Strip-shaped reinforced joint for connection of H-shaped steel beam and short edge of wide steel pipe concrete column

A technology of steel tube concrete columns and H-shaped steel, which is applied in the direction of construction and building construction, and can solve the problems that the cross section of steel columns cannot be too small, the cross section of steel columns cannot be too large, and the use of diaphragms cannot be used, so as to achieve simple node structure processing , good stiffness and strength, and the effect of improving the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

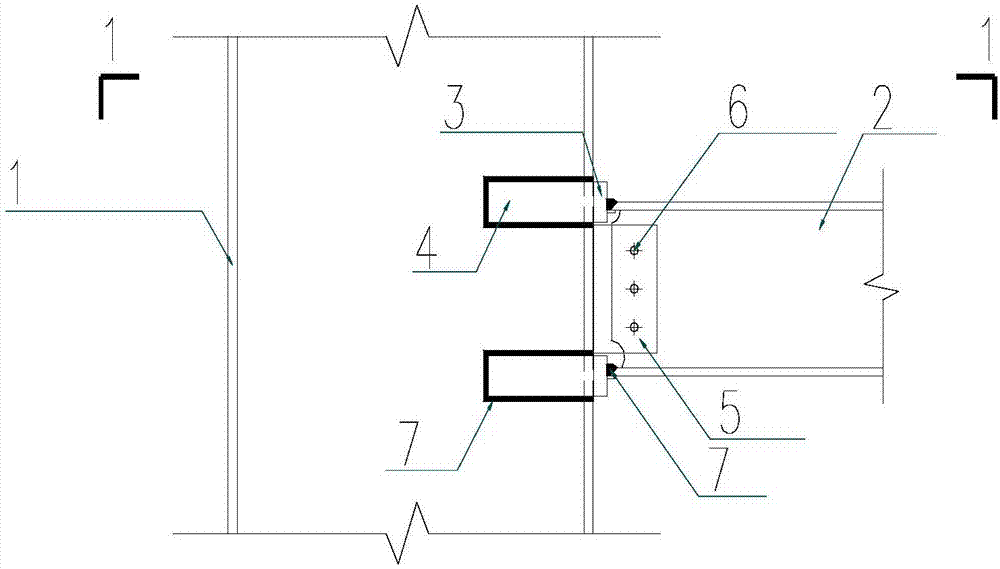

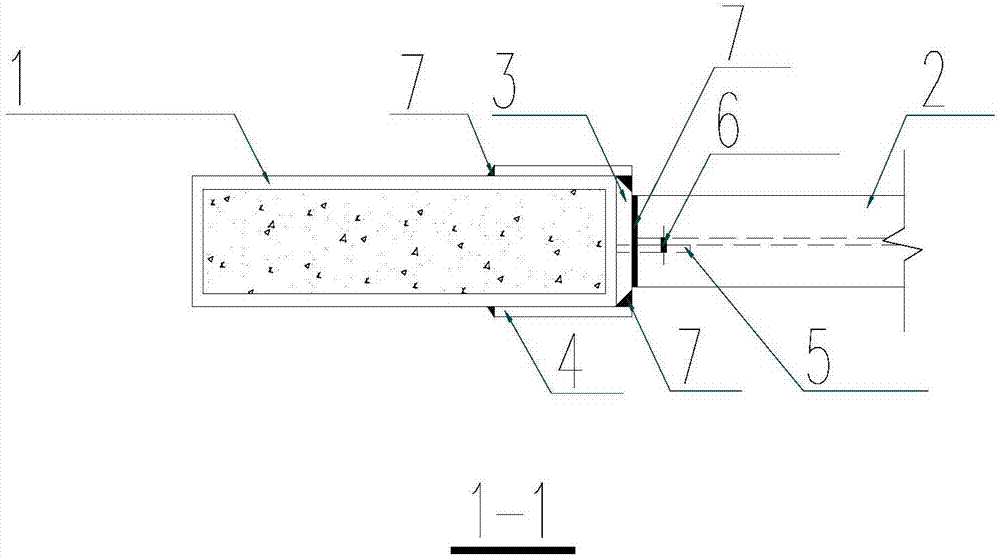

[0046] Such as figure 1 and figure 2 As shown, the embodiment includes: a wide steel pipe concrete column 1, an H-shaped steel beam 2, a strip-shaped reinforcing plate 3, a sticking plate 4, a connecting plate 5 and a high-strength bolt 6.

