Edge coupling standing wave accelerating tube manufacture method and edge coupling standing wave accelerating tube

A manufacturing method and acceleration tube technology, which are applied in the directions of additive manufacturing, linear accelerators, additive processing, etc., can solve the problems of low yield in the field of acceleration tube production, restricting the stability of acceleration tube operation, complex forming technology, etc., so as to shorten the production time. Reduced cycle times, welding times, and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

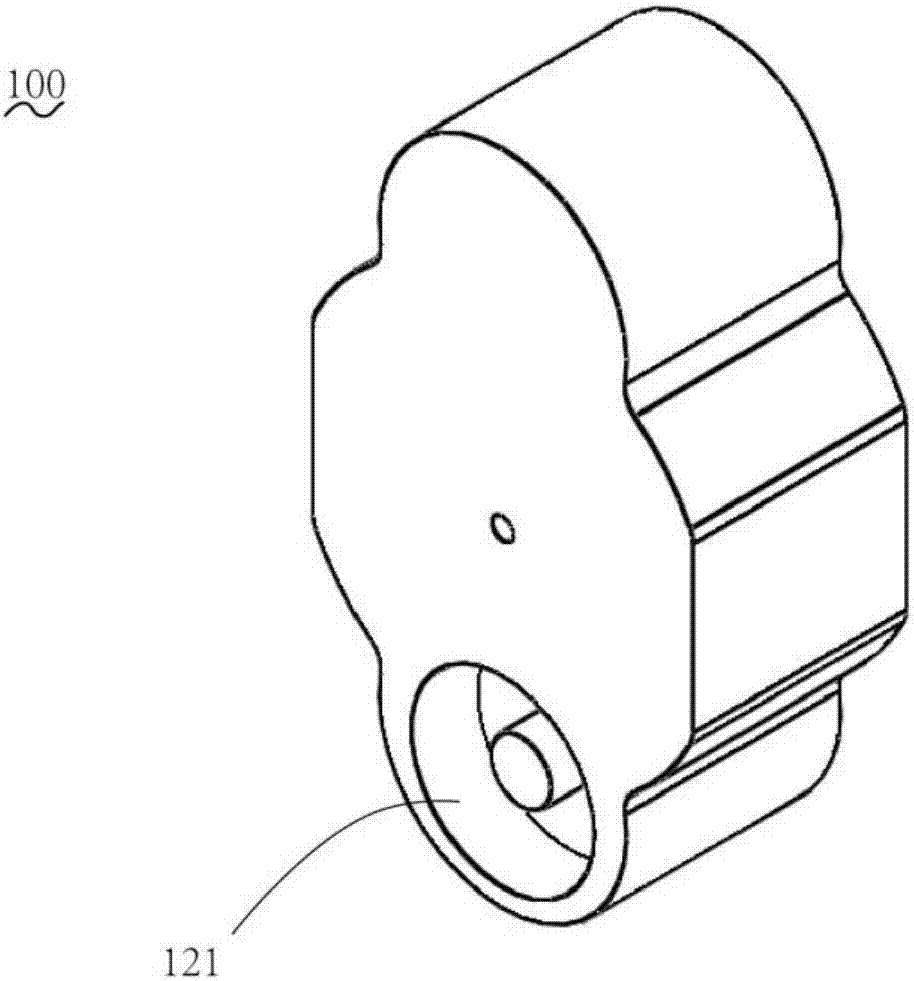

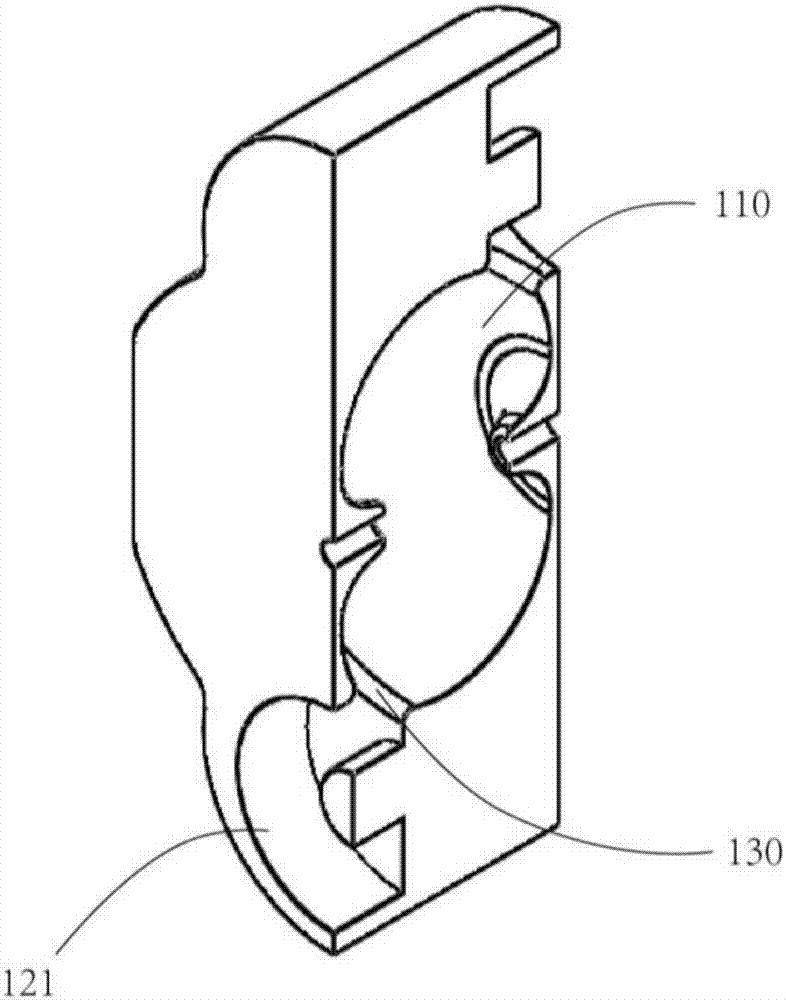

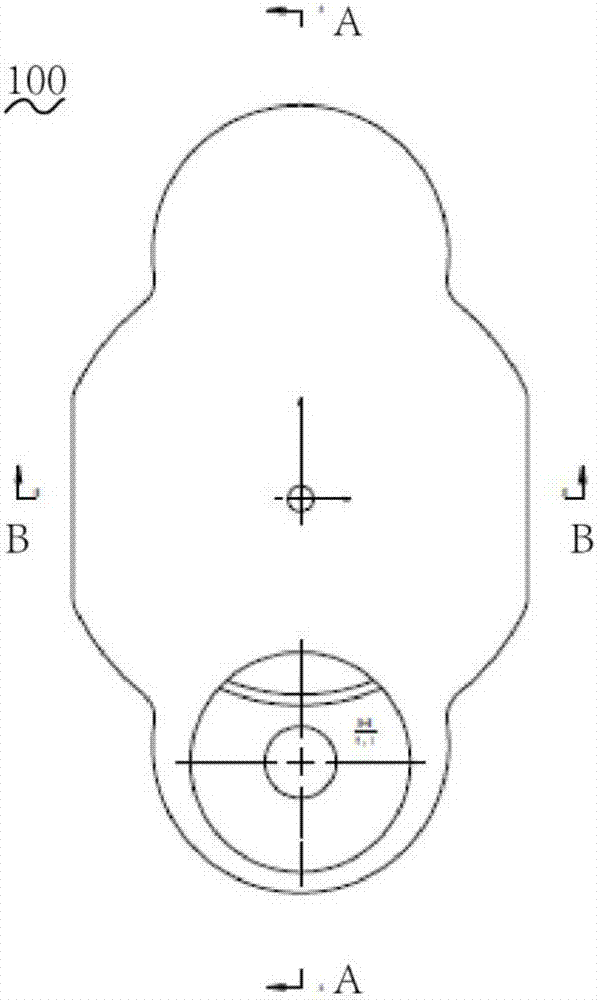

[0047] Such as Figure 1-Figure 5 As shown, the single-period acceleration cavity unit 100 of the side-coupled standing wave acceleration tube in the present invention is integrally formed and made by 3D printing technology, and has a main acceleration cavity 110 and two half-side coupling cavities connected with the main acceleration cavity 110 121. The two half coupling cavities 121 are respectively arranged on both sides of the main acceleration chamber 110 along the particle acceleration direction, and are arranged symmetrically with respect to the center of the main acceleration chamber 110 . Such as Figure 6 and Figure 7As shown, a plurality of single-cycle accelerating cavity units 100 are connected in sequence, the main accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com