Patents

Literature

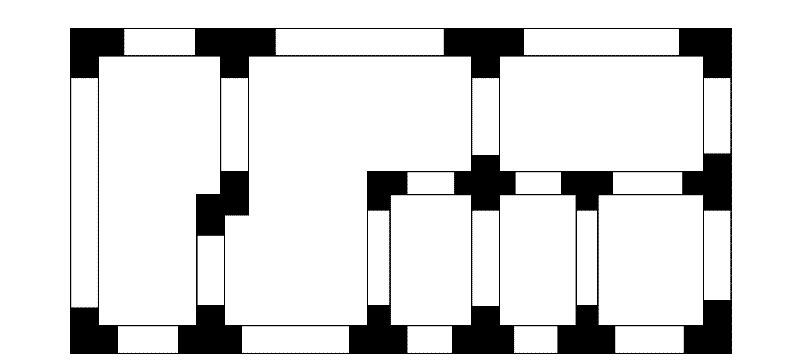

46results about How to "Improves seismic ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

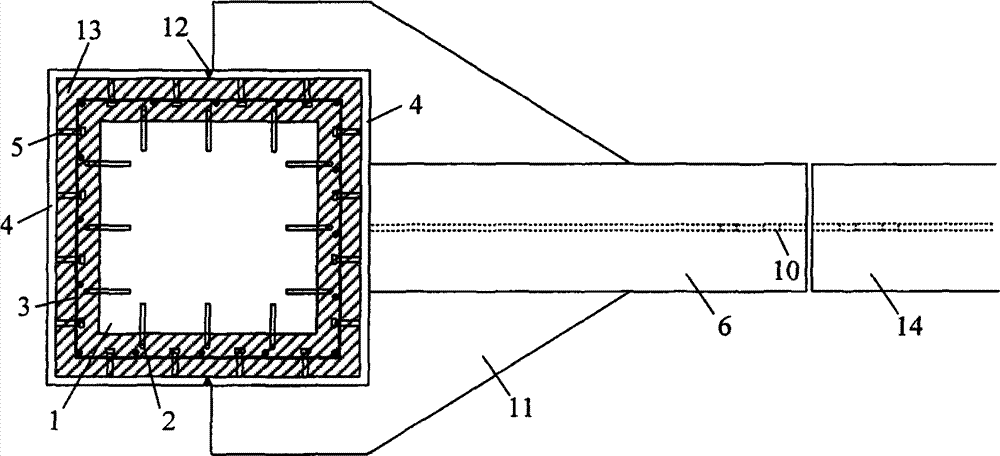

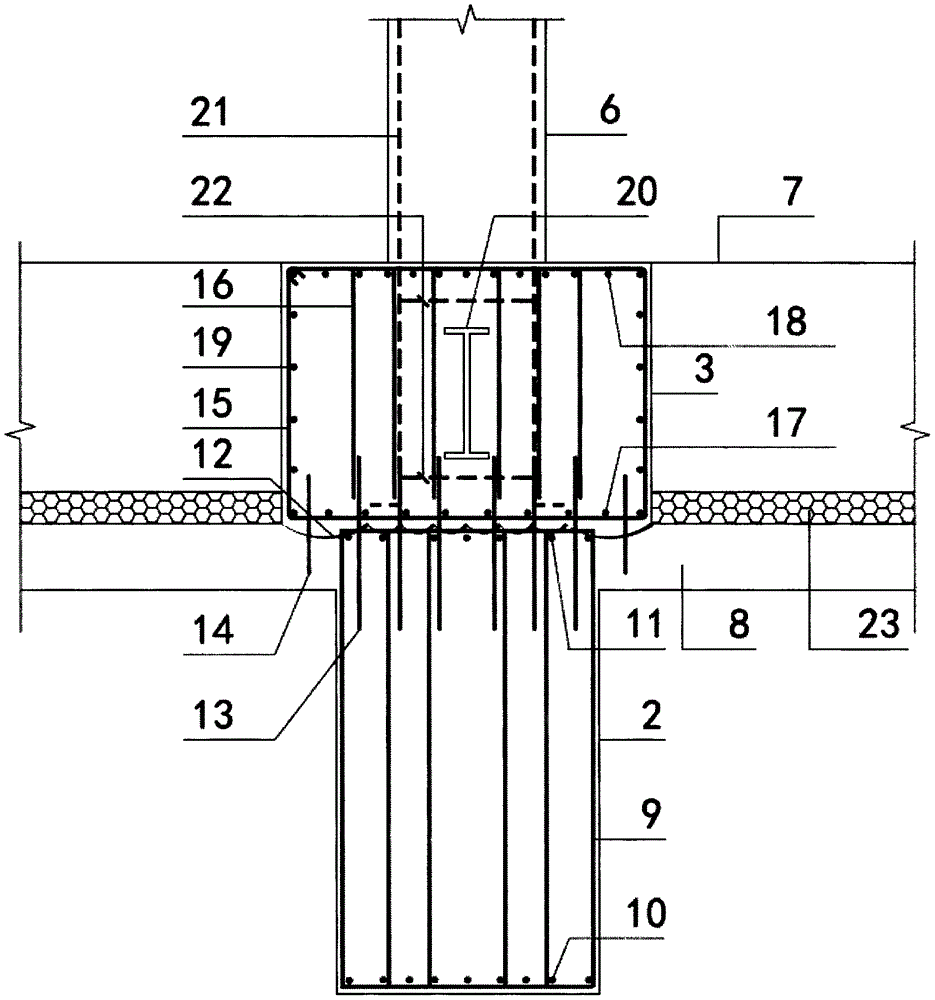

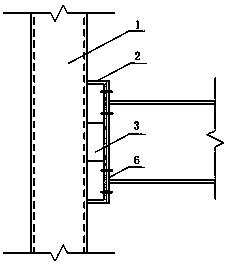

Connecting method of steel beam and existing reinforced concrete column

InactiveCN102966245AEasy to get materialsReduce wet work loadBuilding repairsReinforced concrete columnEngineering

The invention relates to a connecting method of a steel beam and an existing reinforced concrete column, which can be used for reinforced modification of an existing reinforced concrete structure, and belongs to the technical field of structural engineering. The method comprises the steps of: scabbling, planting bars and binding reinforced mesh pieces on the surface around with a node connection domain of the original reinforced concrete column; processing two pieces of channel steel and welding a stud connection piece inside; extending an extending bracket and external reinforcing plate on the channel steel connected to the steel beam; buckling the two pieces of channel steel and wrapping the original reinforced concrete column; welding in an abut manner; pouring node area concrete; and finally connecting the steel beam. The method overcomes the deficiencies of the conventional connection method, is simple in structure, quick and convenient to construct, good in stress performance of the connecting node, reliable in force transfer, and can efficiently prevent a node core area from cracking and being exposed. The core area concrete is wrapped by a steel plate so that the concrete is strongly constrained, and the quake-proof ductility of the node is good. The method has high practicality and wide application prospect.

Owner:TSINGHUA UNIV

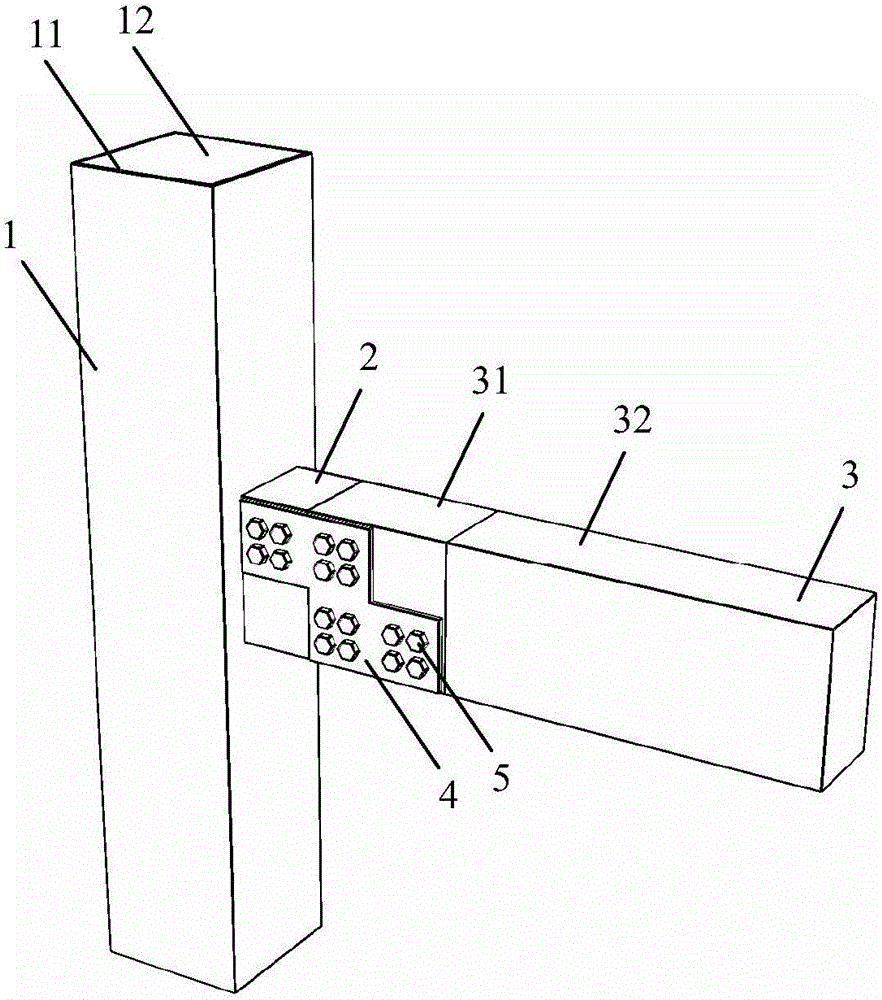

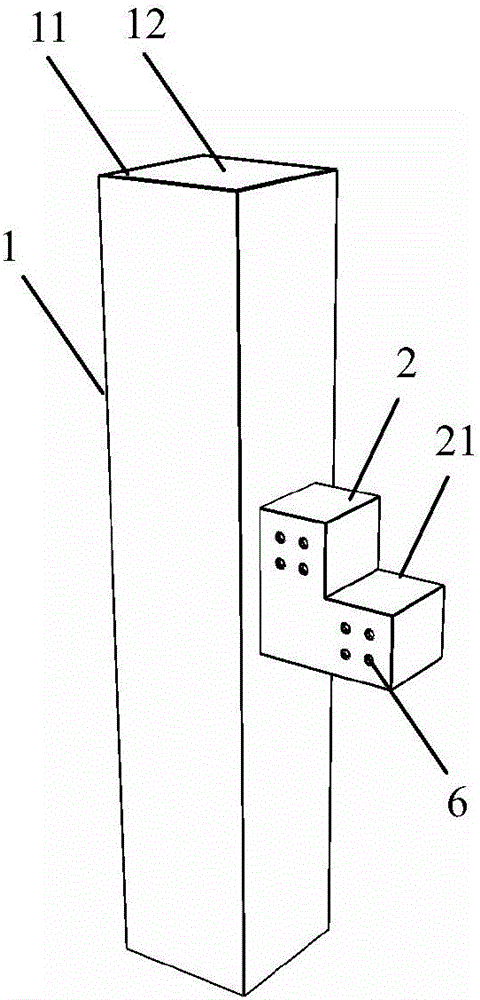

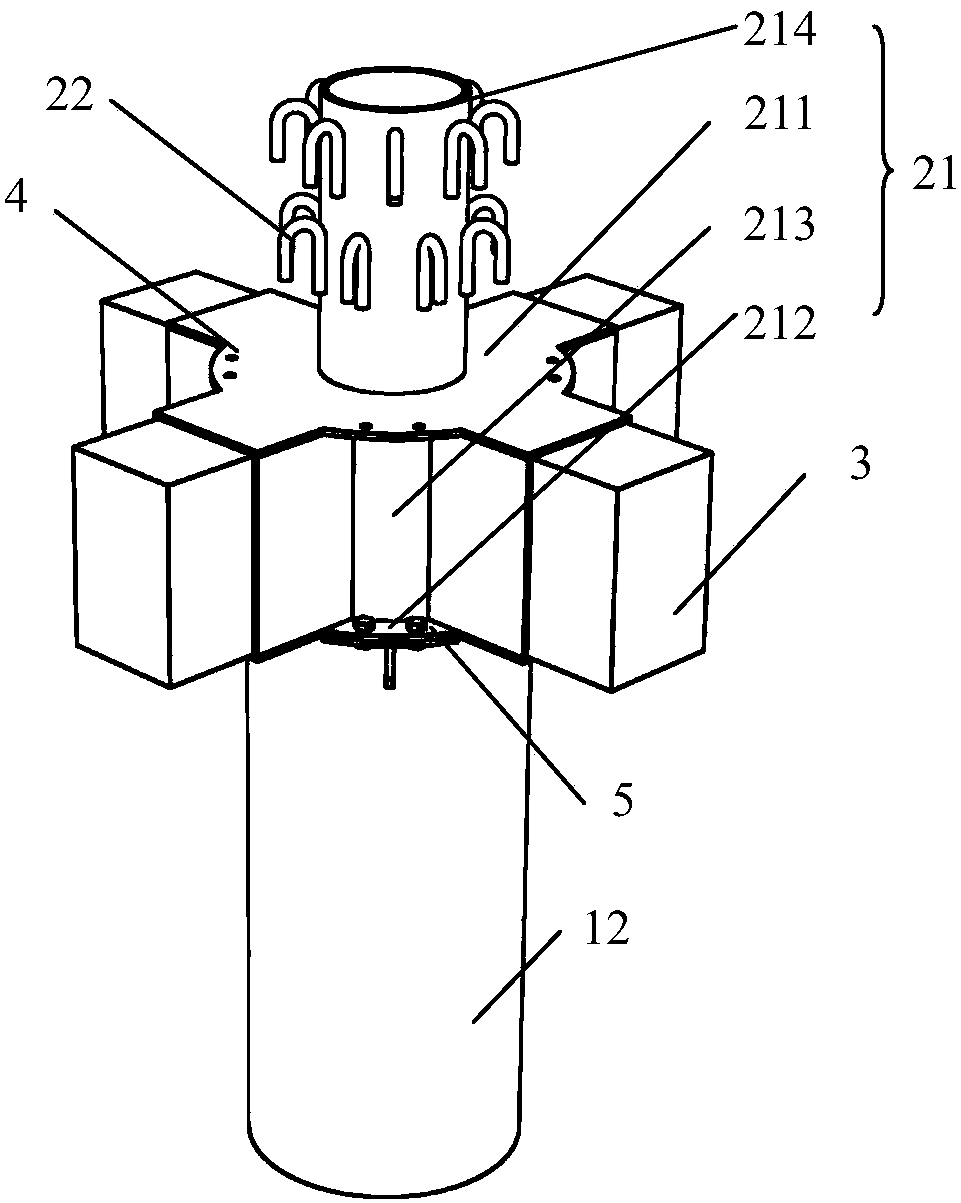

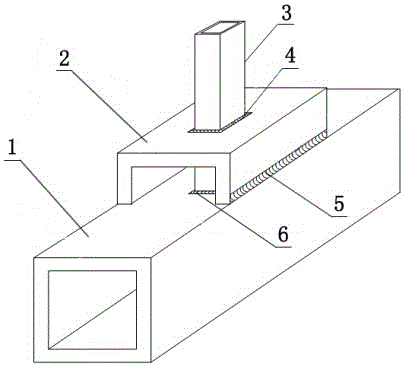

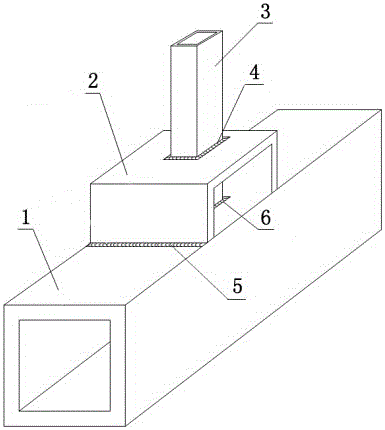

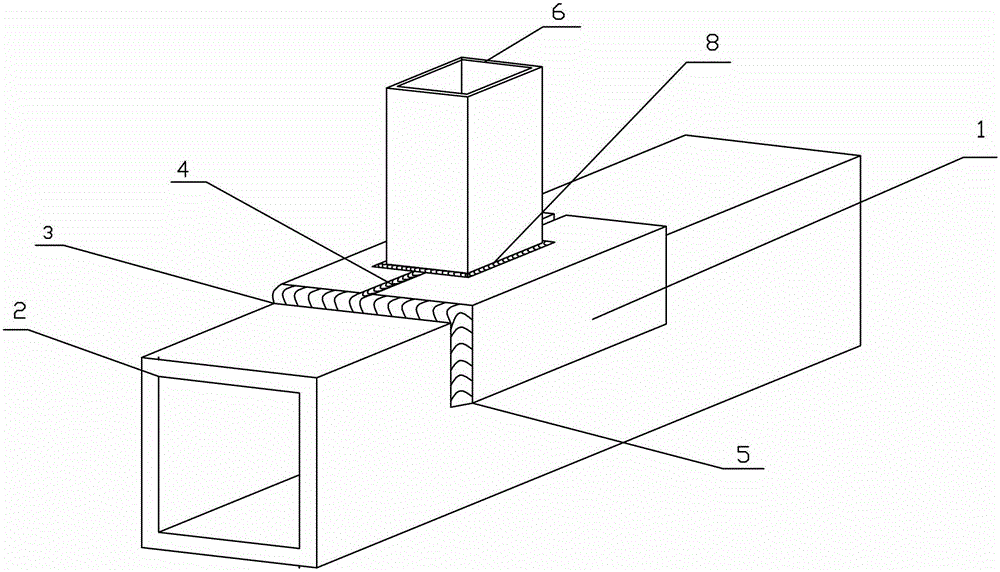

Assembly structure of prefabricated concrete beam and concrete-filled steel tube column

InactiveCN105780923AImproved dissipation capacityAvoid punchingBuilding constructionsConcrete beamsRebar

The invention discloses an assembly structure of a prefabricated concrete beam and a concrete-filled steel tube column. The assembly structure comprises the concrete-filled steel tube column, a concrete-filled steel tube bracket, the prefabricated concrete beam, beam end pre-buried steel and a connection plate, wherein the concrete-filled steel tube bracket is welded with a side part of the concrete-filled steel tube column; the concrete-filled steel tube bracket is step-shaped; the concrete-filled steel tube bracket comprises bracket-shaped steel and bracket concrete filled in the bracket-shaped steel; a plurality of opposite-pull bolt holes are formed in the side surface of the bracket-shaped steel; the prefabricated concrete beam comprises the beam end pre-buried steel and prefabricated reinforced concrete; the beam end pre-buried steel is step-shaped and is matched with the shape of the concrete-filled steel tube bracket; a plurality of opposite-pull bolt holes are also formed in the side surface of the beam end pre-buried steel; the connection plate is arranged on the side surface of the bracket-shaped steel and the beam end pre-buried steel and is locked and fastened by a plurality of opposite-pull bolts. The assembly structure of the prefabricated concrete beam and the concrete-filled steel tube column is high in bearing capacity, high in earthquake-resistant ductility, high in node energy dissipation capacity, convenient to construct and high in construction quality, and can provide effective restraint on the concrete.

Owner:FUJIAN UNIV OF TECH

Double-steel-sheet and concrete combined core-tube structure with built-in corrugated steel sheets

InactiveCN103233509AImprove seismic performanceImprove structural rigidityShock proofingEngineeringSteel frame

The invention provides a double-steel-sheet and concrete combined core-tube structure with built-in corrugated steel sheets. The corrugated steel sheet and a plurality of steel cover plates are vertically welded and connected to form an elongated grille steel tube wall board by borrowing ideas from a steel tube and concrete combined structure, high-strength concrete is poured into grille steel tubes to form an elongated grille steel tube and concrete combined shear wall board, and the elongated grille steel tube wall board and in-tube concrete columns are used in a combined mode, complement each other's advantages and work cooperatively. The novel shear wall board is in welding connection with edge steel columns and edge steel beams, and an end portion steel tube concrete core column is arranged at the intersecting corner position of wall bodies of core-tube shear walls to form the novel double-steel-sheet and concrete combined core-tube structure with the built-in corrugated steel sheets. A steel frame-structural system of the novel combined structure core tubes has the advantages of being large in structural rigidity, high in compression bearing capacity, convenient to construct, strong in anti-bending capacity, high in yield load, good in anti-seismic ductility, good in energy dissipation capacity and the like, and the double-steel-sheet and concrete combined core-tube structure can be used for a 60-storey steel structure building and a super high-rise steel structure building with more than 60 storeys.

