Plastic film pre-feeding device for flat-plate aluminum plastic blister packaging machine

A blister packaging machine, flat-plate technology, applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of affecting the quality of blister packaging, adverse effects of packaging, affecting the uniform wall thickness of blisters, etc., to achieve Highlight substantive features, ensure quality, and avoid overstretched effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

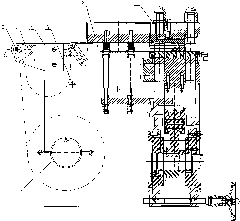

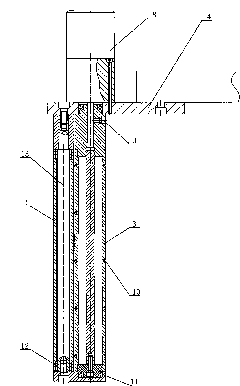

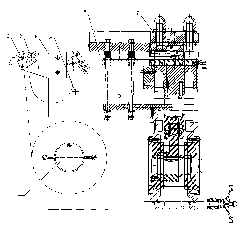

[0010] The accompanying drawings show the technical solutions of the present invention and the embodiments thereof, and the relevant details of the embodiments and their working principles are further described below with reference to the accompanying drawings.

[0011] Refer to the attached figure 1 , 2 , the plastic film pre-feeding device of this flat-type aluminum-plastic blister packaging machine is located between the plastic film discharge reel 1 and the blister forming heating plate 6, and the right side of the blister forming heating plate 6 is the blister forming mold. 7. The plastic film pre-feeding device includes a pair of main feeding rollers 3 and secondary feeding rollers 2 arranged in parallel and abutting each other, wherein both ends of the main feeding roller 3 are movably supported on the bracket plate 4 through bearings 11, and the main feeding roller 3 One end of the roller 3 is provided with a motor 8. The motor shaft and the main feeding roller 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com