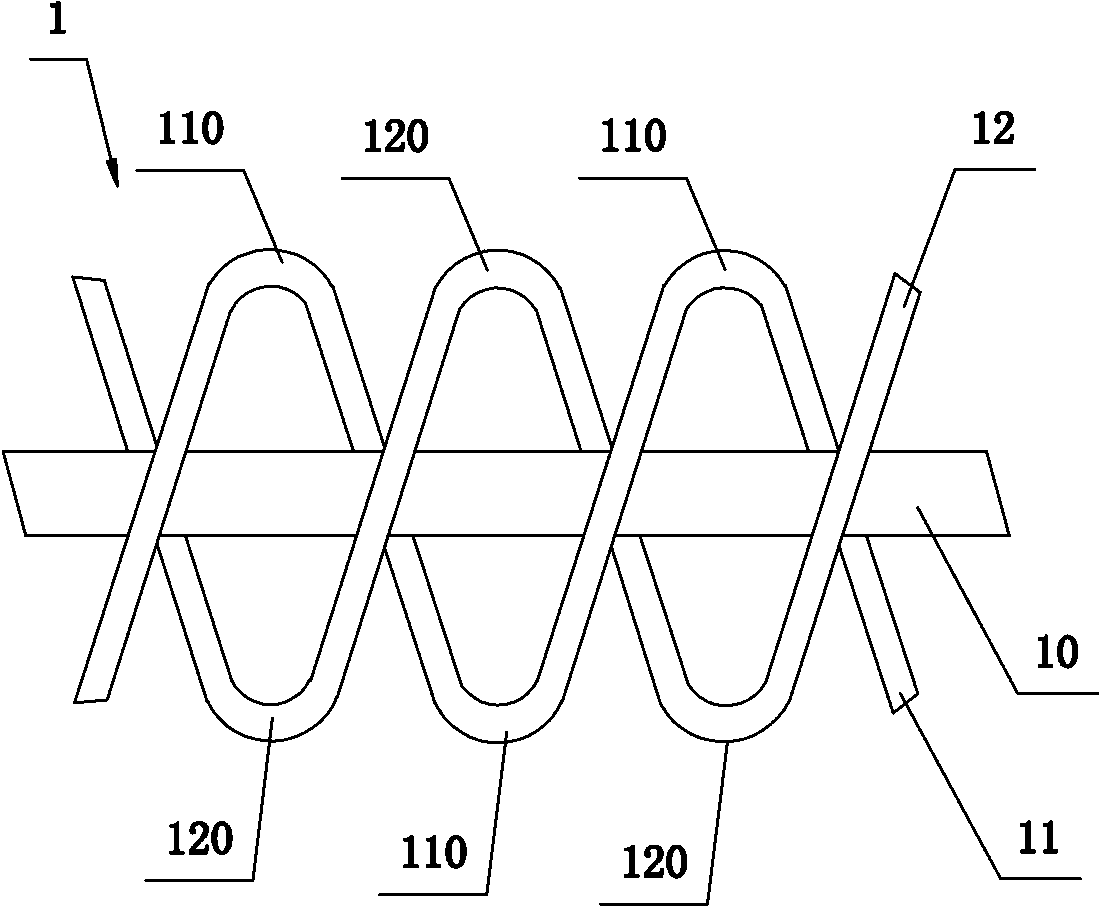

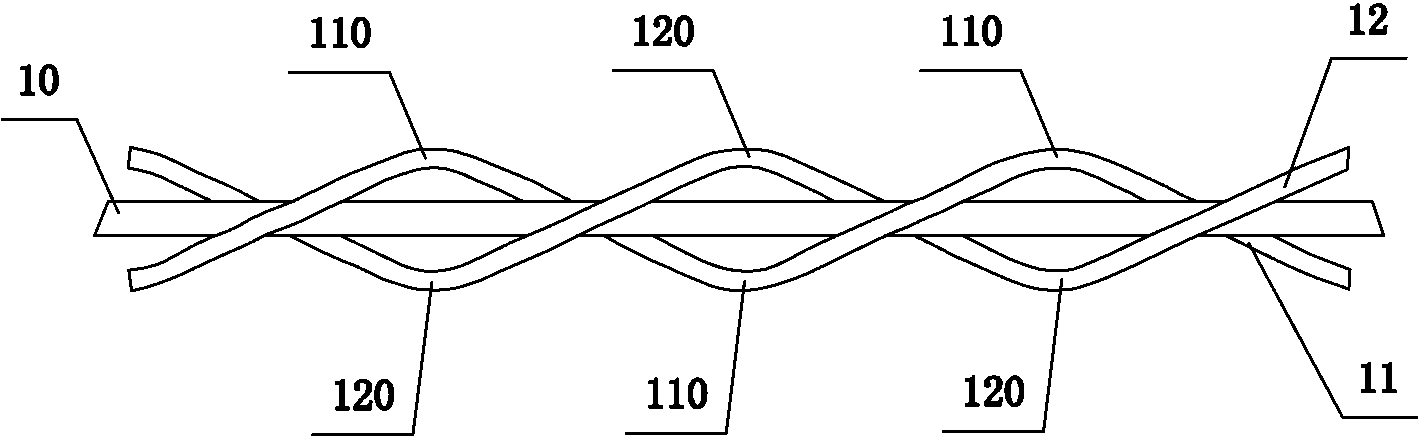

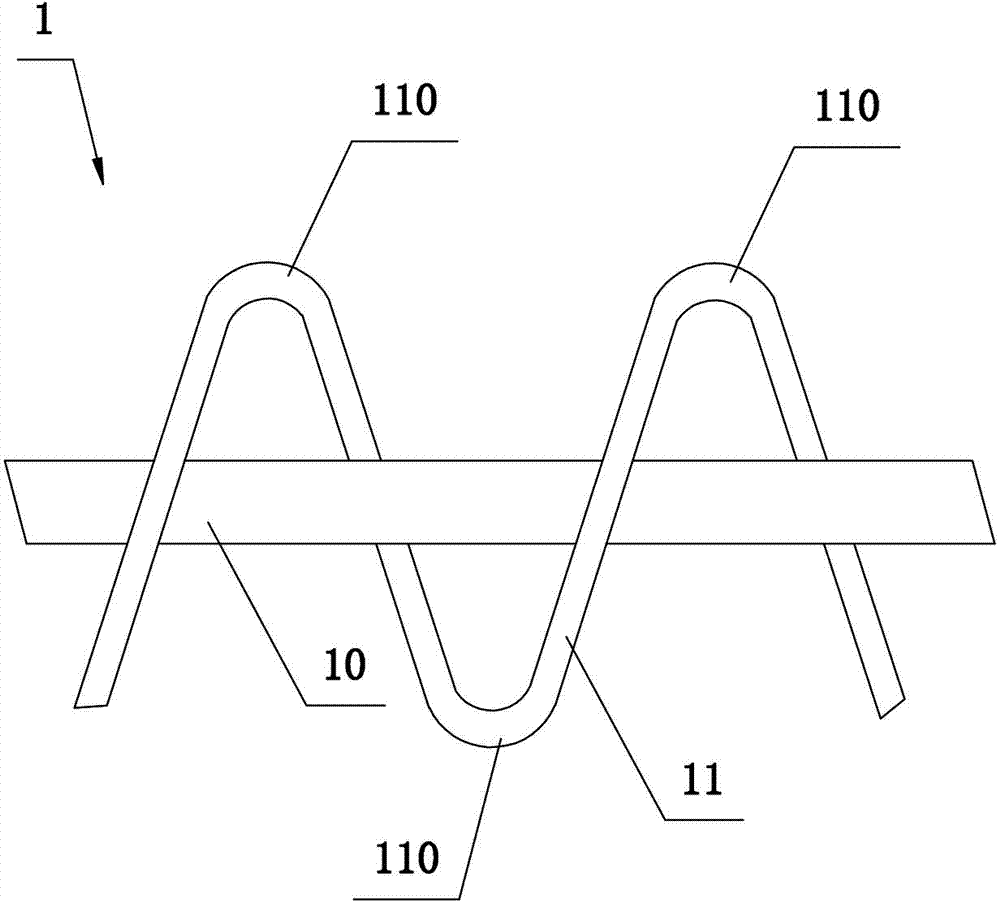

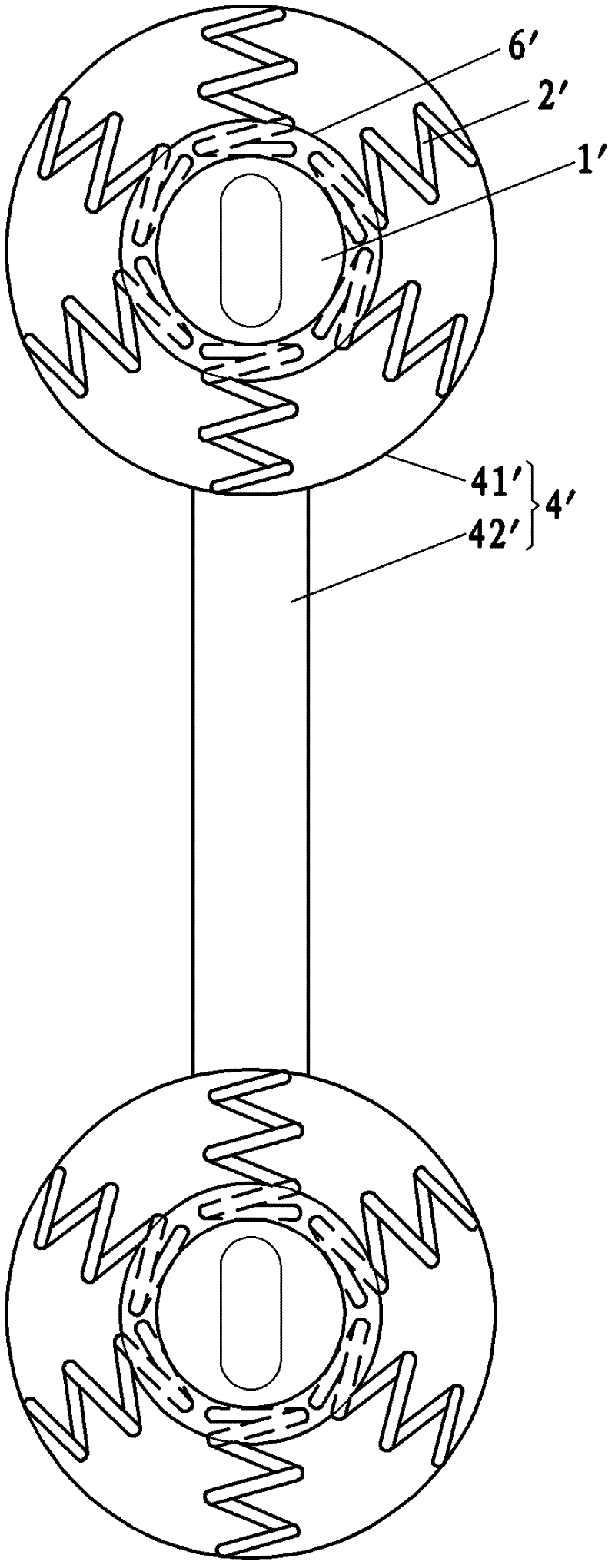

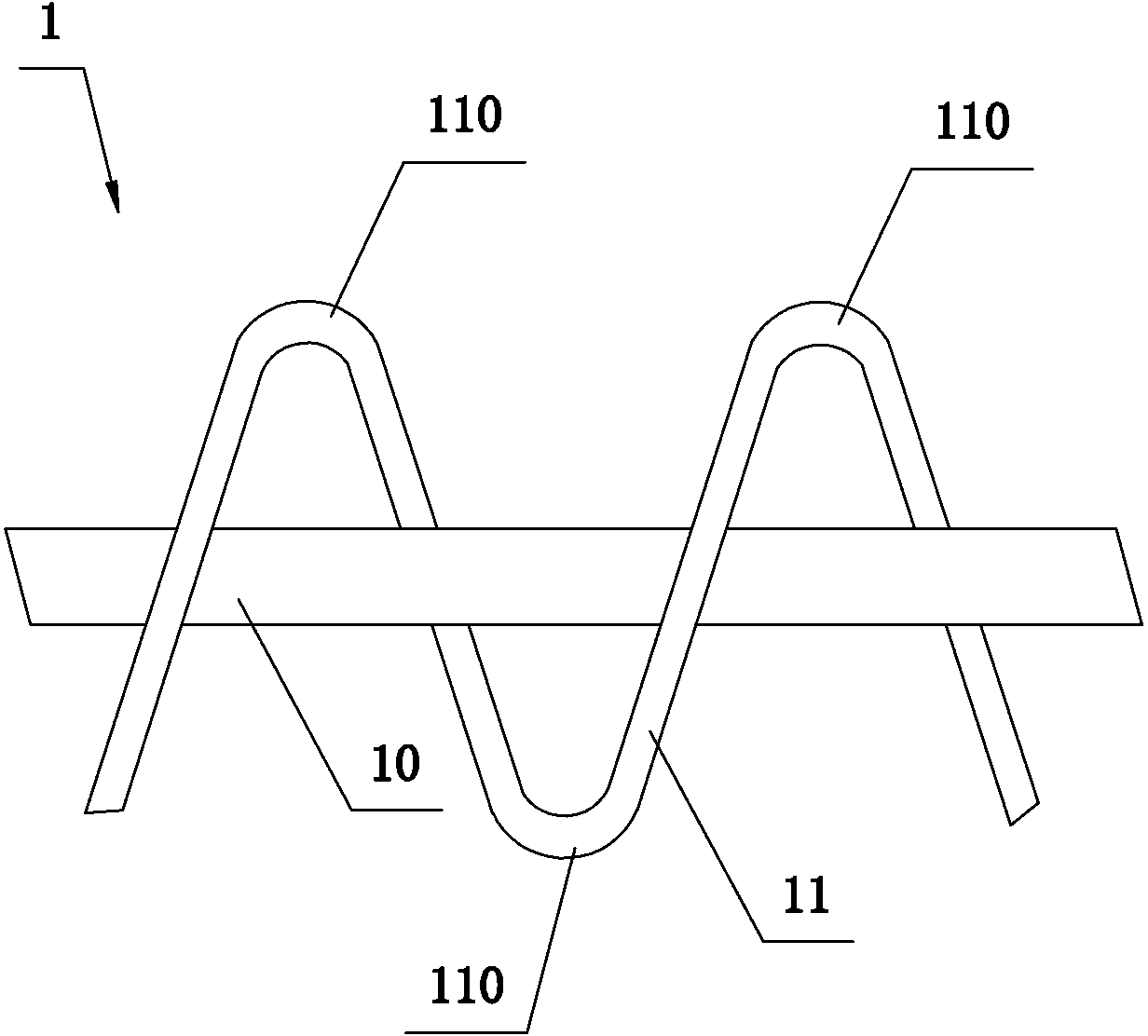

Conductive doubled and twisted yarn

The invention discloses a conductive doubled and twisted yarn which comprises a plurality of elastic fibers, a plurality of conductive fibers and a plurality of positioning adjusting fibers. The conductive fibers are provided with a plurality first bending portions, the positioning adjusting fibers are provided wit a plurality of second bending portions, and the first bending portions and the second bending portions are symmetrical with one another. The conductive doubled and twisted yarn has the advantages that the conductive doubled and twisted yarn is simple in structure and smart in design and is provided with the positioning adjusting fibers, so that the elastic fibers can be stretched or contracted within elastic ranges of the elastic fibers; the conductive fibers with the multiple first bending portions can be stretched and contracted along with the elastic fibers, accordingly, the doubled and twisted yarn is conductive, a fabric made of the doubled and twisted yarn by means of weaving is high in elasticity and resilience, and the conductive doubled and twisted yarn is greatly favorable for improving the stability, the durability and the convenience of the fabric made of the doubled and twisted yarn by means of weaving during actual usage.