Owner:SOUTHEAST UNIV

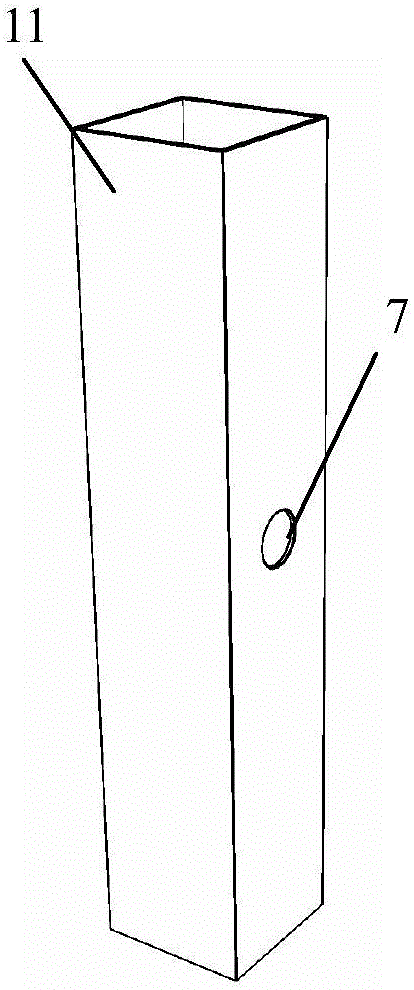

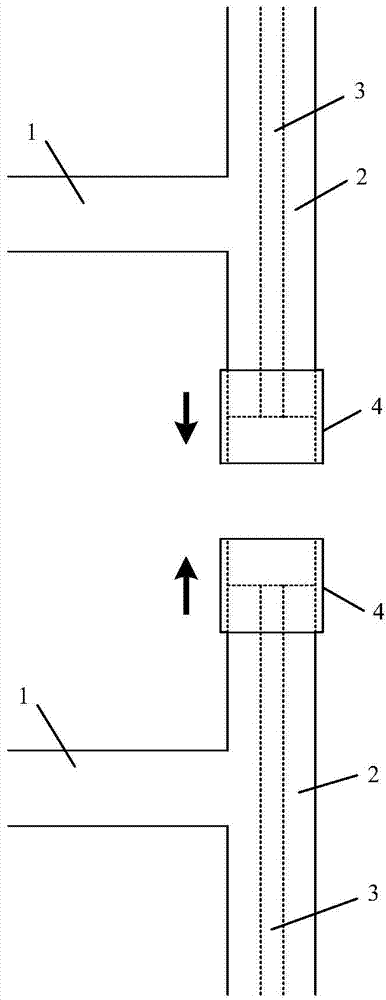

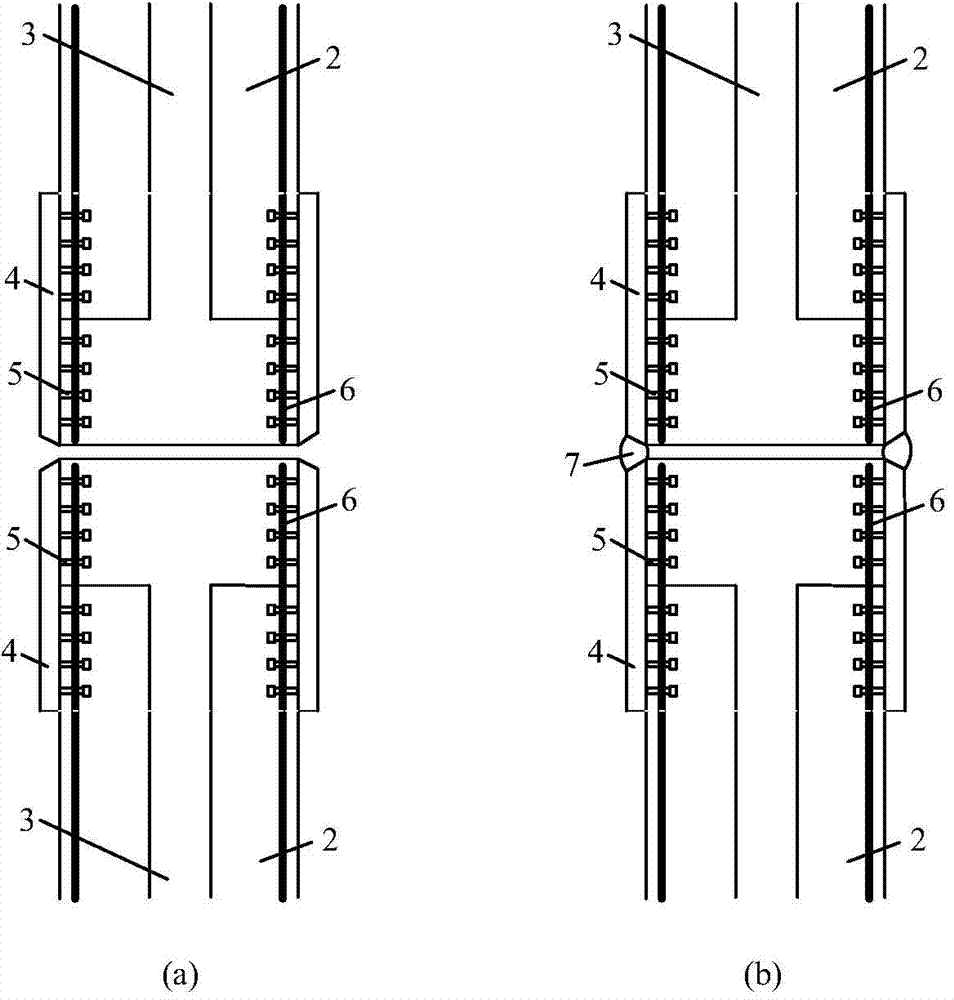

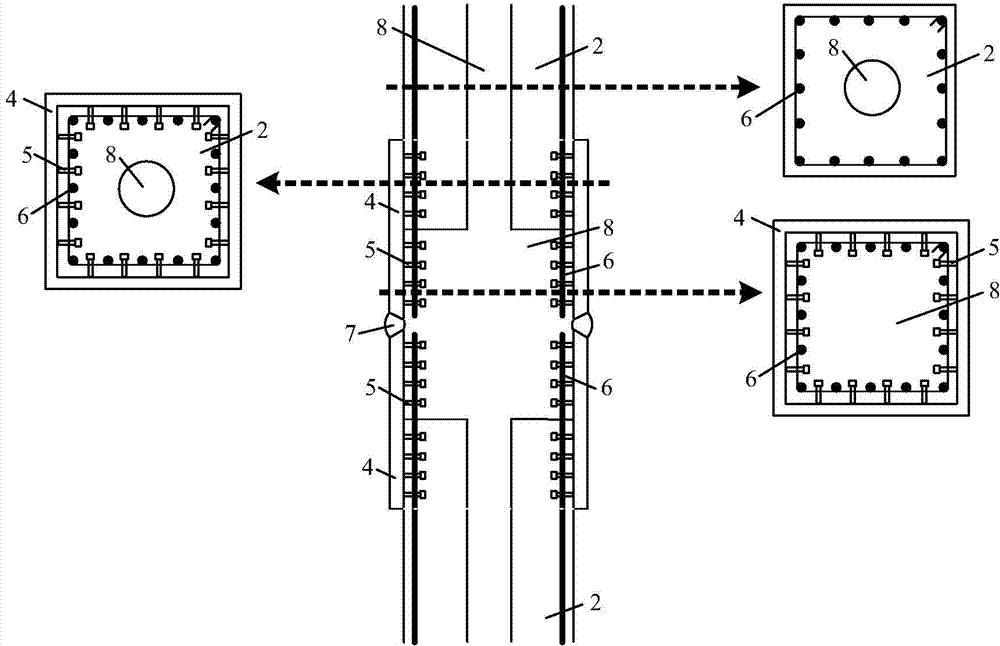

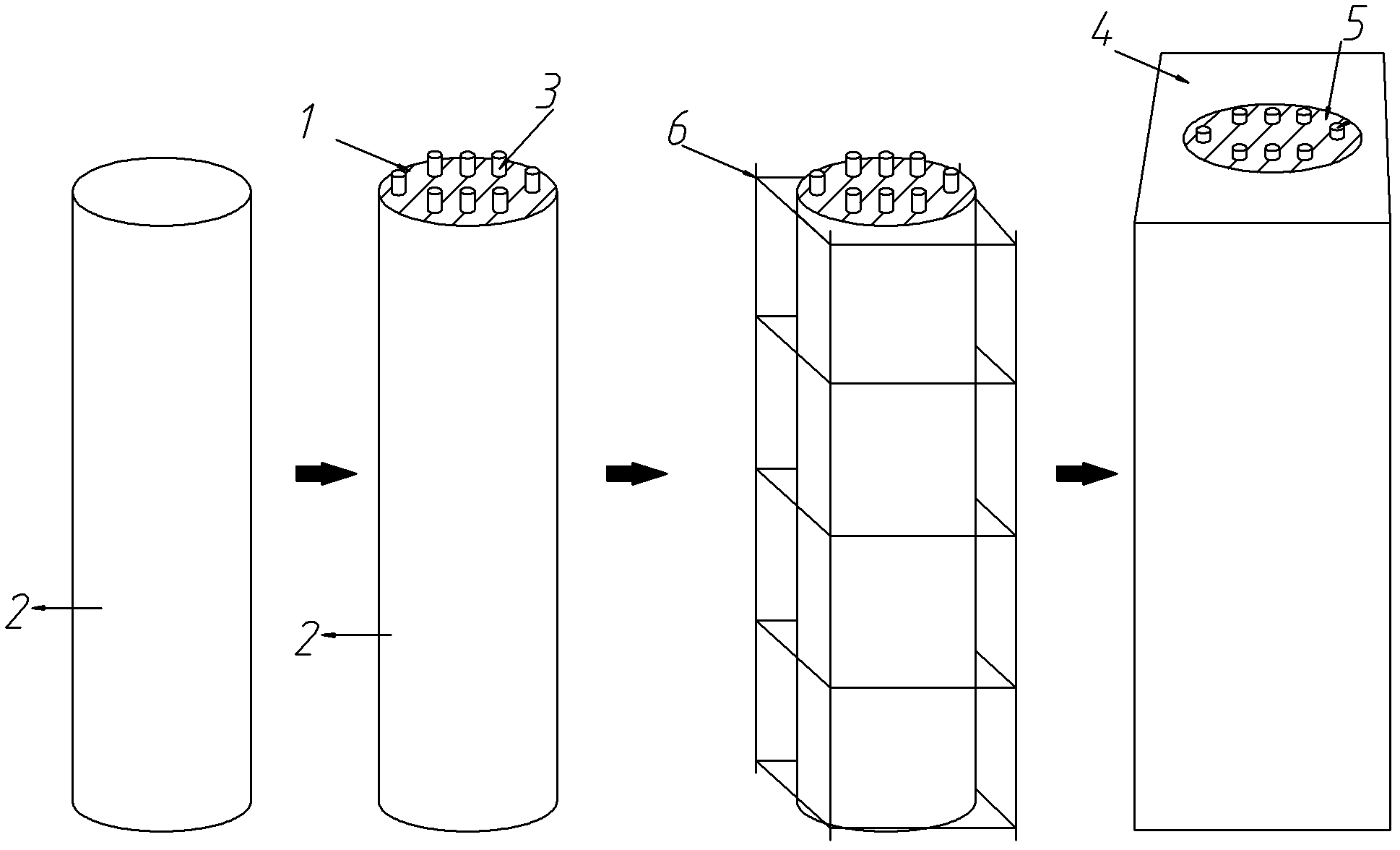

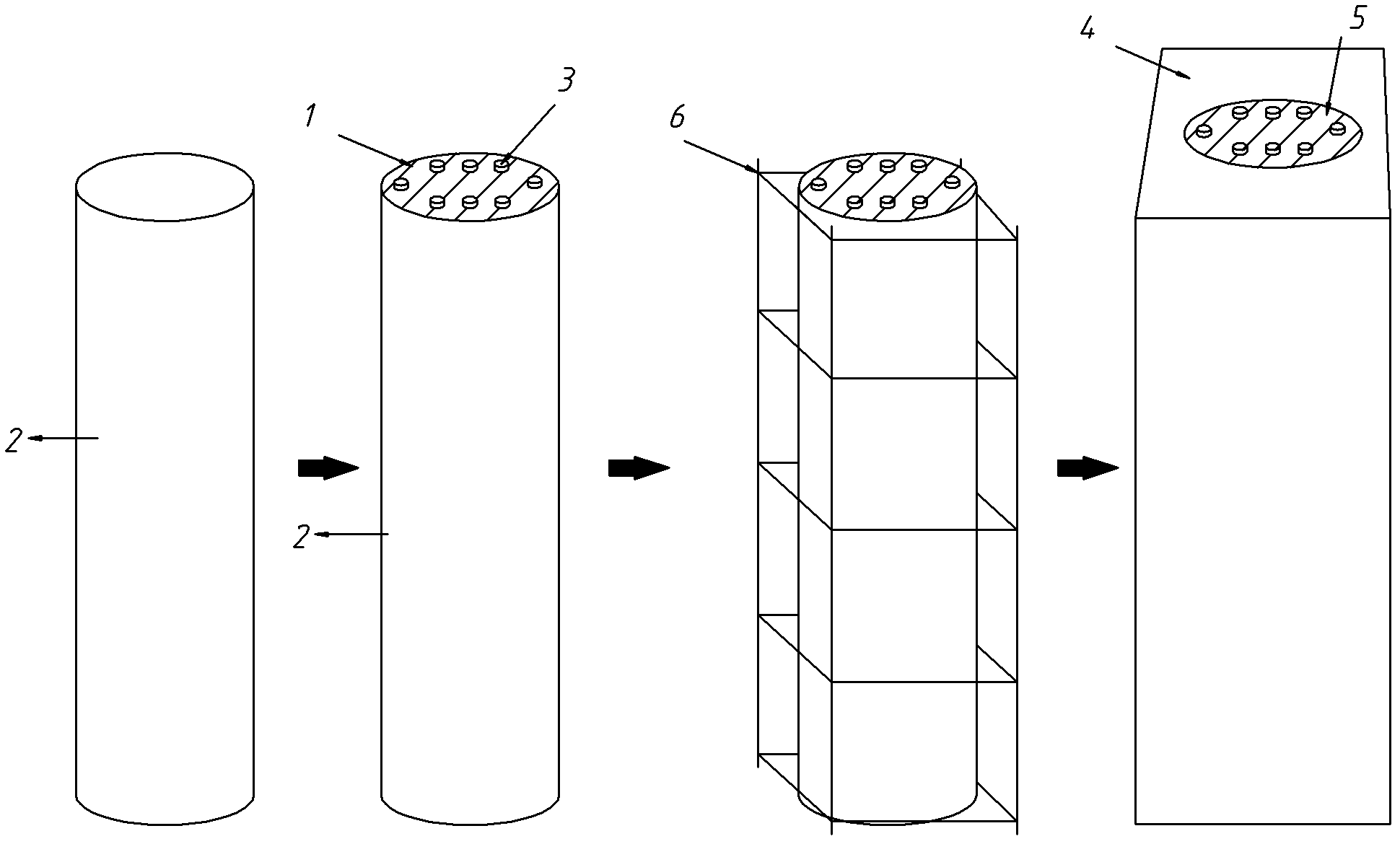

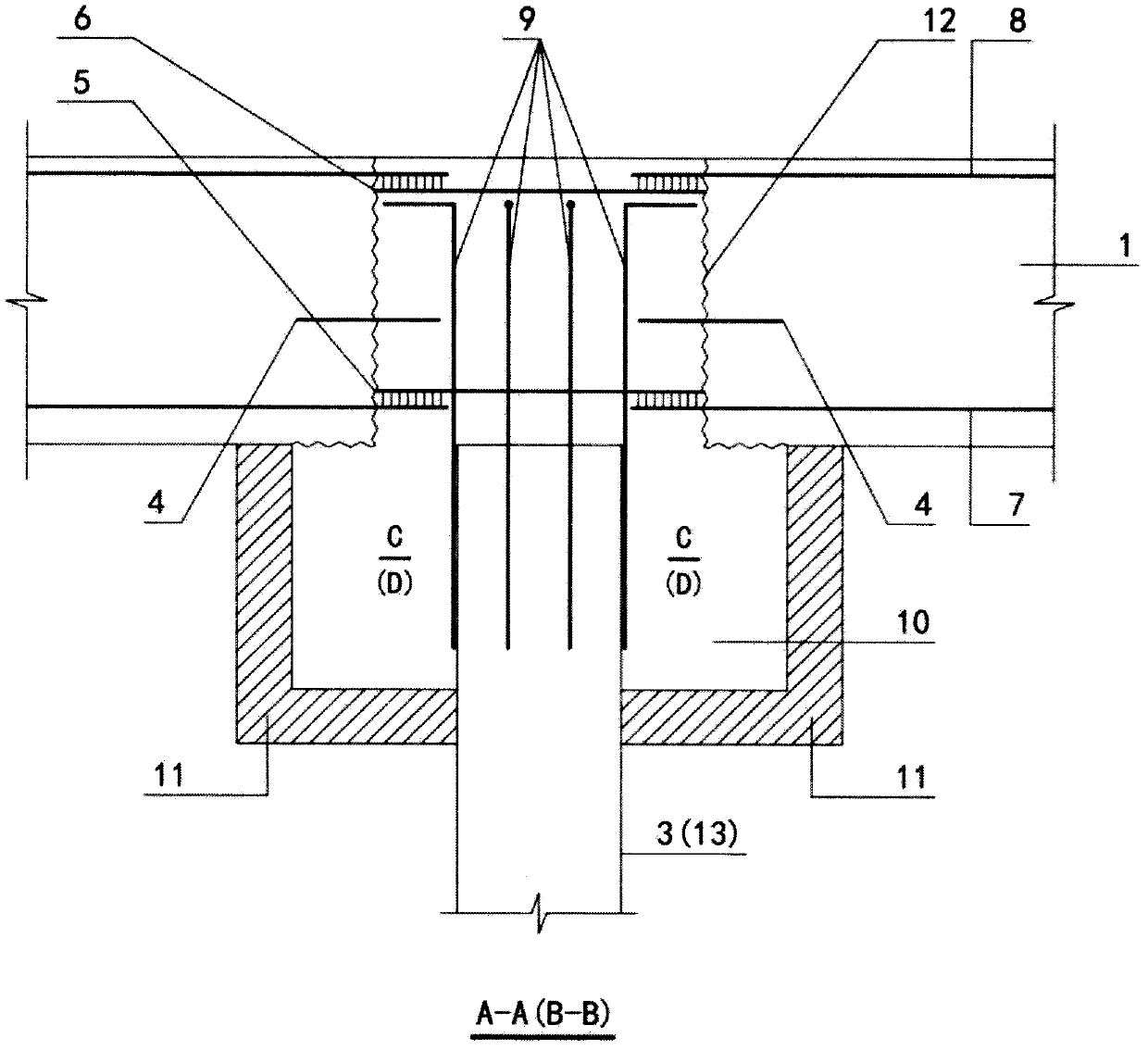

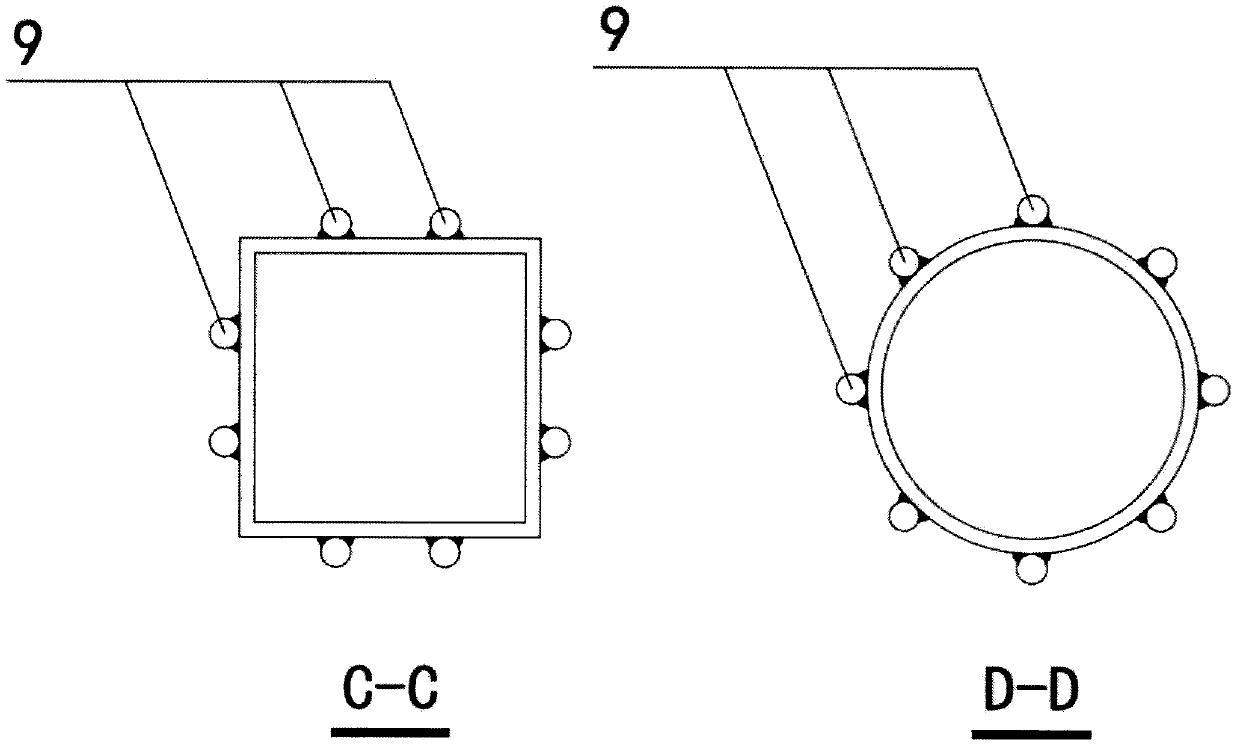

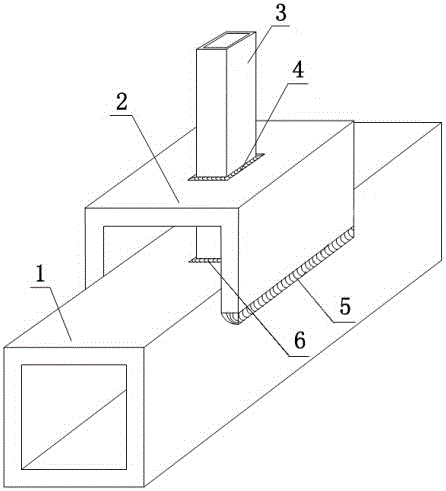

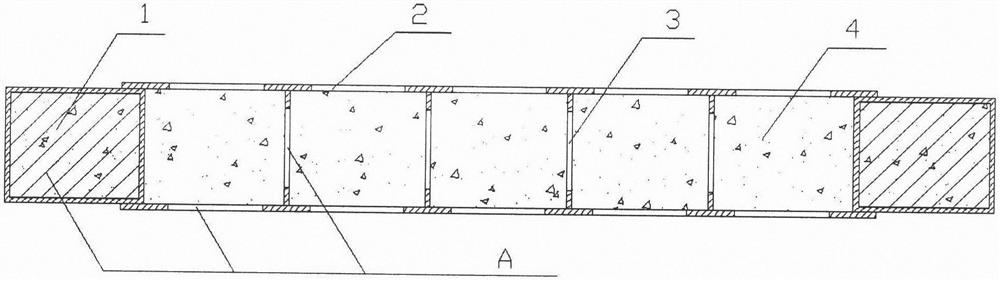

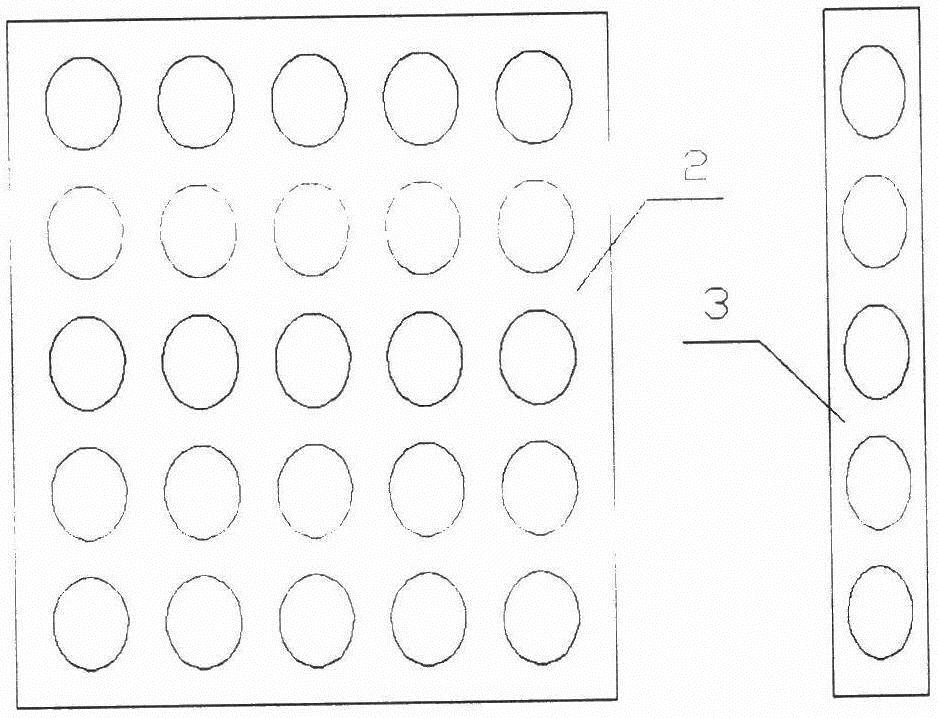

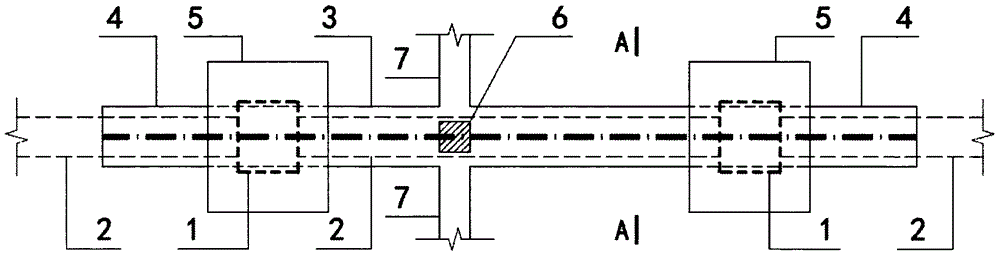

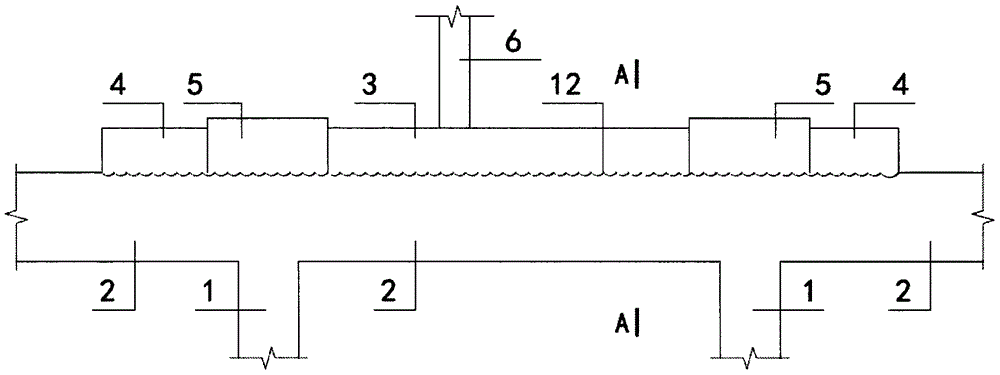

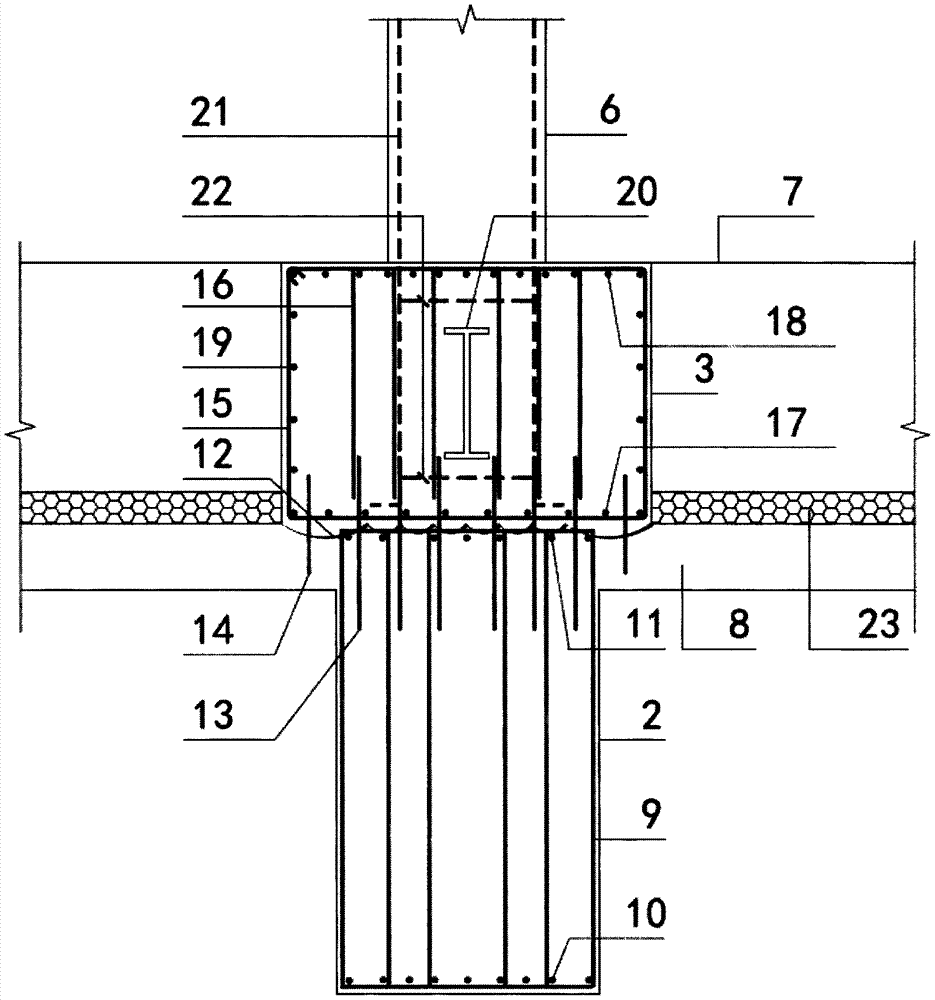

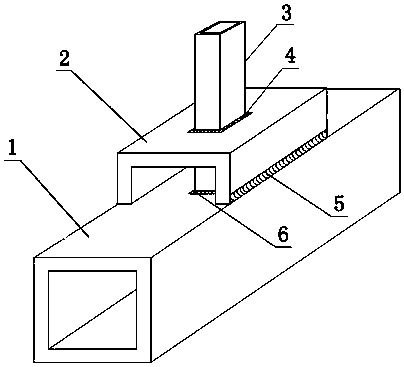

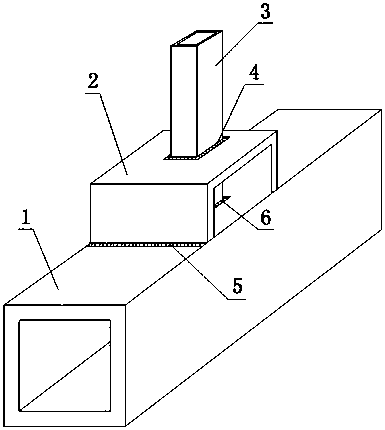

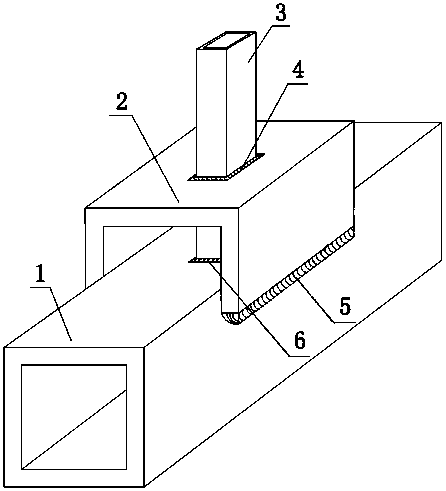

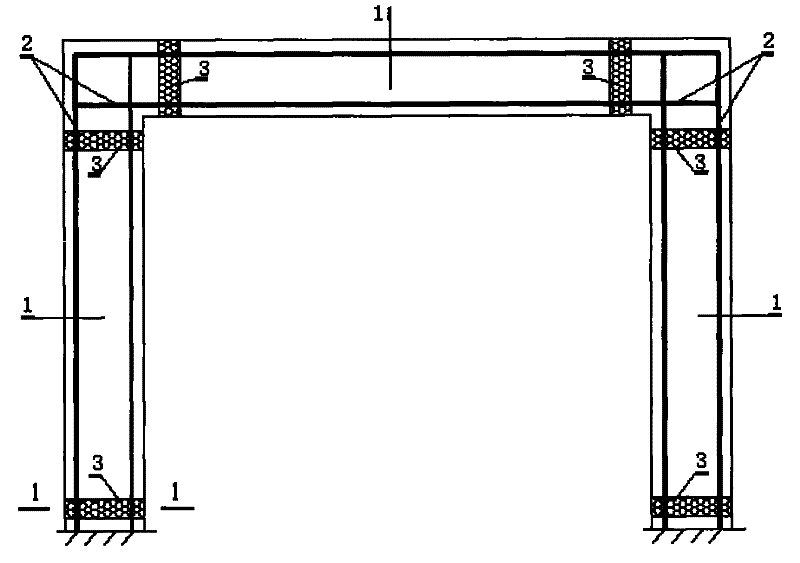

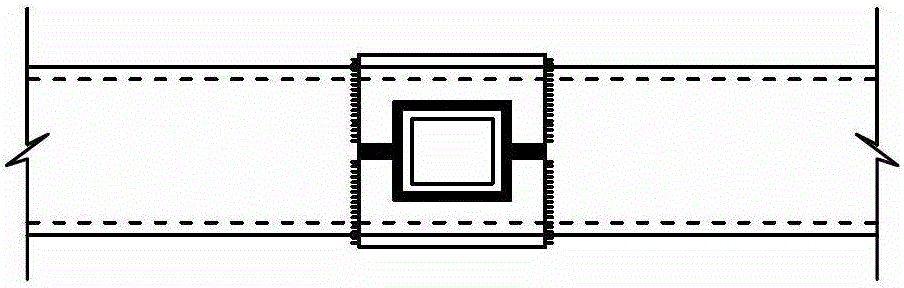

Field connecting method among prefabricated reinforced concrete columns

ActiveCN104775516AGuarantee construction quality and seismic performanceSimple structureBuilding constructionsRebarReinforced concrete column

The invention relates to a field connecting method among prefabricated reinforced concrete columns, facilitates to realize a novel prefabricated assembly technology mode of node factory prefabrication-beam column field connection, prevents the scene casting of concrete in a beam column node area, and belongs to the technical field of structural engineering. The method comprises the following steps: through long round hole ways are reserved in the prefabricated reinforced concrete columns; the ends are coated with steel sleeves; beam column nodes serve as a whole prefabricated unit for lifting on the scene; the steel sleeves at the ends of the upper and lower layers of columns are connected through butt welding joints after being aligned; and finally, concrete is cast in the round hole ways and cavities of the steel sleeves. The method has the advantages of simple configuration, convenience for construction, high field installation speed, low concrete wet operation load, little influence on surrounding environments, excellent stress performance, reliable force transfer, prevention of exposure of concrete cracks in connection areas by means of the steel sleeves, provision of restraint effect, convenience for material taking and processing, low use level of steels and good economical efficiency.

