Improved reaction rod with joint assembly

A reaction rod, an improved technology, applied to springs made of plastic materials, springs/shock absorbers, mechanical equipment, etc., can solve the problems of high production cost, complicated processing technology, detachment, etc., and achieve the goal of saving energy and resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

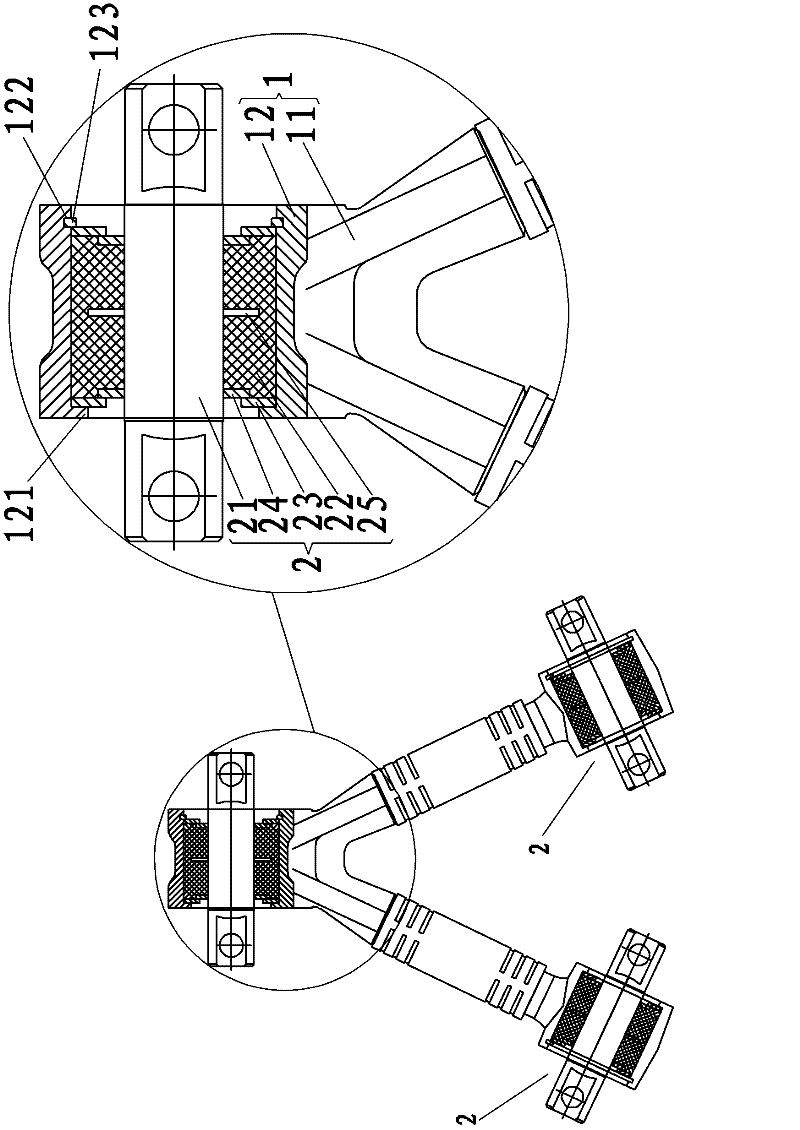

[0029] The improved reaction bar belt joint assembly of the present invention, the embodiment is as image 3 As shown, it includes a reaction rod 1 and a joint assembly 2 , the reaction rod 1 has a shaft 11 and a head 12 connected to the end of the shaft, and the joint assembly 2 is embedded and fixed in the head 12 .

[0030] In this embodiment, the reaction rod 1 adopts a V-shaped structure, and its shaft 11 is V-shaped with three ends, and the three ends are respectively connected with rod heads 12 .

[0031] One axial end of the rod head 12 has a rod head flange 121, and the other axial end of the rod head 12 is provided with a locking groove 122, and a clip spring 123 is embedded in the clip groove 122, through which the rod head flange 121 and the clip spring 123 will The joint assembly 2 is limited and fixed in the rod head 12 .