[0047] The wide steel pipe concrete column 1 is formed by pouring concrete inside a rectangular steel pipe, and the ratio of the long side to the short side of the rectangular steel pipe is 1-4.

[0048] Only one steel beam is rigidly connected to the short side of the wide concrete-filled steel tube column, and two belt-shaped reinforcement plates 3 are fixed on the side where the short side of the wide steel-filled steel tube concrete column 1 is located. The two belt-shaped reinforcement plates 3 correspond to the H-shaped The upper and lower flanges of the steel beam 2, and the end faces of the upper and lower flanges of the H-shaped steel beam 2 are welded to the respective belt-shaped reinforcement plates 3, and the two horizontal ...

Embodiment 2

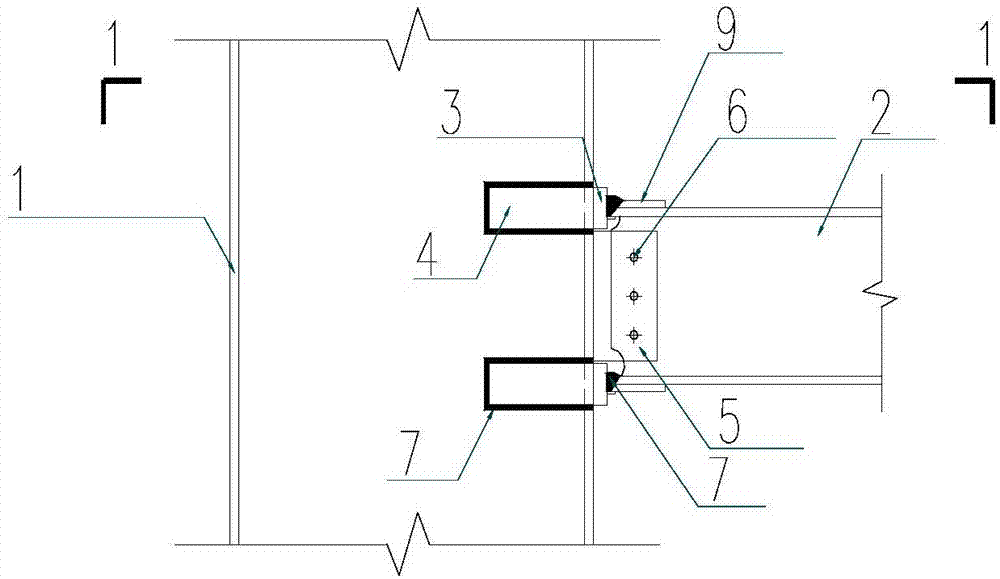

[0055] Such as image 3 and Figure 4 As shown, the present embodiment is based on Embodiment 1, and the upper and lower flanges of the H-shaped steel beam 2 are provided with cover plates 9, and the two cover plates 9 are respectively tightly attached to and welded to the H-shaped steel beam 2, On the surface of the lower flange, the ends of the two cover plates 9 are welded to the respective corresponding strip reinforcement plates 3 .

Embodiment 3

[0057] Such as Figure 5 and Figure 6 As shown, the embodiment includes: wide concrete-filled steel tube column 1 , H-shaped steel beam 2 , belt-shaped reinforcing plate 3 , pasting plate 4 , connecting plate 5 , inserting plate 8 and high-strength bolt 6 .

[0058] The wide steel pipe concrete column 1 is formed by pouring concrete inside a rectangular steel pipe, and the ratio of the long side to the short side of the rectangular steel pipe is 1-4.

[0059] Only one steel beam is rigidly connected to the short side of the wide concrete-filled steel tube column, and two belt-shaped reinforcement plates 3 are fixed on the side where the short side of the wide steel-filled steel tube concrete column 1 is located. The two belt-shaped reinforcement plates 3 correspond to the H-shaped The upper and lower flanges of the steel beam 2, and the end faces of the upper and lower flanges of the H-shaped steel beam 2 are welded to the respective belt-shaped reinforcement plates 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com