Road paver with holding device for carrying and positioning sensor unit

A technology of sensor unit, holding device, applied in the direction of adopting mechanical devices, roads, roads, etc., to achieve the effect of ensuring installability, easy upgrade, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

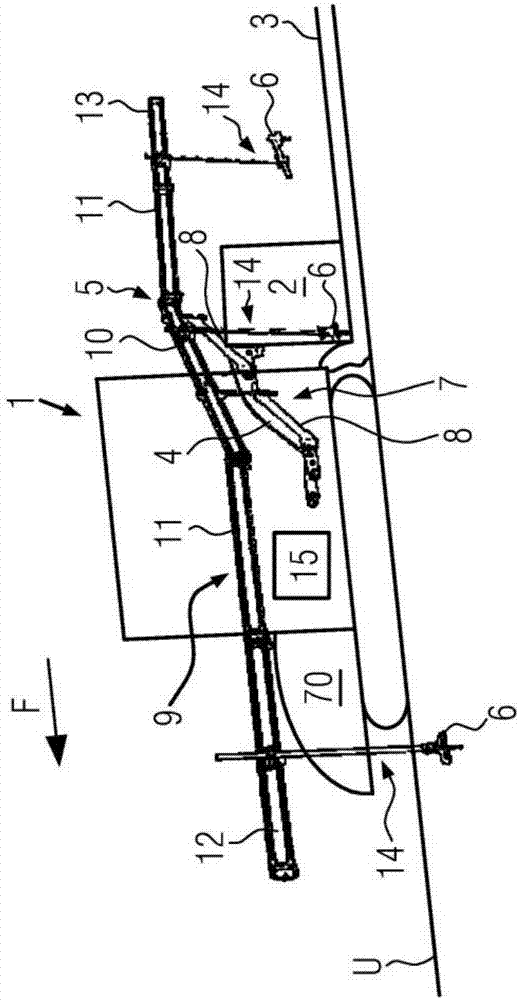

[0057] figure 1 Shown is a road paver 1 with a height-adjustable paving screed 2 for laying a new road layer 3 on a ground U. The road paver 1 has a material hopper 70 which is arranged at the front, viewed in the direction of travel F, and from which the paving material is transported by a material delivery unit, not shown, to the material hopper at the rear. Spread screed 2 for laying.

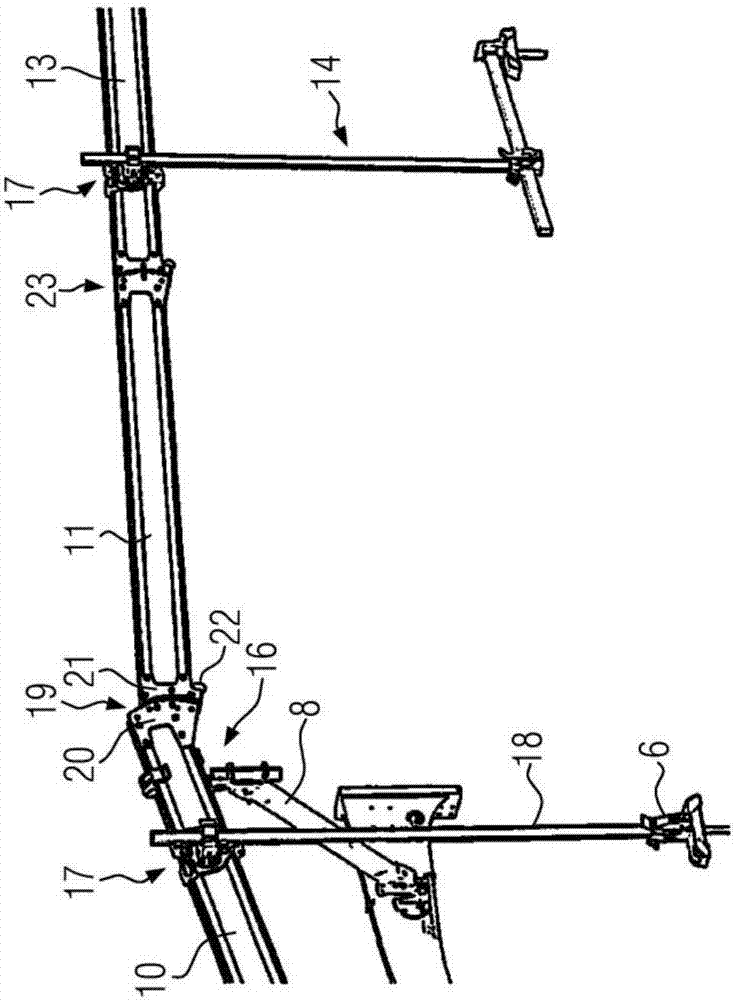

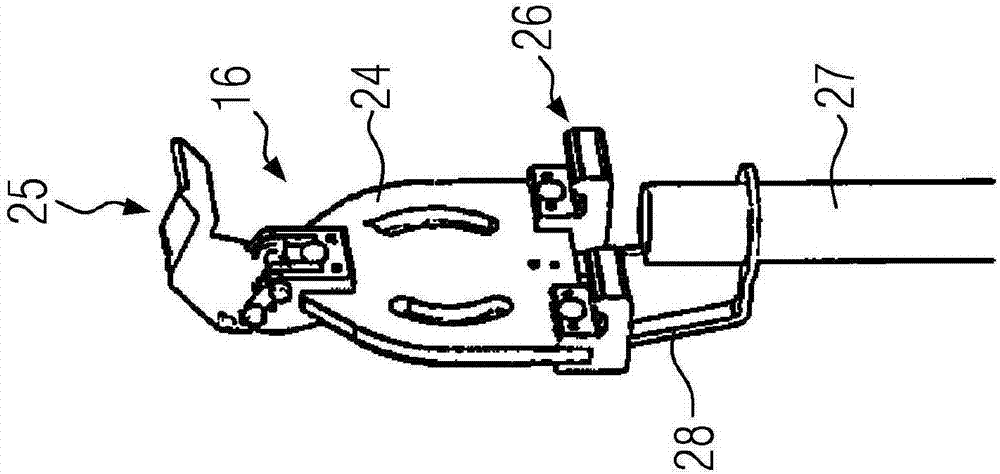

[0058] The paving screed 2 comprises a screed arm 4 to which a holding device 5 is fastened. The holding device 5 is formed for carrying and positioning a plurality of sensor units 6 . The holding device 5 comprises a swivel arm module 7 for fastening the holding device 5 on the road paver 1 . The swivel arm module 7 comprises two swivel arms 8 fastened transversely to the screed arm 4 . Furthermore, the holding device 5 comprises a carrier arm module 9 having a central beam 10 and extension beams 11 fastened on the ends of said central beam 10 . The central beam 10 is carried transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com