[0032] The joint assembly 2 includes a support pin 21 , an elastic body 22 , a rod head rigid limit baffle 23 , a support pin rigid limit ba...

Embodiment 2

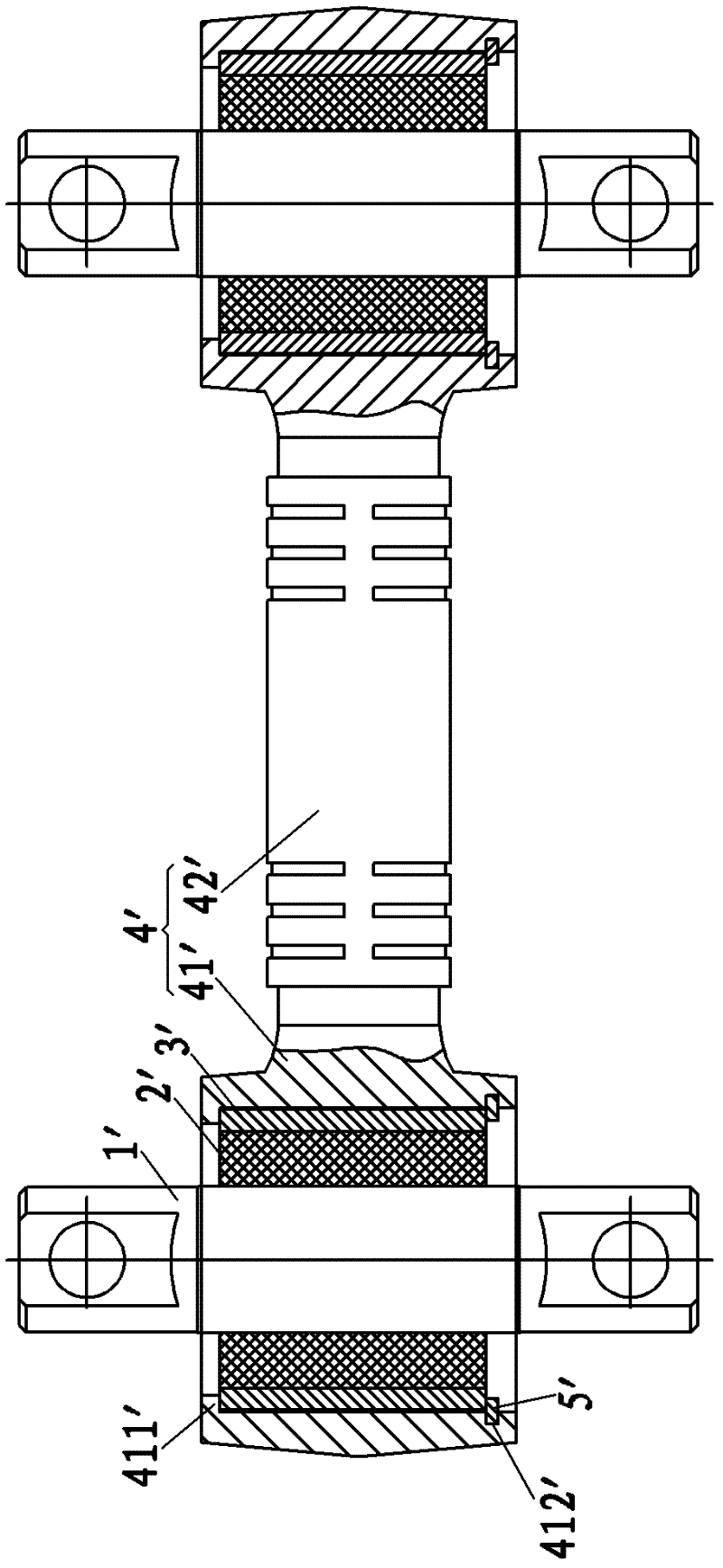

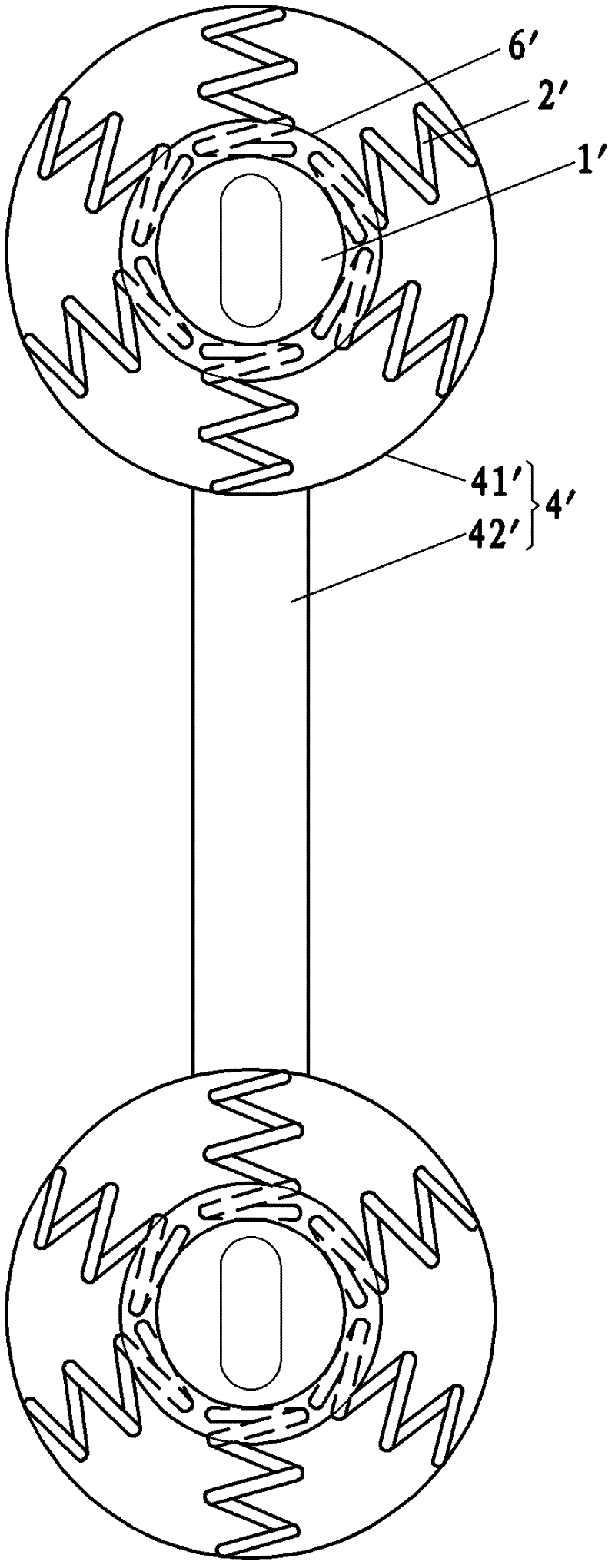

[0037] The improved reaction rod belt joint assembly of the present invention, the second embodiment is as Figure 4 As shown, the difference between it and the first embodiment is that the reaction rod 1 adopts an I-shaped structure, and its shaft 11 is I-shaped with two ends.

Embodiment 3

[0039] The improved reaction rod with joint assembly of the present invention, the third embodiment is as Figure 5 As shown, it includes a reaction rod 1 and a joint assembly 2 , the reaction rod 1 has a shaft 11 and a head 12 connected to the end of the shaft, and the joint assembly 2 is embedded and fixed in the head 12 .

[0040] In this embodiment, the reaction rod 1 adopts a V-shaped structure, and its shaft 11 is V-shaped with three ends, and the three ends are respectively connected with rod heads 12 .

[0041] One axial end of the rod head 12 has a rod head flange 121, and the other axial end of the rod head 12 is provided with a locking groove 122, and a clip spring 123 is embedded in the clip groove 122, through which the rod head flange 121 and the clip spring 123 will The joint assembly 2 is limited and fixed in the rod head 12 .

[0042] The joint assembly 2 includes a support pin 21 , an elastic body 22 , a rod head rigid limit baffle 23 , a support pin rigid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com