Owner:福建泉州市健凯服饰有限公司

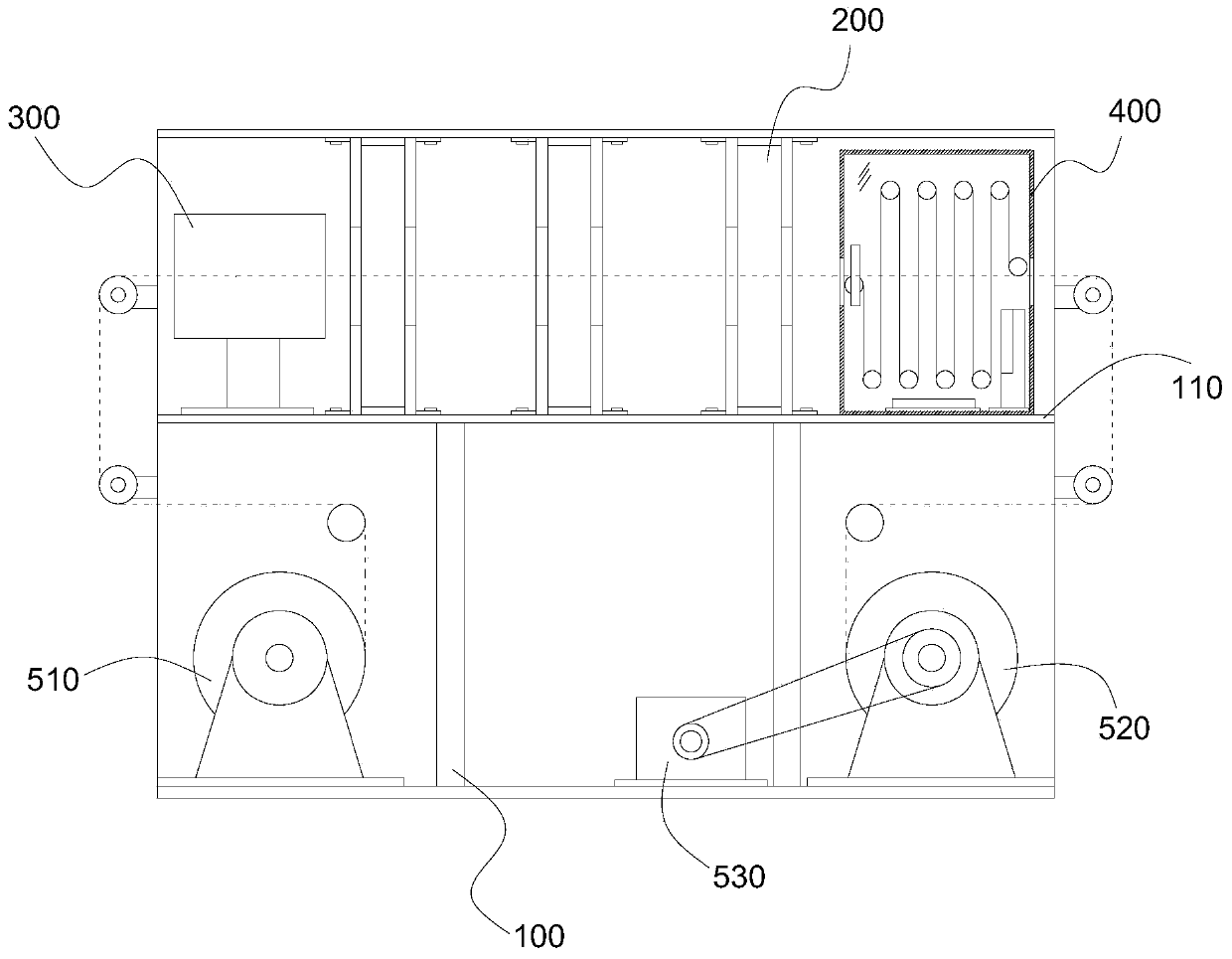

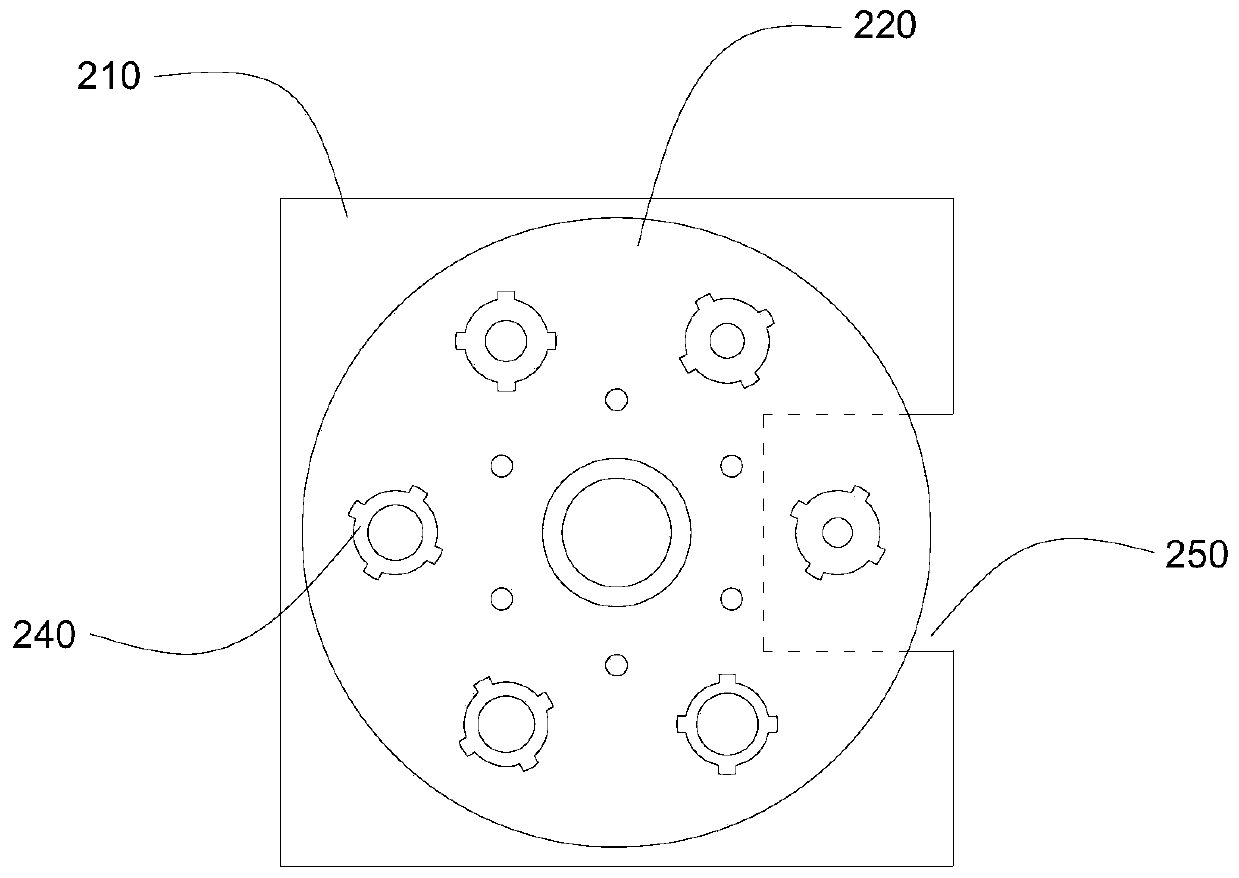

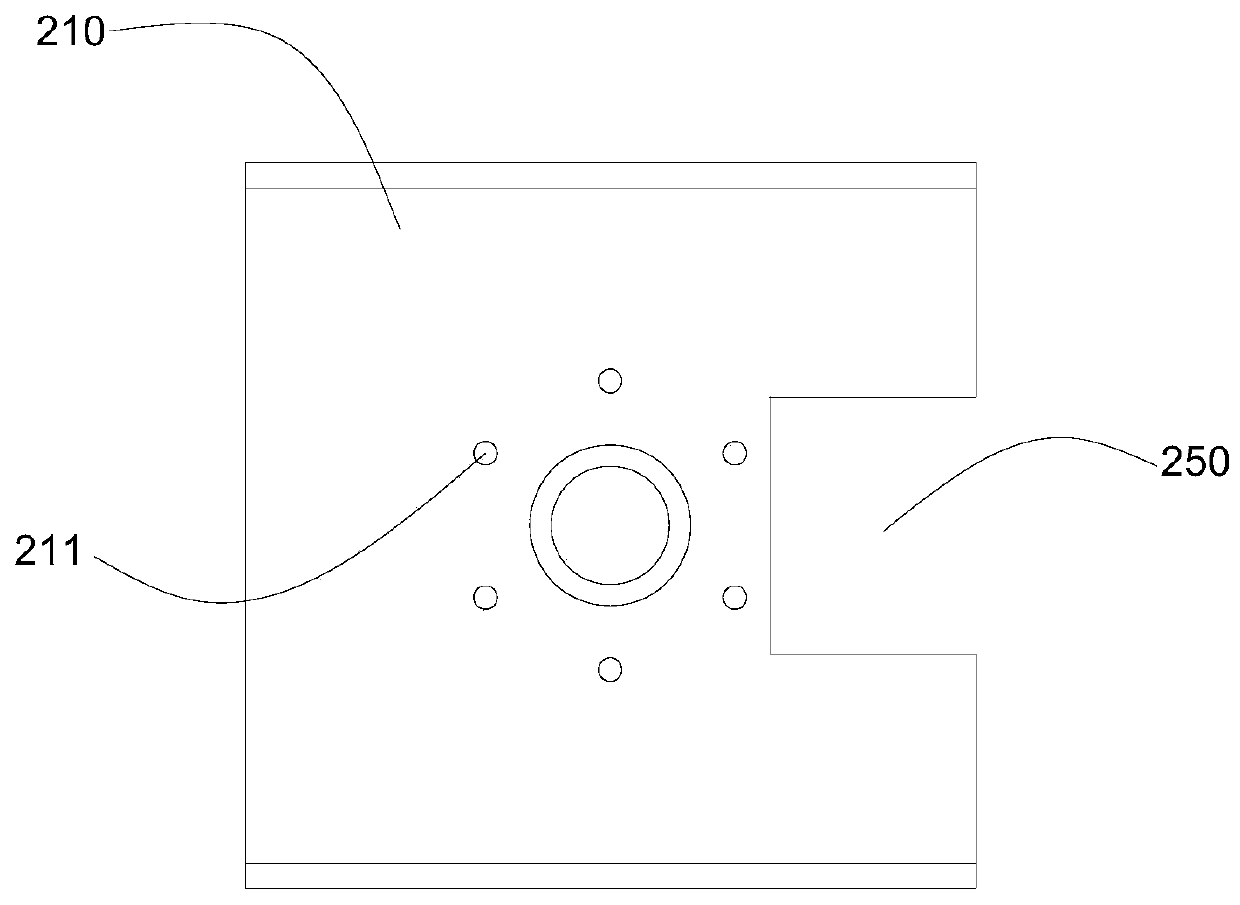

Ultra-high speed drawing equipment for bonding tin-plating alloy wire

The invention provides ultra-high speed drawing equipment for a bonding tin-plating alloy wire. The ultra-high speed drawing equipment for the bonding tin-plating alloy wire comprises a worktable; atleast two drawing mould mechanisms are arranged on the top surface of the worktable and are arranged in parallel; a preheating tube is arranged at one end of the worktable; a cooling box is arranged at the other end of the workable; a wire unwinding wheel and a wire winding wheel are arranged below the worktable; the wire winding wheel is driven by a driving motor; each drawing mould mechanism comprises two clamping plates which are arranged oppositely; a mould mounting disc is arranged between the two clamping plates; the mould mounting disc is rotatably erected between the two clamping plates; a plurality of mounting grooves are formed in the mould mounting disc; a plurality of mounting grooves are distributed in a circumferential array around the circle centre of the mould mounting disc; a drawing mould is mounted in each mounting groove; the diameters of forming holes of various drawing moulds are different; the replacement of the drawing mould is realized by rotating the mould mounting disc so as to produce bonding wires with different diameter requirements; and multi-stage drawing and pulling treatment can be performed on the wires, so that steady wire drawing work is ensured, and the wire drawing speed is effectively improved.

Owner:JIANGXI FUHONG METAL CO LTD

Novel corrugated pipe for automobile and manufacturing process thereof

PendingCN111535913AAvoid overstretchingReduce heat transferExhaust apparatusSilencing apparatusMechanical engineeringCommercial vehicle

The invention relates to a novel corrugated pipe for an automobile and a manufacturing process thereof. The novel corrugated pipe for the automobile comprises a metal corrugated pipe body with two straight edge sections at two ends, wherein a metal winding pipe is embedded in the inner wall of the metal corrugated pipe body; and a fish pattern net uniformly covers the outside of the metal corrugated pipe body. The novel corrugated pipe for the automobile has the advantages of high flexibility, heat-insulation performance, corrosion-resistant performance, good sealing performance and long service life. A main body corrugated pipe and the winding pipe have good high-temperature-resistant and corrosion-resistant performance; the fish pattern net, a Z-shaped outer ring and a joint break through the process scheme that a traditional corrugated pipe carbon steel workpiece joint for a commercial vehicle needs paint spraying; work procedures of joint phosphorization, paint spraying, salt spraytests and the like are omitted; the production and manufacturing cost is reduced; and the problems that the joint gets rusty because of paint falling in the use process by a user, and the appearancequality is influenced are solved. The metal corrugated pipe, the fish pattern net and the metal winding pipe adopt special assembly processes; a product is enabled to have a certain telescopic allowance; the installation state of the product is also controlled; the fracture of the product caused by excessive deformation is effectively prevented; and the service life of the product is prolonged.

