Processing and manufacturing method for ultra-long ultra-fine special-shaped multi-channel cooling plate

A technology for processing, manufacturing and cooling plates, which is applied in the design field of the International Thermonuclear Fusion Experimental Reactor, can solve problems such as the inability to process cooling plates, and achieves the effect of avoiding the difficulty of non-destructive testing, being easy to operate, and improving the success rate of processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] Step 1. Raw material preparation for cooling plate processing

[0038] Step 1.1: The length, width and thickness of the raw material are 800mm, 80mm and 7mm respectively, the flatness of the raw material is required to be 0.1mm, and the direction of the flow channel is the length direction of the raw material;

[0039] Step 1.2: If figure 1 As shown, it is divided into two pieces A and B along the direction of the flow channel. After cutting, the length of each piece along the direction of the flow channel is 400mm;

[0040] Step 2. EDM drilling

[0041] Step 2.1: Fix raw materials A and B on the fixture respectively;

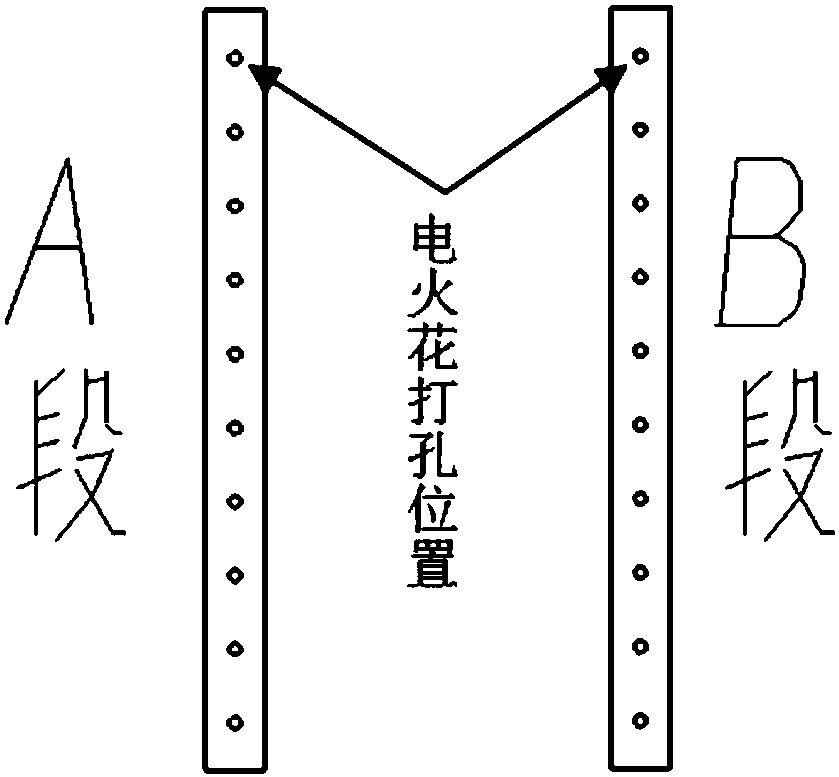

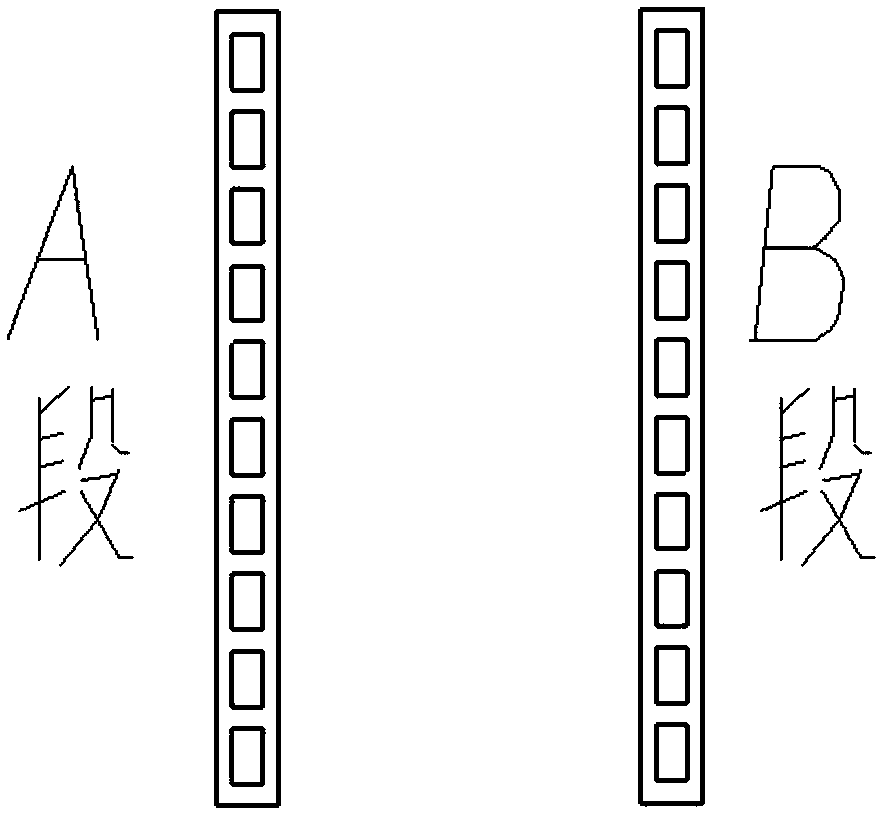

[0042] Step 2.2: If figure 2 As shown, a numerical control electric spark punching machine is used to drill holes in A and B sequentially along the flow channel arrangement direction. The punching position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com