Connecting node for trusses made of composite materials

A technology of composite materials and connecting nodes, which is applied in the direction of architecture and building structure, can solve the problems of slow construction speed, sudden change in stiffness, and easy damage, etc., and achieves the effects of being conducive to popularization and implementation, simple node structure, and convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described in detail by taking a circular section composite material truss pipe as an example in conjunction with the accompanying drawings.

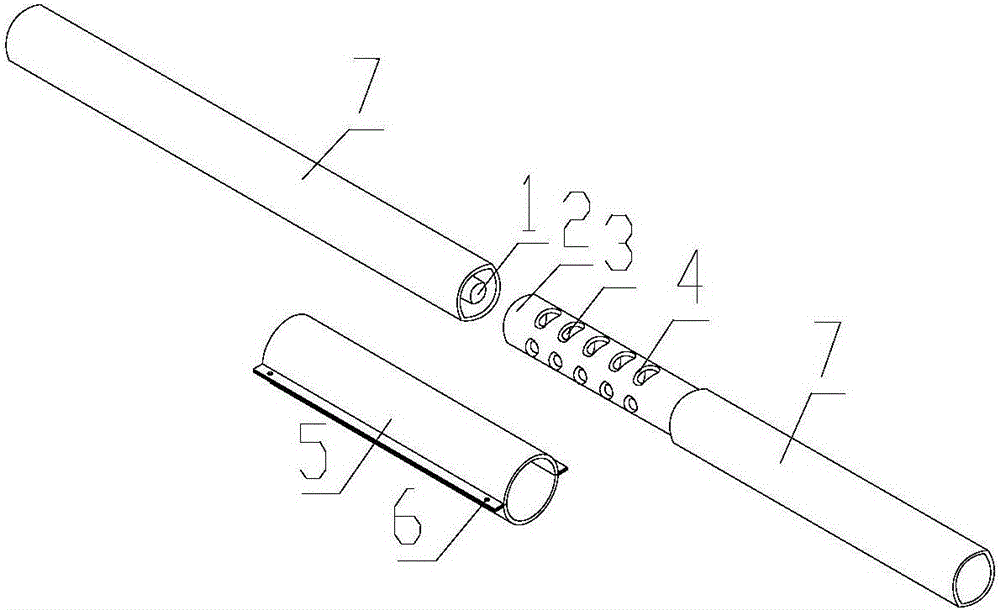

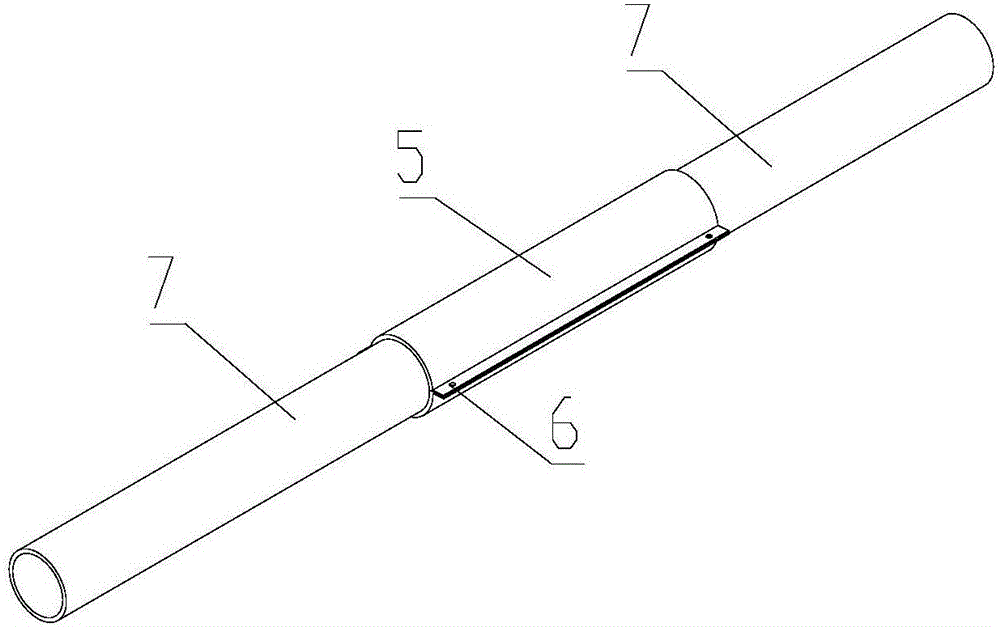

[0029] combine figure 1 with figure 2 , a composite material truss connection node includes a conical connecting body 1 , a conical connecting cylinder 2 and a metal buckle 5 . A through hole 4 is arranged on the conical connecting cylinder, and a sealed colloid hose 3 is arranged around the through hole 4, and the inside of the colloid hose is filled with colloid.

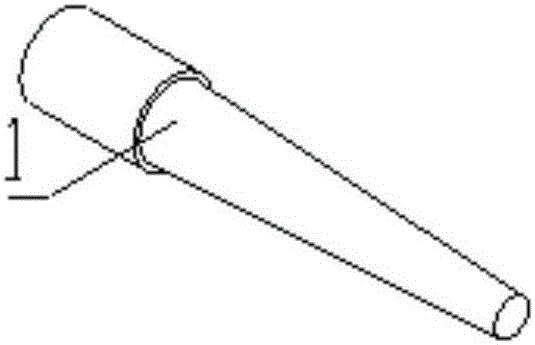

[0030] combine Figure 3 to Figure 5 , the conical connecting body 1 is integrally formed with the truss tube 7 in advance, the front section diameter of the conical connecting body 1 should not be less than 0.5D (D is the truss tube section diameter), the rear section diameter should be 0.7D-0.85D, and the slope should be at Between 1 / 6-1 / 8. For the large-diameter truss tube 7, the conical connector 1 shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com