Double-side-plate joint in bolted connection and assembling method

An assembly method and double-sided plate technology, applied in the direction of construction and building construction, can solve the problems of large welding residual stress, complicated construction, large amount of materials, etc., and achieve the elimination of triaxial stress concentration, unique force transmission mode, and easy assembly high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of the technical scheme of the present invention, has provided detailed implementation mode and concrete operation process, but protection scope of the present invention is not limited to the following the embodiment.

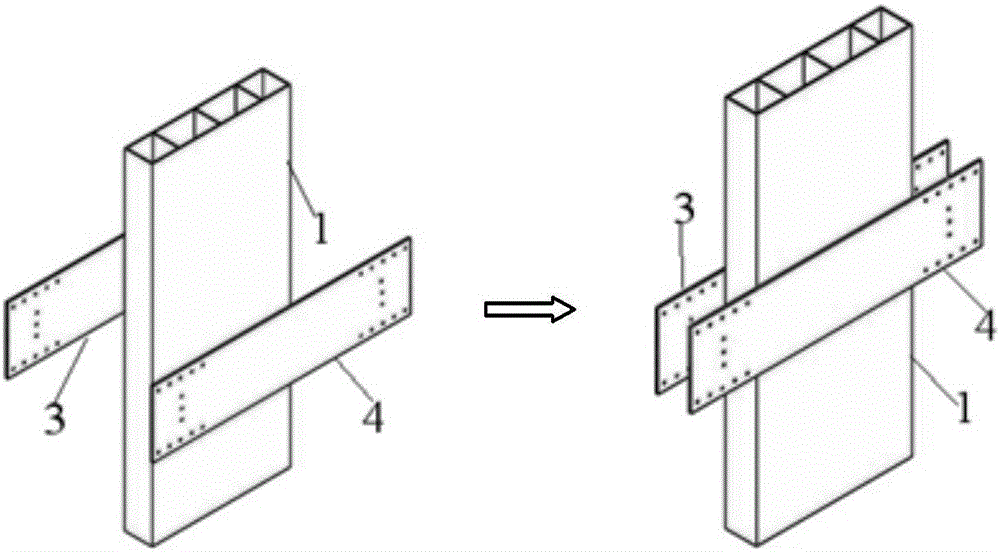