Owner:常州市常联波纹管有限公司

Multifunctional accompanying nurse bed

The invention discloses a multifunctional accompanying nurse bed and belongs to the technical field of medical care beds. The multifunctional accompanying nurse bed comprises a main bed and a headboard, wherein a bed board is suspended under the main bed and connected with the bottom of the main bed through first telescopic links; guide rails are arranged on bed legs of the main bed, and rollers are mounted at four corners of the bed board and located in the guide rails; a partition board for dividing interior of the headboard into a first layer located at the lower part and a second layer located above the first layer is arranged in the headboard, an accommodating box provided with a cover is arranged in the second layer, and a cover opening device comprising a controller, electric drive pushers and a travel switch and used for opening the accommodating box is arranged on the headboard. The bed board can be retracted when not used in the daytime, so that the space utilization rate is increased; by means of matching of the rollers on the bed board and the guide rails on the bed legs, power required for pulling down the bed board is reduced, the bed board can descend rapidly, and the multifunctional accompanying nurse bed has the characteristics of being efficient and labor-saving.

Owner:AFFILIATED HOSPITAL OF YOUJIANG MEDICAL UNIV FOR NATTIES

Conductive blended yarn

The invention discloses a conductive blended yarn. The conductive blended yarn comprises a plurality of elastic fibers and a plurality of composite fibers, wherein the composite fibers are provided with a plurality of flexural parts and are formed by combining a plurality of conductive fibers and a plurality of positioning adjustment fibers. The conductive blended yarn is simple in structure and ingenious in design; due to the fact that the composite fibers formed by combining the conductive fibers and the positioning adjustment fibers are arranged and are provided with the flexural parts, when the elastic fibers are drawn or contracted within the elasticity range of the elastic fibers, the composite fibers can be drawn or contracted with the elastic fibers, the blended yarn has the characteristic of conductivity, a fabric woven from the blended yarn has high elasticity and rebound resilience, and the stability, the durability and the convenience of the fabric woven from the blended yarn in practical use are greatly improved.

Owner:福建泉州市健凯服饰有限公司

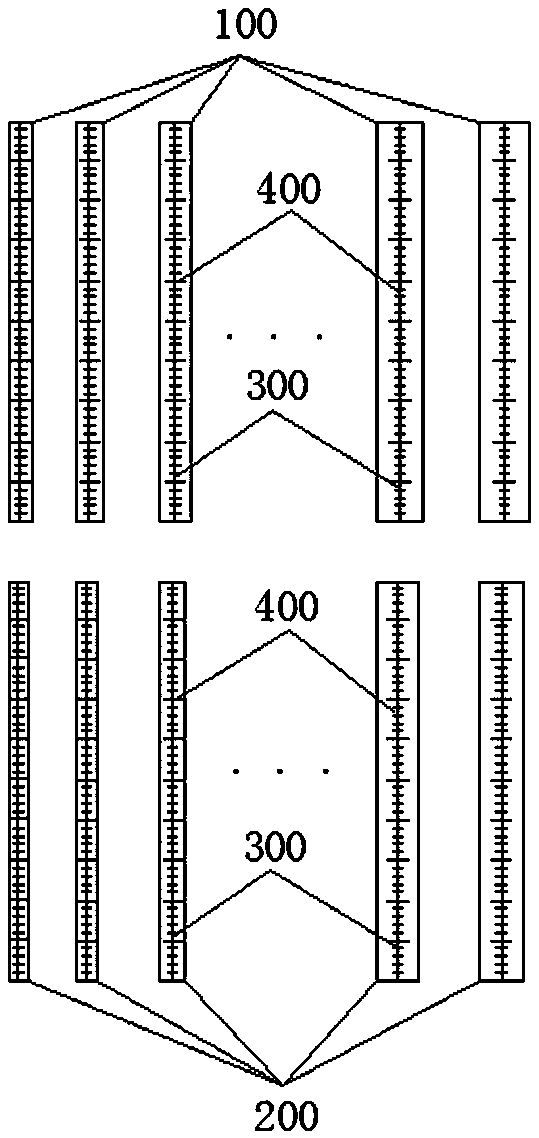

Steel wire pre-forming measuring rod and application method thereof

ActiveCN110756707AHigh measurement accuracyEasy to removeMechanical diameter measurementsOptical detectionEngineeringStructural engineering

The invention discloses a steel wire pre-forming measuring rod and an application method thereof, and belongs to the technical field of high-pressure steel wire winding rubber tube processing. The steel wire pre-forming measuring rod comprises a plurality of pre-forming rods and standard measuring rods, which are of different diameters, wherein length graduated scales are marked on the pre-formingrods and the standard measuring rods in a length direction; during application, the standard measuring rods of the same diameter and the pre-forming rods of relatively great diameters are selected according to a corresponding steel wire reinforcing layer, steel wires are wound on the pre-forming rods to manufacture pre-formed steel wires, the pre-formed steel wires sleeve the standard measuring rods so as to stretch by a stretching device until the steel wires are completely attached to the surfaces of the standard measuring rods, and screw pitches of the stretched steel wires can be directlyobtained through the length graduated scales, and the screw pitches are judged to whether reach standards or not. Pre-forming and measuring operation of the steel wires are relatively simple; the stretching device adopted during application can conveniently dismount the standard measuring rods, and can stably clamp the pre-formed steel wires, so that stretching control is simple, and stretching of the pre-formed steel wires further can be timely stopped.

Owner:中金液压胶管股份有限公司

External-use spray for treating spondyloarthritis

InactiveCN110841181ATo achieve the effect of self-administered medicinePain reliefMedical applicatorsSpinal columnSacroiliitis

The invention relates to the technical field of spondyloarthritis spray equipment and discloses an external-use spray for treating spondyloarthritis. The external-use spray comprises a shell and is characterized in that connecting bands are movably connected to the surface of the shell, a winding column is fixedly connected into each connecting band, a pull rope is movably connected to the surfaceof each winding column, spring rods are movably connected to one ends, away from the corresponding winding column, of each pull rope, clamping plates are movably connected to one ends, away from thepull rope, of the spring rods, and a liquid conveying pipe is movably connected to the surfaces of every two clamping plates. When a patient does not have a place to lie prone, the shell can be woundon the waist by the aid of the connecting bands to allow the connecting bands to be located at the abdomen and the shell to be located at the waist, the connecting bands can be pulled to horizontallymove the shell after vertical direction adjustment, the spring rods can be pulled by pulling the pull ropes, liquid medicine flows towards the surface of an elastic mesh when the amount of liquid medicine on the surface of the negative pressure films is larger than the pressure of the negative pressure films, and accordingly a patient can apply the medicine by himself / herself anytime anywhere.

Owner:周建国

High-stability sleeve compensator

PendingCN108980502AAvoid overstretchingExtended service lifePipeline expansion-compensationArchitectural engineeringCompensation effect

The invention provides a high-stability sleeve compensator. The high-stability sleeve compensator comprises a stable sleeve pipe, and channel opening ports are formed in the two ends of the stable sleeve pipe, an inner sleeve pipe sleeves the stable sleeve pipe, and a stable buckle is arranged at the bottom of the outer side of the inner sleeve pipe; an outer sleeve pipe is arranged outside the inner sleeve pipe, the bottom of the outer sleeve pipe is fixedly connected with the outer wall of the stable sleeve pipe, and a fixing buckle corresponding to the stable buckle is arranged on the innerwall of the outer sleeve pipe; a filling pressing cover is further filled in a gap formed between the outer sleeve pipe and the inner sleeve pipe, a tight pressing ring is arranged at the bottom of the filling pressing cover, a sealing cavity is formed among the tight pressing ring, and the outer sleeve pipe and the inner sleeve pipe; and a filling material is arranged in the sealing cavity, andthe outer sleeve pipe and the upper end face of the filling pressing cover are fixed through a tight pressing bolt. According to the sleeve compensator, the inner sleeve pipe is prevented from being excessively stretched, the stability of the compensator is increased, and the service life of the compensator is prolonged; the sleeve compensator is novel in design and good in compensation effect.

Owner:江苏永昌膨胀节有限公司

Active and automatic adhesive tape deviation rectifying mechanism

ActiveCN113415664ASkewAvoid overstretchingFinal product manufactureWrappingStructural engineeringSilicone tape

The invention belongs to the field of processing and application of adhesive tapes and particularly discloses an active and automatic adhesive tape deviation rectifying mechanism. The active and automatic adhesive tape deviation rectifying mechanism comprises frames, a first deviation rectifying mechanism and a second deviation rectifying mechanism which are arranged at intervals in an adhesive tape walking direction, wherein an adhesive tape roller is rotatably arranged between the upper ends of the rear parts of a left frame and a right frame through a mounting shaft; the first deviation rectifying mechanism comprises a deviation rectifying roller; the deviation rectifying roller is arranged above an adhesive tape and is in tangent contact with the adhesive tape; a first adjusting assembly can adjust the deviation rectifying roller to vertically lift and fall and can move left and right between the left frame and the right frame to adjust the position of the adhesive tape; the second deviation rectifying mechanism comprises a deviation rectifying flat plate B and a vacuum deviation rectifying suction cup; a second adjusting assembly can adjust the vacuum deviation rectifying suction cup to vertically lift and fall and / or move left and right relative to a portal frame through the deviation rectifying flat plate B so as to adjust the position of the adhesive tape; the first deviation rectifying mechanism and the second deviation rectifying mechanism are applied to active rectification of deviation of the adhesive tape during operation of equipment and before operation of the equipment; deviation of the adhesive tape is more accurately rectified; the system is stable; the efficiency is high; and the operation accuracy is high.

