Labeler and a labeling method for labeling plastic bottles in a blow mold

一种贴标签机、吹塑模具的技术,应用在贴标签、标签、运输和包装等方向,能够解决不适瓶子设计、限制印刷质量、不利等问题,达到快速移动、避免过度拉伸、高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

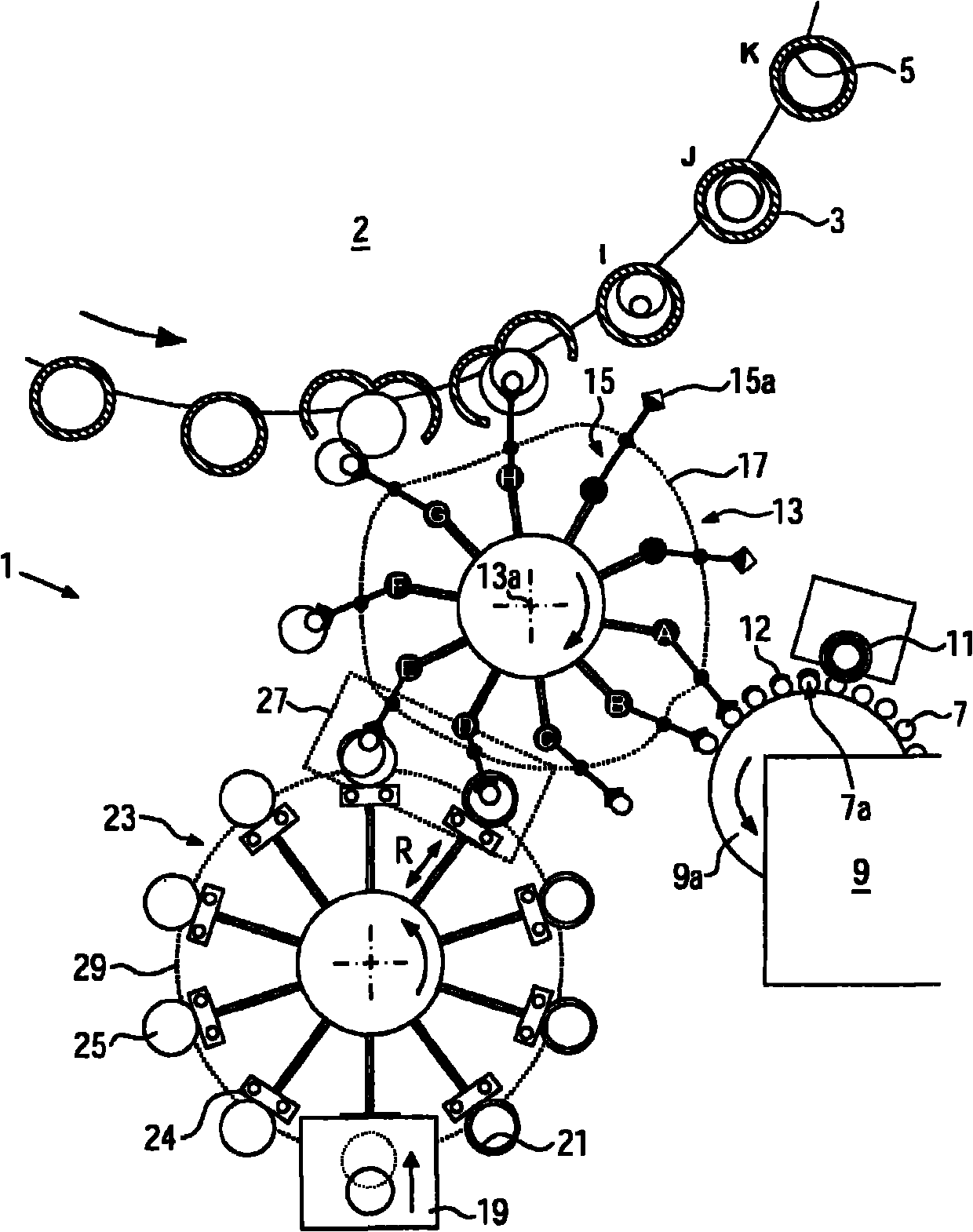

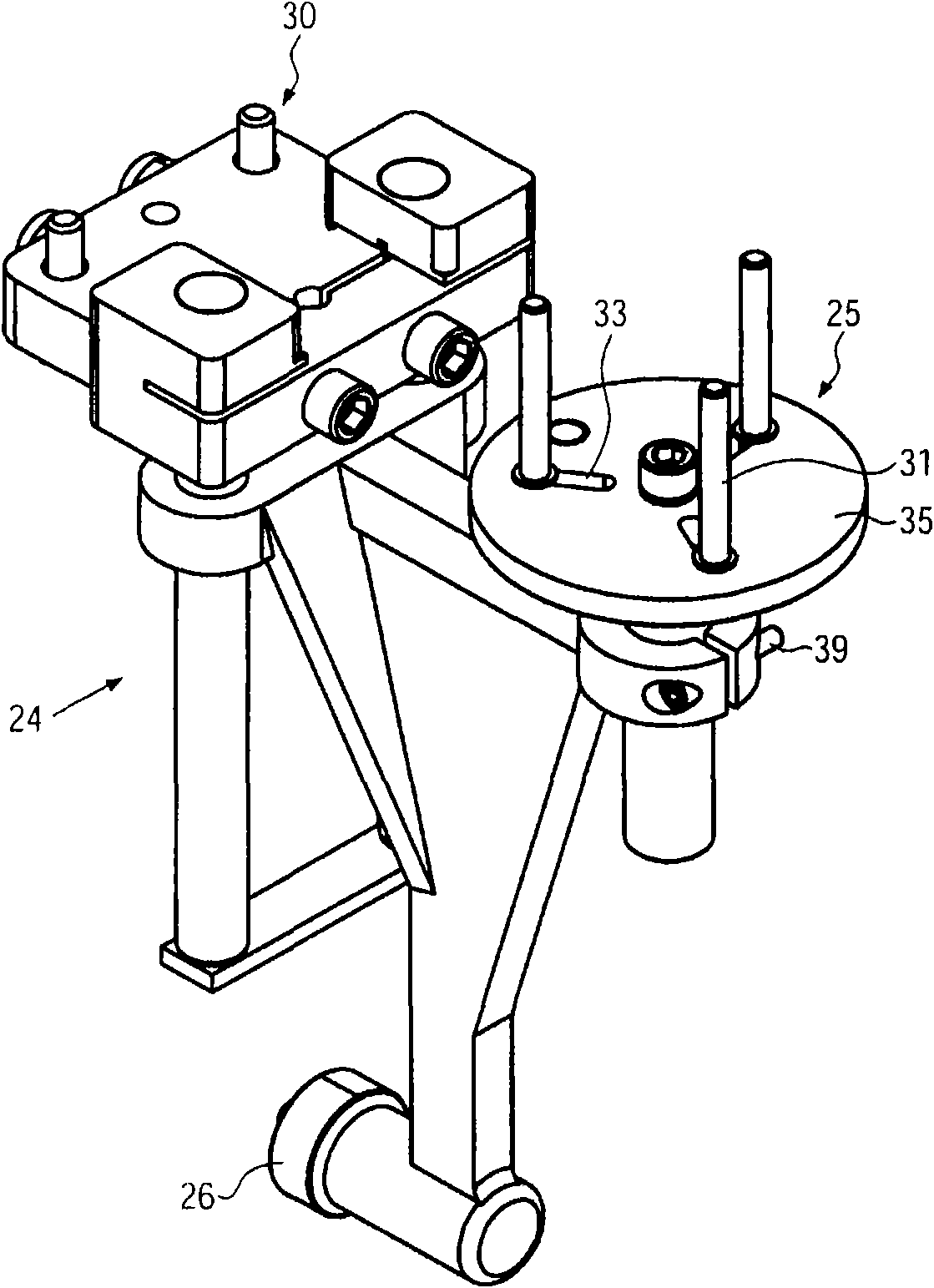

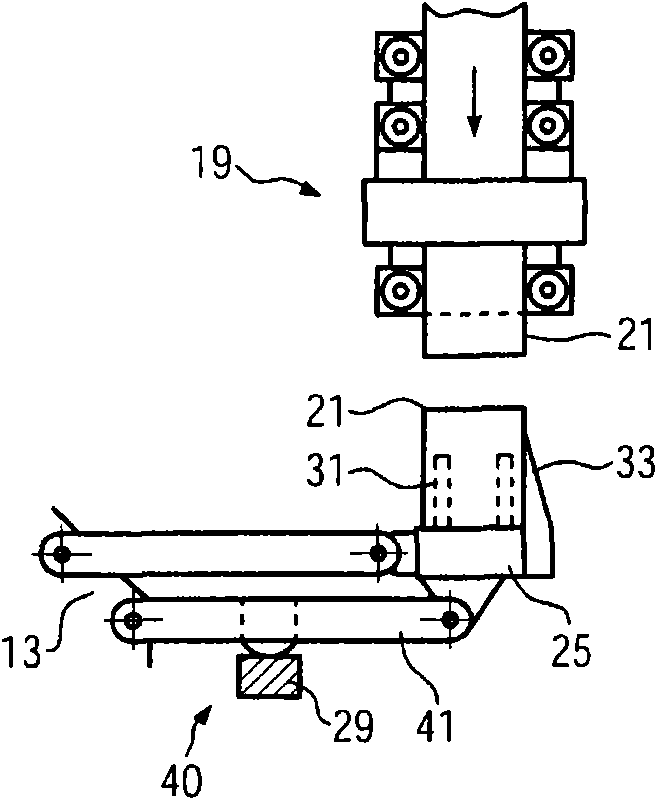

[0031] if possible from figure 1 It is seen that a first embodiment of a labeling machine 1 comprises a blowing wheel 2 with a plurality of blow molds 3 for producing labeled bottles 5 or other plastic containers from preforms 7 . The preform 7 is heated in an oven 9 in a known manner, glue 12 is then applied tangentially to the circumferential section 7a of said preform 7 by means of a glue roller 11, and the preform 7 is formed, for example, by a joint Received from transfer starwheel 13 from adaptive starwheel or the like. On the circumference of said transfer star wheel 13 are arranged a rotatably supported clamping arm 15 and a first control cam 17, the clamping arm 15 being of variable length and equipped with a clamping element 15a for the preform 7, the first A control cam 17 is used for controlling the clamping arm 15 , in particular for adjusting the radial position and orbital speed of the clamping arm 15 .

[0032] Furthermore, at least one label dispenser 19 suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com