Tire crown for an airplane

A technology for aircraft tires and tires, applied in aircraft tires, tire treads/tread patterns, tire parts, etc., can solve problems such as insufficient reduction of irregular tread wear, and achieve extended life and increased wear area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

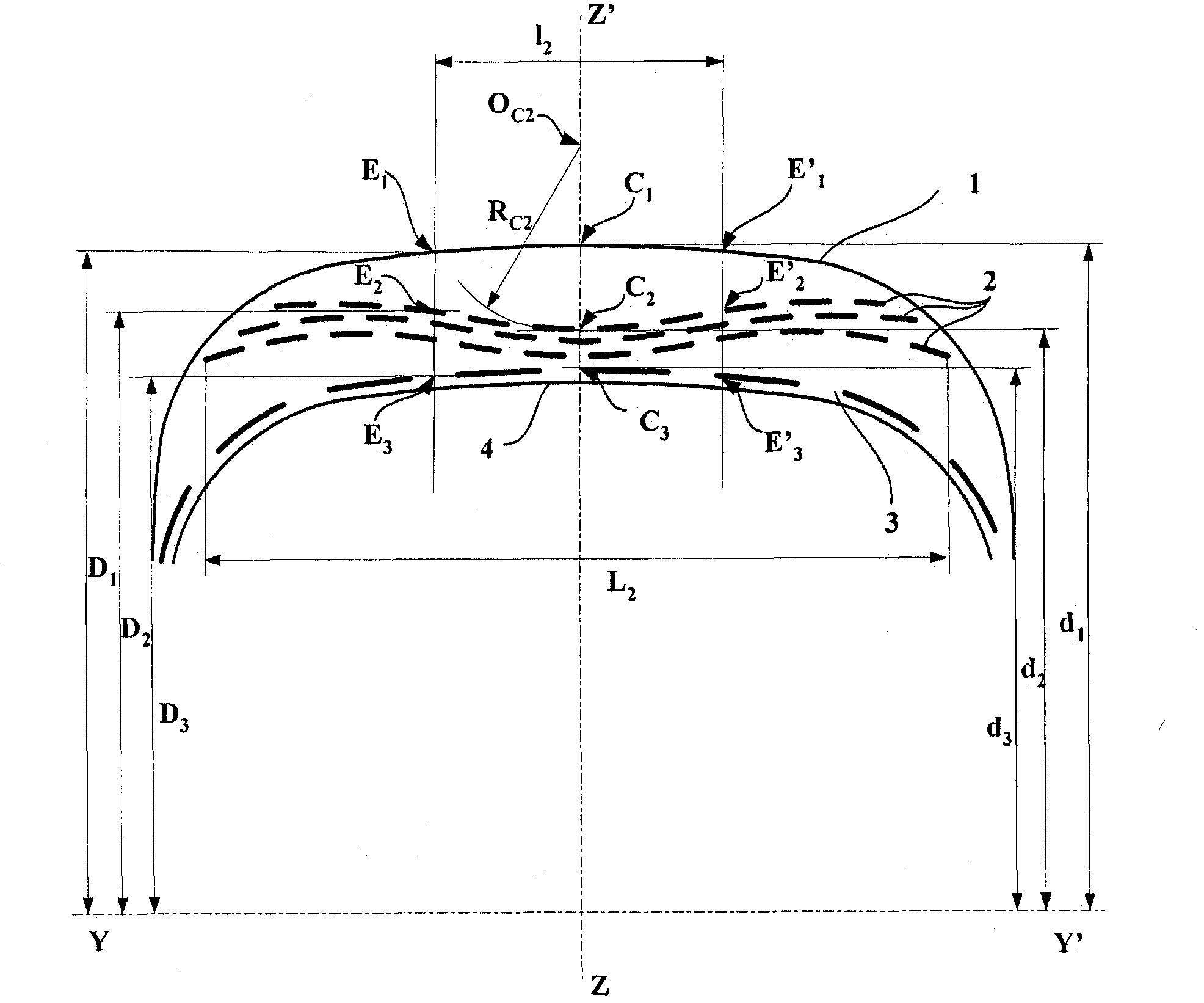

[0089] figure 1 The initial meridian profile (radially outermost portion) of the tread surface 1 is shown. Central point C of the central portion of the initial meridian profile of the tread surface 1 1 (located on the equatorial plane indicated by the axis ZZ' in the meridian plane) at a radial distance d measured from the axis of rotation YY' of the tire 1 place. Point E of the initial meridian profile of the tread surface 1 1 and E' 1 (which is symmetric with respect to the equatorial plane and whose radial distance is D 1 ) are the end points of the central portion of the initial meridian profile of the tread surface 1 and are axially separated by an axial width l 2 , the initial meridian profile of the crown reinforcement 2 is locally concave across this axial width l 2 . exist figure 1 In , the initial meridian profile of the tread surface 1 is convex.

[0090] Radially inside the initial meridian profile of the tread surface 1 is the initial meridian profile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com