Owner:洛阳尚奇机器人科技有限公司

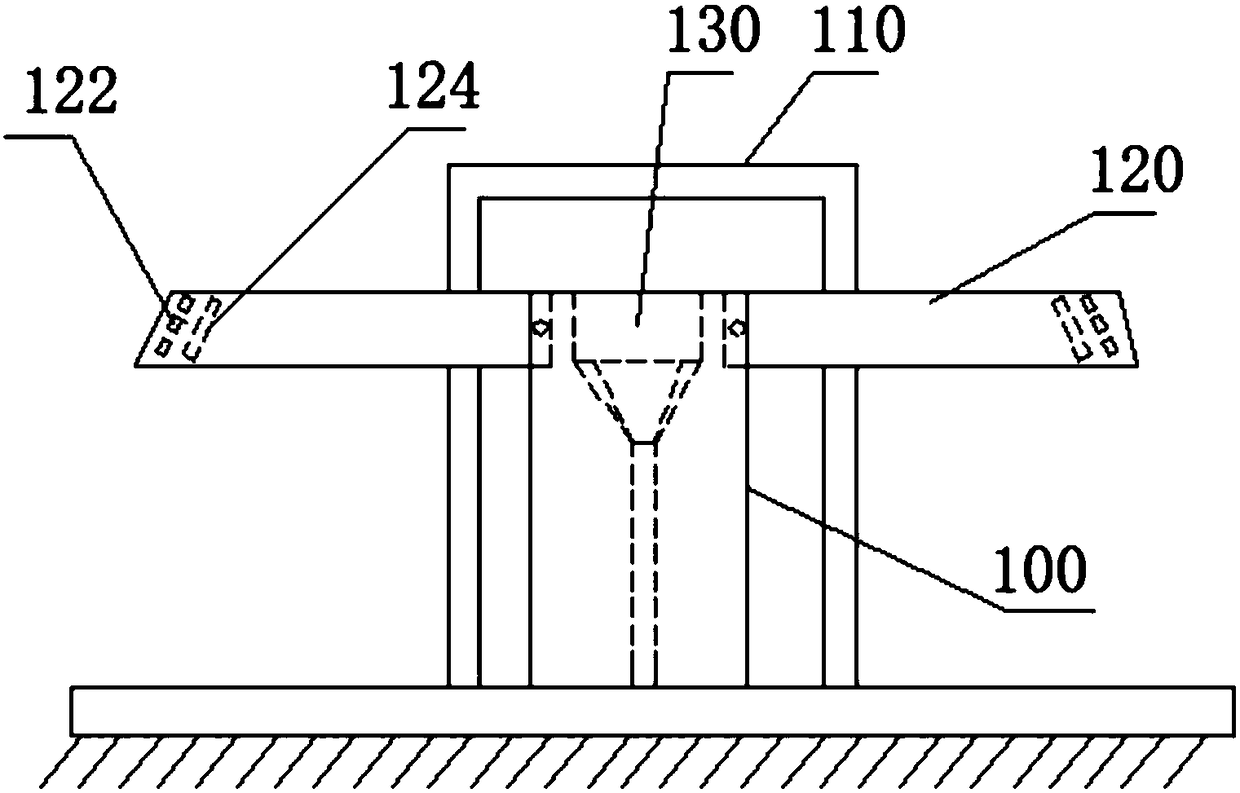

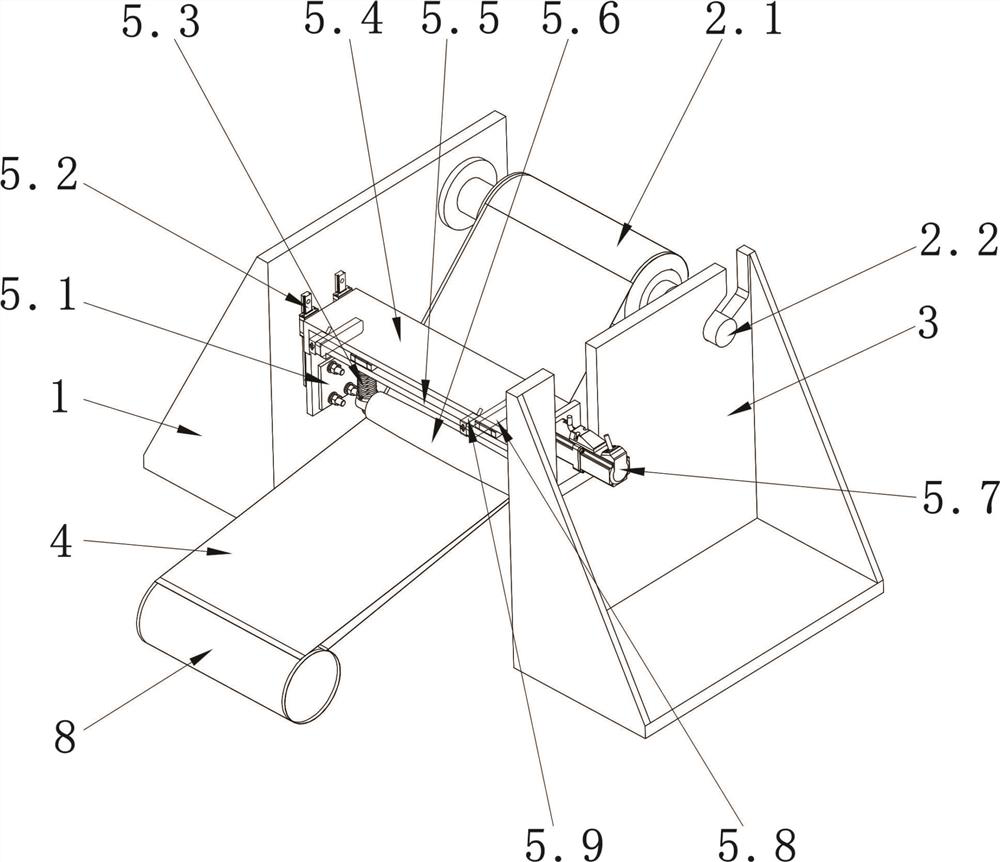

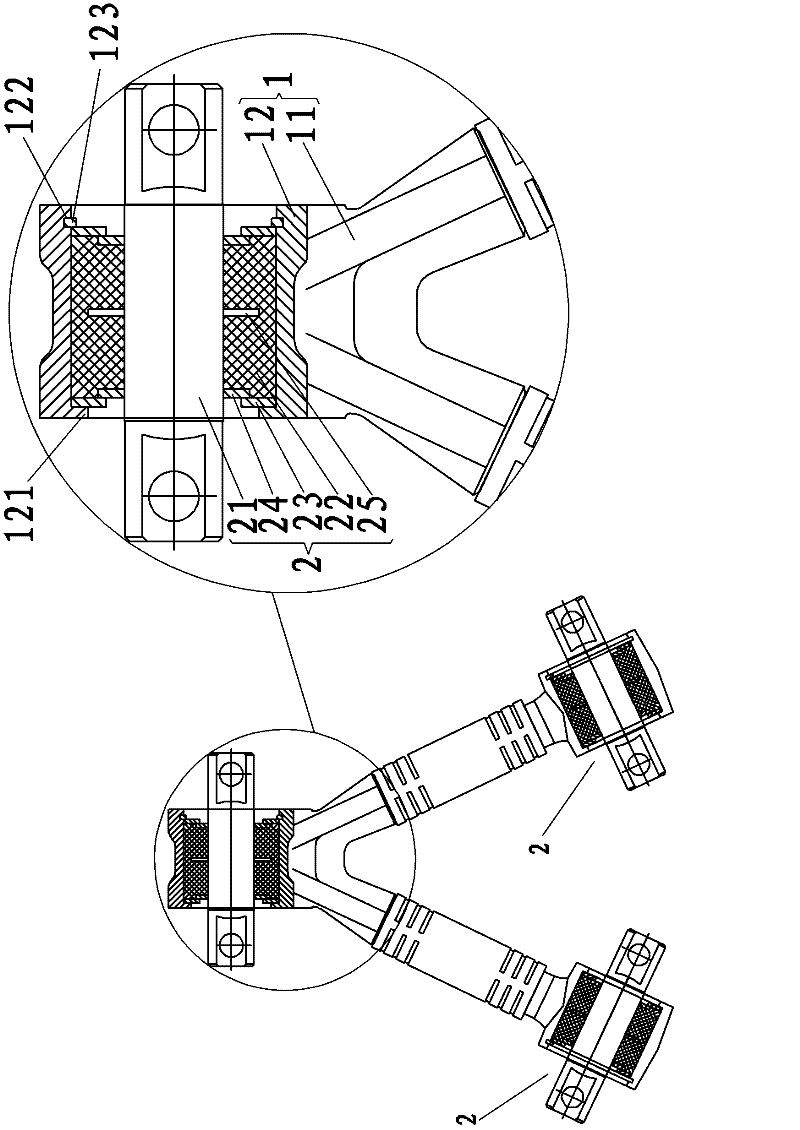

Ultrathin material clamping device and clamping method thereof

ActiveCN113601025AStretch flatAvoid overstretchingMeasurement devicesLaser beam welding apparatusEngineeringMechanical engineering

The invention belongs to the technical field of material clamping, and particularly relates to an ultrathin material clamping device and a clamping method thereof. The ultrathin material clamping device comprises a stretching device, a detection device used for detecting the thickness of an ultrathin material, a rack and a control device, wherein one side of the ultrathin material is fixed to the rack; the driving end of the stretching device is connected with the other side of the ultrathin material; the signal output end of the detection device is connected with the input end of the control device; the output end of the control device is connected with the control end of the stretching device, and the control device controls the stretching device to move to tension the ultrathin material; and the stretching device and the detection device are both fixed to the rack. According to the device, the corresponding tensioning force can be matched according to the thickness data of the ultrathin material, and automatic tensioning of the ultrathin material is achieved; and the stretching device controls the movable clamping device to be far away from the fixed clamping device, so that the ultrathin material is stretched flatly, the thickness of the ultrathin material is measured through the detection device to be matched with corresponding tensioning force, the ultrathin material is prevented from being stretched excessively, control is convenient, and the structure is simple.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

