Positioning draw die for connecting sheet

A technology for positioning stretching and connecting pieces, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as unstable stretching structures and mechanical deformation of connecting pieces, and achieve precise stretching and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

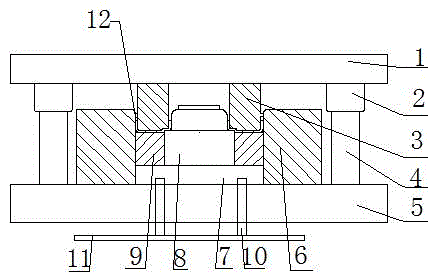

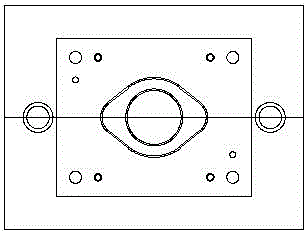

[0013] Such as figure 1 and figure 2 The connecting piece positioning stretching film shown includes an upper template 1 and a lower template 5, and guide sleeves 2 arranged on both sides of the bottom surface of the upper template, and a punch arranged on the bottom surface of the lower template 5 and installed between the guide sleeves 3, and one end of the guide post 4 cooperating with the guide sleeve, the other end of the guide post 4 is installed with the lower formwork 5, and the fixing plate 7 arranged above the lower formwork 5; and the die 6 arranged outside the fixing plate, And the jacking block 9 that is arranged on the inner side of the die, and the flanging punch 8 that is arranged on the inside of the jacking block, the punch 3 is provided with an upper positioning protrusion 12 near the die 6 side; the fixing plate 7 Install two sliding posts 10 on the top; the sliding posts 10 pass through the lower formwork 5 and the horizontal plate 11 and are fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com