External pressure universal expansion joint

An expansion joint, horizontal type technology, applied in the field of expansion joints, can solve the problems of inconvenience in production and residents' life, leakage of corrugated pipes, water interruption and maintenance, etc., and achieve the effect of preventing excessive stretching, avoiding load-bearing deformation, and ensuring overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

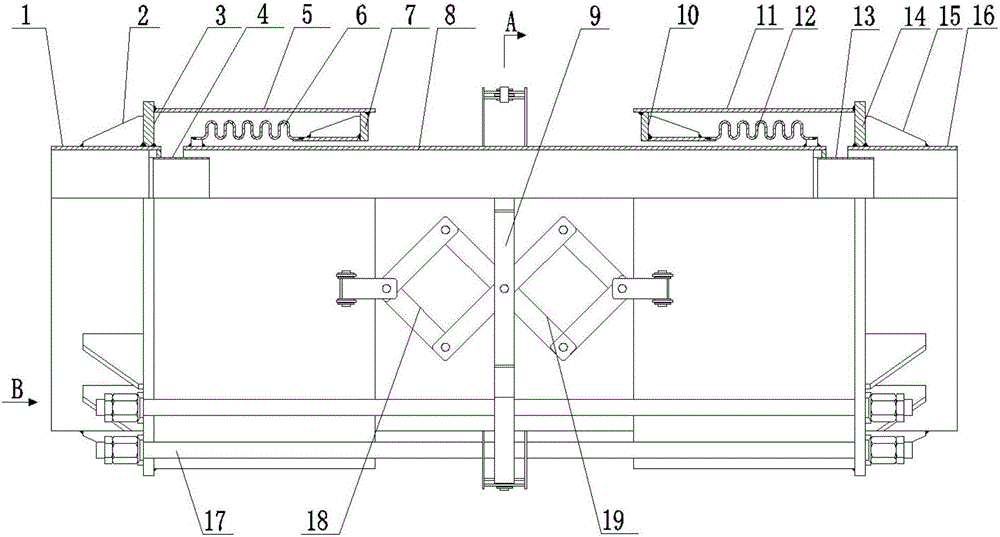

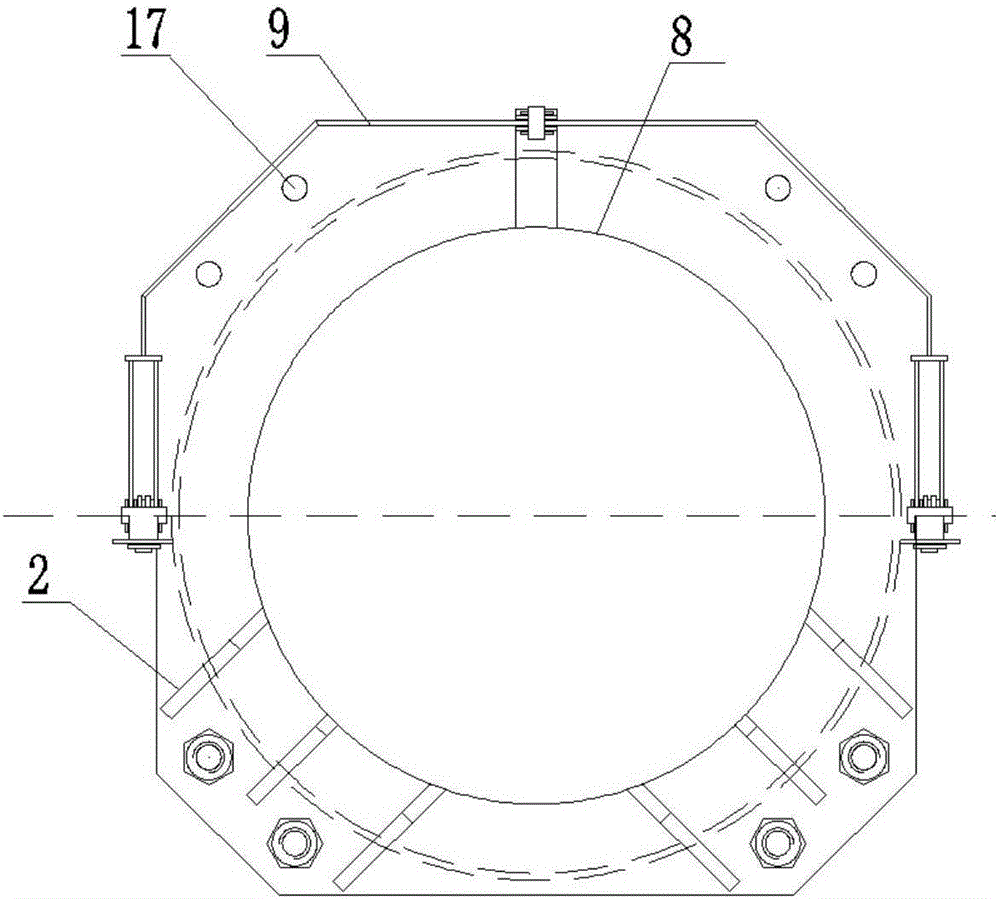

[0017] Such as figure 1 , figure 2 The external pressure transverse expansion joint shown includes a left connecting pipe 1 and a right connecting pipe 16, the left connecting pipe 1 is connected to the left outer casing 5, the left outer casing 5 is coaxially fitted with a left bellows 6, and the left outer casing 5 is connected to the left outer casing 5. The bellows 6 is connected at the end through the left pressure ring plate 7; the right connecting pipe 16 is connected with the right outer casing 11, and the right outer casing 11 is coaxially fitted with the right bellows 12, and the right connecting pipe 16 and the right bellows 12 pass through at the end The right pressure-bearing ring plate 10 is connected; it also includes an intermediate connecting pipe 8 arranged in the left bellows 6 and the right bellows 12, and the two ends of the intermediate connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com