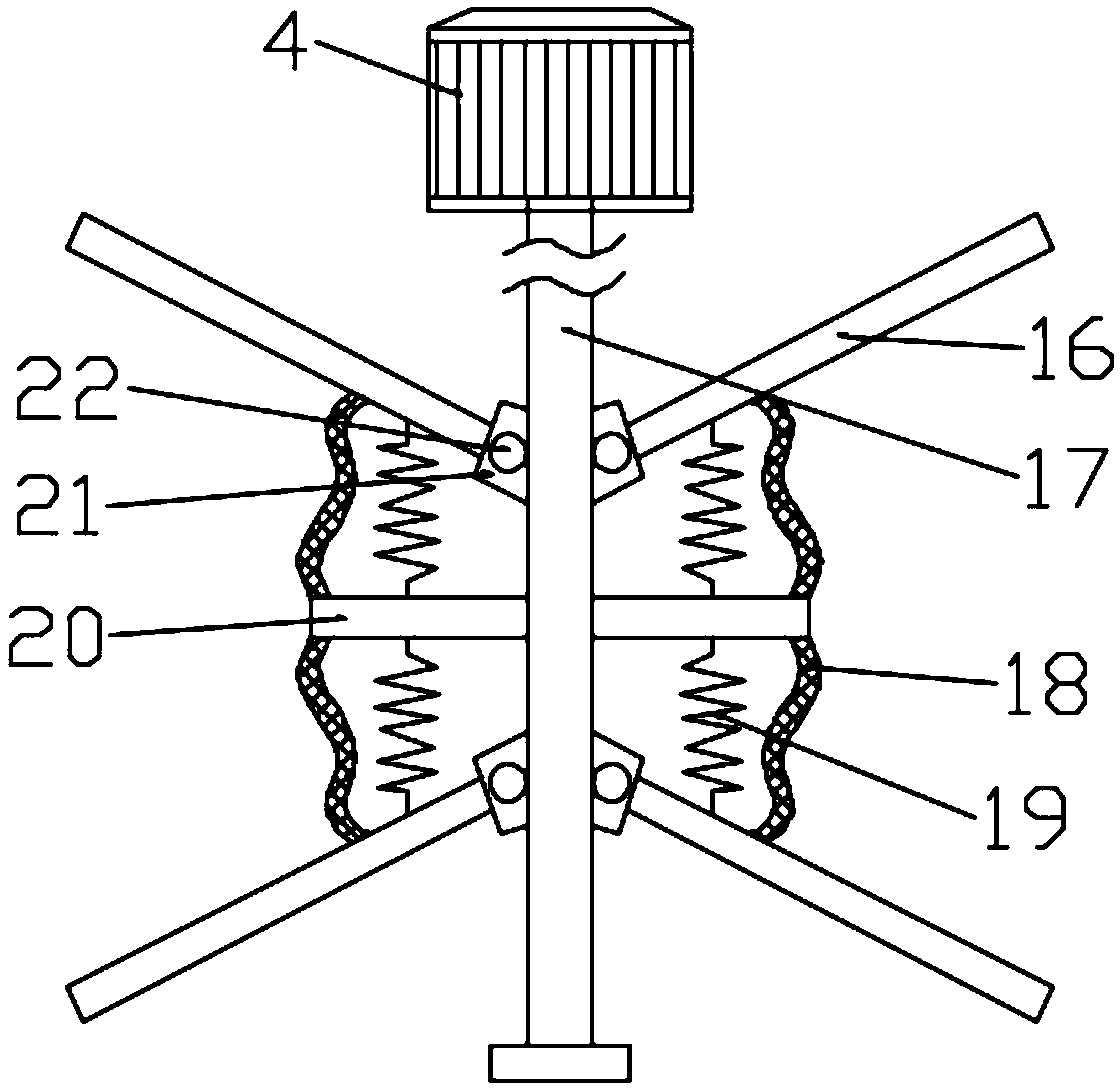

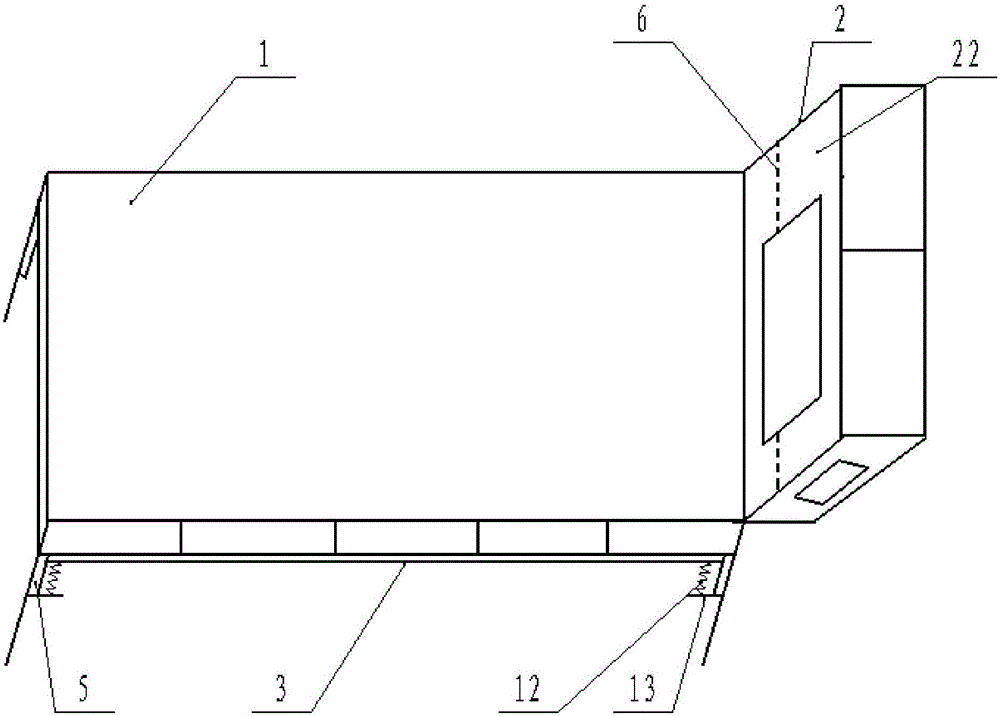

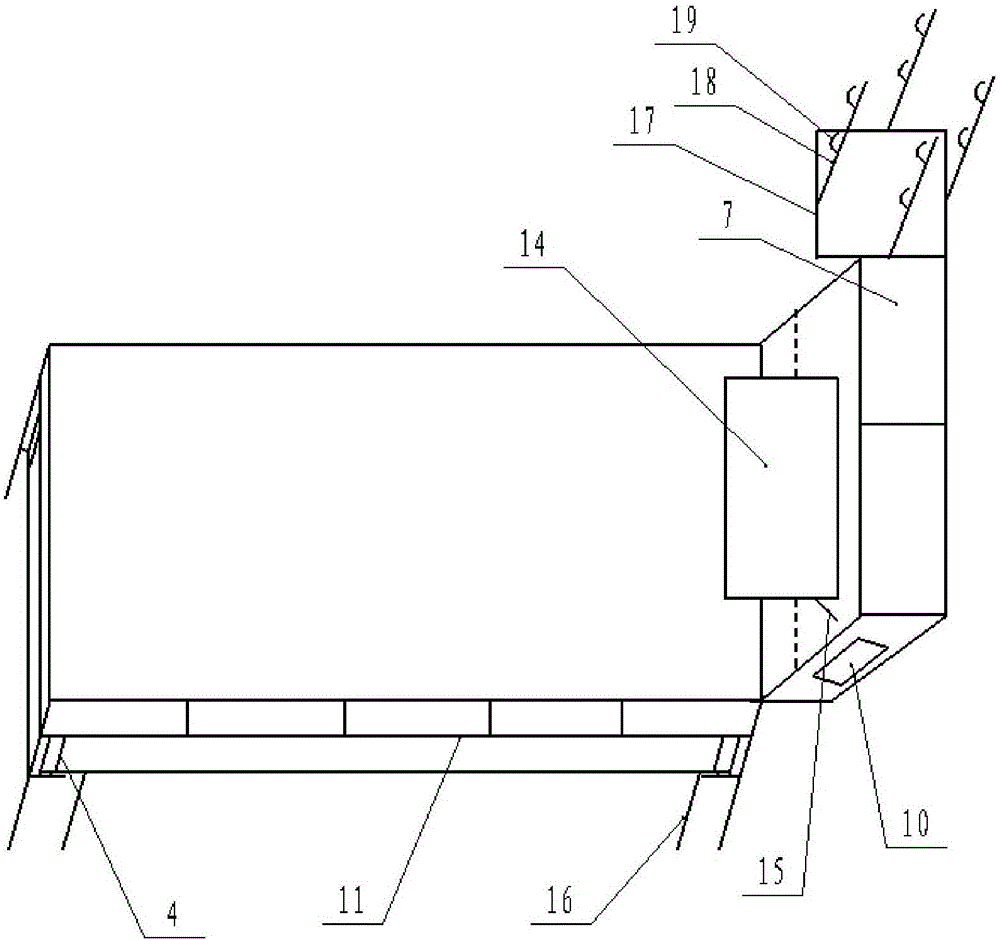

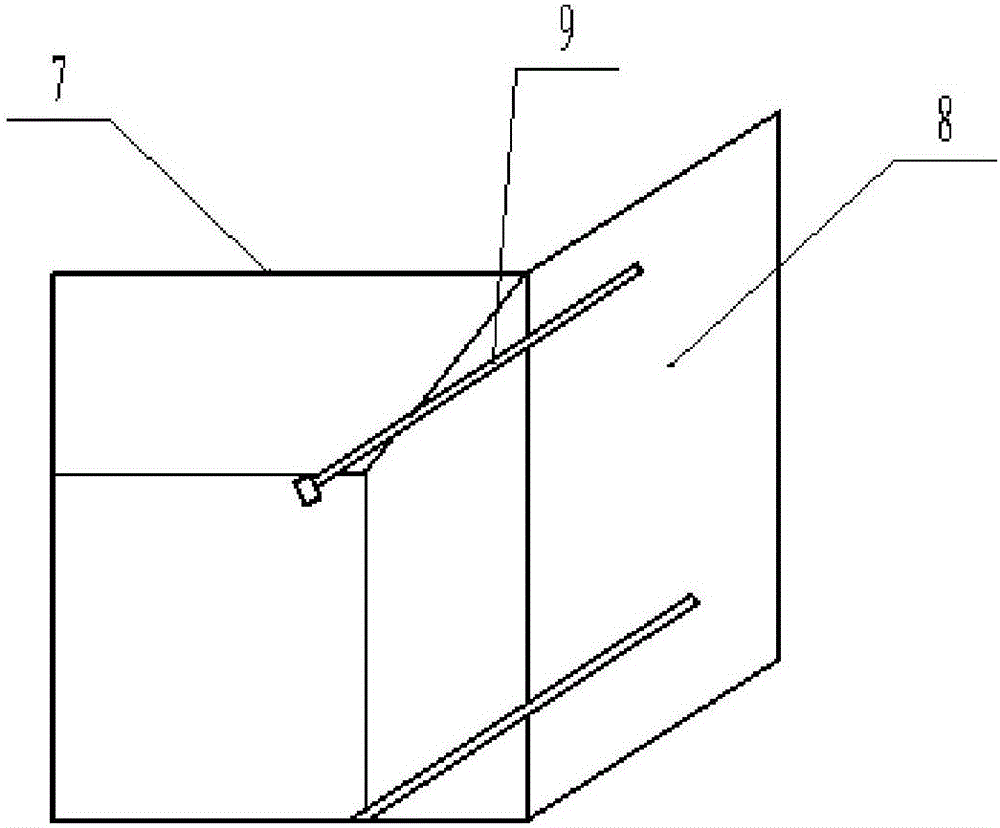

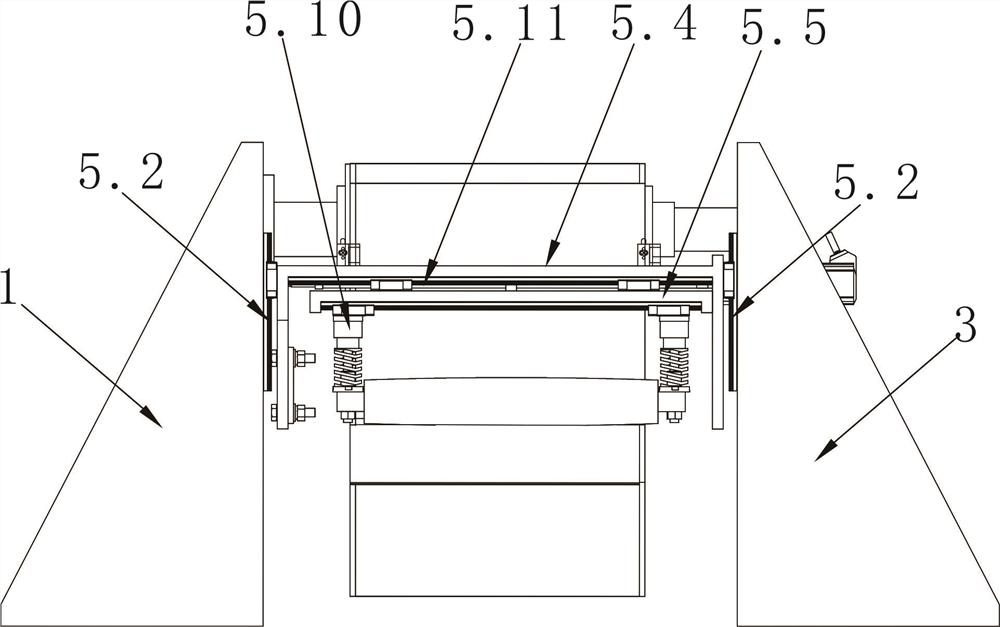

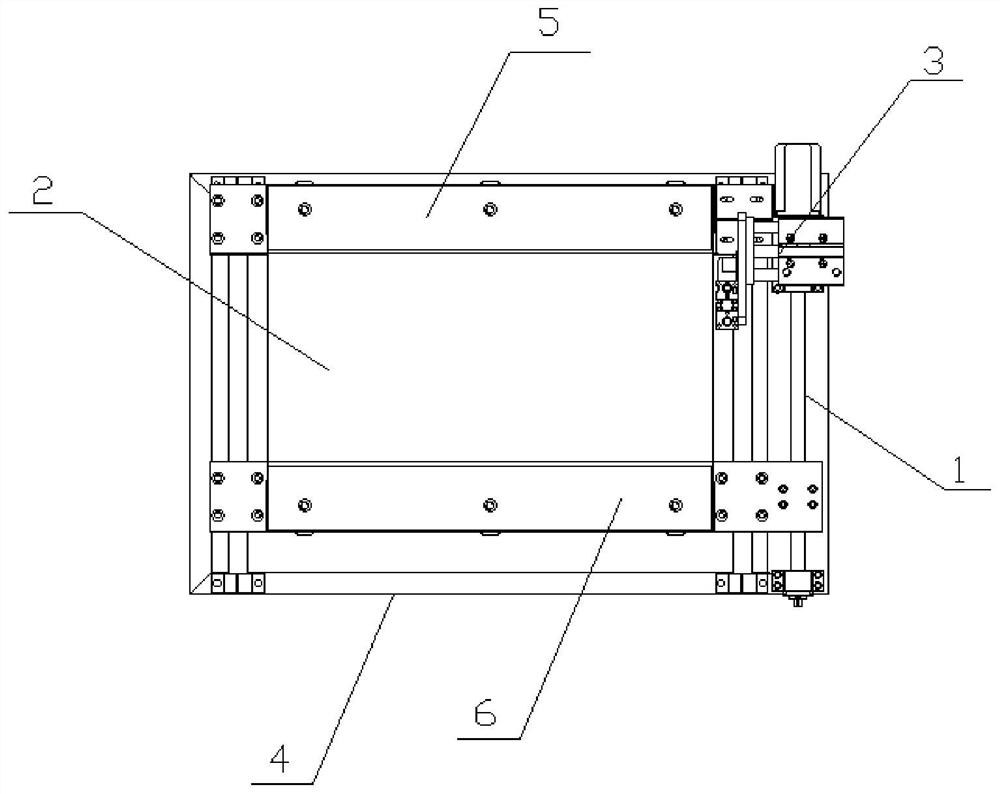

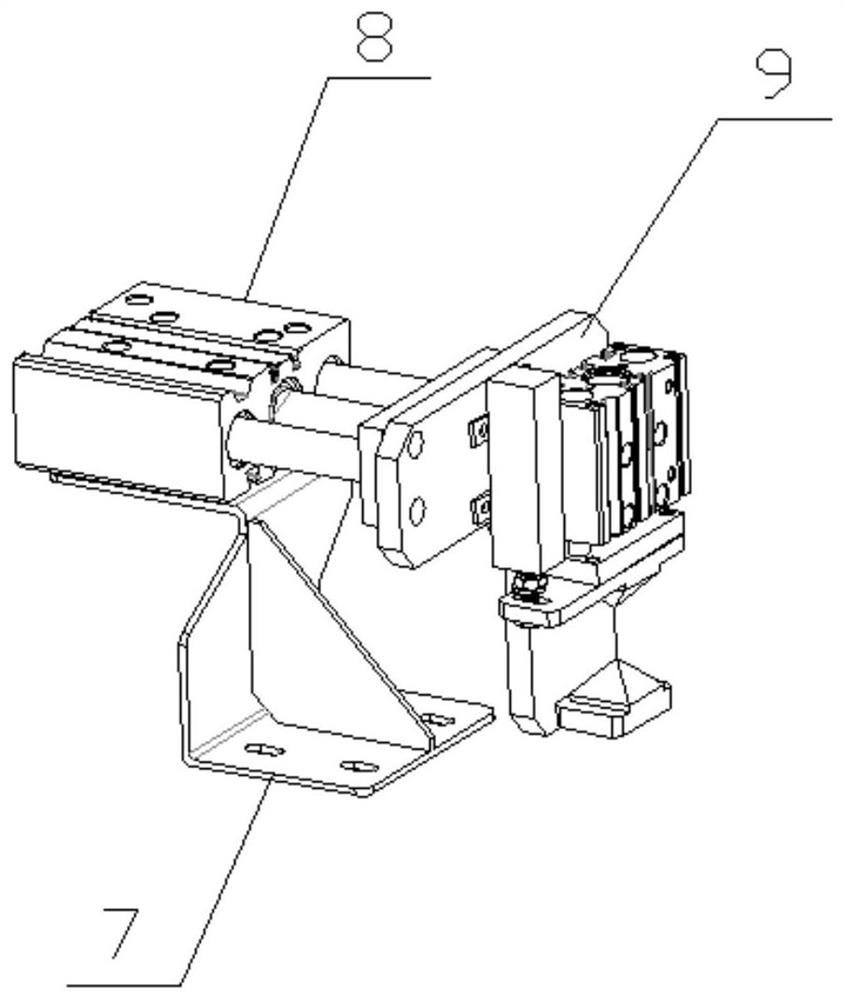

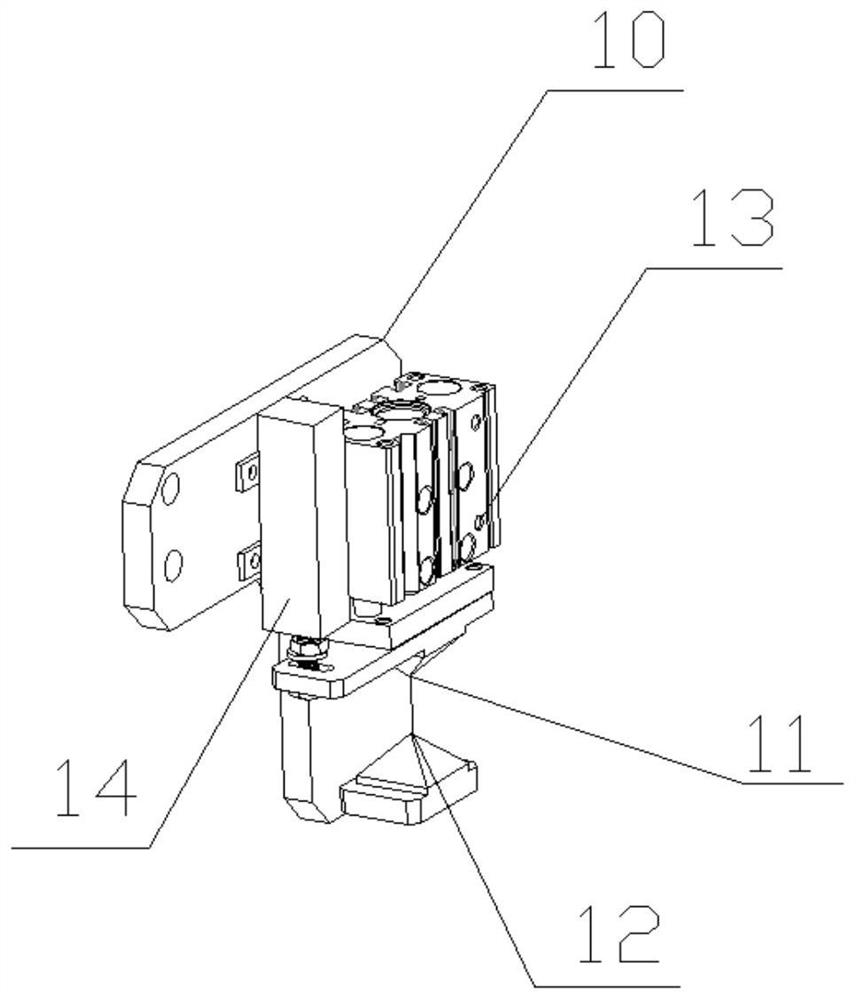

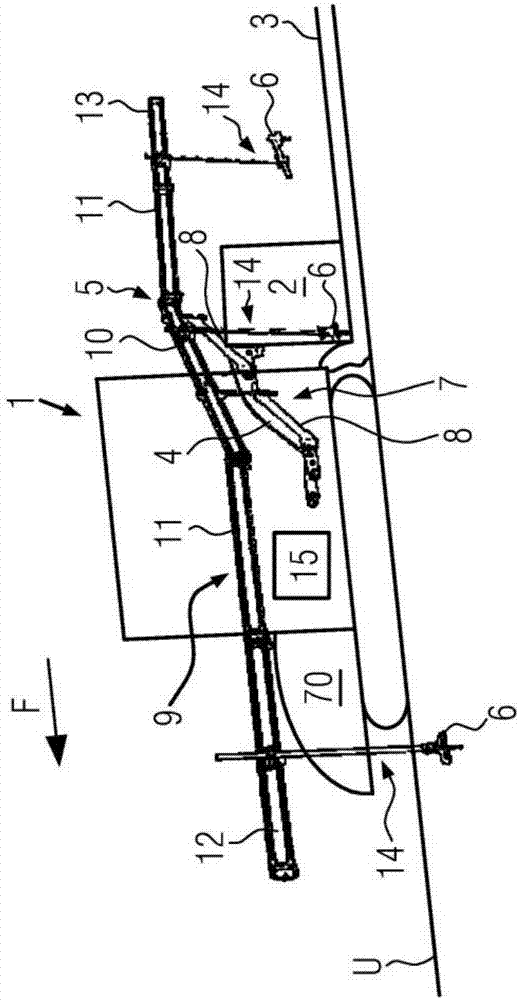

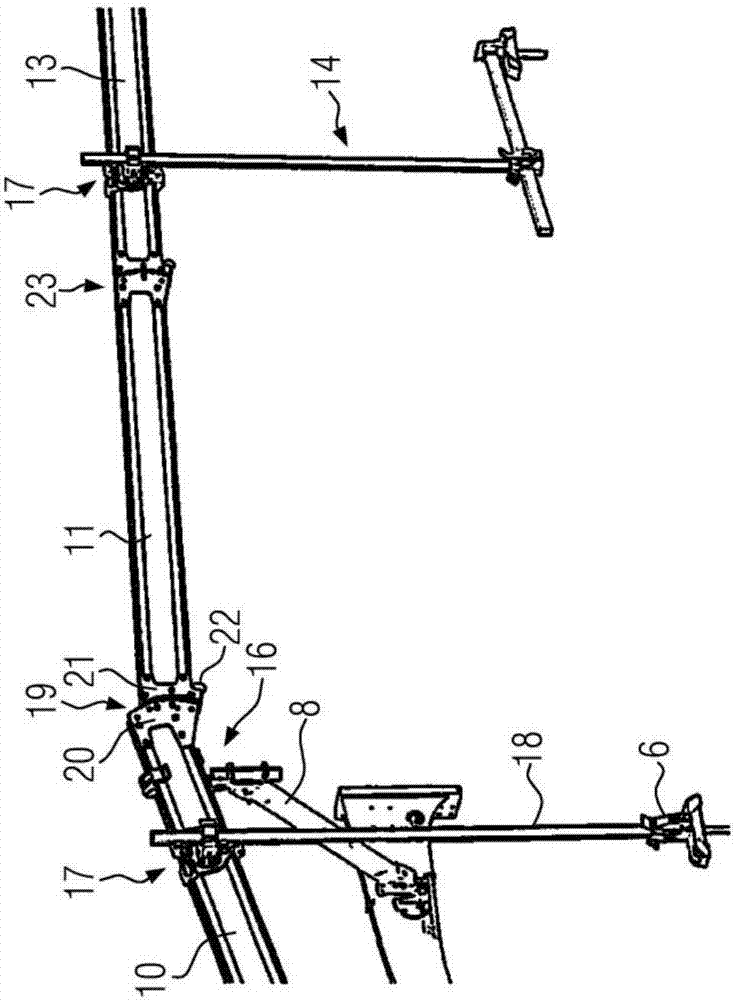

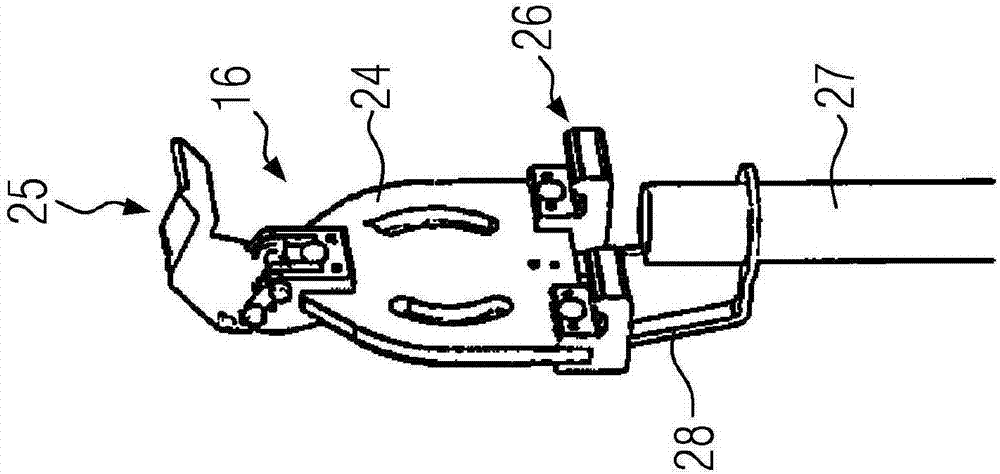

Road paver with holding device for carrying and positioning sensor unit

ActiveCN107268395AGuaranteed adjustabilityAvoid overstretchingRoads maintainenceMechanical measuring arrangementsScreedEngineering

The invention relates to a road paver (1) with a paving screed (2) with an adjustable height for installing a road surface layer (3) and at least one holding device (5) for carrying and positioning of at least one sensor unit (6), wherein the holding device (5) has at least one swivel arm module (7) for fastening the holding device (5) on the road paver (1), at least one carrier arm module (9) and at least one sensor module (14) comprising the sensor unit (6), wherein the carrier arm module (9) is fastened by means of a first clamping device (16) on the swivel arm module (7) and the sensor module (14) by means of a second clamping device (17) on the carrier arm module (9), and wherein the first and second clamping devices (16, 17) are formed respectively for a predetermined clamping force (K) when the respective clamping devices (16, 17) are in a closed position.

Owner:JOSEPH VOEGELE AG

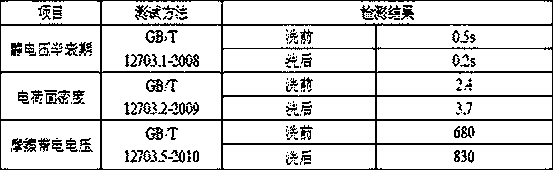

Color-spun polyester-viscose fabric and production method thereof

PendingCN110983573AImprove featuresPromote sheddingWoven fabricsLiquid/gas/vapor textile treatmentPolyesterViscose

The invention provides a color-spun polyester-viscose fabric and a production method thereof. Four-time continuous hair grabbing is adopted in hairiness grabbing and shearing, one-time hairiness shearing is realized, integral molding is realized, the production efficiency is improved, relatively large tension force is used in the first-time hairiness grabbing to facilitate quick