Anti-corona structure of strip winding VPI bar of high-voltage generator

An anti-corona and generator technology, applied in the shape/style/structure of winding insulation, etc., can solve the problems of unfavorable end heat dissipation, affecting the dipping and curing effect of anti-corona layer, and affecting the safety of the motor, so as to ensure safety. Long-term operation, prevent corona phenomenon, reduce the weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

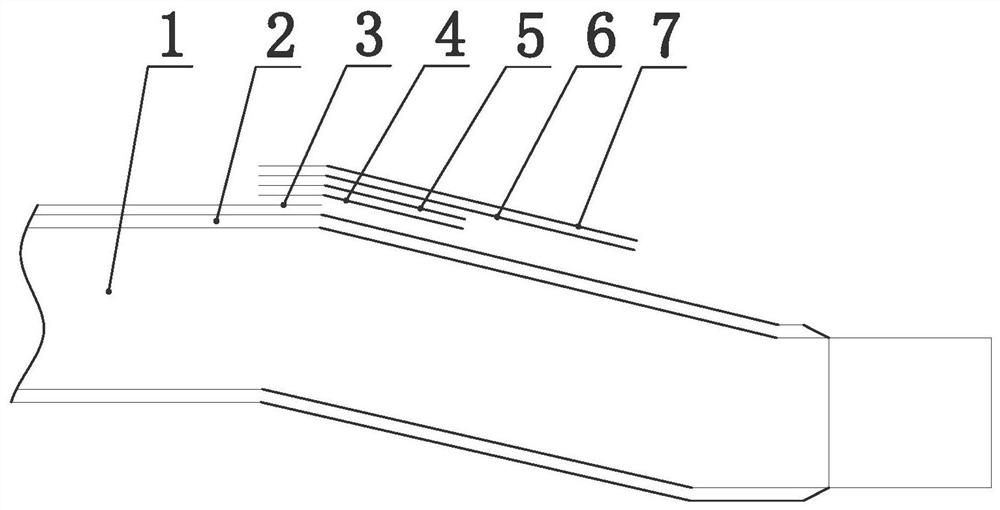

[0022] figure 1 It is a structural schematic diagram of the present invention, such as figure 1 The anti-corona structure of a high-voltage generator strip winding VPI wire rod shown includes an inter-strand wire rod 1, a main insulating layer 2 and an anti-corona layer, and the anti-corona layer is coated on the inter-strand wire rod 1 Externally, the main insulating layer 2 is wrapped on the outside of the interstrand bar 1, and the outer layer of the main insulating layer 2 is wrapped with a VPI low-resistance band 3 through a half-stack, and the outer layer of the VPI low-resistance band 3 is wrapped through a half-fold Wrapped with a VPI intermediate stop band 4, the VPI middle stop band 4 extends to the curved section along the corner, and the VPI middle stop band 4 located in the curved section is wrapped with a multi-glue mica tape 5 by flat wrapping, and the multi-glue mica tape 5 The VPI high-resistance band 6 is wrapped by the half-stack and extends at the end, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com