Spatial panel point structure of steel truss and web PC (poly carbonate) combined bridge and construction method of spatial panel point

A technology of space joints and steel trusses, applied in bridge construction, bridges, bridge parts, etc., can solve problems such as non-perpendicularity between truss web steel pipes and embedded slabs, welding residual stress and stress concentration, complex joint structures, etc., to reduce on-site The effect of construction workload, large shear bearing capacity, and no need for post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

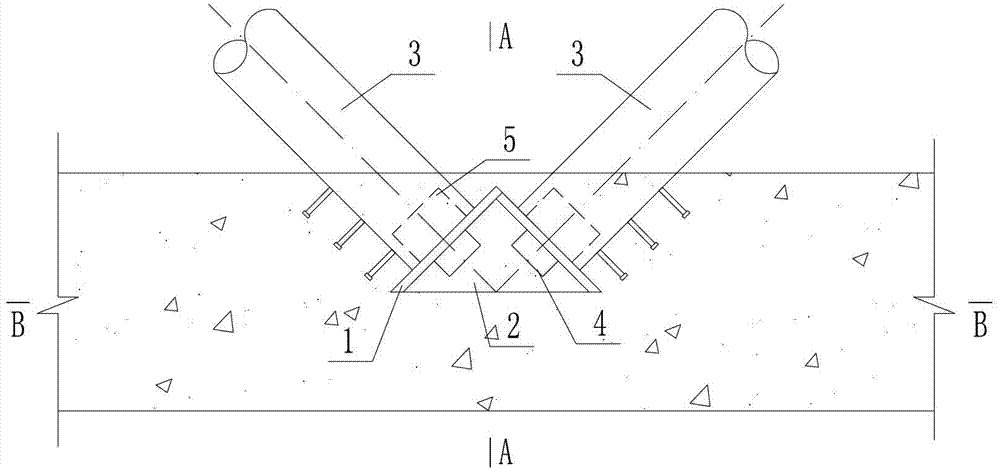

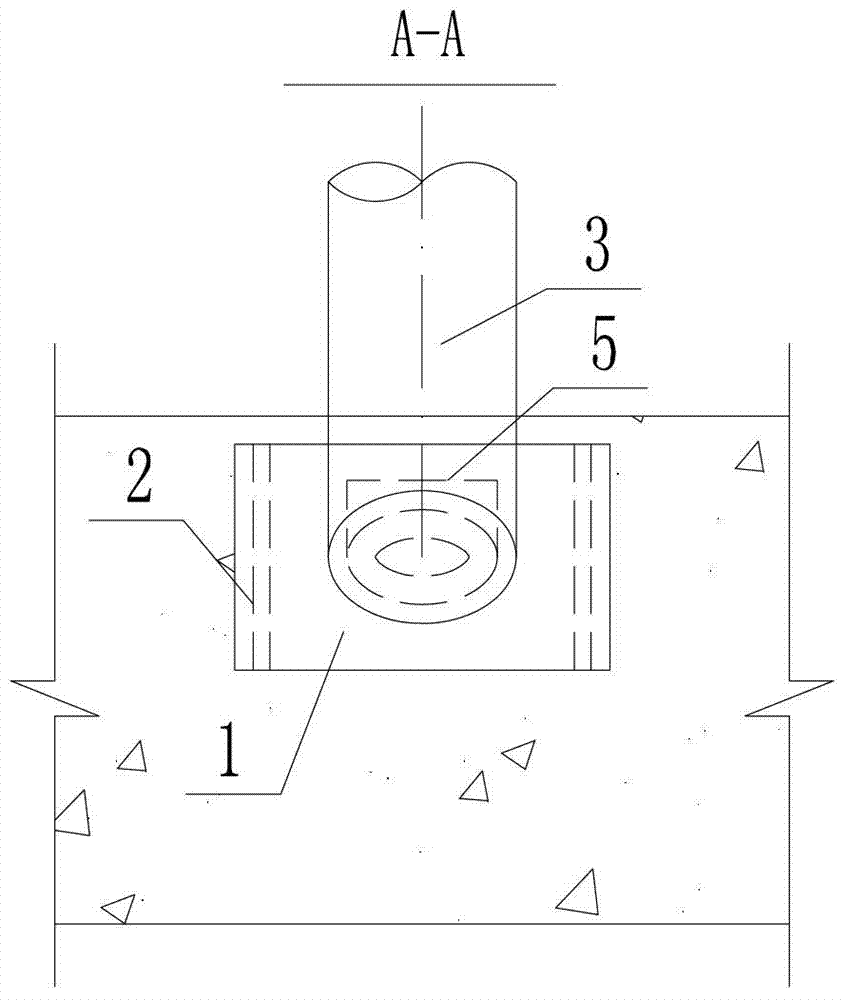

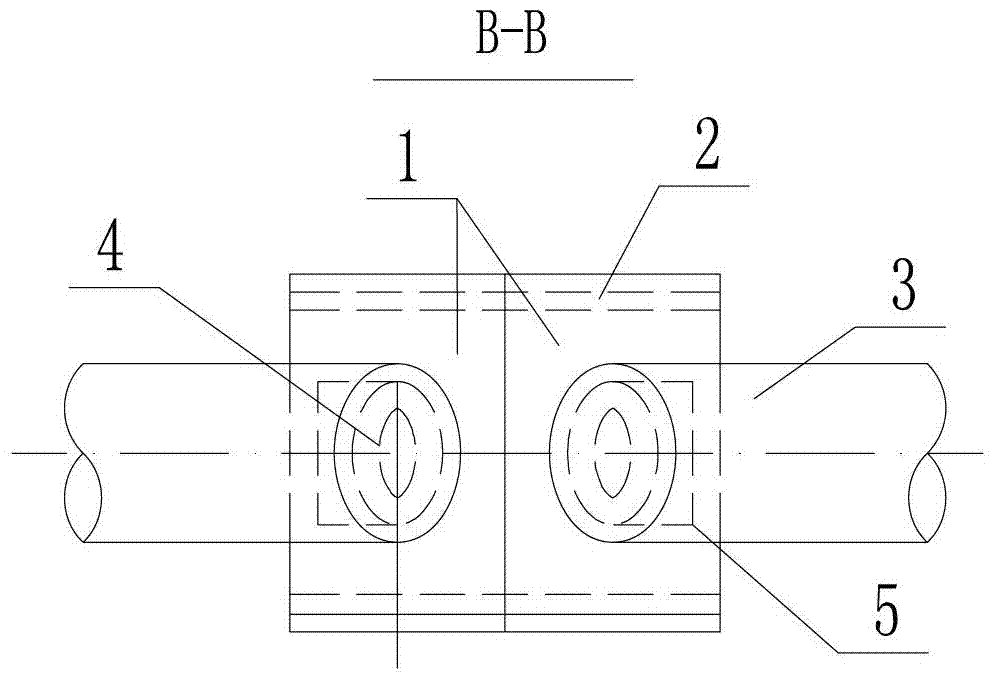

[0029] Such as Figure 1 to Figure 3 As shown, a steel truss web PC composite bridge space node structure, the concrete at the node is embedded with pre-embedded panels, the pre-embedded panels are connected with two truss-web steel pipes 3, and the clamping of two truss-web steel pipes 3 The angle is 90°. The pre-embedded plate includes two welded rectangular steel plates 1 and at least two triangular stiffened steel plates 2, the triangular stiffened steel plates 2 are welded to the inner side of the rectangular steel plates 1, and the angle between the two rectangular steel plates 1 is 90°. The ends of the two truss-web steel pipes 3 are welded to the outer surfaces of the two rectangular steel plates 1 respectively. There is a positioning inner conduit 5 in the end of the truss web steel pipe 3, and the positioning inner conduit 5 is also welded with the rectangular steel plate 1, and the positioning inner conduit 5 plays a positioning role. After calculation, it is dete...

Embodiment 2