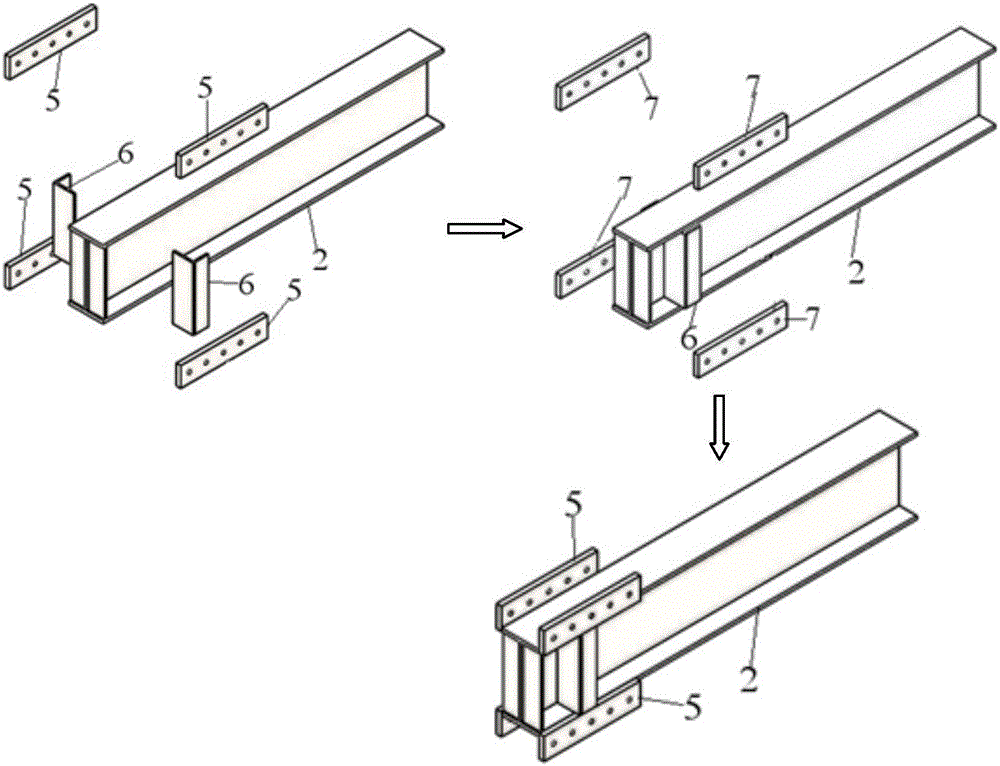

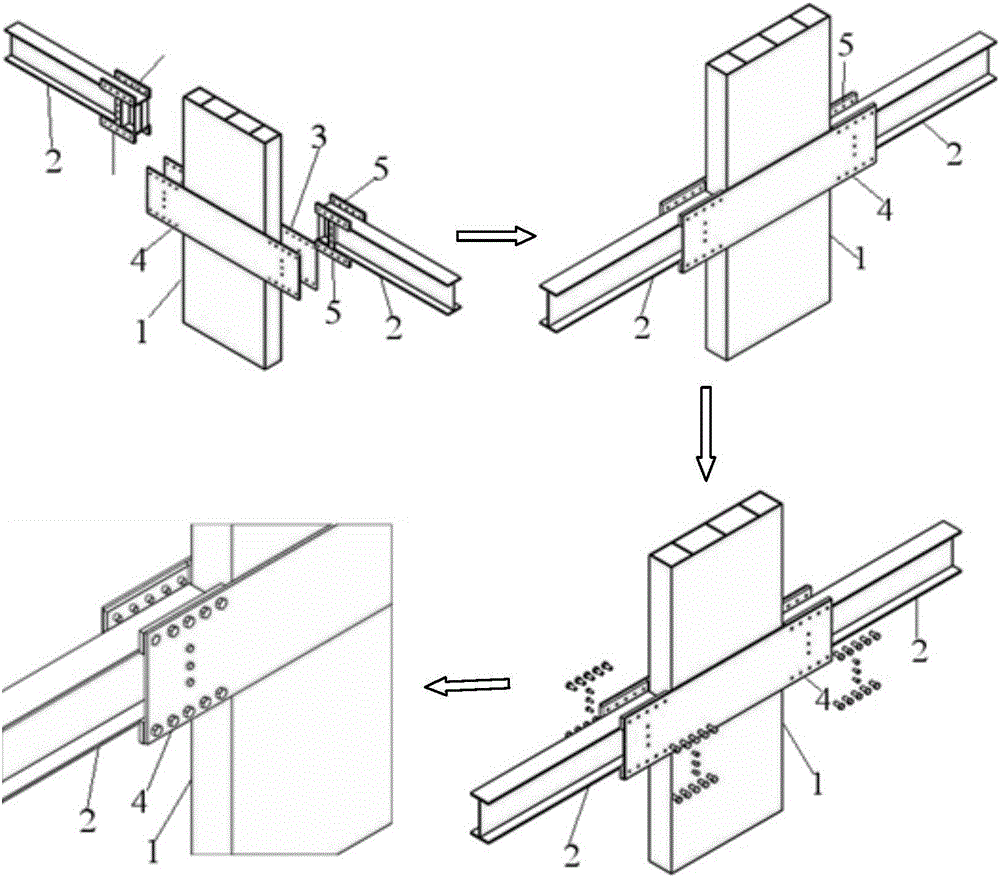

[0033] see image 3 , the present invention includes the first steel plate 3 and the second steel plate 4 arranged on both sides of the multi-cavity steel pipe concrete composite column, that is, two steel plates are arranged on both sides of the multi-cavity steel pipe concrete composite column, and the first steel plate 3 and the second steel plate 4 are parallel Setting; two parallel ear plates 5 are arranged along the length direction on the top of the upper flange of the steel beam, and two parallel ear plates 5 are arranged along the length direction on the bottom of the lower flange of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com