Steel wire pre-forming measuring rod and application method thereof

An application method and technology of preformed rods, applied in the direction of measuring device, mechanical diameter measurement, mechanical gap measurement, etc., can solve the problems of cumbersome operation, complicated parameter control, inconvenient application, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

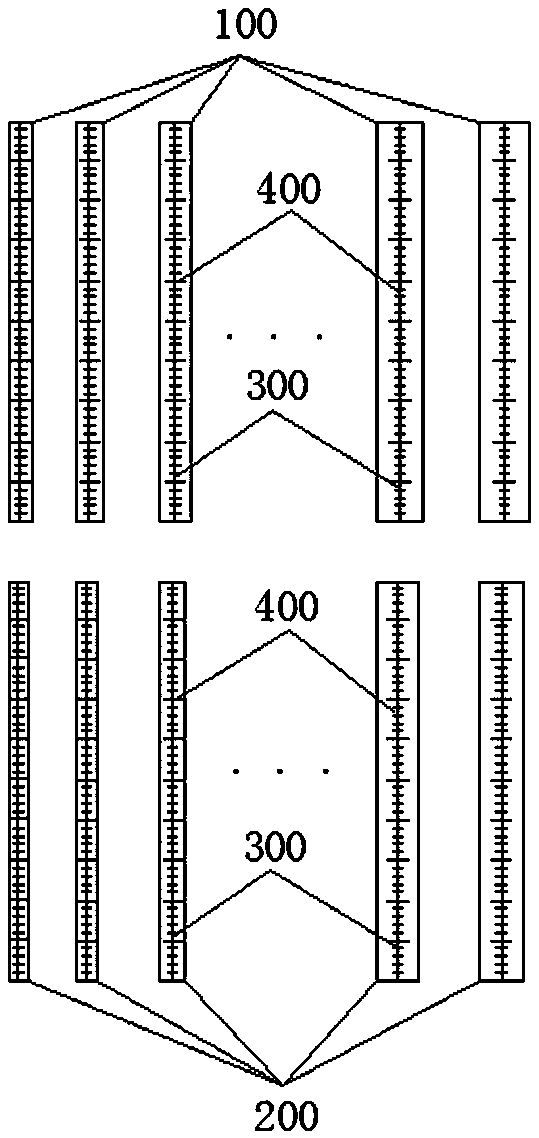

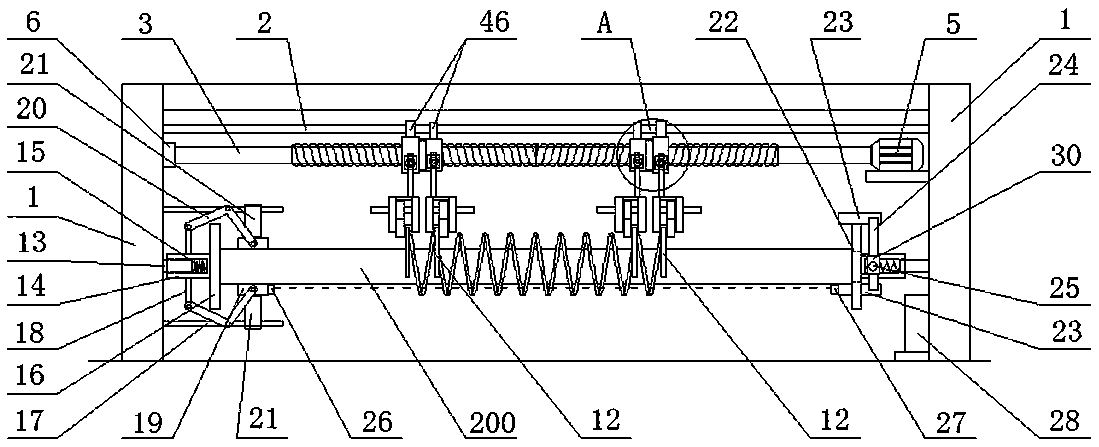

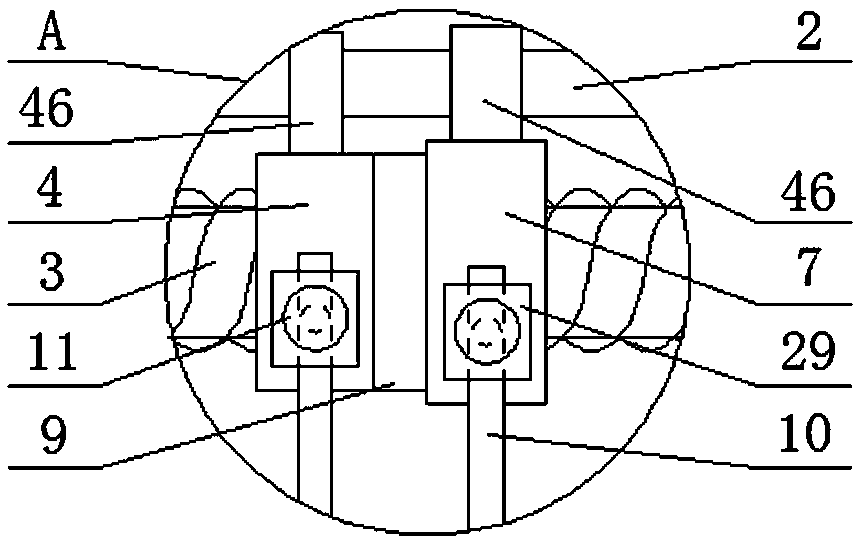

[0036] Such as figure 1 A steel wire preformed measuring rod shown includes several preformed rods 100 of different diameters and several standard measuring rods 200 of different diameters. Both the preformed rod and the standard measuring rod are marked with a straight line 300 along their length direction, and the straight line 300 is marked with a length scale 400; the materials of the preformed rod 100 and the standard measuring rod 200 are both nylon. Nylon has strong properties such as wear resistance, and the preformed rod 100 and standard measuring rod 200 made of it have good structural stability and can prevent being scratched and worn by steel wires.

[0037] For the 4SP-10 rubber hose (which includes four layers of steel wire reinforcement, and the diameter and pitch of each layer of steel wire reinforcement are known), now use the above steel wire preformed measuring rod to select materials that can be directly used to prepare the steel wire reinforcement steel w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com