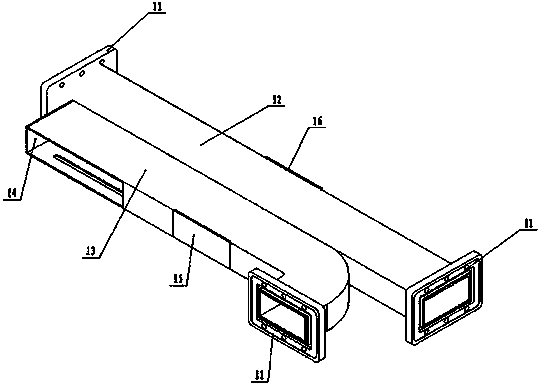

Self-positioning narrow-side bridge waveguide and vacuum brazing technology thereof

A brazing process and self-positioning technology, applied in waveguides, waveguide-type devices, circuits, etc., can solve problems such as deformation, and achieve the effect of enhancing corrosion resistance, overcoming waveguide corrosion, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

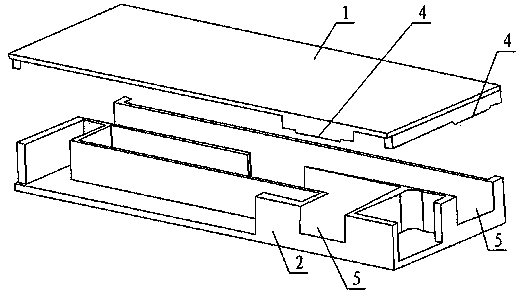

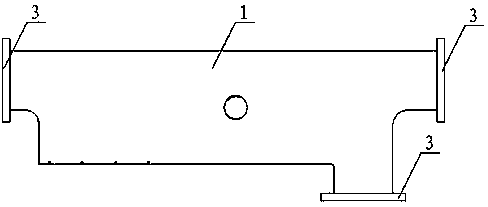

[0064] [Example 1] Self-positioning narrow-side bridge waveguide vacuum brazing process, such as Figure 4 shown, it includes the following steps

[0065] S1: Complete the mechanical processing of cover plate 1 and cavity 2 according to the design;

[0066] S2: Perform surface treatment on the machined cover plate 1 and cavity body 2 respectively;

[0067] S3: making brazing material, making brazing material according to the size of the contact surface combined with cover plate 1 and cavity body 2, and assembling the brazing material on cavity body 2, and assembling cover plate 1 and cavity body 2;

[0068] S4: Vacuum brazing, fix the assembled waveguide on the fixture, put it into a vacuum aluminum brazing furnace for vacuum brazing, complete the vacuum brazing when the brazing temperature in the vacuum aluminum brazing furnace is 615°C, and then furnace cooling;

[0069] S5: Perform further numerical control processing on the shape of the waveguide and the flange, drill h...

Embodiment 2

[0092] [Example 2] Self-positioning narrow-side bridge waveguide vacuum brazing process, such as Figure 4 shown, it includes the following steps

[0093] S1: Complete the mechanical processing of cover plate 1 and cavity 2 according to the design;

[0094] S2: Perform surface treatment on the machined cover plate 1 and cavity body 2 respectively;

[0095] S3: making brazing material, making brazing material according to the size of the contact surface combined with cover plate 1 and cavity body 2, and assembling the brazing material on cavity body 2, and assembling cover plate 1 and cavity body 2;

[0096] S4: Vacuum brazing, fix the assembled waveguide on the fixture, put it into a vacuum aluminum brazing furnace for vacuum brazing, complete the vacuum brazing when the brazing temperature in the vacuum aluminum brazing furnace is 615°C, and then furnace cooling;

[0097] S5: CNC further processes the shape of the waveguide and the flange, drills holes and reams the flange...

Embodiment 3

[0120] [Example 3] Self-positioning narrow-side bridge waveguide vacuum brazing process, such as Figure 4 shown, it includes the following steps

[0121] S1: Complete the mechanical processing of cover plate 1 and cavity 2 according to the design;

[0122] S2: Perform surface treatment on the machined cover plate 1 and cavity body 2 respectively;

[0123] S3: making brazing material, making brazing material according to the size of the contact surface combined with cover plate 1 and cavity body 2, and assembling the brazing material on cavity body 2, and assembling cover plate 1 and cavity body 2;

[0124] S4: Vacuum brazing, fix the assembled waveguide on the fixture, put it into a vacuum aluminum brazing furnace for vacuum brazing, complete the vacuum brazing when the brazing temperature in the vacuum aluminum brazing furnace is 615°C, and then furnace cooling;

[0125] S5: Perform further numerical control processing on the shape of the waveguide and the flange, drill h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com