Connection node construction of concrete-filled square steel tube column and rectangular section steel beam

A technology of rectangular cross-section and concrete columns, which is applied in the direction of building structure and construction, can solve the problems of high cost of connection nodes, long construction period, unfavorable assembly construction, etc., and achieve clear force and reliability, high level of industrialization and low cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments.

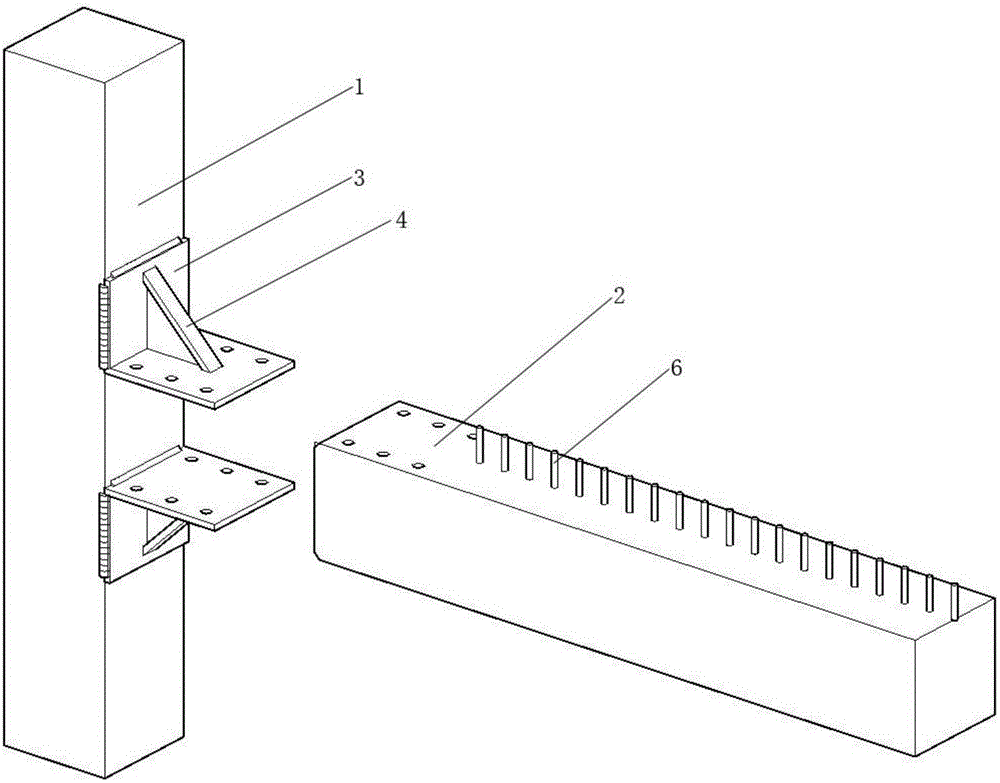

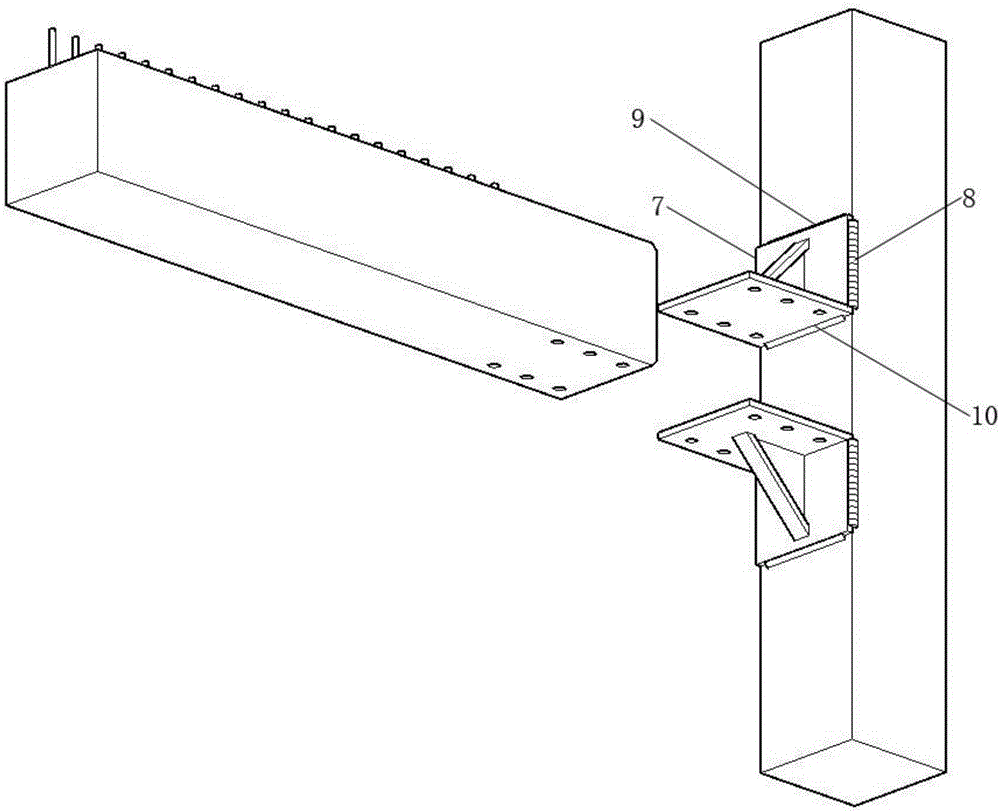

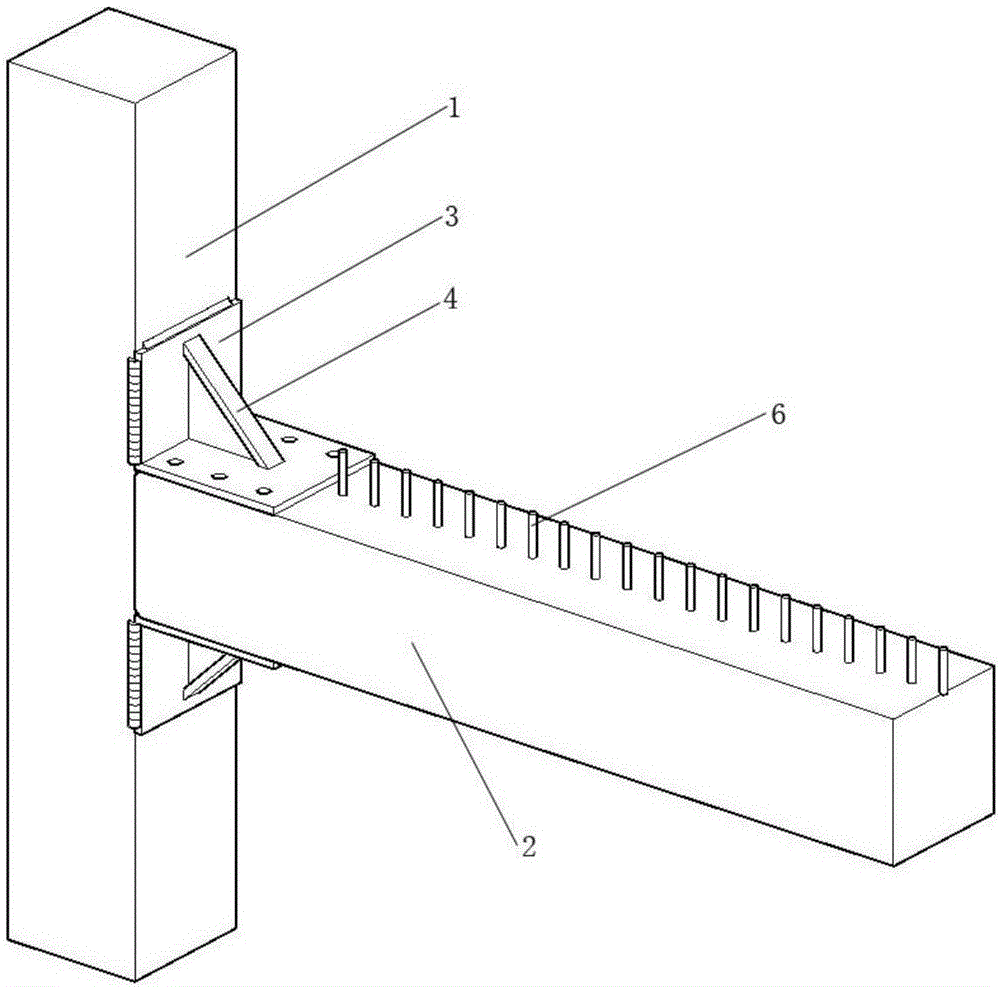

[0030] Such as Figure 1-4 As shown, a connection node structure between a square steel tube concrete column and a rectangular section steel beam, the connection node includes a square steel tube concrete column (1), a rectangular section steel beam (2), a right angle connecting plate (3), and a "T" shape Triangular ribs (4), high-strength bolts (5), studs (6) on the top surface of the steel beam.

[0031] The section design of the square steel tube concrete column can be carried out according to the required bearing capacity, including changing the side length of the section, the wall thickness of the square steel tube, and the strength level of the inner concrete, etc. Right-angle connecting plates and "T"-shaped triangular ribs can also be designed according to the bending moment and shear force at the beam ends of rectangular cross-section steel beams, including changi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com