Owner:TSINGHUA UNIV

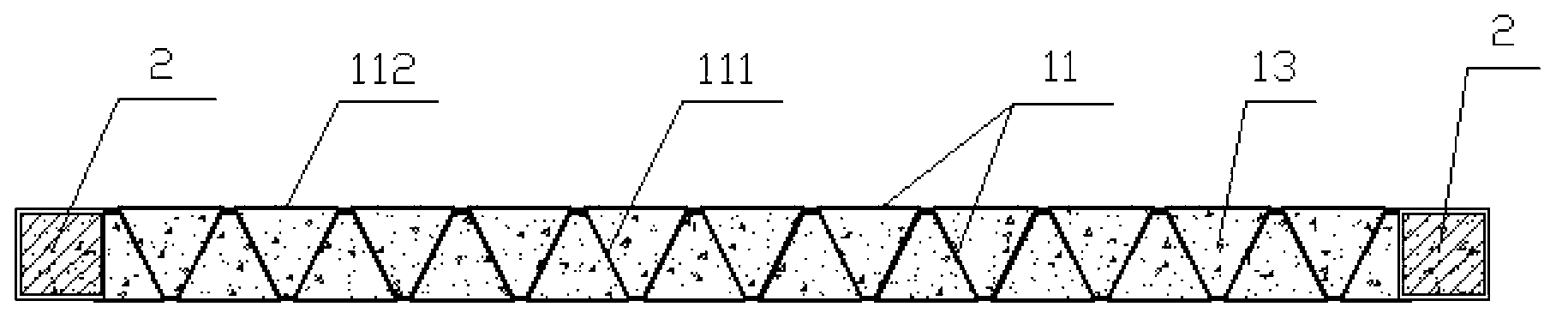

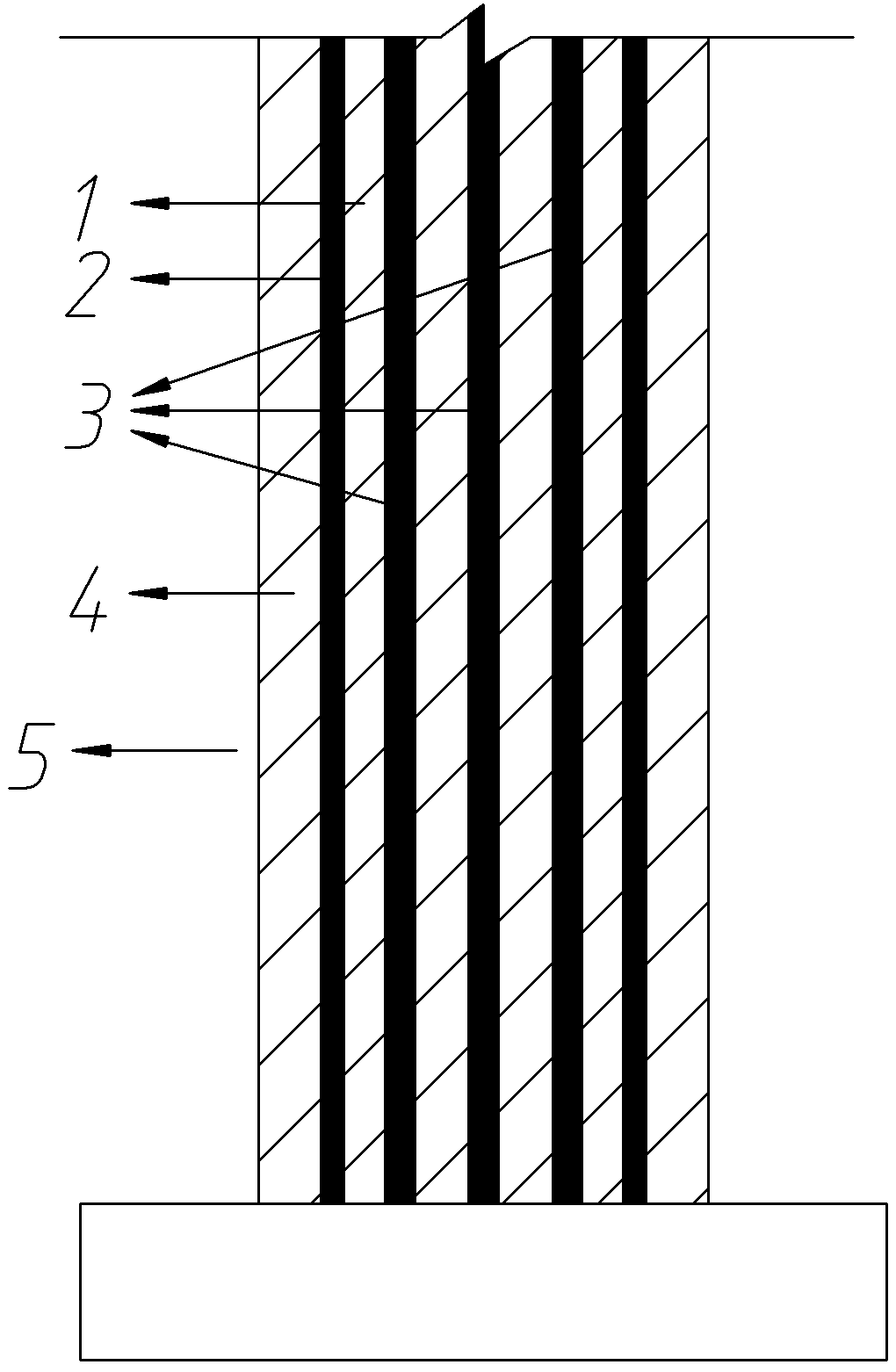

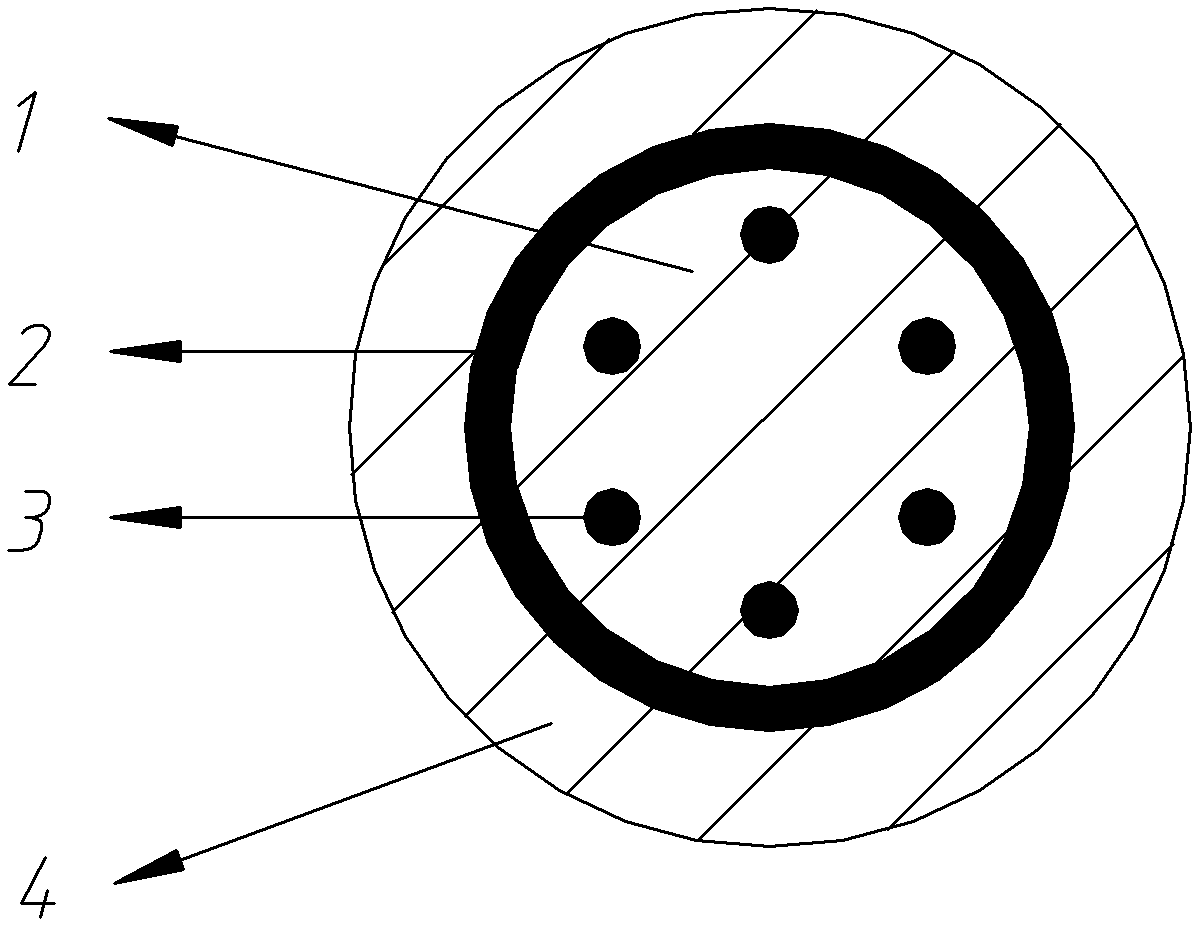

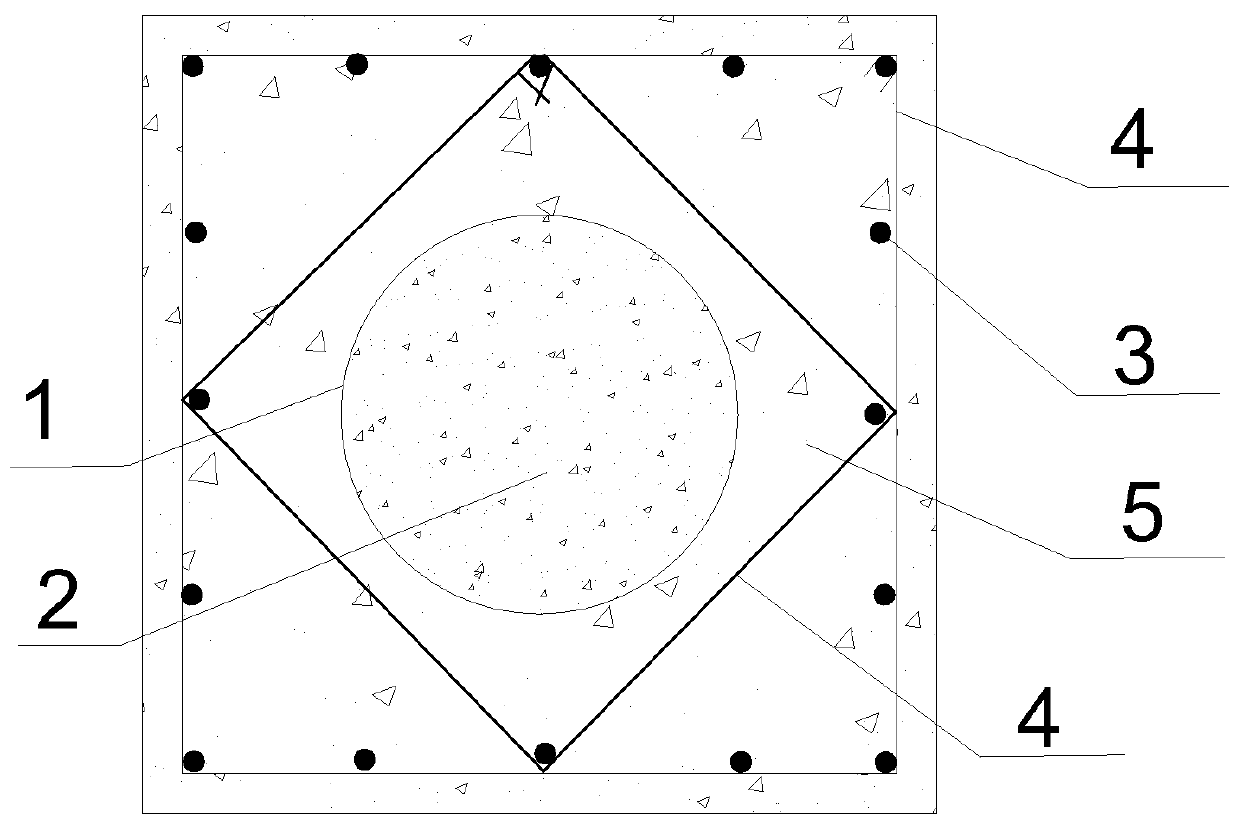

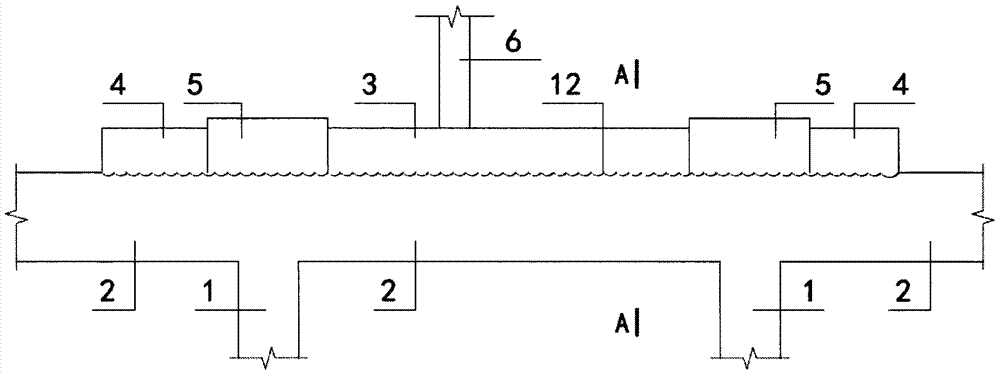

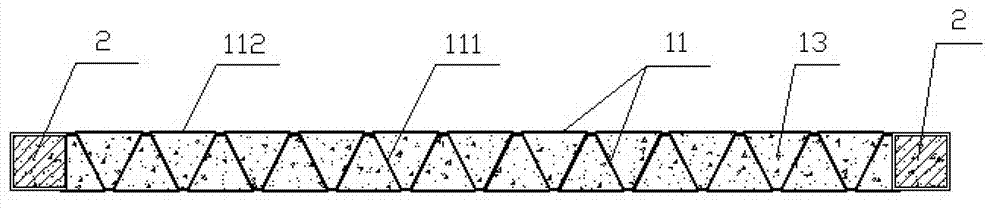

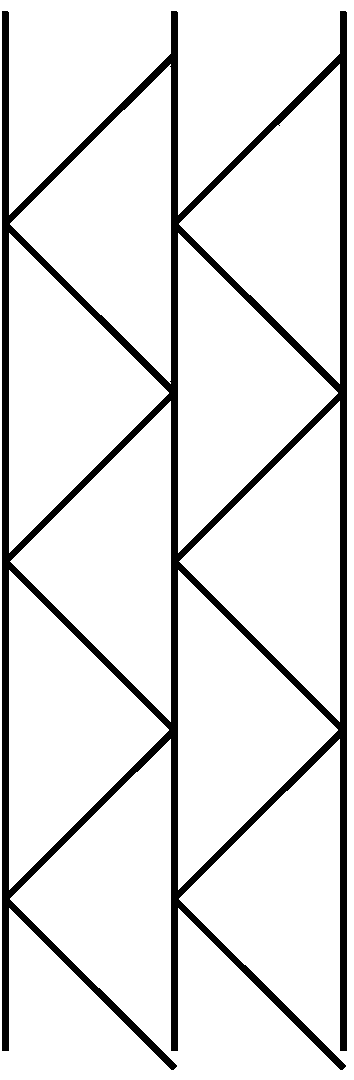

Lattice type single-row reinforcement crisscross-section concrete column and manufacture method thereof

InactiveCN102433963AReduce dosageImprove shear resistanceStrutsBuilding material handlingResistBrick

The invention provides a lattice type single-row reinforcement crisscross-section concrete column and a manufacture method of the lattice type single-row reinforcement crisscross-section concrete column, belonging to the technical field of quake resistance and disaster mitigation. A crisscross column steel bar framework is crisscross, and four pieces of lattice single-row reinforcement meshes 3 are welded into four crisscross limbs; a plurality of lattice-shaped common reinforcing meshes 2 are vertically welded at the ends of the four limbs of each crisscross lattice single-row reinforcement mesh; and a plurality of steel ties 4 are vertically welded at the center of a transverse horizontal steel bar of each common reinforcing mesh 2 and are distributed along the direction of the column height at an equal distance. The lattice type single-row reinforcement crisscross-section concrete column adopts single-row reinforcement, thereby being simple to construct and small in the use level of the steel bar; the reinforcement is formed by welding the lattice steel bar pieces, so that the invention is suitable for the industrial production; after the lattice reinforcement is adopted, the slantwise web bar is good in shearing resistance, the abnormal-cross section short column can not be broken by the brittle shearing, and the vibration-resistant ductility of the column can be improved; and the end of the cross section of the column is tightly combined with an ecological wall board or an ecological wall brick by a short bar, and the aims of enhancing the integrity of a house and improving the whole vibration-resist and energy-dissipating capability can be achieved, so that the invention is applicable to rural buildings.

Owner:BEIJING UNIV OF TECH

Latticed single-row reinforced special-shaped sectional concrete column-wallboard shock absorption house and making method

InactiveCN102561509AImproves seismic ductilityReduce dosageStrutsBuilding reinforcementsBrickReinforced concrete

The invention discloses a latticed single-row reinforced special-shaped sectional concrete column-wallboard shock absorption house and a making method, and belongs to the technical field of earthquake prevention and disaster reduction. The house mainly comprises a plain concrete cushion layer, foundation beams, latticed single-row reinforced special-shaped sectional concrete columns, lightweight ecological wallboards or wall bricks, reinforced concrete framework beams, and a reinforced concrete floor (roof). The latticed single-row reinforced special-shaped sectional concrete columns are reinforced in single row, and a steel bar framework is welded by using two reinforcing meshes of different forms, so that the house is simple in construction, low in consumption of steel bars and convenient for industrialized production; latticed oblique web reinforcement shearing resistance is good, crisp shearing damage of the special-shaped sectional short columns is prevented, and the anti-earthquake ductility is improved; and walls are made of the lightweight ecological wallboards or wall bricks, the wallboards or the wall bricks are connected with the special-shaped columns through steel ties, and the wallboards or the wall bricks are mutually engaged by means of key grooves and mutually connected reliably, so that the aims of reinforcing the integrity of the house and promoting the integral anti-earthquake and energy dissipation capacity are fulfilled, and the house is suitable to be used as a rural house.

Owner:BEIJING UNIV OF TECH

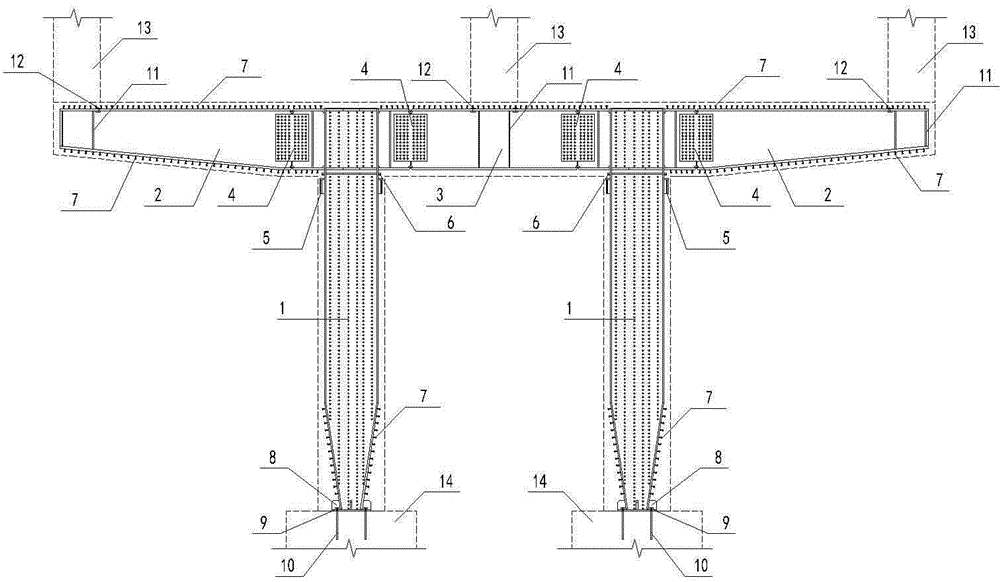

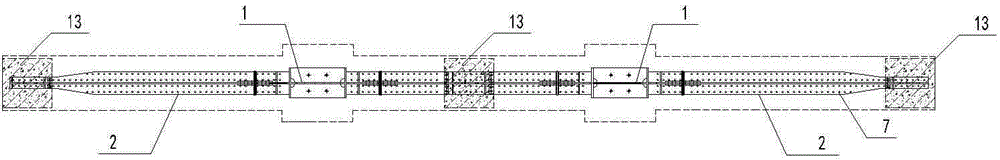

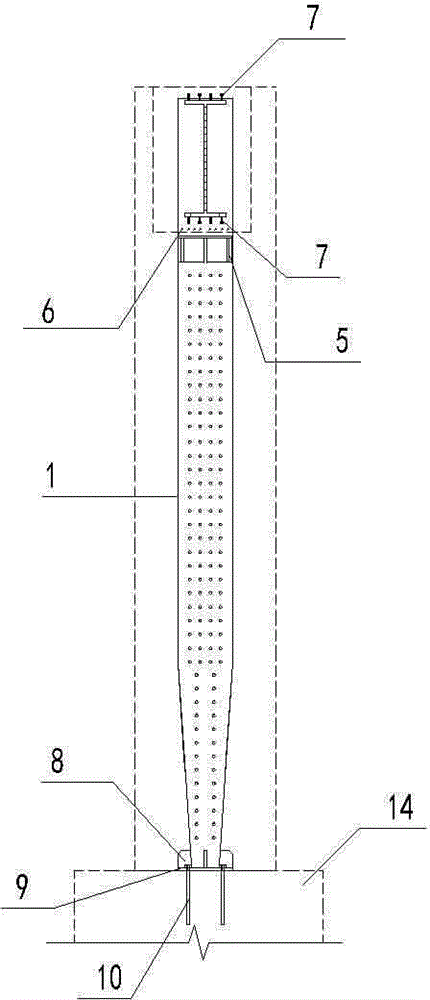

Post-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and construction method thereof

InactiveCN102635063AEffective Small Bias DestructionReduce section sizeBridge structural detailsBridge erection/assemblyHigh strength concreteCarrying capacity

The invention relates to a post-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and a construction method of the bridge pier. The bridge pier comprises steel pipes, wherein the steel pipes are provided with multiple unbonded tendons, pipe-in concrete is poured among the inner walls of the steel pipes and the unbonded tendons, and the steel pipes, the unbonded tendons and the pipe-in concrete form a core column; pipe-outside concrete is poured at the exterior of the core column so as to form the superposition bridge pier, the conventional reinforced concrete bridge pier is internally provided with a plurality of high-strength preforming steel pipe concrete core columns with vertical prestressing tendons; and the interior prestressing steel pipe high-strength concrete core column are installed and constructed, then a reinforced concrete framework arranged outside the bridge pier is banded and the exterior concrete is poured, namely the vertical prestressing steel pipe high-strength concrete superposition bridge pier poured by interior and exterior concrete of the steel pipe in different stages is formed, wherein the interior prestressing core column is manufactured by adopting a post-tensioning method. According to the bridge pier and the construction method, effectively improve the aseismic safety and the validity of the conventional bridge pier structure, and the bridge pier has the characteristics of high carrying capacity, good seismic performance, convenience in construction and self reset.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

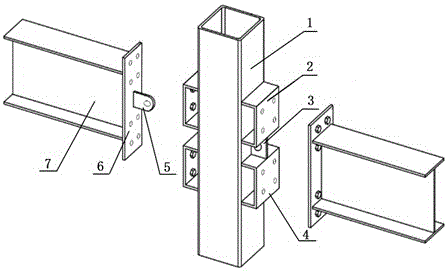

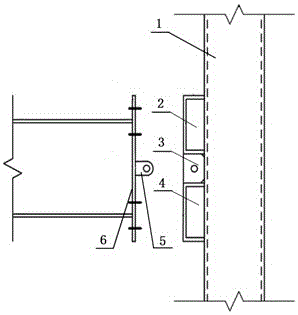

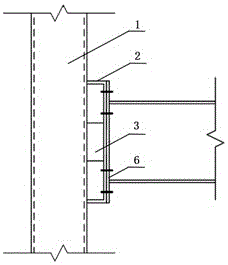

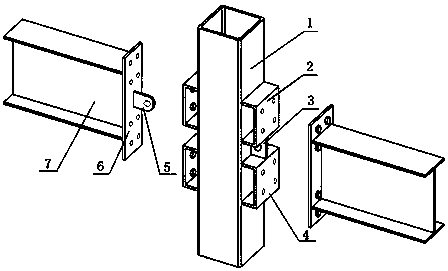

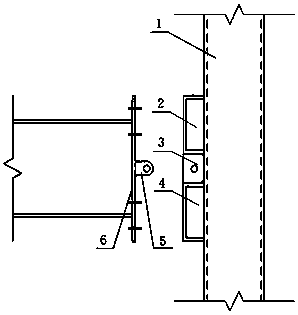

Novel steel pipe column and shaped steel beam assembling method

InactiveCN105839788ANo brittle failureSolve the inconvenience of assemblyBuilding constructionsSteel frameEngineering

The invention discloses a novel steel pipe column and shaped steel beam assembling method. Top flange U-shaped steel or channel steel provided with multiple bolt holes is vertically welded to the two sides faces of a steel pipe column with the section closed and is symmetrical about the axis, lower flange U-shaped steel or channel steel provided with multiple bolt holes is correspondingly welded to the lower portion of the steel pipe column, and a shear web provided with bolt holes is welded to the gap between the top flange U-shaped steel or channel steel and the lower flange U-shaped steel or channel steel; an open type steel beam has an open section, a beam end plate is welded to the end of one side of the open type steel beam, a beam end lug plate is welded to the middle of the beam end plate, bolt holes in the beam end plate correspond to those in the top flange U-shaped steel or channel steel and the lower flange channel steel, and the beam end lug plate corresponds to the bolt holes in the shear web. The method is suitable for assembly and connection between the steel pipe column with the closed section and the steel beam with the open section, the anti-seismic property and ductility of a joint can be improved, the bearing capacity of the joint can be improved, brittle failure of the steel pipe column under static force or earthquake action is avoided, and then high earthquake-resistant ductility of a steel frame structure is guaranteed.