[0034] Such as Figure 4 with Figure 5 As shown, a steel truss web PC composite bridge space node structure, the concrete at the node is embedded with pre-embedded panels, and the embedded panels and the PBL stiffening plate 9 outside the concrete (referring to the open-hole stiffening plate, PBL stiffened plate for short, the same below) is connected with two truss web steel pipes 6, the embedded plate includes PBL shear connector 7 and multiple PBL vertical and horizontal stiffeners 8, the top panel 10 of PBL shear connector 7 is Plane steel plates, the top panel 10 of the PBL shear connector 7 is flush with the top surface of the concrete, the PBL vertical and horizontal stiffeners 8 are welded to one side of the top panel 10 of the PBL shear connector 7, and the end of the truss web steel pipe 6 is connected to the The other side of the top panel 10 of the PBL shear connector 7 is welded, and the angle between the two truss web steel pipes 6 is

[0035] 90°, the PBL sti...

Embodiment 3

[0038] Such as Image 6 with Figure 7 As shown, a steel truss web PC composite bridge space node structure, the concrete at the node is embedded with embedded panels, and the embedded panels are connected with semicircular stiffeners 13 located outside the concrete, and the semicircular stiffeners The plate 13 is connected with two truss-web steel pipes 12. The embedded plate includes a PBL shear connector 14 and multiple PBL vertical and horizontal stiffeners 15. The top panel 16 of the PBL shear connector 14 is a flat steel plate, and the PBL shear The top panel 16 of the connector 14 is flush with the top surface of the concrete, the PBL vertical and horizontal stiffeners 15 are welded to one side of the top panel 16 of the PBL shear connector 14, and the semicircular stiffener 13 and the PBL shear connector 14 are welded together. The other side of the top panel 16 is welded, the end of the truss web steel pipe 12 is welded to the semicircular stiffener 13, the angle bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com