Lead crimping tube

A technology of crimping tubes and wires, which is applied in the direction of connecting contact materials, connections with permanent deformation, multi-core cable end parts, etc., which can solve problems such as poor connection effect and difference in crimping stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

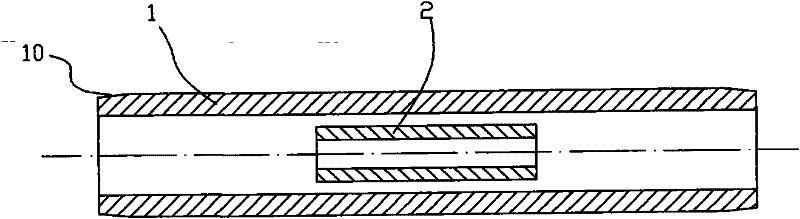

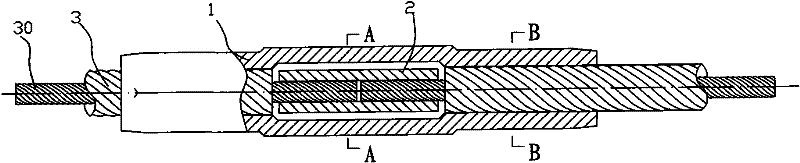

[0018] The present invention as Figure 1-7 As shown, the outer surfaces of the nozzles at both ends of the crimping tube 1 are provided with a taper 10 .

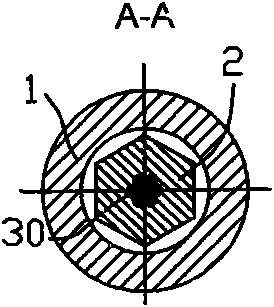

[0019] The inner diameter of the crimping tube 1 is larger than the wire ( figure 2 ACSR or Image 6 The aluminum stranded wire 4) has an outer diameter of 1-5%, and the ratio of the inner diameter of the crimping tube 1 to the length of the crimping tube 1 is 1:5-20.

[0020] Conductor is provided with steel core 30 (i.e. as figure 2 The steel-cored aluminum stranded wire in it), the outside is the aluminum stranded wire layer 3, and the connection pipe 2 is also provided in the crimping pipe 1, and the connection pipe 2 inner diameter is 1-5% greater than the steel core 30 outer diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com