Owner:CHINA UNIV OF MINING & TECH

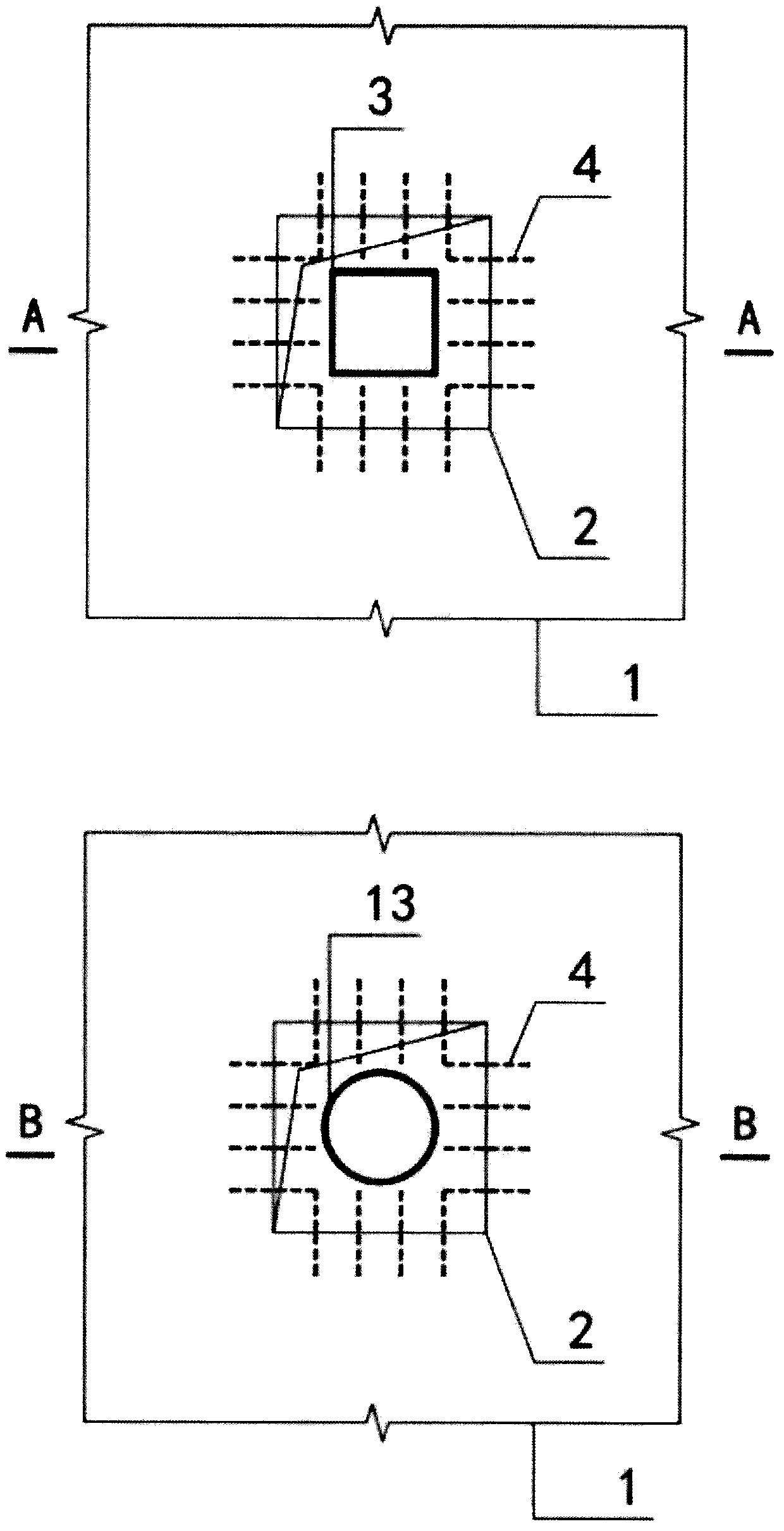

Encased concrete composite shear wall embedded with dense steel plate beams between concrete-filled steel tube columns and construction method thereof

InactiveCN102704597AReduce crackingReduces crack developmentWallsBuilding material handlingSteel barHigh rise

An encased concrete composite shear wall embedded with dense steel plate beams between concrete-filled steel tube columns and a construction method thereof belong to the field of steel-concrete composite shear walls. The encased concrete composite shear wall is composed of concrete-filled steel tube frame columns, concrete-filled steel tube core columns, dense steel plate beams and a reinforced concrete shear wall with an I-shaped wall section. The encased concrete composite shear wall embedded with dense steel plate beams between concrete-filled steel tube columns is formed by the following steps that the concrete-filled steel tube frame columns are arranged at both ends of the reinforced concrete shear wall; the concrete-filled steel tube core columns are arranged between the concrete-filled steel tube frame columns; the level parallel dense steel plate beams are arranged between the concrete-filled steel tube frame columns and the concrete-filled steel tube core columns and between the concrete-filled steel tube core columns along the height direction of the reinforced concrete shear wall; the dense steel plate beams pass through the concrete-filled steel tube columns to be welded with steel tubes on intersection lines; shear wall reinforcing steel bars are bound; and concrete is poured. The encased concrete composite shear wall has the advantages that the bearing capability is enhanced, the ductility and the energy dissipation of the shear wall are enhanced due to multi-defenses, and the earthquake resistant capability is excellent. The encased concrete composite shear wall also has the advantages of convenience in construction and easiness in operation, and can be used in high-rise or large complex multi-storey buildings.

Owner:BEIJING UNIV OF TECH

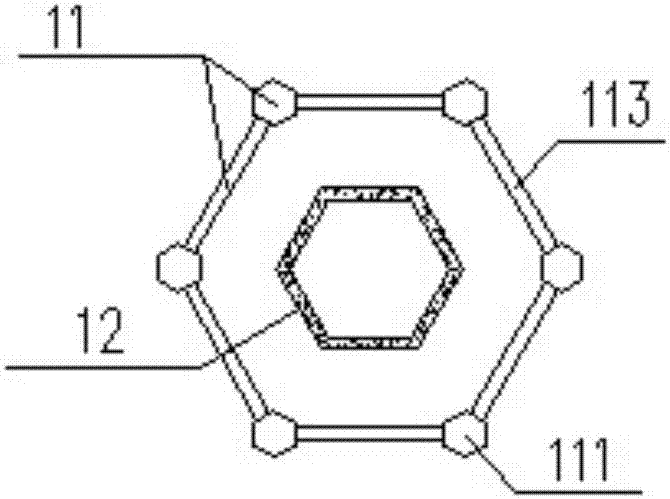

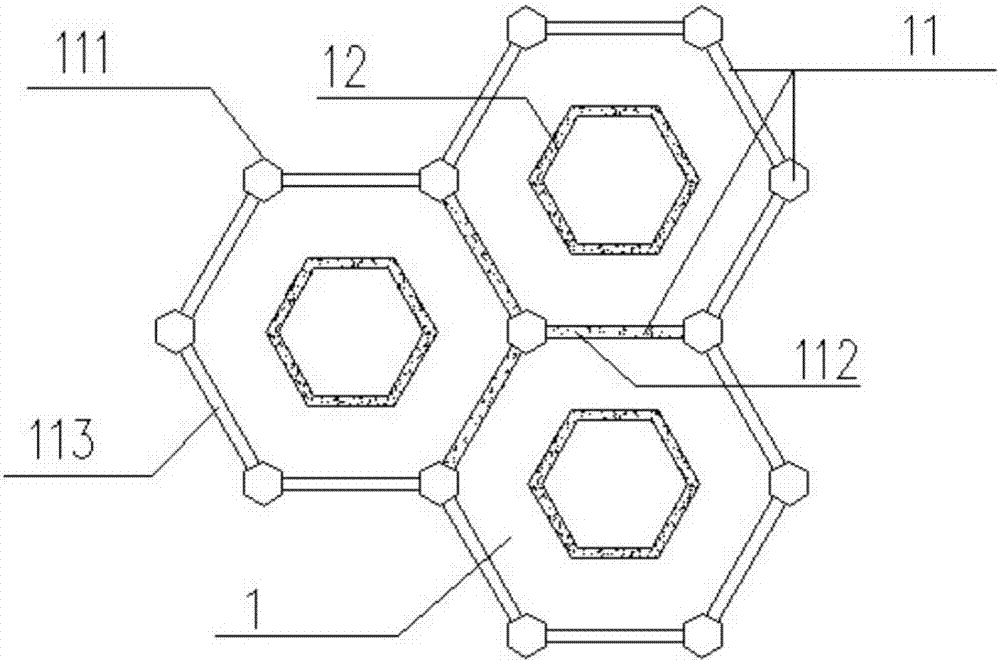

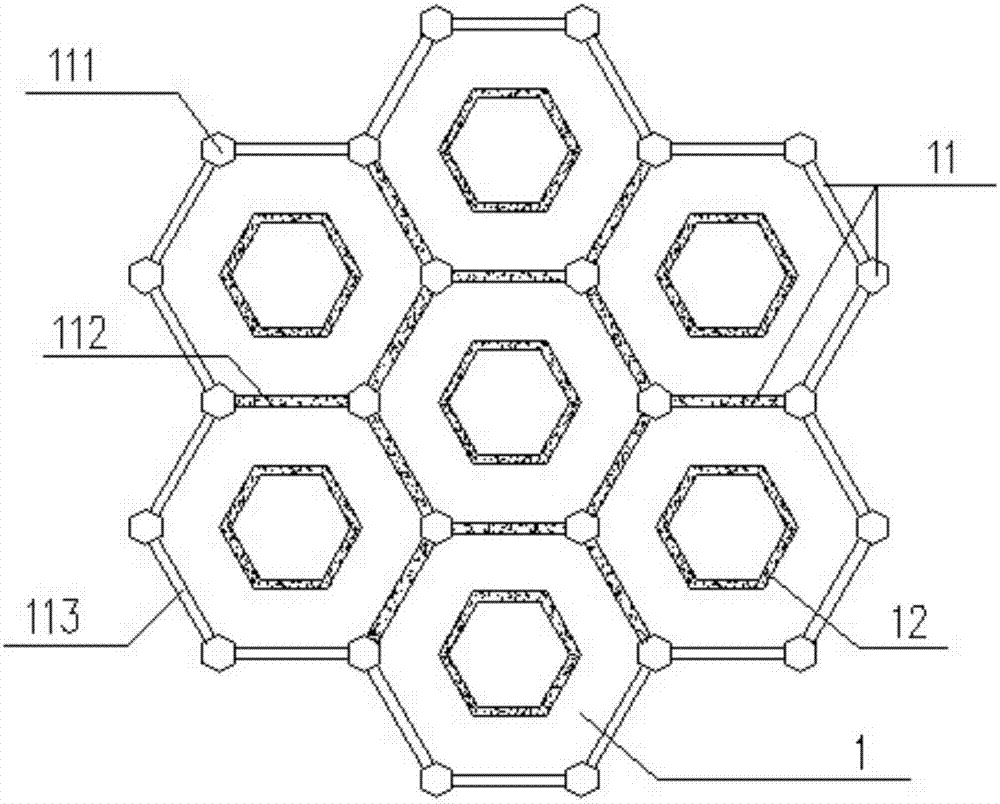

Super high-rise tower structure system of hexagonal barrels arranged in honeycomb-shaped cluster

ActiveCN107060096AReduce in quantityImprove carrying capacityWallsExtraordinary structuresHoneycomb PatternVertical load

The invention provides a super high-rise tower structural system of hexagonal barrels arranged in a honeycomb-shaped cluster. According to a honeycomb structure, a plurality of structural units of giant hexagonal barrels are combined in a cluster mode; and along with the increase of the height of a building, the number of the structural units of the giant hexagonal barrels is gradually reduced, and a novel pagoda-shaped super high-rise structural system is formed. A hexagonal barrel structure composed of giant hexagonal concrete filled steel tubular columns and grilling tubular type double steel plate concrete shear walls is adopted inside the super high-rise tower structural system, and the giant vertical load and the giant horizontal load of the super high-rise building are borne; and a frame tube structure composed of giant hexagonal concrete filled steel tubular columns and giant oblique supporting frames is adopted outside the super high-rise tower structural system, and the requirement for natural lighting of the super high-rise building can be met. The super high-rise tower structural system of the hexagonal barrels arranged in the honeycomb-shaped cluster has the advantages of large structural rigidity, rich facade shape, simplicity, stability, good wind stability performance, good anti-seismic capability, convenient construction and the like, and a super high-rise building structure over one thousand meters can be built.

Owner:SOUTHEAST UNIV

Metro double-column elevated station steel reinforced concrete transformation structure reinforcing bar and construction method thereof

ActiveCN104018521AIncrease stiffnessReduce distortionArtificial islandsBuilding constructionsCantilevered beamEarthquake resistance

The invention relates to a metro double-column elevated station steel reinforced concrete transformation structure reinforcing bar and a construction method thereof. A transformation structure needs to be arranged on a metro elevated station because of the limit of road conditions, and an ordinary steel reinforced concrete transformation structure can not provide good bearing performances and earthquake-resistant performances. The metro double-column elevated station steel reinforced concrete transformation structure reinforcing bar comprises a reinforcing bar column section, a short beam of the reinforcing bar column section, reinforcing bar cantilever beam sections on two sides, and a reinforcing bar middle beam section in the middle, wherein the short beam is fixed together with the reinforcing bar cantilever beam sections and the reinforcing bar middle beam section by virtue of a reinforcing bar splitting plate and a high-strength bolt; a transition section with variable cross sections is respectively arranged at the lower part of the reinforcing bar column section and the end part of each reinforcing bar cantilever beam section; a column reinforcing steel bar connecting plate and a beam reinforcing steel bar connecting sleeve are arranged on a beam-column joint of the reinforcing bar column section; a column supporting joint column rib through hole reinforcement plate and a column supporting joint reinforcing bar beam section stiffening plate are arranged on a beam body at an underpinned column position. The reinforcing bar construction transformation structure disclosed by the invention is high in anti-bending and shear bearing capacity of components and small in deformation, can be used for improving the earthquake-resistance performances, and has wide application values in the metro double-column elevated stations.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

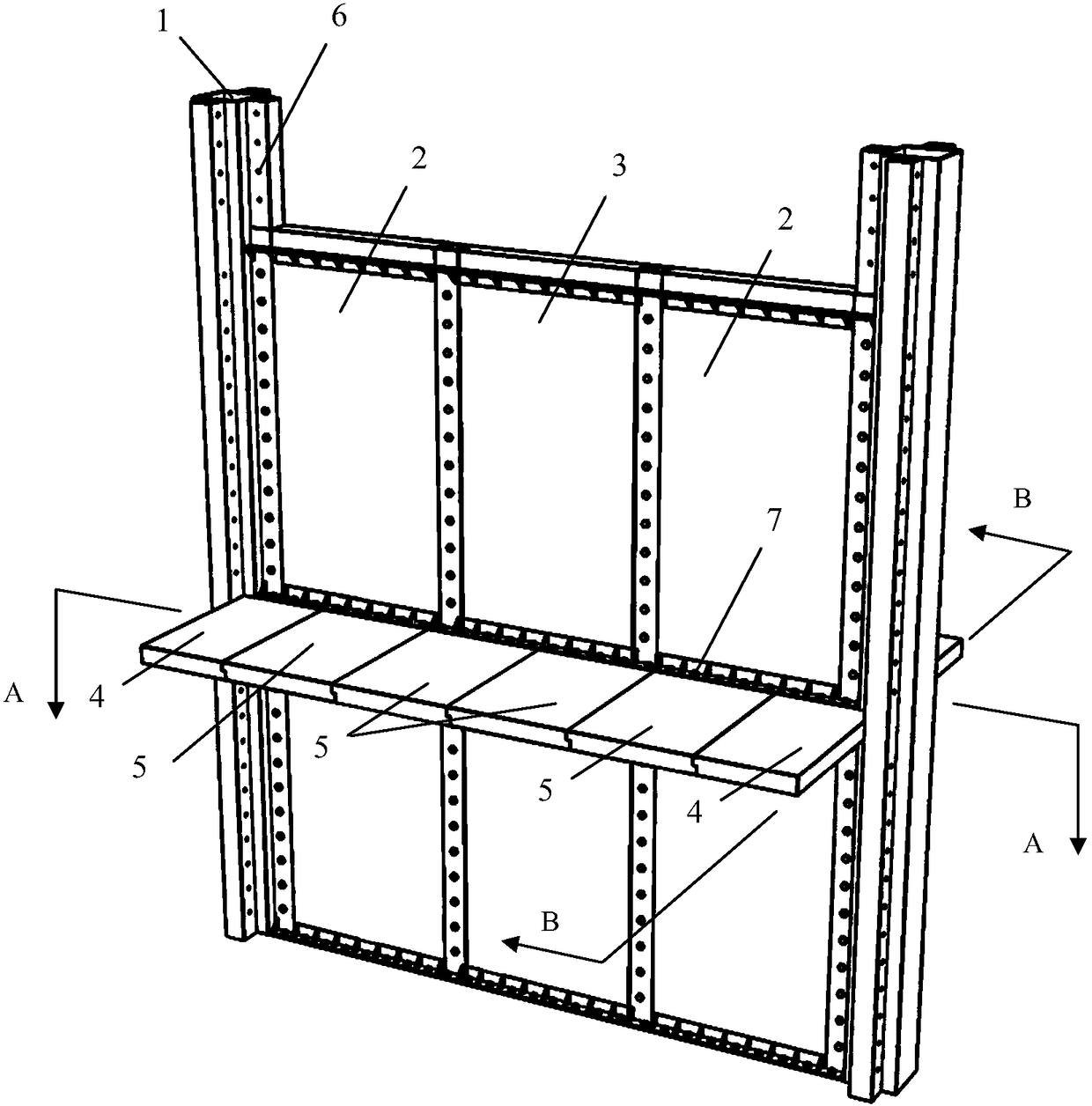

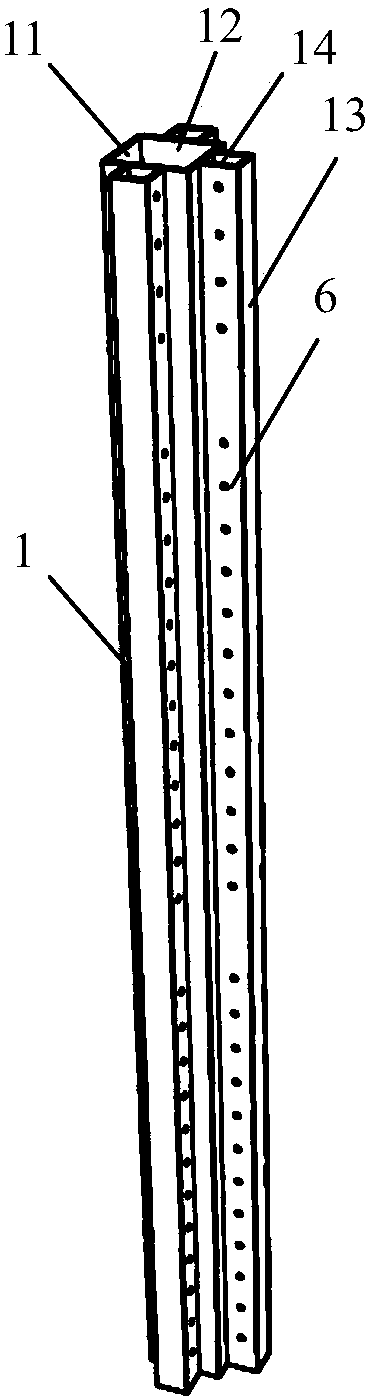

Concrete-filled steel tube row column type connection prefabricated shear wall structure and construction method

PendingCN114319977AAvoid breakingReduce lateral stiffnessProtective buildings/sheltersShock proofingArchitectural engineeringSteel tube

The invention discloses a concrete-filled steel tube row column type connection prefabricated shear wall structure and a construction method, the concrete-filled steel tube row column type connection prefabricated shear wall structure comprises a prefabricated shear wall, row column connection components and laminated slabs which are connected with one another, the multiple groups of row column connection components are arranged in the prefabricated shear wall at intervals, and the laminated slabs are fixed on the prefabricated shear wall in a penetrating and inserting manner; the concrete-filled steel tube row column connecting component is connected with the prefabricated shear wall and the laminated slab, the application range of the concrete-filled steel tube is widened, the structure is very novel, due to the application of the concrete-filled steel tube row columns, the connecting bearing capacity is high, the anti-seismic ductility is good, the problem that concrete of the shear wall structure is prone to being damaged at the bottom is solved, and connection is reliable.

