Multi-layer mixed pressing printed circuit board and manufacturing method, apparatus thereof

A technology for printed circuit boards and manufacturing methods, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuits, etc., can solve problems such as high cost, and achieve the effects of improving quality, reducing cost, and good high-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

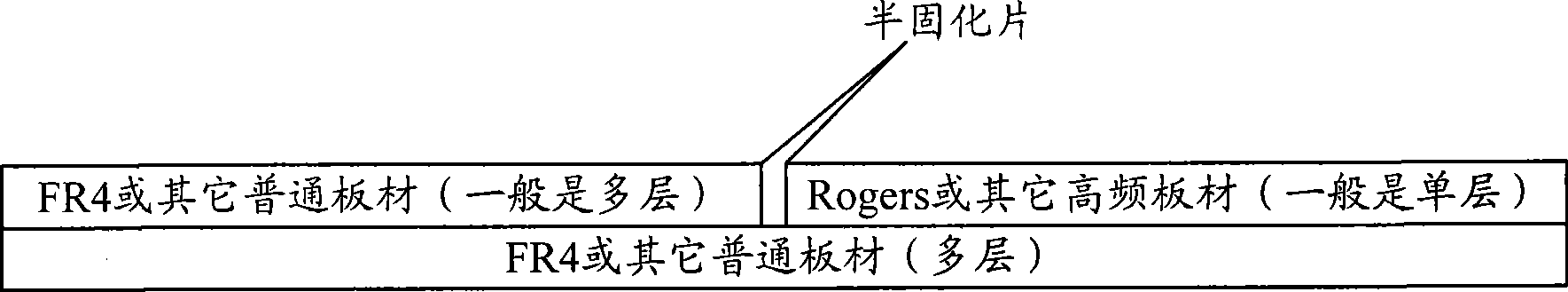

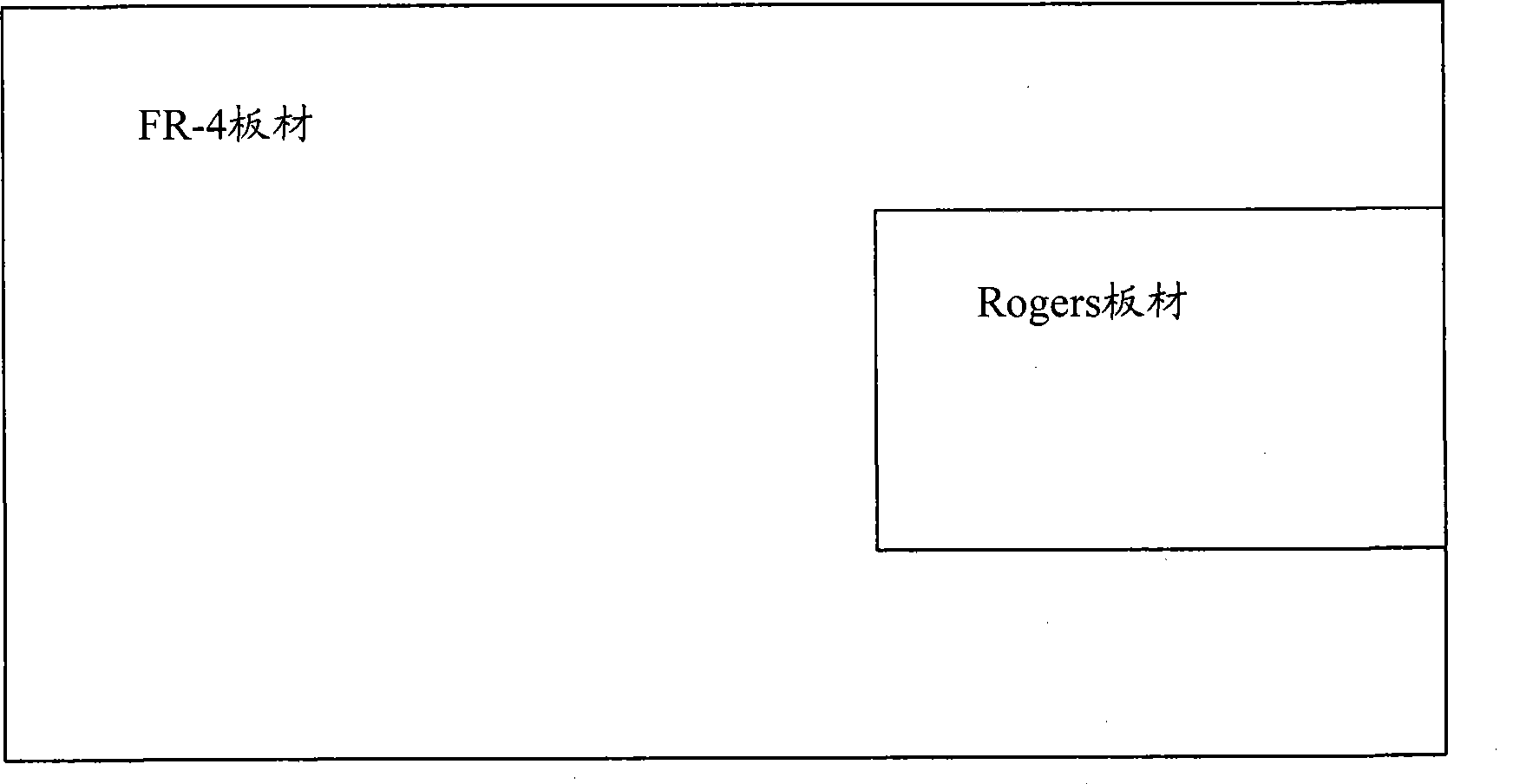

[0034] Generally speaking, the radio frequency part on the printed circuit board only needs to use a small part, or the place where the board material is more strict is very small, so the inventor considers only partially stacking, Mixed pressure to form a multi-media laminated printed circuit board structure that can achieve good high-frequency characteristics and reduce costs.

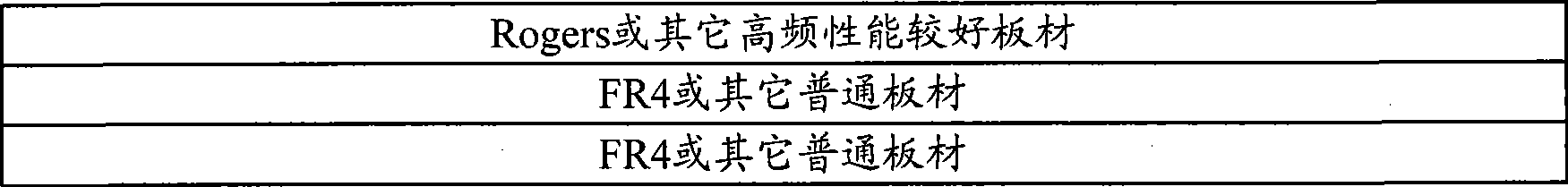

[0035] The multilayer mixed-voltage printed circuit board in the embodiment of the present invention includes:

[0036] At least one layer on the top, wherein each layer is formed by splicing at least one board of the first type of board and at least one of the second type of board;

[0037] The other layers below the top are made of at least one panel from the first type of panel;

[0038] The layers on the top and below the top are joined together in a laminated and mixed pressure manner.

[0039] In one embodiment, the top layer may have only one layer, that is, in a multilayer printed circuit b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com