fuzzing, relatively small tension force is used in the second-time and third-time hairiness grabbing to avoid damaging the fabric surface, grabbed hairiness is denser and more uniform, relatively large tension force isused in the fourth-time hairiness grabbing to comb the grabbed hairiness so as to facilitate subsequent hairiness shearing, hairiness grabbing and shearing are uniform through control of the tensionforce in the four-time hairiness grabbing, the fabric is good in wool-like effect, is fluffy and soft in hand feel and is resistant to fuzzing and pilling, difficult in hair slip, good in water washing appearance, comfortable to wear and excellent in antistatic property, the method is advanced and reasonable in processing flow, the product quality is stable, the method is simple and reliable, is high in production rate, short in period and high in color fixation rate and reduces sewage discharge from the perspective of energy saving and environmental protection, the product quality can be improved, and the fabric is good in quality sense and excellent in market economic benefit.

Owner:LILANG CHINA

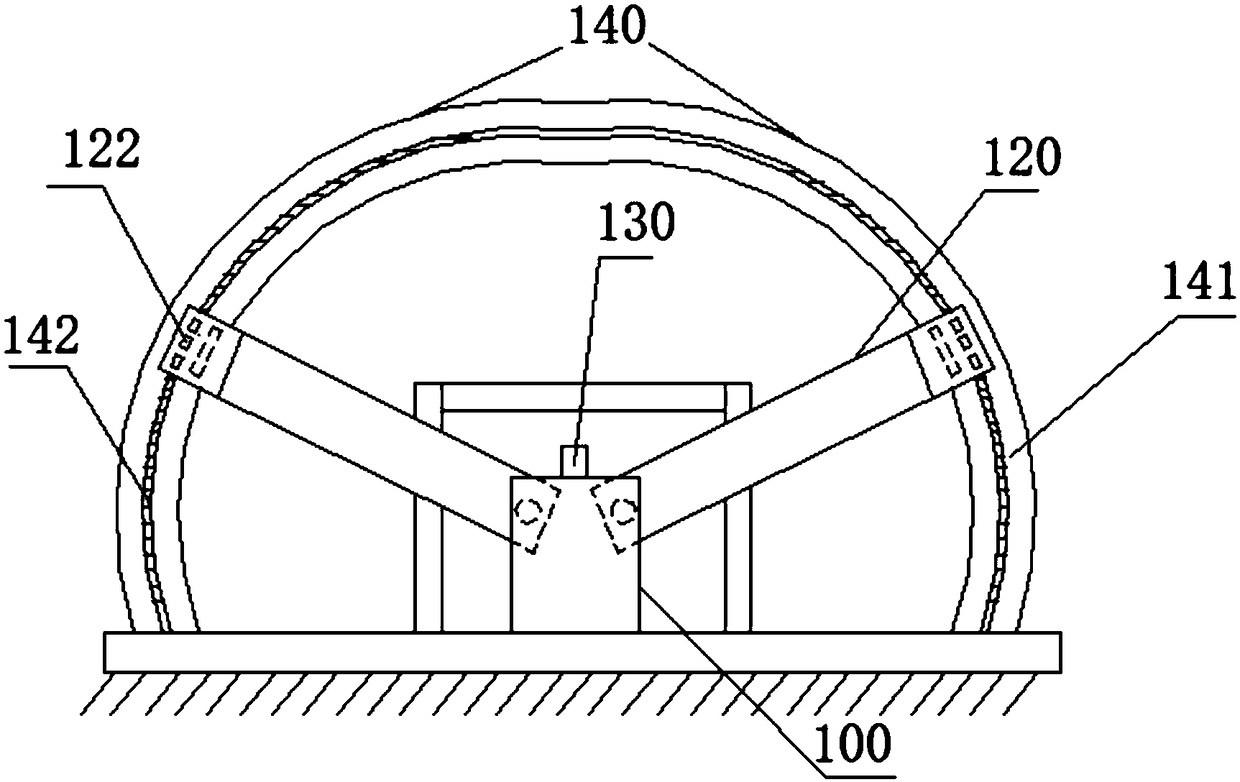

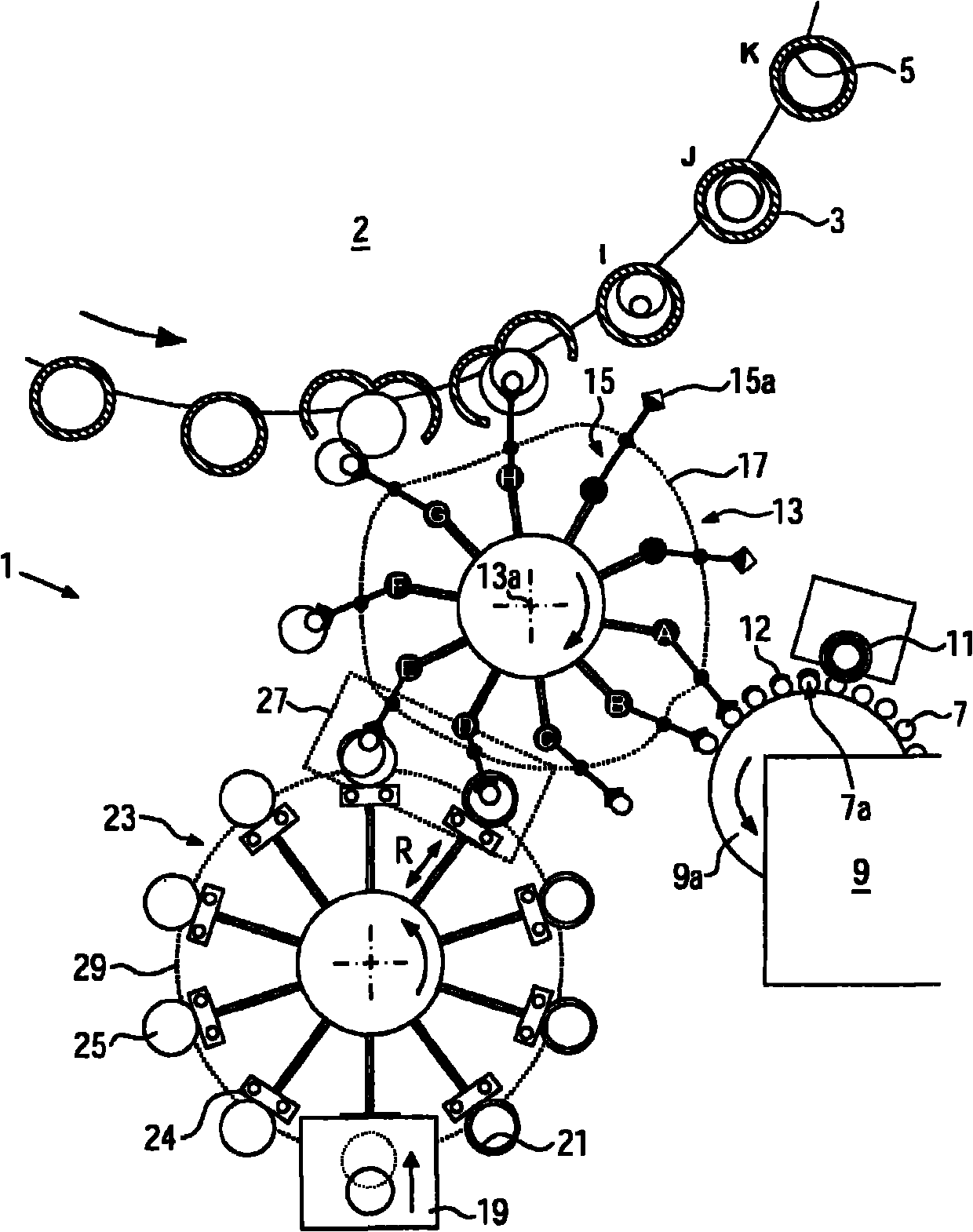

Labeler and a labeling method for labeling plastic bottles in a blow mold

InactiveCN102166815AAvoid overstretchingIncrease production capacityLabelling non-rigid containersBlow moldingMolding machine

The invention relates to a labeler and a labeling method for labeling plastic bottles in a blow mold. A labeler for labeling plastic bottles in the blow mold, in particular in the rotary blow molder comprising a plurality of blow molds; a transfer star wheel for introducing preforms into the blow molds; and at least one transfer device for transferring labels to the preforms, and the transfer star wheel and the transfer device move the preforms and the labels towards one another in a transfer region in such a way that a respective label is affixed to a circumferential subarea of a preform. In this manner, the label can be inserted in the blow mold in a particularly fast and reliable manner and excessive stretching of the label during blow molding can be avoided.