Owner:FUJIAN UNIV OF TECH

Pre-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and construction method thereof

InactiveCN102635064AEffective Small Bias DestructionEffective shear failureBridge structural detailsBridge erection/assemblyHigh strength concreteReinforced concrete

The invention discloses a pre-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and a construction method of the pre-tensioned prestressing steel pipe high-strength concrete superposition bridge pier. The bridge pier comprises steel pipes, wherein the steel pipes are provided with multiple prestressed tendons, high-strength concrete is poured among the inner walls of the steel pipes and the prestressed tendons, and the steel pipes, the prestressed tendons and the high-strength concrete form a core column; normal concrete is poured outside the core column to form the superposition bridge pier, and the interior of a traditional reinforced concrete bridge pier is provided with a plurality of prefabrication steel pipe high-strength concrete core columns with the vertical prestressing tendons; after the installation construction of the prestressing steel pipe high-strength concrete core columns is completed, a reinforced concrete skeleton frame of the bridge pier is bound and exterior concrete is poured, so that the vertically-prestressed steel pipe high-strength concrete superposed column pier with internal and external concrete of the steel pipe poured at different periods is formed, wherein the internal prestressed core column is fabricated by adopting a pre-tensioning way. With the adoption of the pre-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and the construction method, the aseismic safety and effectivity of the existing bridge pier structure are effectively improved, and pre-tensioned prestressing steel pipe high-strength concrete superposition bridge pier has the advantages of high carrying capacity, good earthquake-resisting property, convenience in construction and self reset.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Anti-pulling steel pipe pile structure supplemented on existing structure foundation slab and construction method of anti-pulling steel pipe pile structure

PendingCN108678033ASmall sectionStrong pile penetration abilityBuilding repairsProtective foundationBearing capacityDuctility

The invention belongs to the field of constructional engineering, and particularly relates to an anti-pulling steel pipe pile (including rectangular steel pipe piles and circular steel pipe piles) structure supplemented on an existing structure foundation slab. The anti-pulling steel pipe pile structure supplemented on the existing structure foundation slab comprises the existing structure foundation slab, pile pressing holes are formed in the existing structure foundation slab, the steel pipe piles are pressed in foundation soil under the existing structure foundation slab through the pile pressing holes, and pile driving construction is conducted through the pile pressing holes after pile pressing is completed. By means of the anti-pulling steel pipe pile structure, the characteristic that the existing structure has certain bearing capacity can be sufficiently utilized, the temporary construction safety supporting measure does not need to be taken, the construction cost is reduced, and the construction efficiency is also improved; damage to the existing structure is little, and use of normal functions of existing buildings does not need to be suspended; and the improving effect of the anti-floating bearing capacity of the transformed structure foundation slab is obvious, the requirements for use safety, durability and seismic ductility can be met, and the application range iswide.

Owner:ZHEJIANG GAD

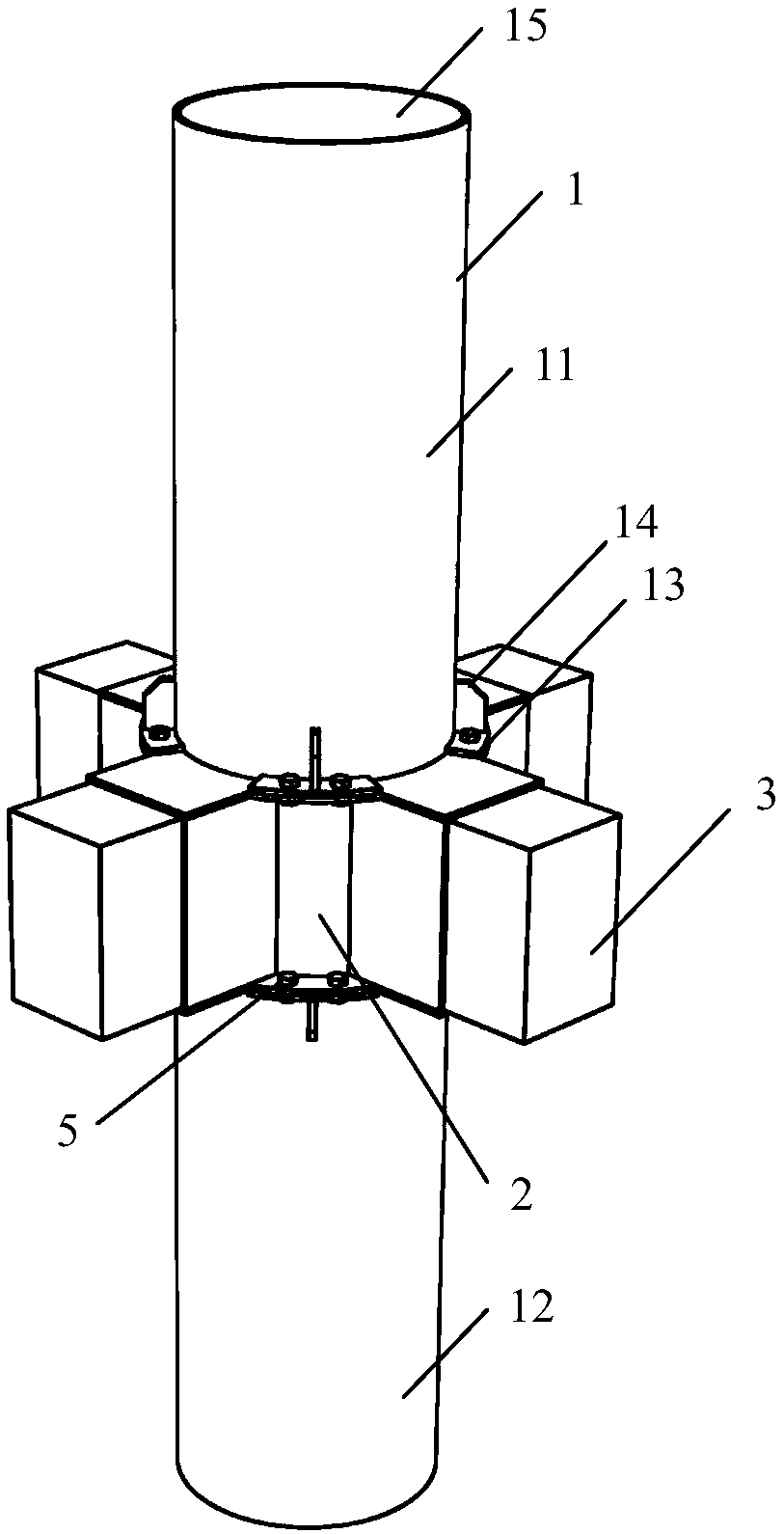

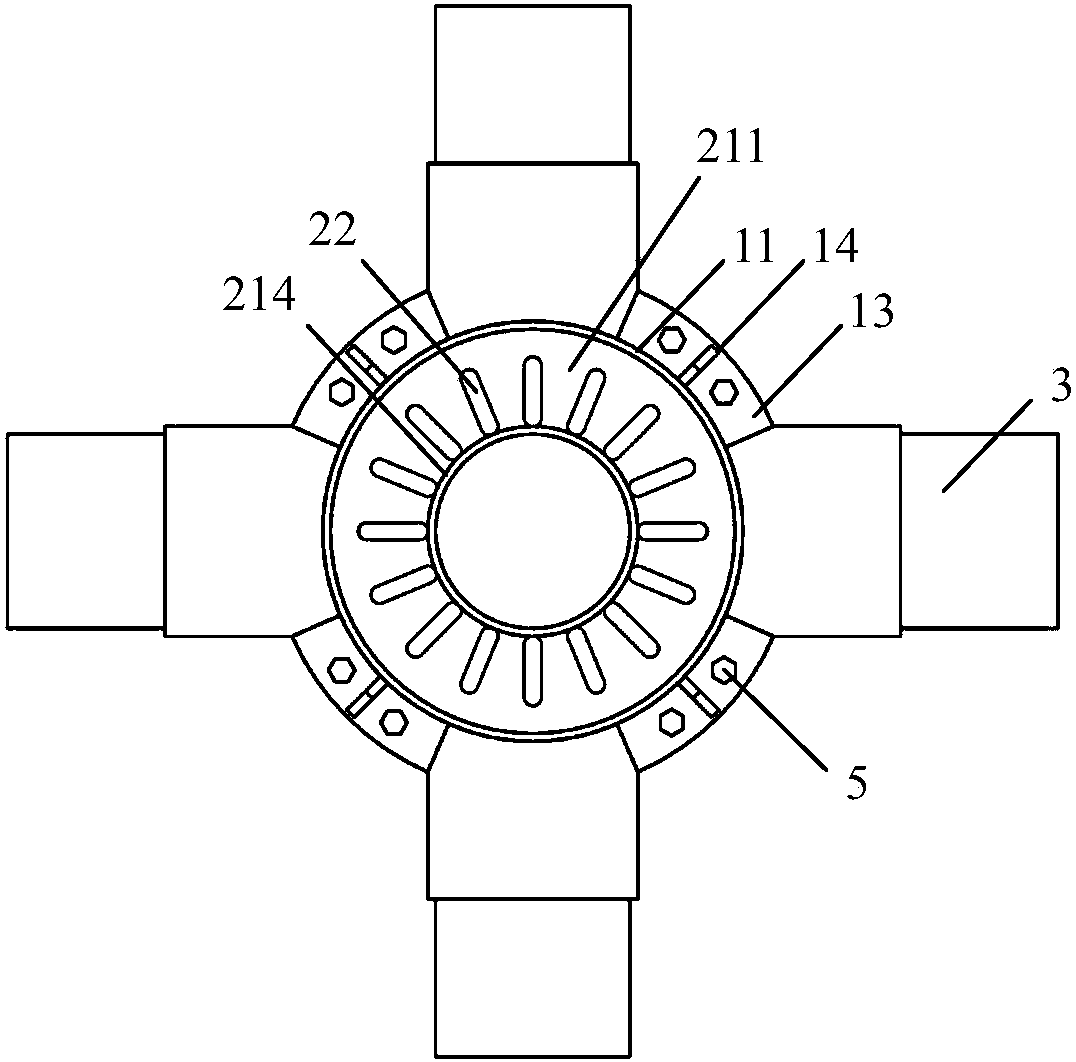

Precast steel tube concrete ring beam structure and construction method

PendingCN108571070AConvenient constructionNovel structureBuilding constructionsSteel platesSteel tube

The invention provides a precast steel tube concrete ring beam structure and a construction method. The structure comprises a steel tube concrete column, a steel tube concrete ring beam and a precastreinforced concrete beam, wherein the steel tube concrete column comprises an upper steel tube column, a lower steel tube column, connecting plates, stiffening ribs and column concrete; the pluralityof connecting plates and stiffening ribs are welded at the lower end of the upper steel tube column and the upper end of the lower steel tube column; the stiffening ribs are vertically arranged on corresponding connecting plates; the column concrete is poured inside the upper steel tube column and the lower steel tube column; the steel tube concrete ring beam comprises ring beam steel tubes, anchor bars and ring beam interior reinforced concrete; the ring beam steel tubes comprise upper steel plates, lower steel plates, side steel plates and inner steel tubes; and the upper steel plates and the lower steel plates are respectively arranged at the upper and lower ends of the side steel plates. The precast steel tube concrete ring beam structure disclosed by the invention is high in bearing capacity, high in stiffness, excellent in seismic ductility, excellent in integrity, convenient and rapid in construction, high in construction quality and capable of realizing shift-away of plastic hinge, and meets the requirements of 'strong column and weak beam, strong joints'.

Owner:FUJIAN UNIV OF TECH

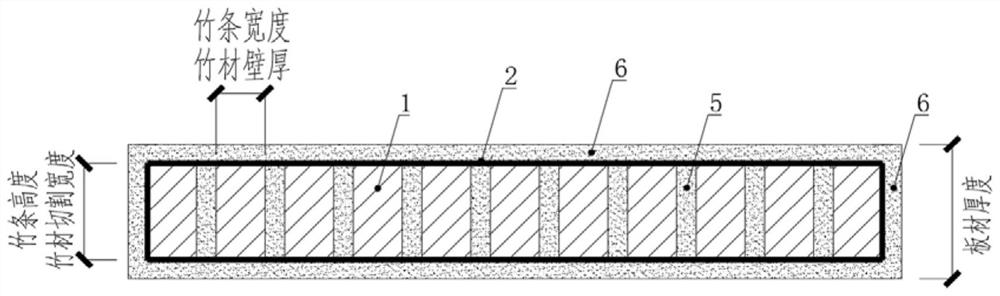

Permanent bamboo-based composite bearing plate and processing technology

The invention relates to a permanent bamboo-based composite bearing plate. The permanent bamboo-based composite bearing plate comprises assembly bamboo canes, fiber gridding cloth and a cementing material, wherein the assembly bamboo canes are formed by longitudinally cutting bamboos, the bamboo canes are vertically placed during assembly, and first gaps are formed between the adjacent bamboo canes at intervals; the fiber gridding cloth is attached to the upper surfaces and the lower surfaces of the assembly bamboo canes and completely wraps the side surfaces and the end surfaces of the assembly bamboo canes from the peripheries; the cementing material is poured into the first gaps, as well as the upper surface and the lower surface of the outer side and the peripheral side surface of thefiber gridding cloth, the cementing material in the first gaps forms thin-wall connecting supporting ribs, and the cementing material on the upper surface and the lower surface of the outer side and the peripheral side surface of the fiber gridding cloth forms a bearing protection bonding layer. The permanent bamboo-based composite bearing plate not only can give consideration to bearing strength,but also can realize the advantages of energy conservation, environmental protection, safety, low consumption, high temperature resistance, low temperature resistance, wear resistance, corrosion resistance, seepage resistance and high fire resistance.

