Rubber plastic strip tensile capacity detection device

A detection device and a technology for plastic strips, which are applied in the field of rubber manufacturing, can solve the problems of insufficient fixation and low measurement accuracy, and achieve the effects of accurate tensile property measurement, improved stability, and convenient fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

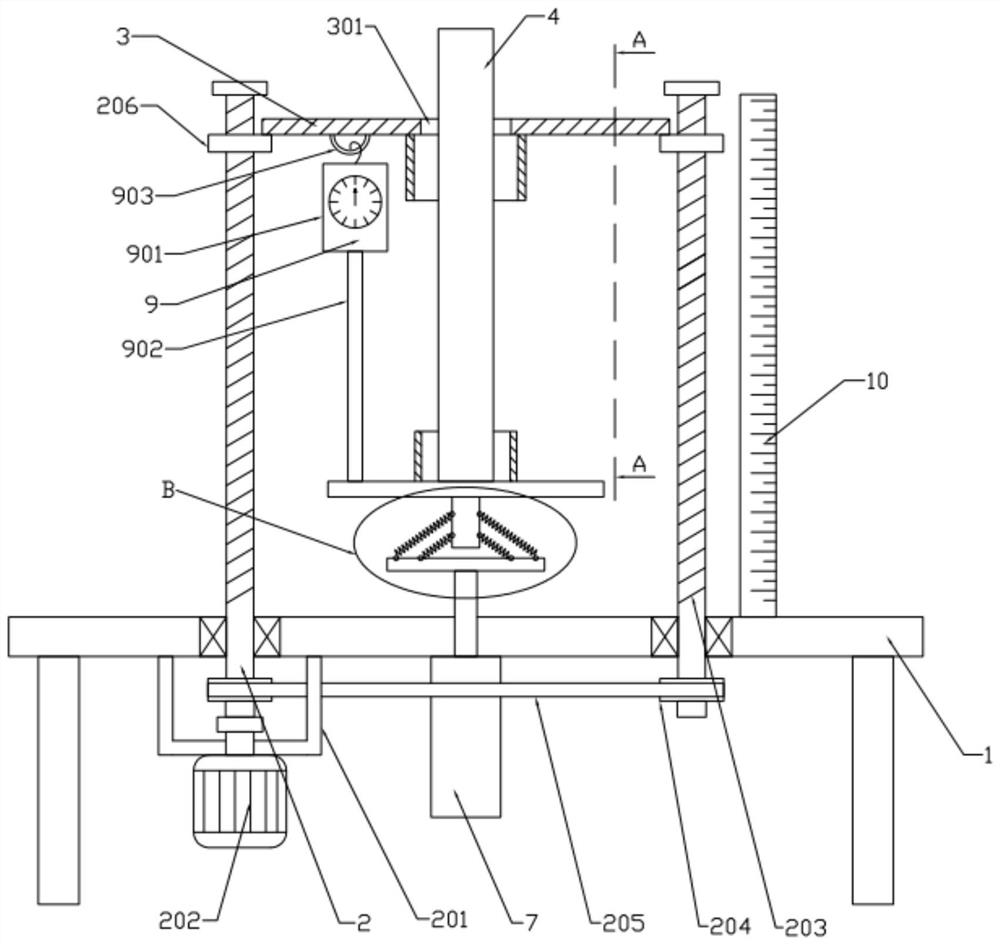

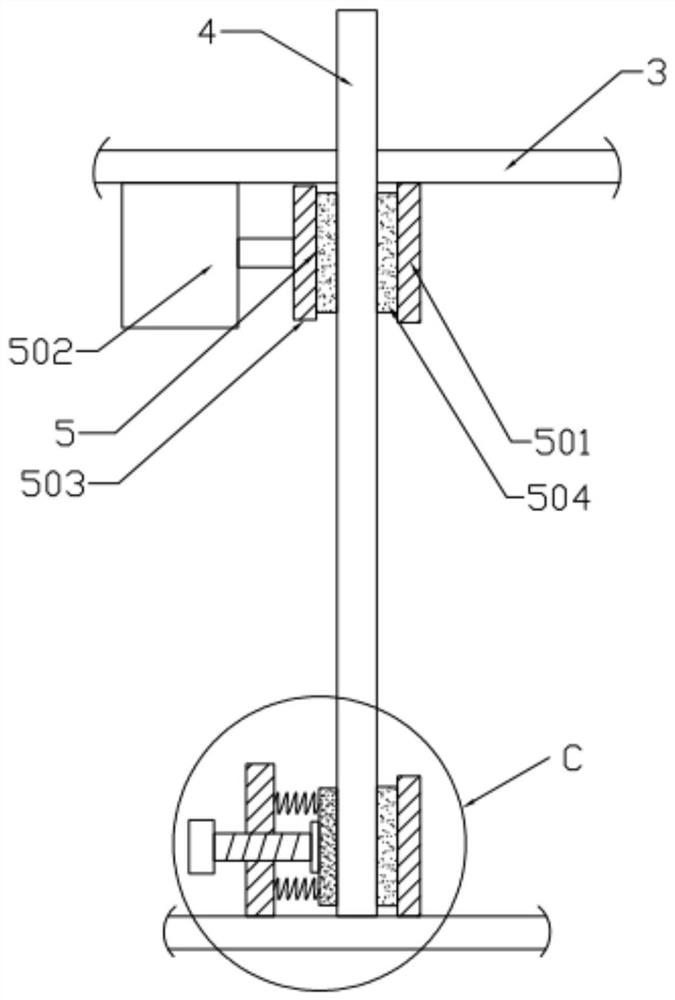

[0021] see Figure 1~4 , in an embodiment of the present invention, a rubber and plastic strip tensile capacity detection device includes a workbench 1, a height adjustment device 2 is installed on the workbench 1, a lifting plate 3 is installed on the height adjustment device 2, and the Said height adjustment device 2 comprises: frame 201, servo motor 202, ball screw 203, synchronous wheel 204, synchronous belt 205 and slide block 206, and described frame 201 is installed on the lower side of workbench 1, and described frame Servo motor 202 is installed on 201, two ball screws 203 are connected in rotation on the workbench 1, and a synchronous wheel 204 is respectively installed on the two ball screws 203, and the two synchronous wheels 204 are synchronized by The belt 205 is rotationally connected, and a slider 206 is installed on the two ball screws 203 respectively, and a lifting plate 3 is connected between the two sliders 206, and the output shaft of the servo motor 202 ...

