Electrohydraulic vibration exciter

An electro-hydraulic vibration excitation and vibration excitation device technology, which is applied in the directions of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc. , poor anti-pollution performance, etc., to achieve the effect of low cost, strong load adaptation, and good anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

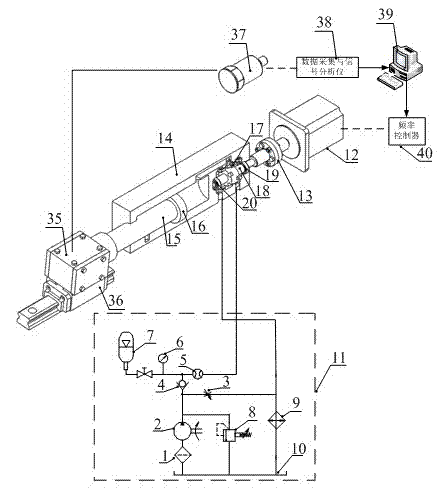

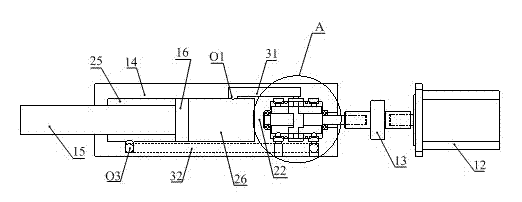

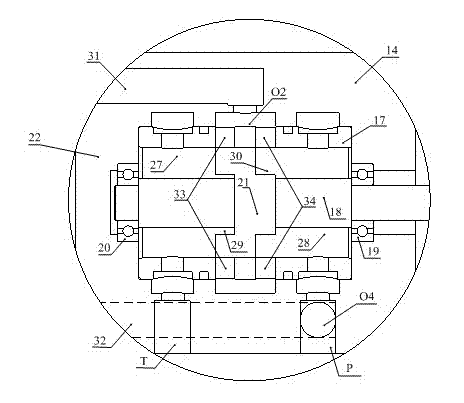

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] Such as Figure 1 to Figure 7As shown, the electro-hydraulic vibrator of the present invention includes a stepping motor 12 and a vibrating device. Among them, the vibration excitation device is mainly composed of a housing 14 with a cavity, a partition 22, a single-acting piston rod 15, a valve sleeve 17, a single-shouldered valve core 18, and the like. The cavity of the housing 14 is divided into a first cavity 23 and a second cavity 24 by a partition 22, the first cavity 23 has a built-in single-acting piston rod 15, and the first cavity 23 is separated by the piston 16 of the single-acting piston rod 15 A rod chamber 25 and a rodless chamber 26 are formed. The single-acting piston rod 15 protrudes outward from the first cavity 23 and can be connected with the external load mass 35 , thereby driving the load mass 35 to perform linear reciprocating motion on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com