Owner:KRONES AG

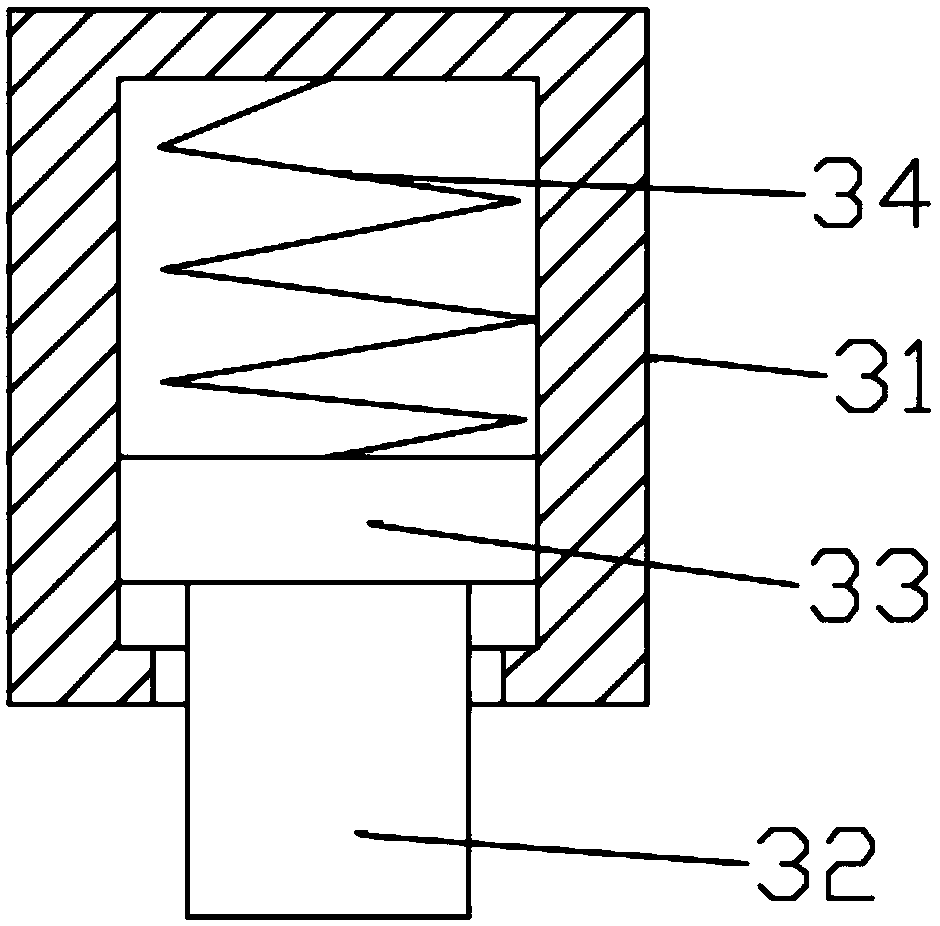

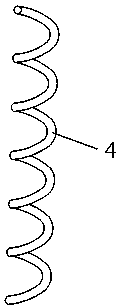

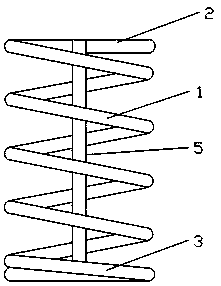

Stretching limiting spring

InactiveCN108930739AAvoid overstretchingEnough elasticityWound springsEngineeringMechanical engineering

The invention discloses a stretching limiting spring, and belongs to the field of mechanical parts. The stretching limiting spring comprises a spring body, a spring base body arranged extending from the spring body to one side, a spring end body arranged extending from the spring body to the other side, and a limiting strip arranged between the end of the spring base body and the end of the springend body. The inner diameter is gradually increased from the end of the spring base body to the direction of the spring body, and the inner diameter is gradually increased from the end of the springend body to the direction of the spring body. The spring body, the spring base body and the spring end body are of an integrated structure. Anticorrosive layers are arranged on the surfaces of the spring body, the spring base body and the spring end body correspondingly. By arranging the limiting strip, the spring is prevented from being excessively stretched, the spring is protected while it is guaranteed that the spring has sufficient elasticity, the structure is simple, and using is convenient.

Owner:十堰凯林汽车运输有限公司

A kind of rubber plastic strip tensile capacity detection device

ActiveCN111650042BStretch PreciselyEasy to stretchMaterial strength using tensile/compressive forcesHydraulic cylinderEngineering

The invention discloses a device for detecting the tensile capacity of rubber and plastic strips. An automatic clamping mechanism is installed on the side, a hydraulic cylinder is installed on the worktable under the lifting plate, and the hydraulic cylinder is connected with the buffer mechanism. The top of the buffer mechanism is installed with a manual clamping device, and the bottom of the rubber plastic strip is fixed to the manual clamping device. Inside, a tension measuring device is connected between the lifting plate and the buffer mechanism. The invention is convenient for fixing the rubber-plastic strip, and accurately measures the tensile properties of the rubber-plastic strip.

Owner:SUZHOU CANGMIN EIECTRONIC TECH CO LTD

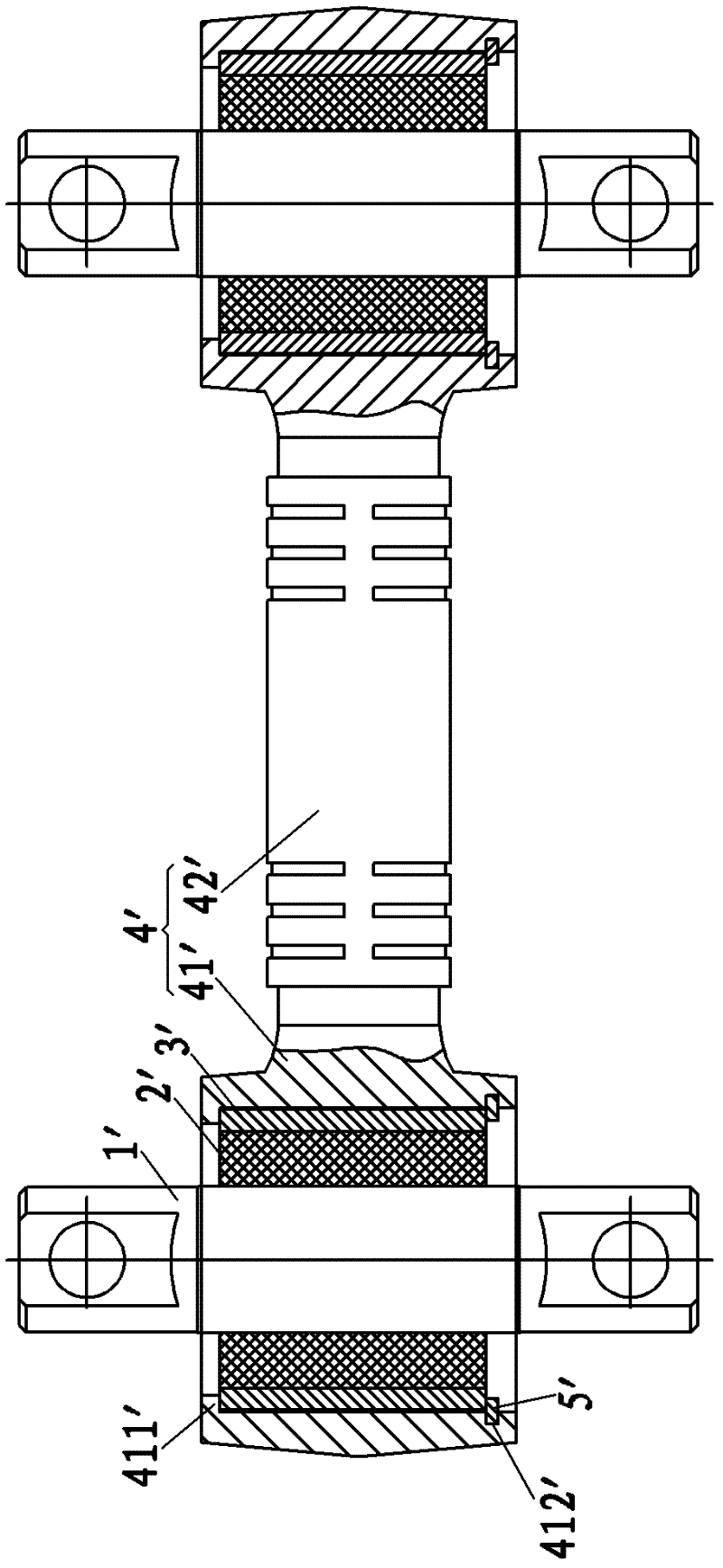

Improved reaction rod with joint assembly

ActiveCN102269232ANo pollutionSave energyNon-rotating vibration suppressionRubber-like material springsActin rod assemblyMechanical engineering

The invention discloses an improved-type counteractive rod with a joint assembly. The rod comprises the counteractive rod and the joint assembly which is embedded in and fixed in a rod head of the end part of the counteractive rod; the joint assembly comprises a bearing pin, an elastic body, a rod head rigid limit baffle plate, a bearing pin rigid limit baffle plate and a rigid internal fixed baffle plate; the bearing pin, the rod head and the bearing pin rigid limit baffle plate form an annular containing chamber for filling the elastic body, and a radial limit clearance is respectively arranged between the rod head, the bearing pin rigid limit baffle plate and the inner side wall of the rod head or the bearing pin; the rigid internal fixed baffle plate is fixedly arranged on the bearingpin and is positioned in the containing chamber, and separates the containing chamber axially into two parts which are relatively independent, and a radial limit clearance is arranged between the outer diameter of the rigid internal fixed baffle plate and the inner side wall of the rod head. After adopting the technical scheme, the shock absorption effect of the improved-type counteractive rod with the joint assembly is optimal, the elastic body can be effectively prevented from cracking and dropping off due to excessive tension, the structure is very stable, and the service life is longer.

Owner:QUANZHOU XINLONG AUTOMOBILE PARTS MFG CO LTD

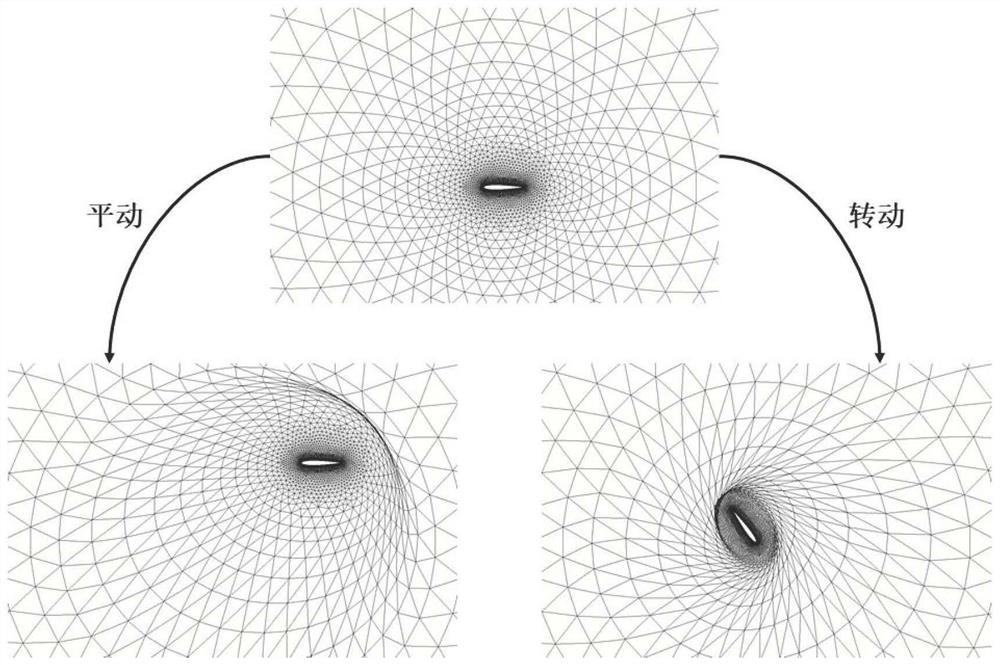

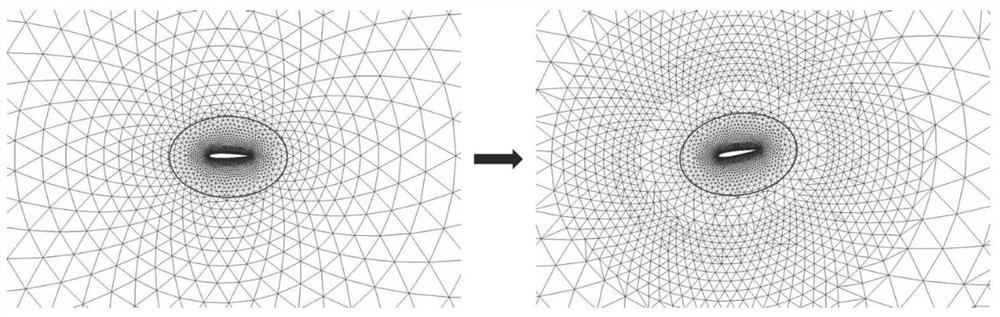

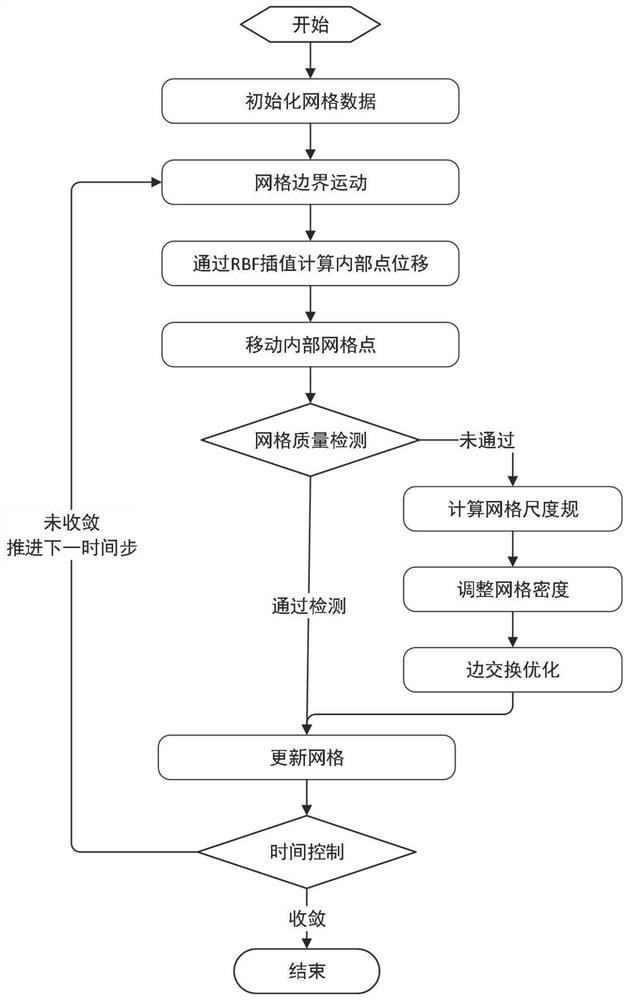

Hybrid dynamic grid method based on radial basis function interpolation and adaptive reconnection

InactiveCN111881633AQuality improvementAvoid overstretchingDesign optimisation/simulationSelf adaptiveMesh grid

The invention provides a hybrid dynamic grid method based on radial basis function interpolation and self-adaptive reconnection, which comprises the following steps: acquiring initialized grid data ofa simulation object, and initializing time; updating the initialized grid data by adopting a radial basis function interpolation algorithm to obtain first grid data of the current time step; when a fragment grid unit lower than a quality threshold value exists in the first grid data, performing scale gauge calculation on the grid unit in the first grid data according to a preset growth factor; according to a calculation result of a scale gauge, performing adaptive reconnection on grid cells in the first grid data to obtain second grid data; and when a preset time condition is reached, outputting the second grid data. The method provided by the invention can improve the calculation capability of the discrete grid for large-displacement and large-deformation motion boundary problems, and enhances the applicability and robustness of the dynamic grid method.