Embodiment 2

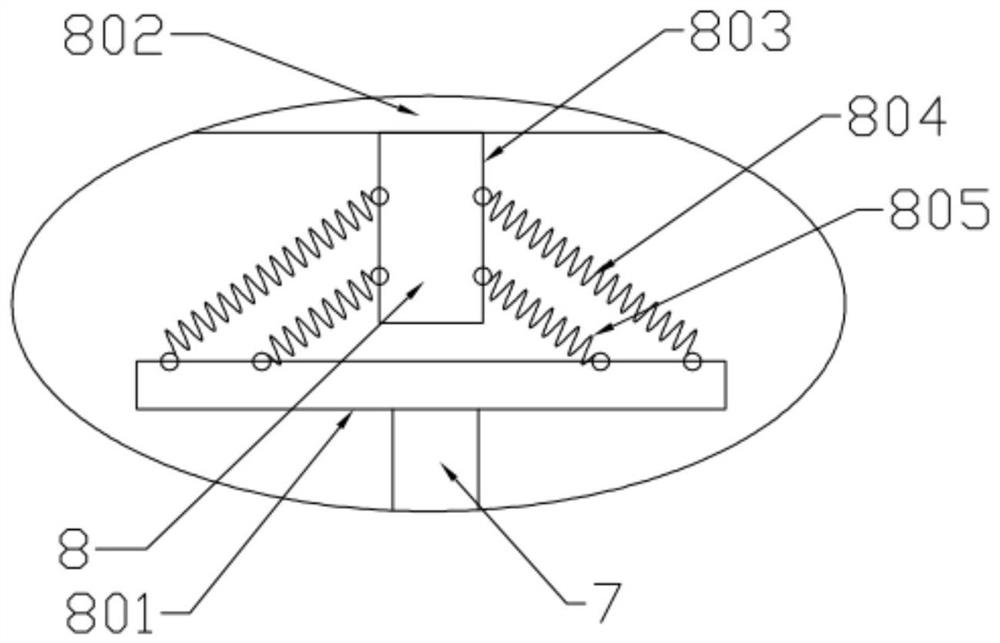

[0023] see figure 1 , in the embodiment of the present invention, the tension measuring device 9 includes: a tension gauge 901, a pull wire 902 and a suspension ring 903, the top of the tension gauge 901 is connected to the suspension ring 903, and the suspension ring 903 is installed on the bottom of the lifting plate 3, so A pull wire 902 is installed on the bottom of the tension gauge 901, and the bottom of the pull wire 902 is connected to the support plate 802, and the length of the pull wire 902 can be adjusted.

[0024]In this rubber and plastic strip tensile capacity detection device, the rubber and plastic strip 4 is put into the manual clamping device 6 through the lifting plate 3, and the ball screw 203 is driven by the servo motor 202 to rotate, and the ball screw 203 is rotated to drive the slide. The block 206 moves up and down, the lifting plate 3 moves up and down by the sliding block 206 moving up and down, the fixed position of the rubber plastic strip 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com