Glass processing apparatus and method

A processing device, glass technology, applied in metal processing equipment, manufacturing tools, machine tools suitable for grinding the edge of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail with reference to the drawings.

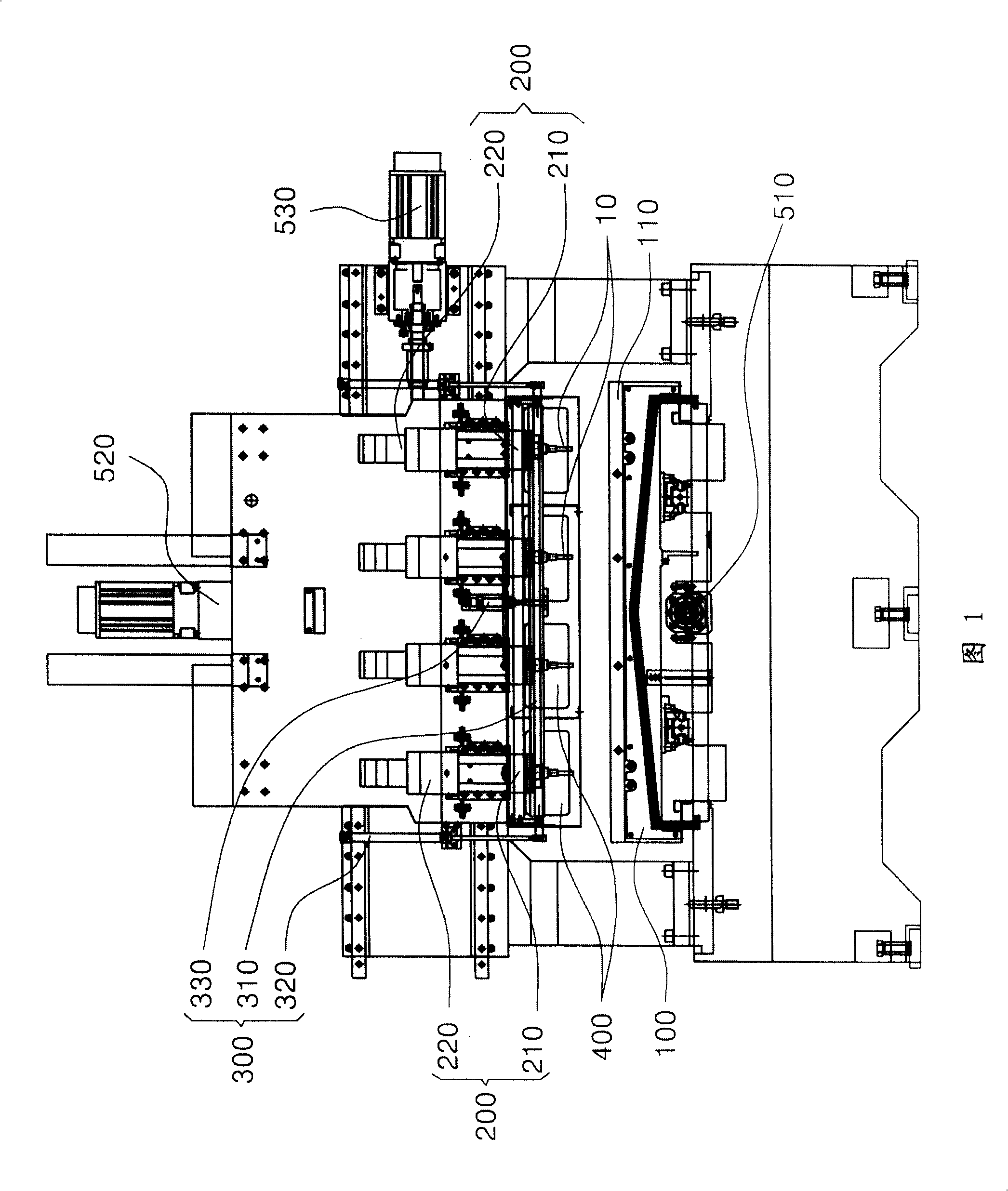

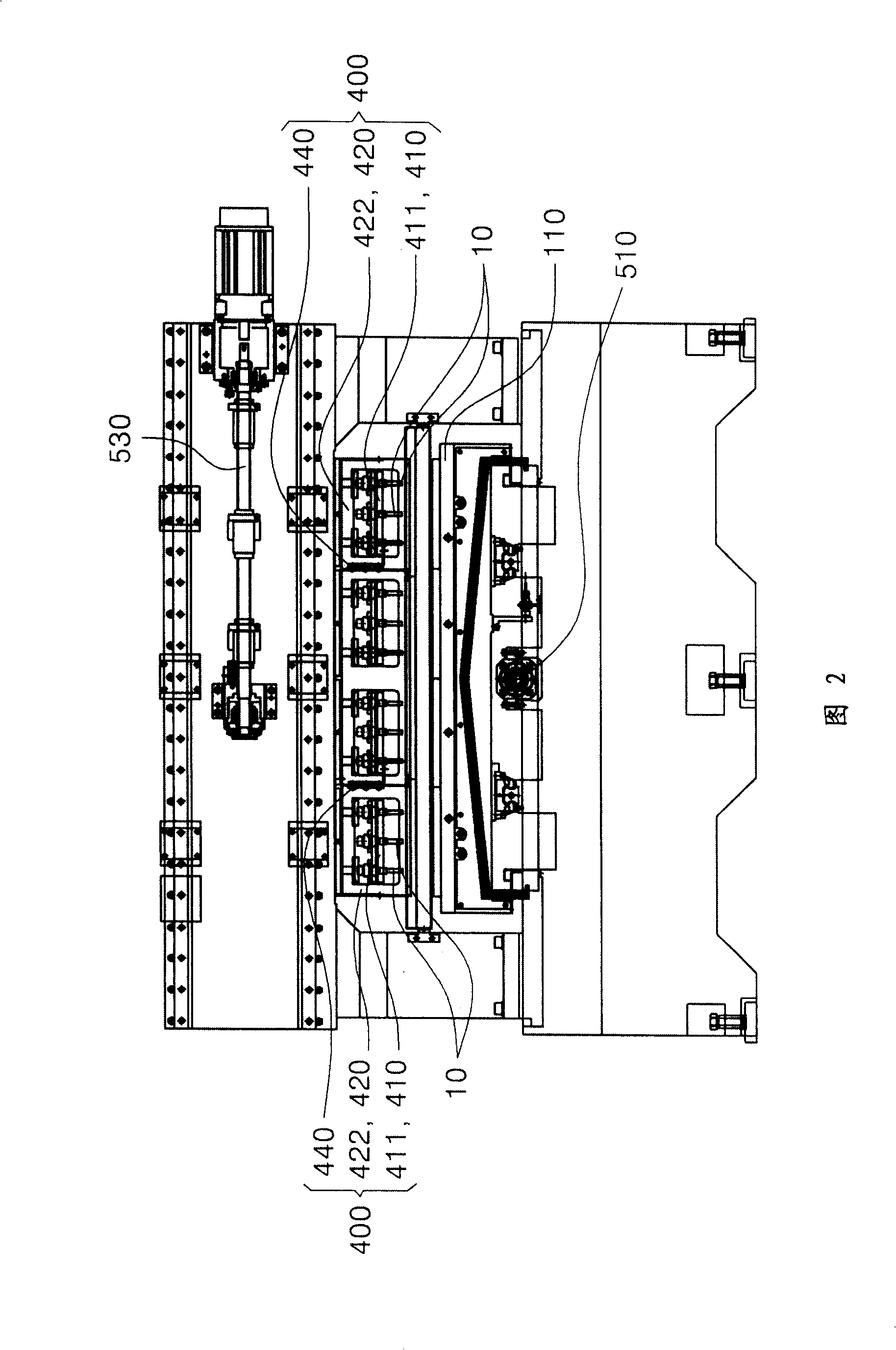

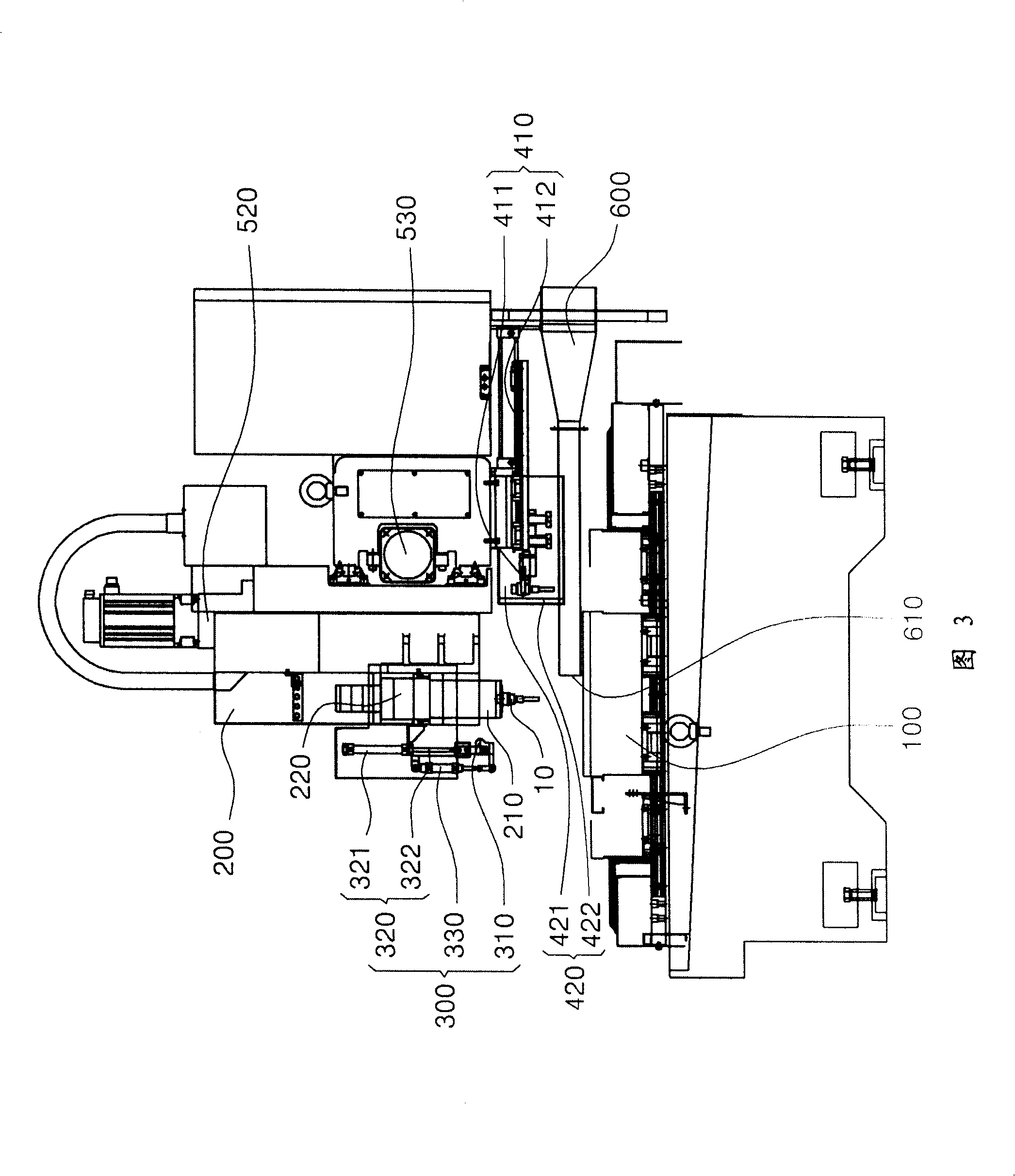

[0031] Fig. 1 is a front view of the first embodiment of the glass processing device provided by the present invention, Fig. 2 is a front view of main parts of the automatic tool exchange part, Fig. 3 is a right side view of Fig. 1, Figure 4It is the rear view of the main part of the longitudinal section of the auxiliary container, Figure 5 Fig. 6 is a plan view of the tool changer, which is a right side view of the main part showing the angle adjustment of the air knife part. Figure 7 To show the main part right side view showing the case opening and closing state by the movement of the tool changer, Figure 8 It is a flowchart showing the first embodiment of the glass processing method provided by the present invention.

[0032] The glass processing device provided according to the present invention is roughly composed of a table part 100, a tool rotating part 200, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com