Owner:NAT UNIV OF DEFENSE TECH

Production method of conductive blended yarn

The invention provides a production method of a conductive blended yarn. The production method comprises the following steps: a, three rows of rollers are arranged into a first drafting region between front and middle rollers and a second drafting region between middle and rear rollers, and the two drafting regions are different in drafting rate; b, an elastic fiber and a complex fiber are suspended on the bobbin hanger of a three-roller spinning frame used in the step a, respectively, next, the complex fiber is continuously fed by the middle roller of the spinning frame, and overfeeding and the drawing of the first drawing region are performed by virtue of the change of the speed of the middle roller so that a complex fiber strand in a sudden changing bamboo joint style can be formed; meanwhile, the elastic fiber is continuously fed by the rear roller of the spinning frame, and overfeeding and the sequential drawing of the second drawing region and the first drawing region are performed by virtue of the change of the speed of the rear roller so that an elastic fiber strand also in the sudden changing bamboo joint style can be formed; c, the complex fiber strand and the elastic fiber strand obtained in the step b are combined and twisted simultaneously by the front roller to form the blended yarn in the special style.

Owner:福建泉州市健凯服饰有限公司

High-efficiency drying equipment for gluten powder and its application method

ActiveCN113375428BDehydration fastEasy to dryDrying solid materials without heatDrying gas arrangementsCentrifugationWater production

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

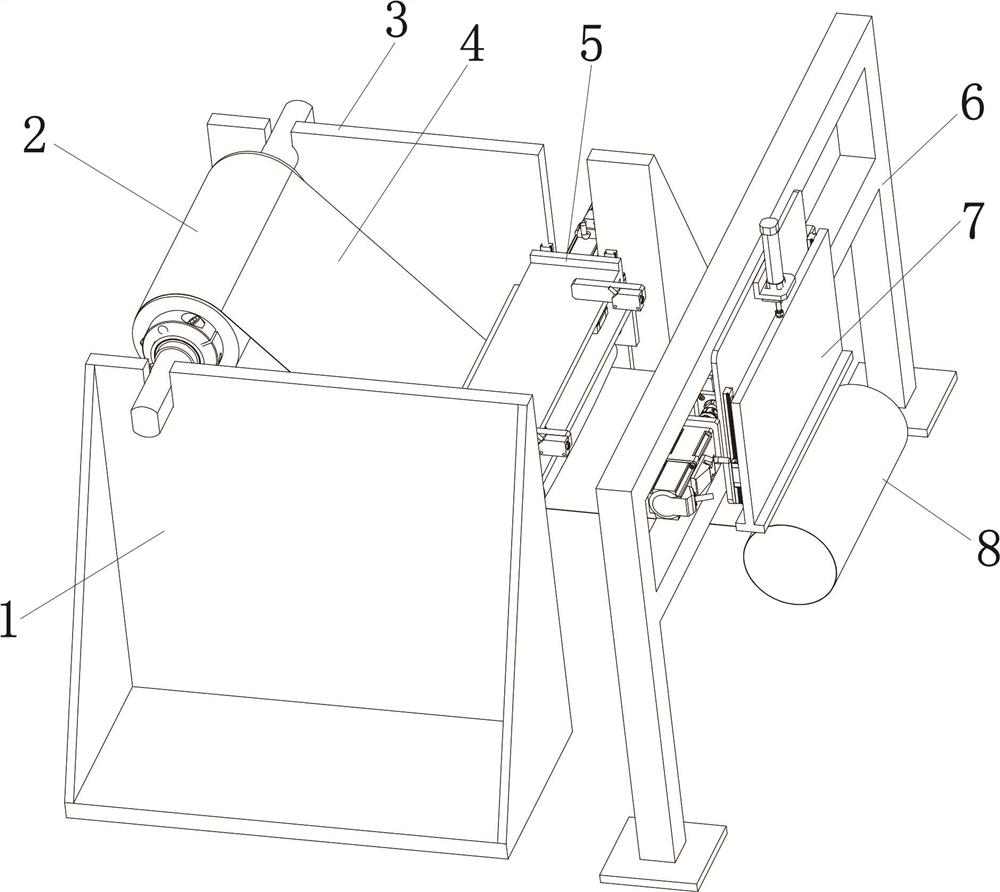

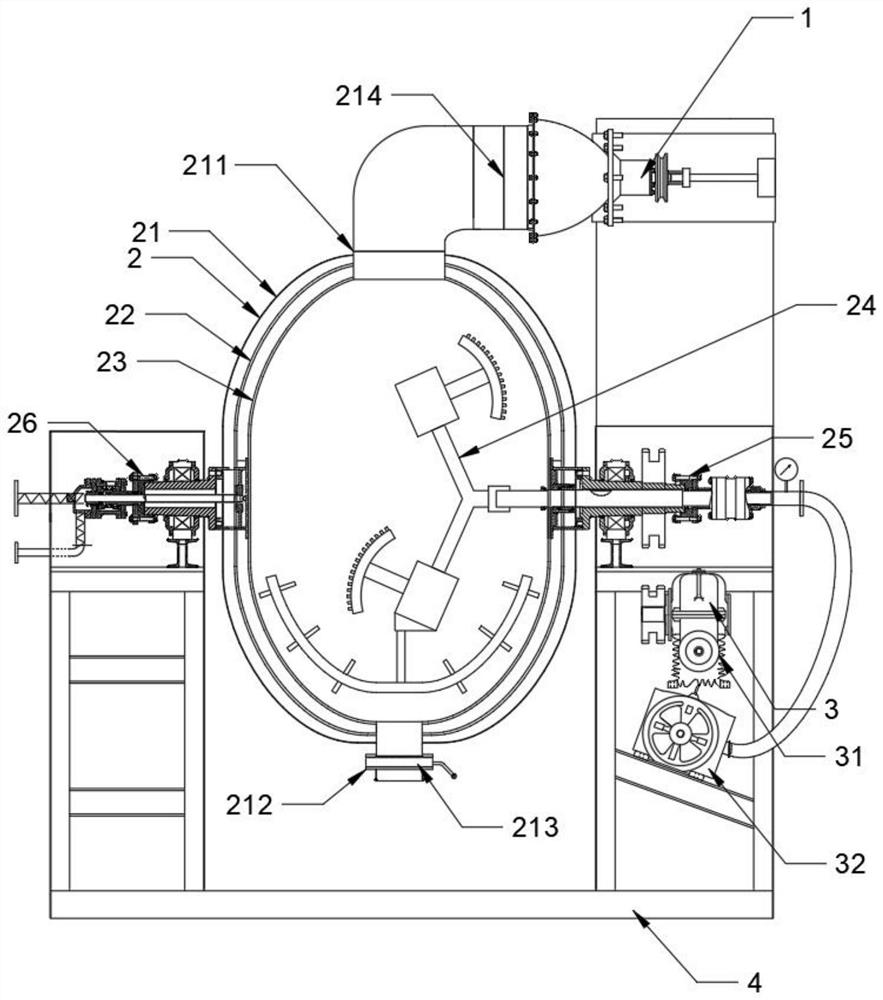

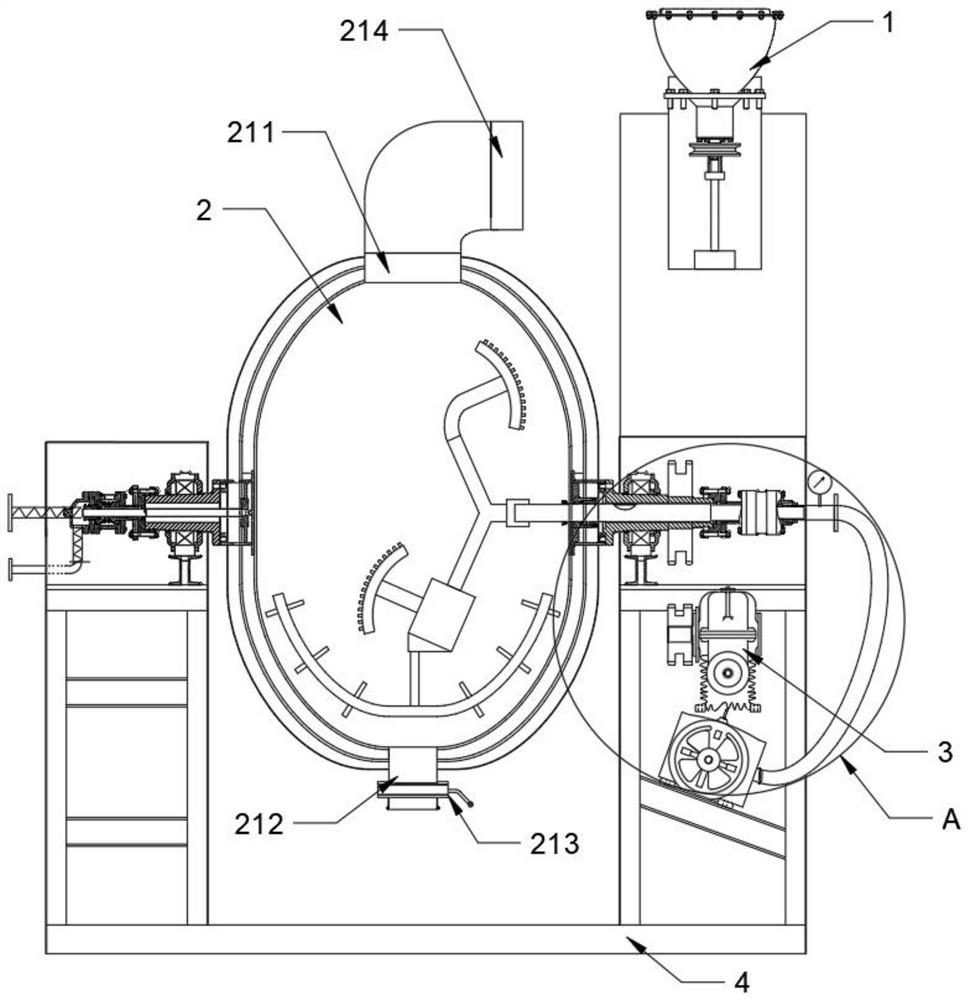

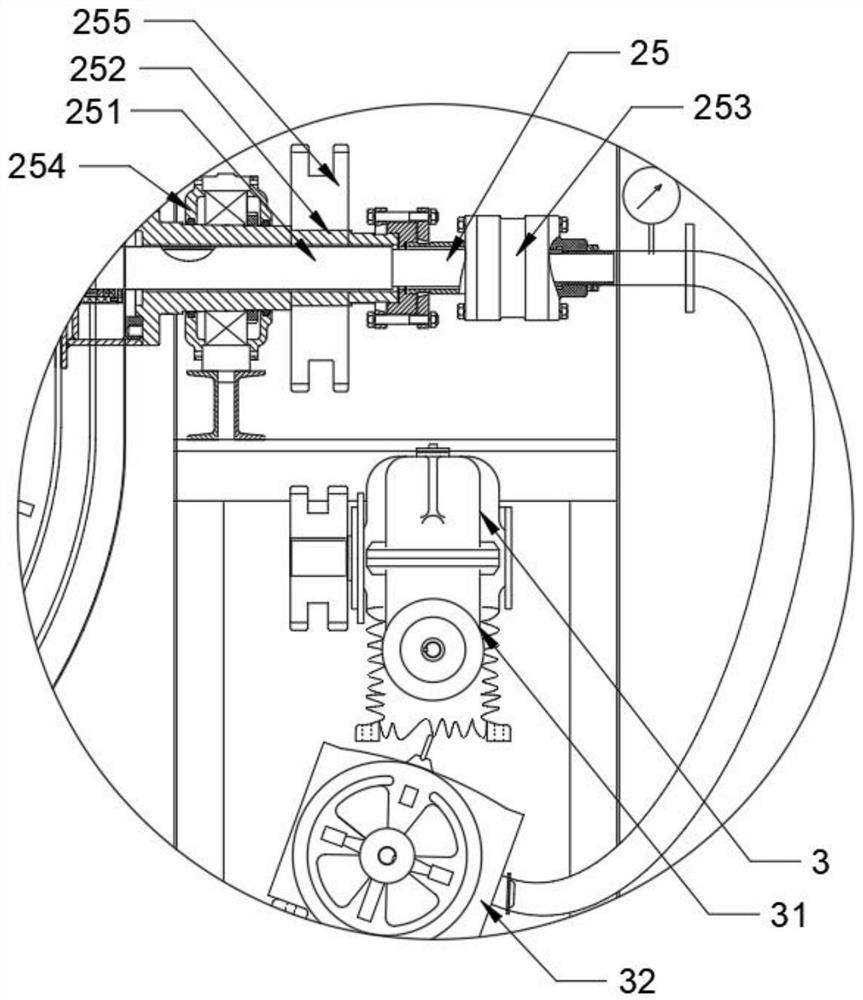

Rubber hose forming detection robot

ActiveCN111458224AIncrease the degree of clampingPlay a role in suppressingMachine part testingMaterial strength using tensile/compressive forcesEngineeringWorkbench

The invention relates to a rubber hose forming detection robot. The rubber hose forming detection robot comprises a workbench, a stretching detection mechanism and an internal pressure detection mechanism, and the stretching detection mechanism is installed on the upper end face of the workbench in a sliding fit mode. The internal pressure detection mechanism is arranged at the right end of the stretching detection mechanism; and the lower end of the internal pressure detection mechanism is in sliding fit with the upper end of the workbench. According to the invention, the design concept of anintegrated controllable structure of stretching and expansion detection is adopted to detect the formed rubber hose; in the horizontal stretching detection process, a multiple clamping structure is adopted to fix and limit the rubber hose, and in the gas expansion process, a structure capable of achieving the fixing, limiting and guiding effects at the same time is adopted to guarantee direct butt joint between the rubber hose and the internal pressure detection mechanism.

Owner:东台汇赢创融科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com