Owner:西藏涛扬集团有限公司

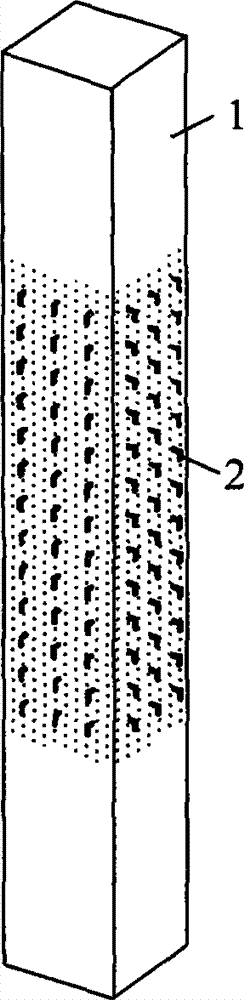

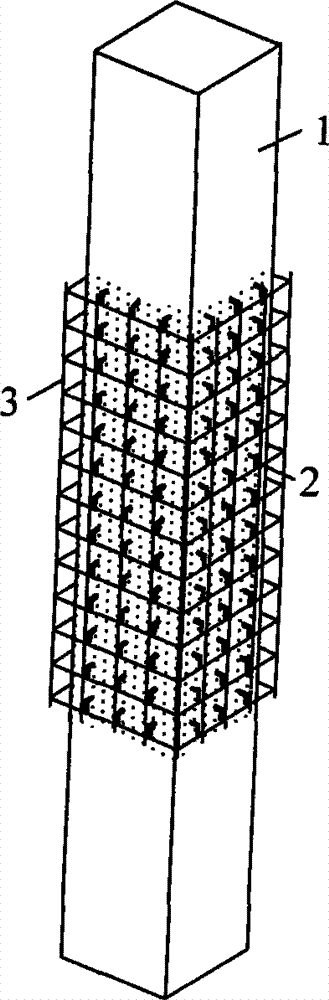

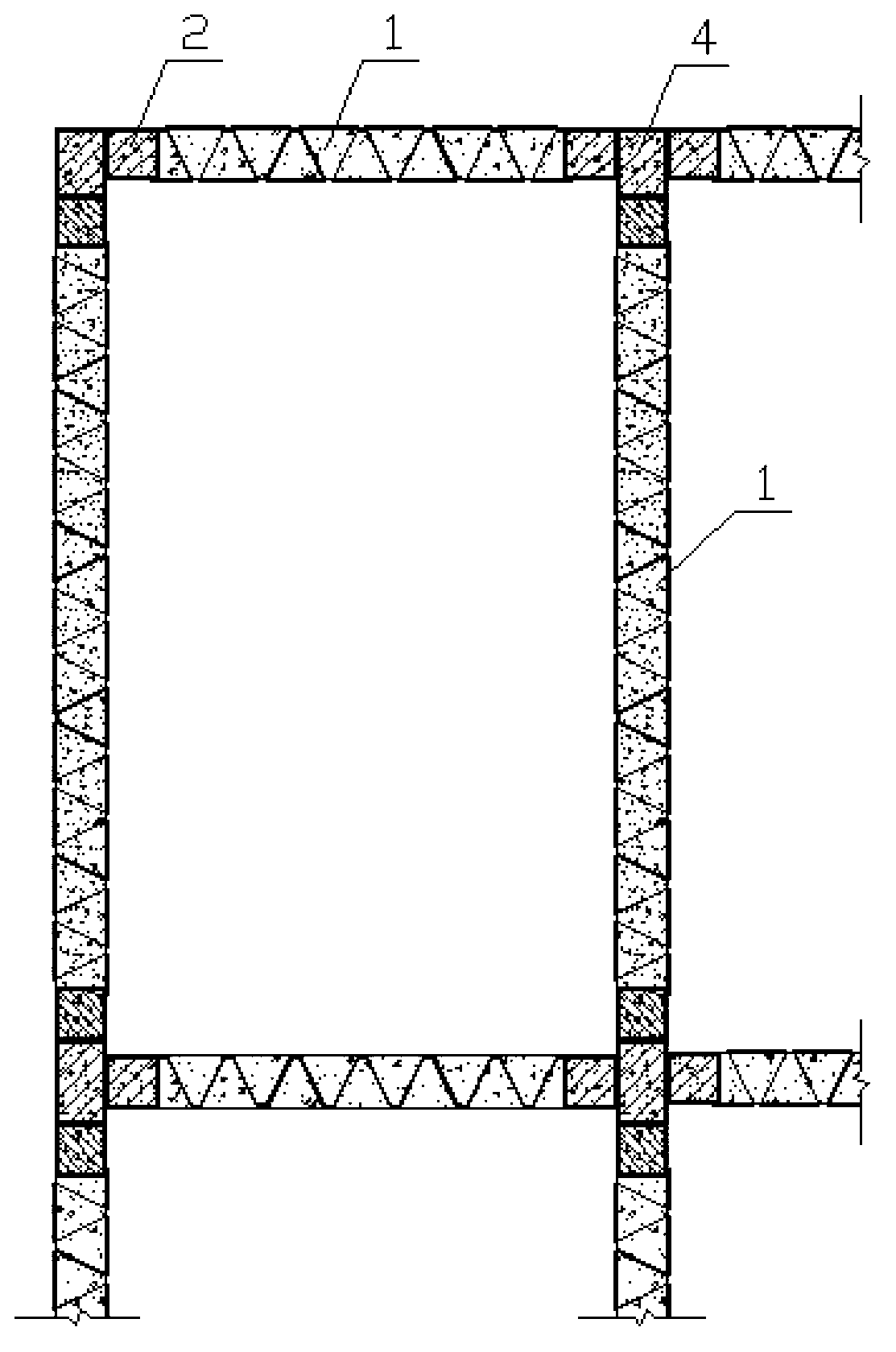

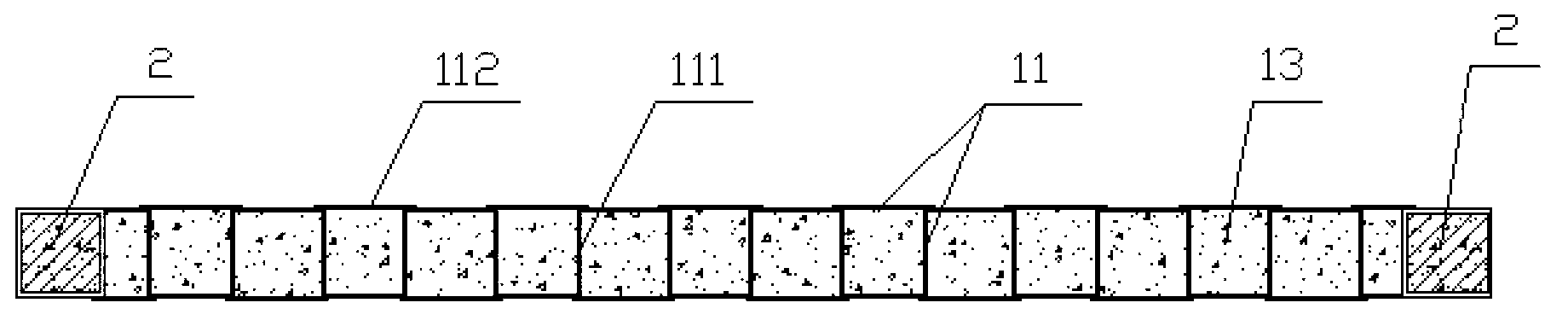

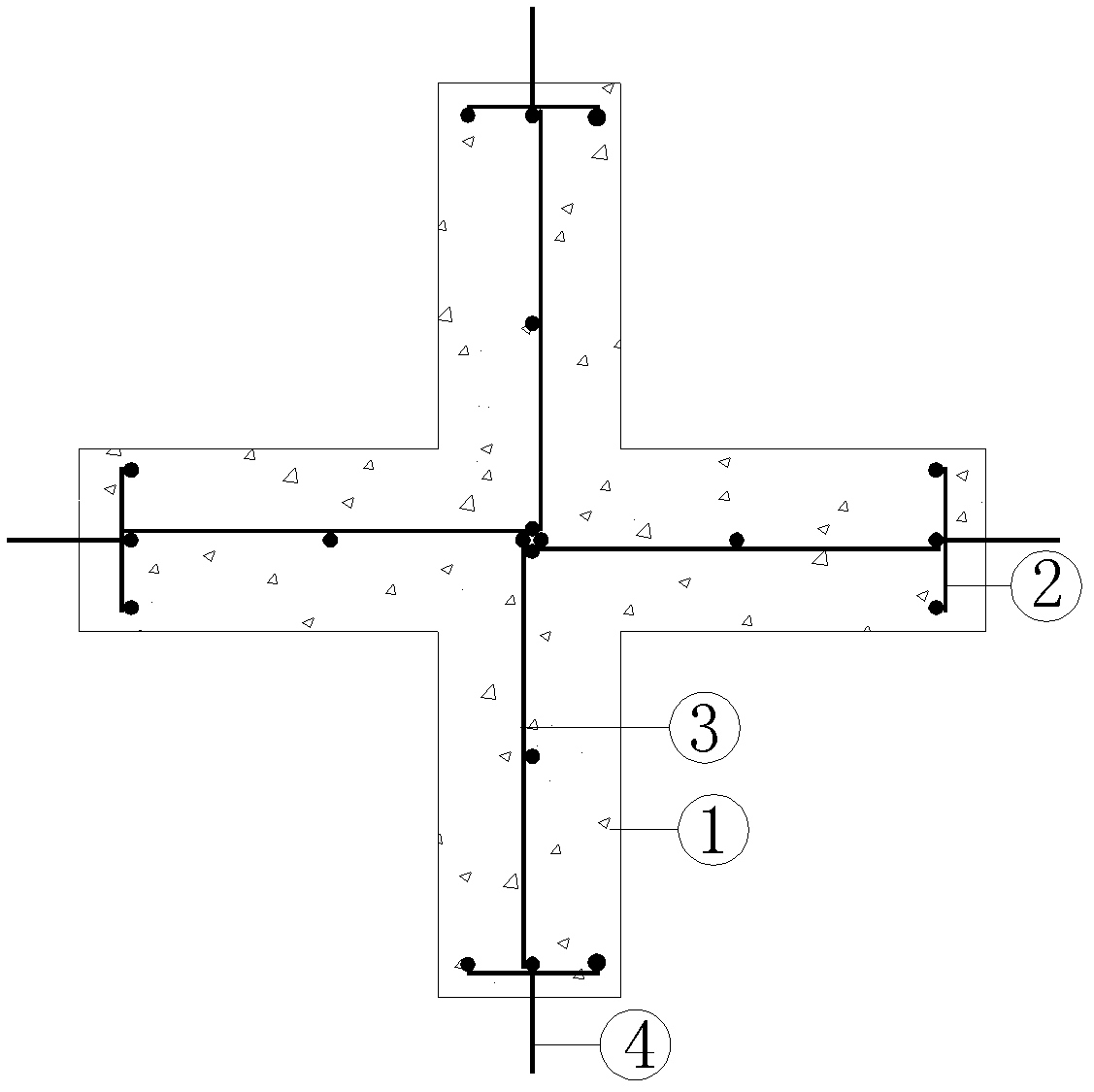

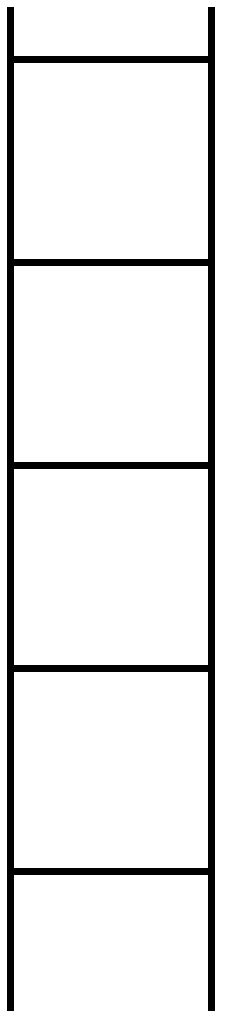

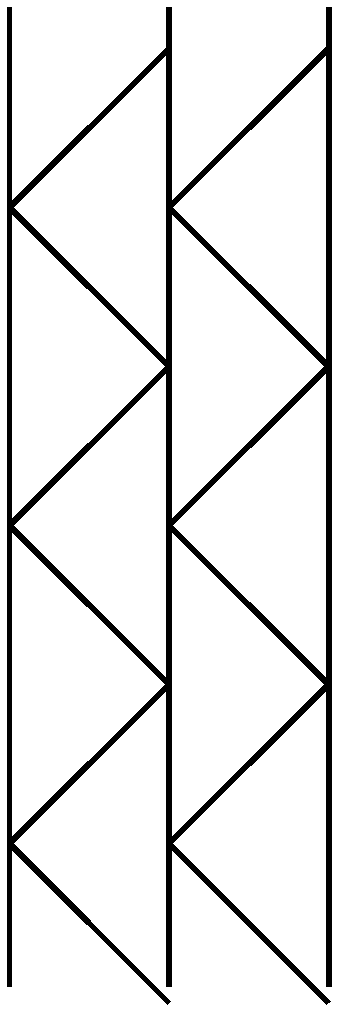

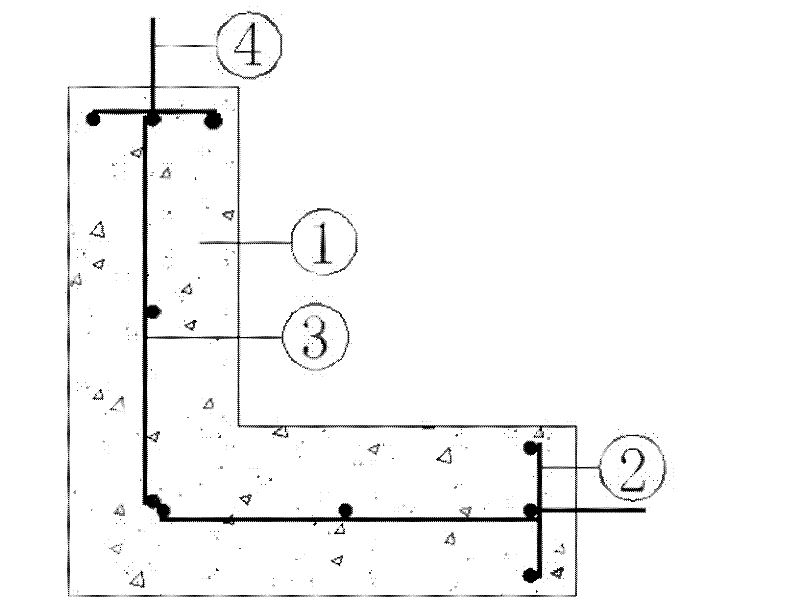

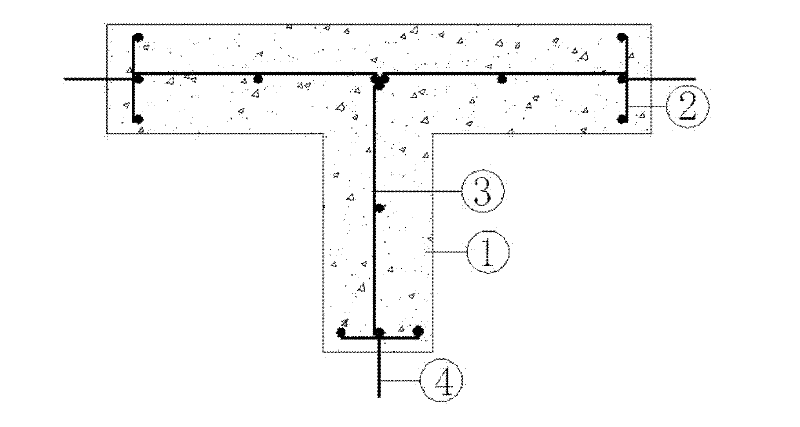

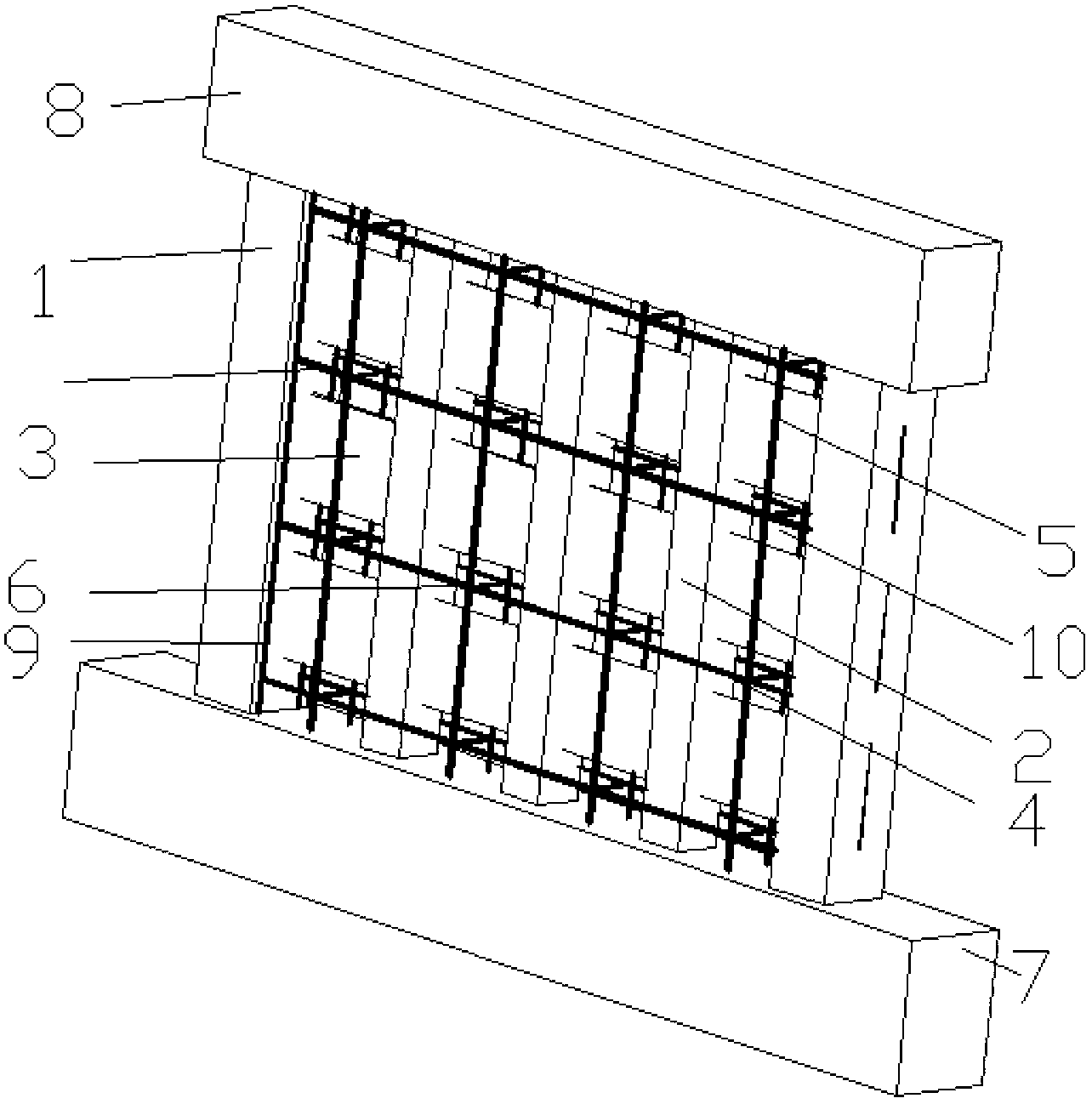

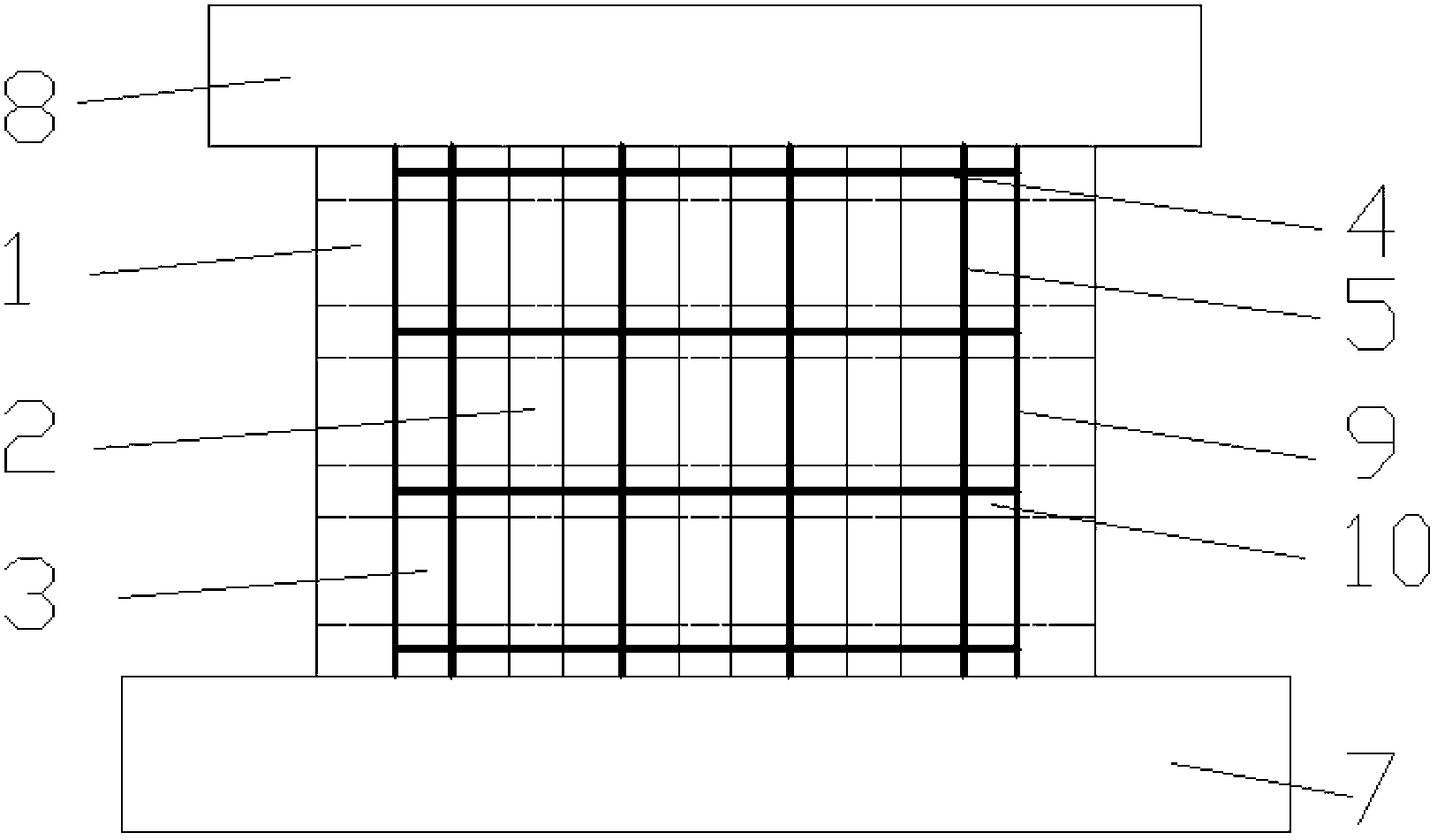

