Textile machine

A technology for textile machines, machine parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

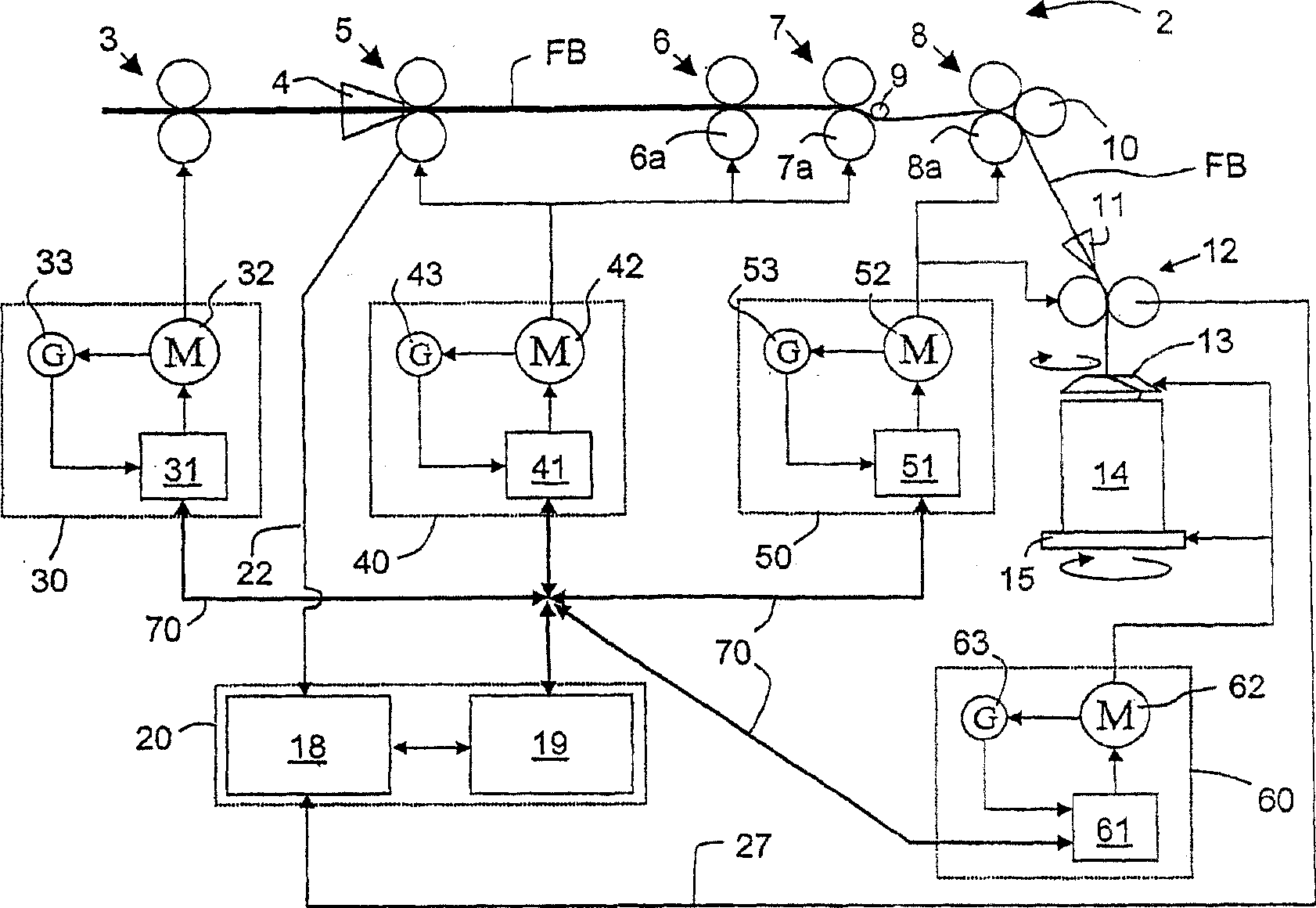

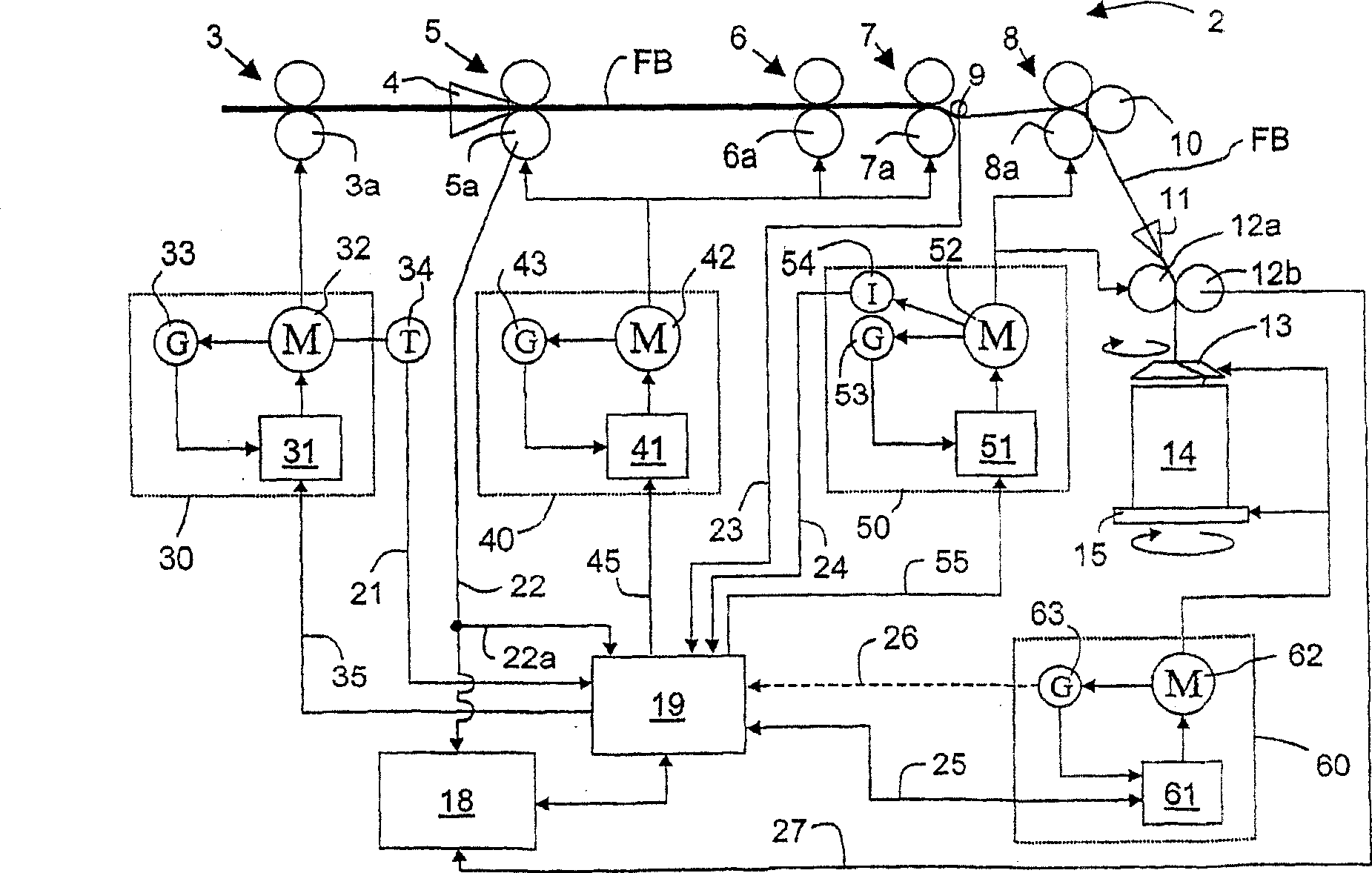

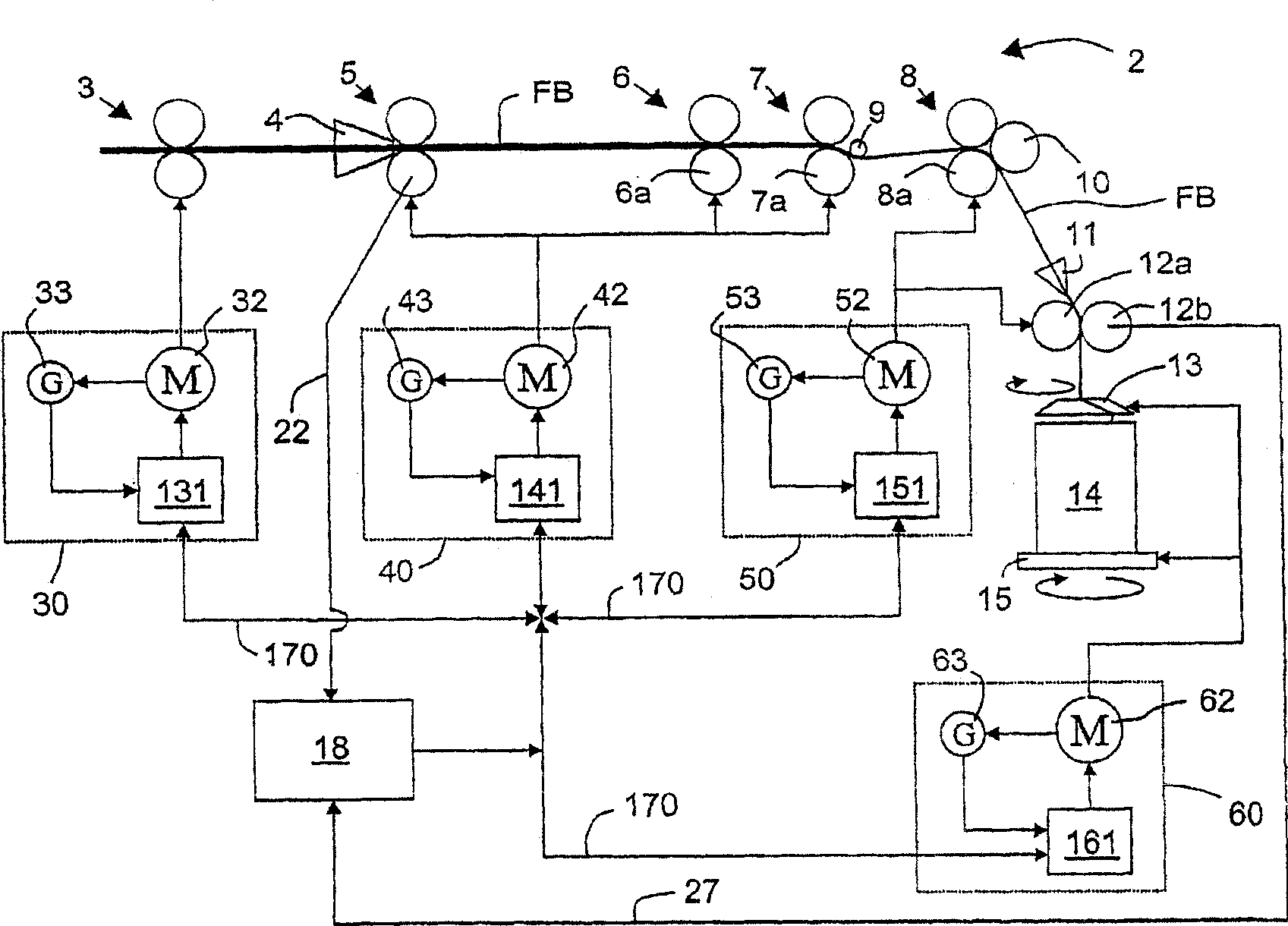

[0031] figure 1 Shows a side view of an adjustable draw frame with a drafting device 2 according to the invention as an example of a textile machine, comprising a pair of input rollers 6, a pair of central rollers 7, and a pair of output rollers 8. Upstream of the drafting device 2 is a pair of take-off rollers 3 for drawing one or several fiber strands (FB) from cans, not shown here. A sliver cross-section measuring device 5 in the form of a pair of scanning rollers upstream with a collecting funnel 4 is installed between the drafting device 2 and the pair of draw-off rollers 3 and provides a signal about the cross-section of at least one fiber strip (FB) . Instead of a pair of scanning rollers other cross-section measuring devices 5 are also possible, for example microwave resonators, capacitive sensors, ultrasonic sensors and the like. The fiber strip (FB) is drawn in a known manner under the effect of different rotational speeds of the roller pairs 6 , 7 , 8 . Between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com