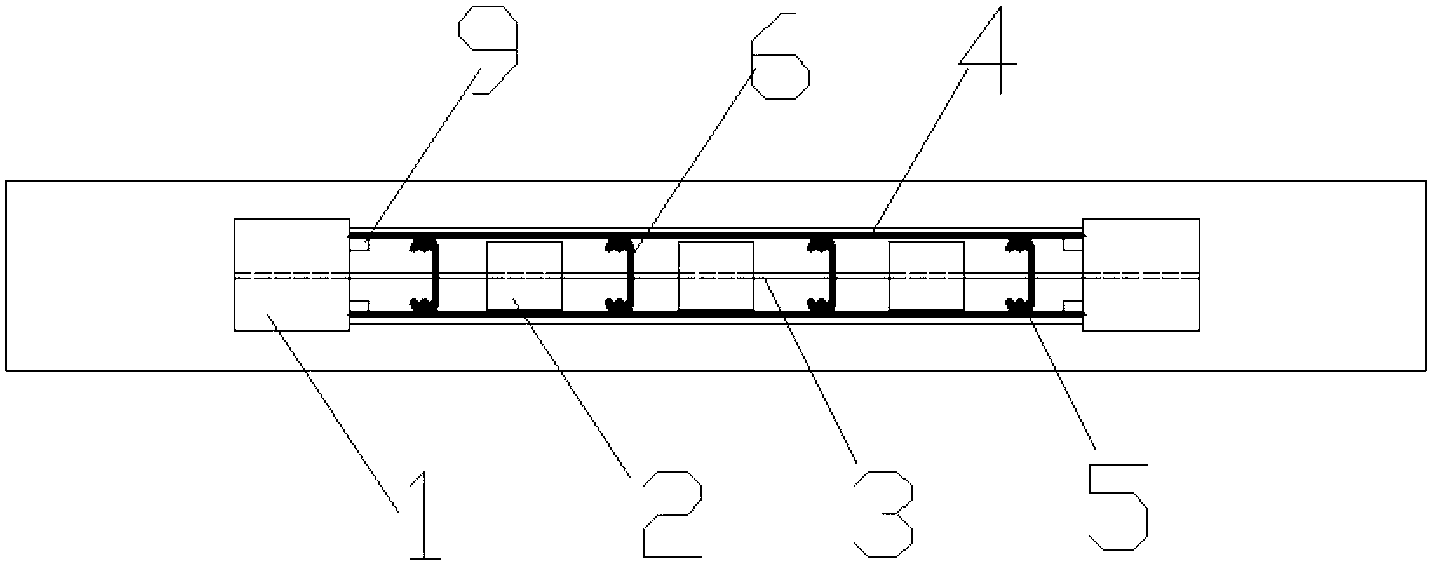

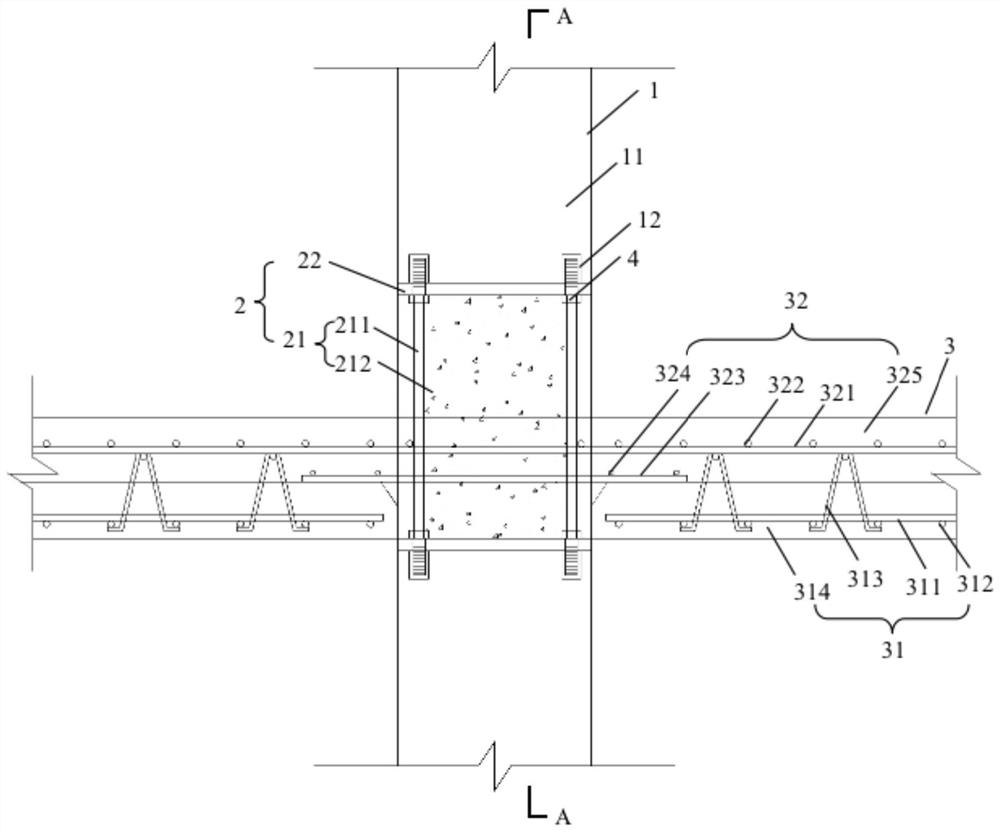

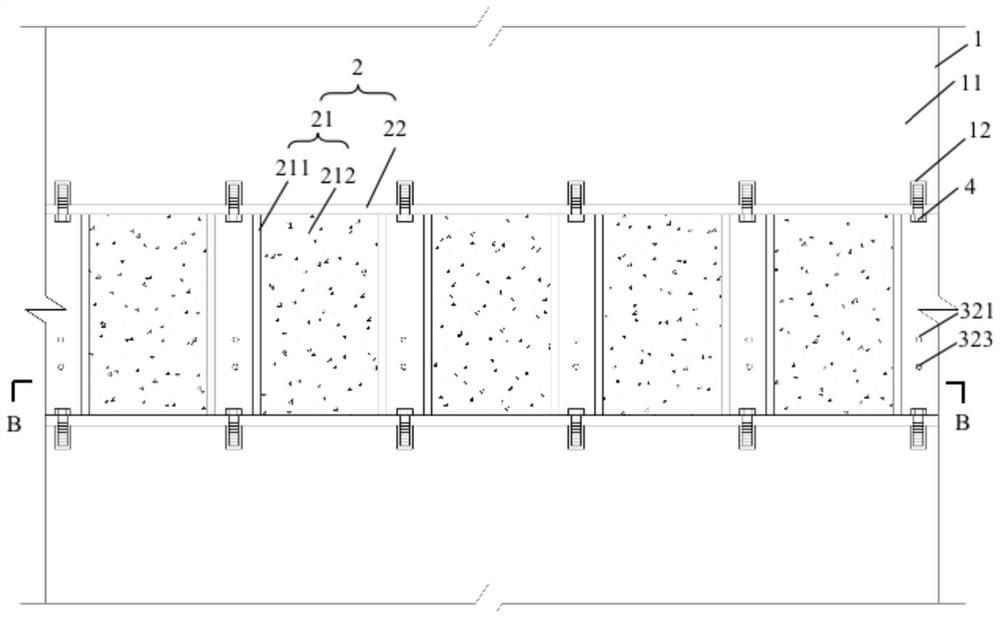

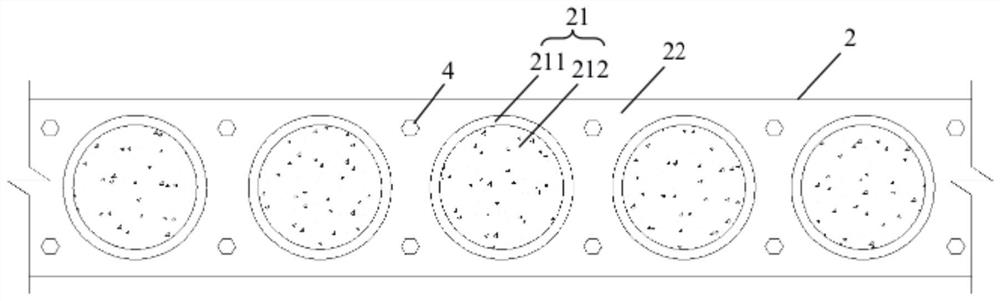

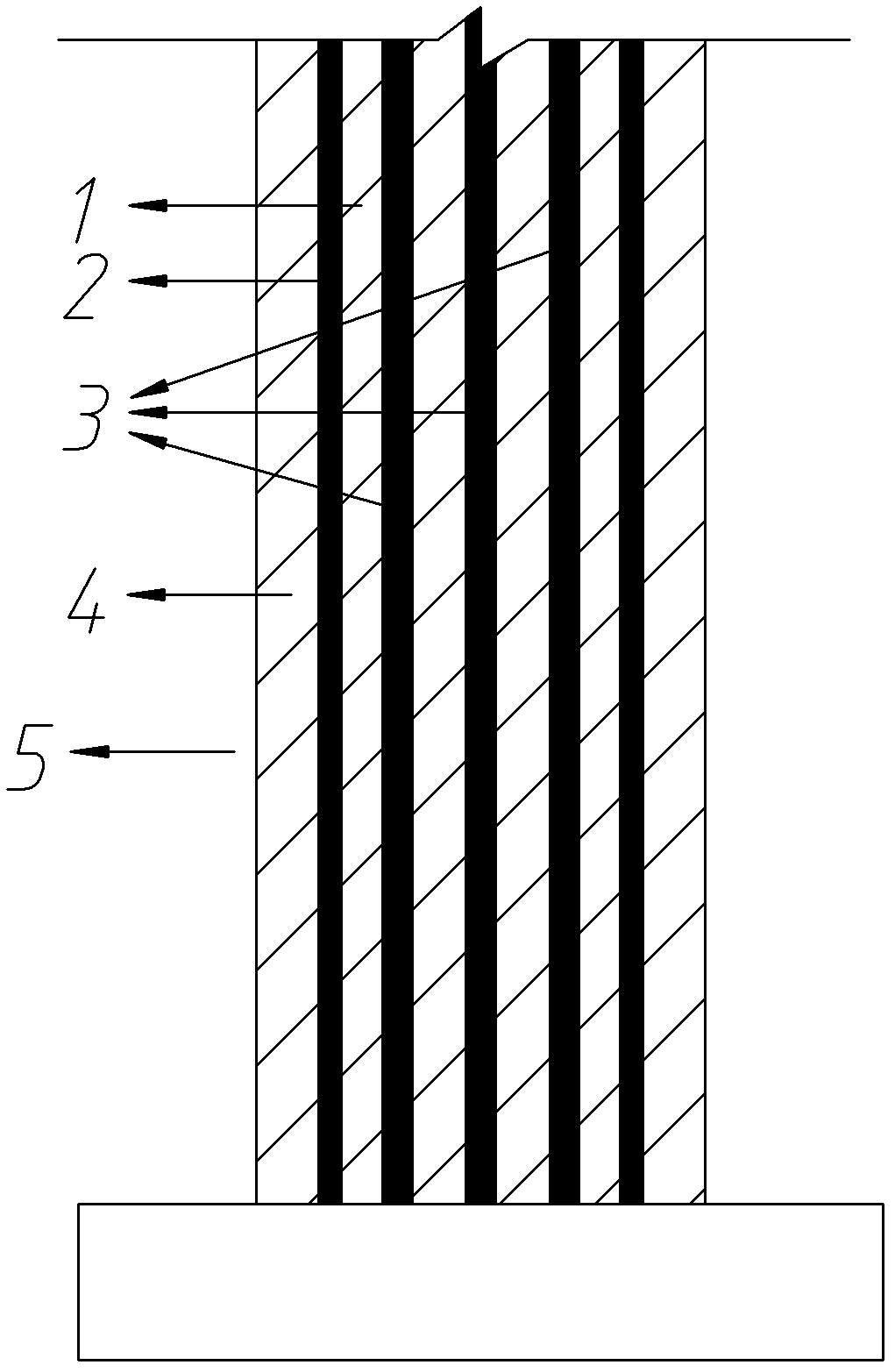

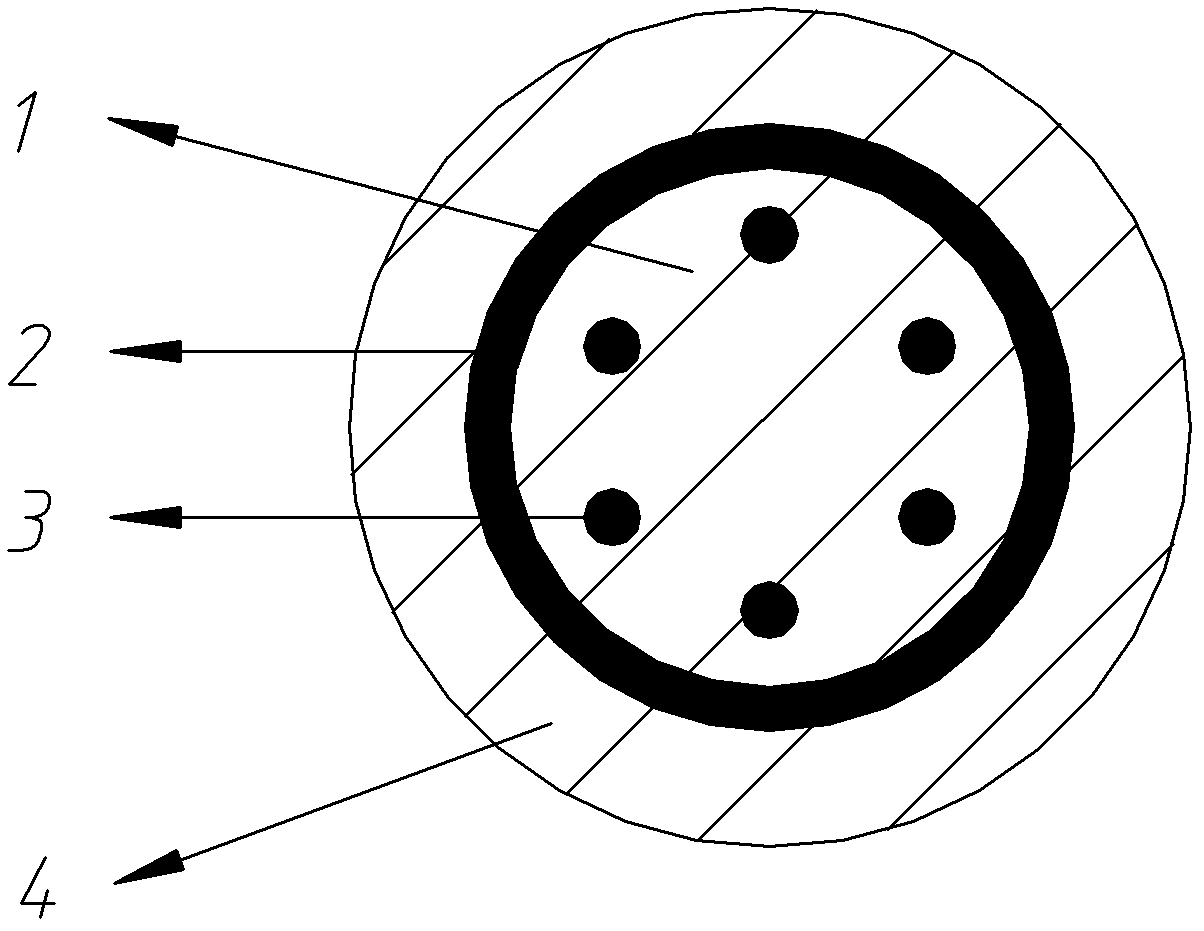

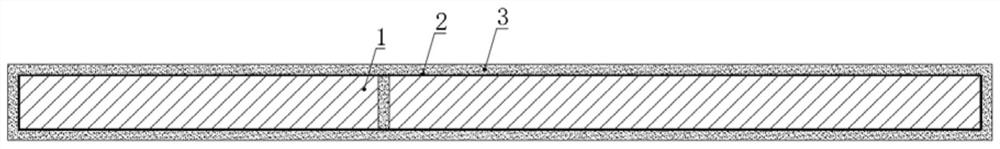

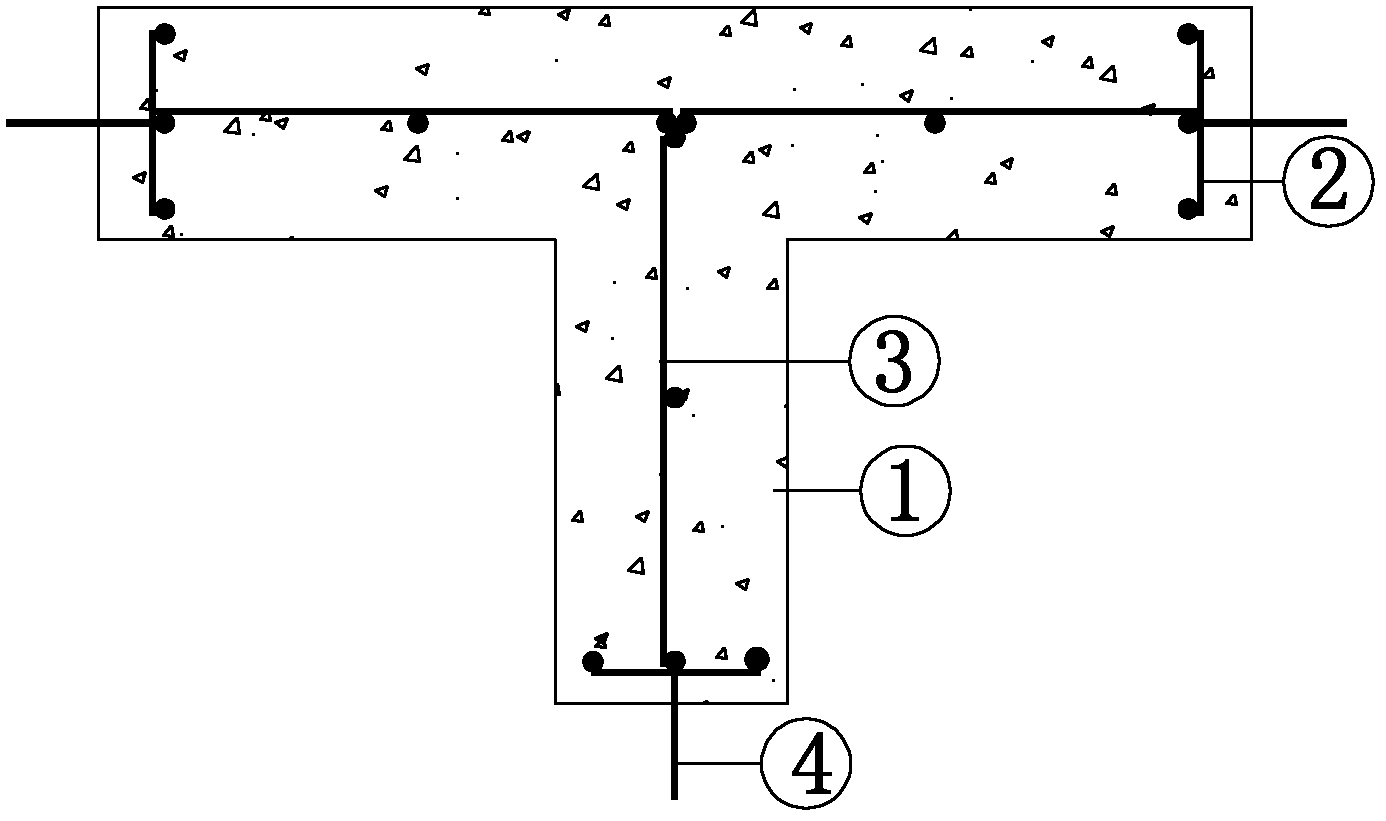

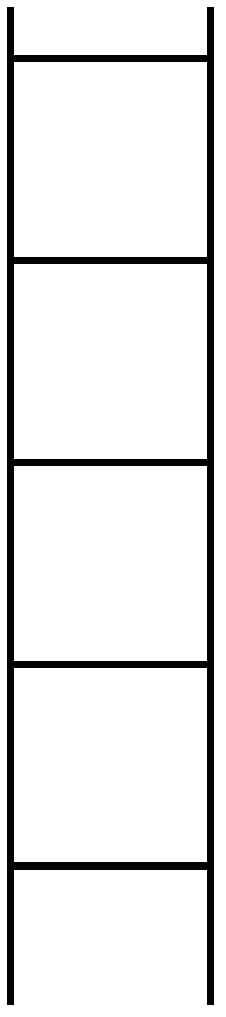

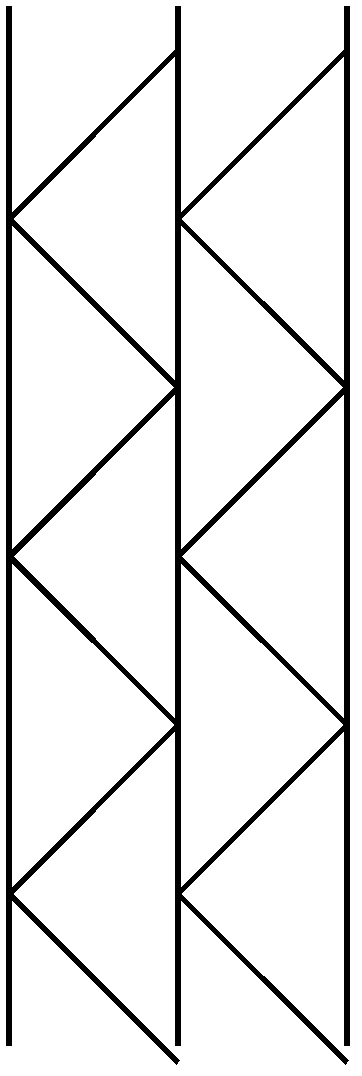

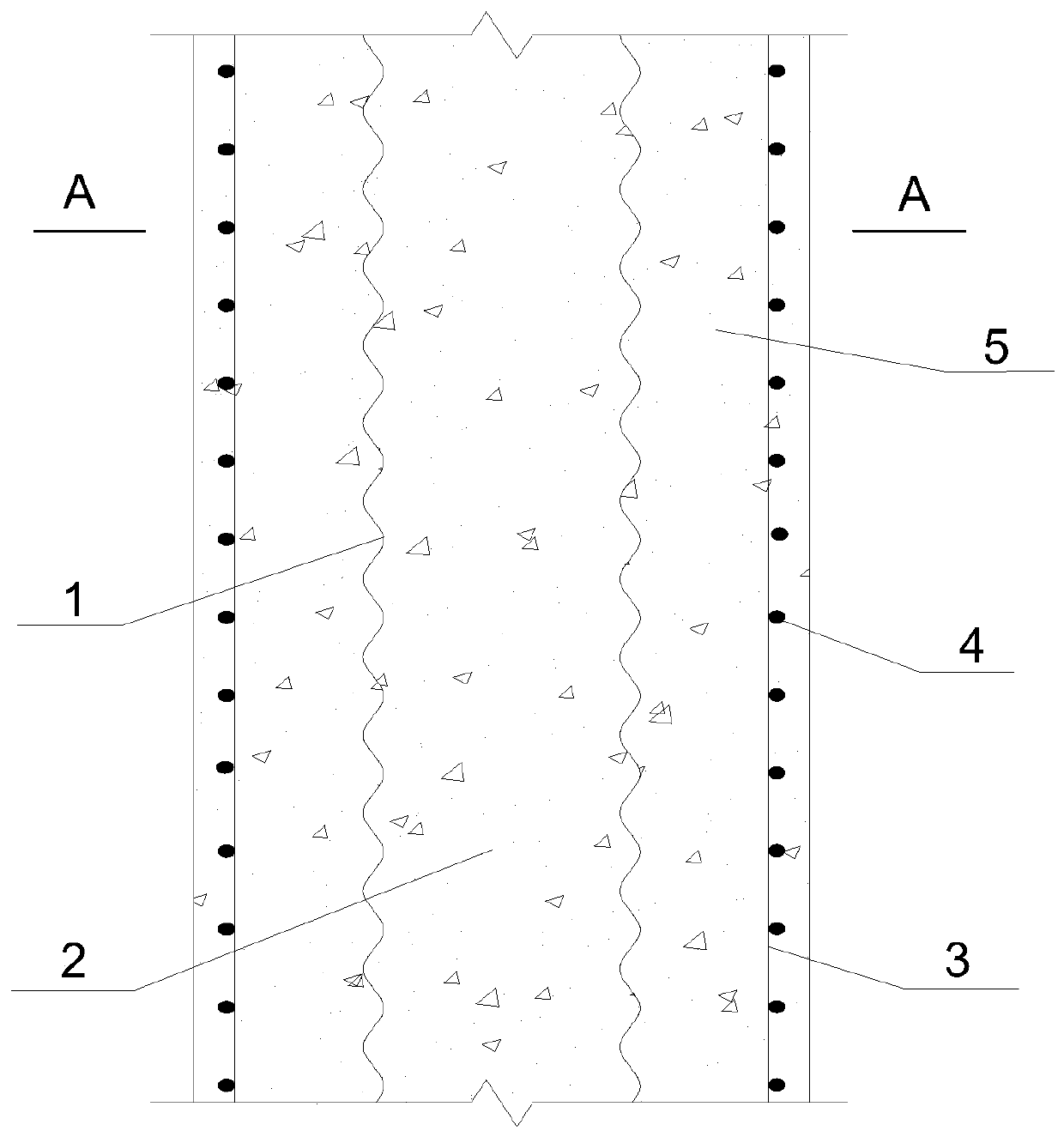

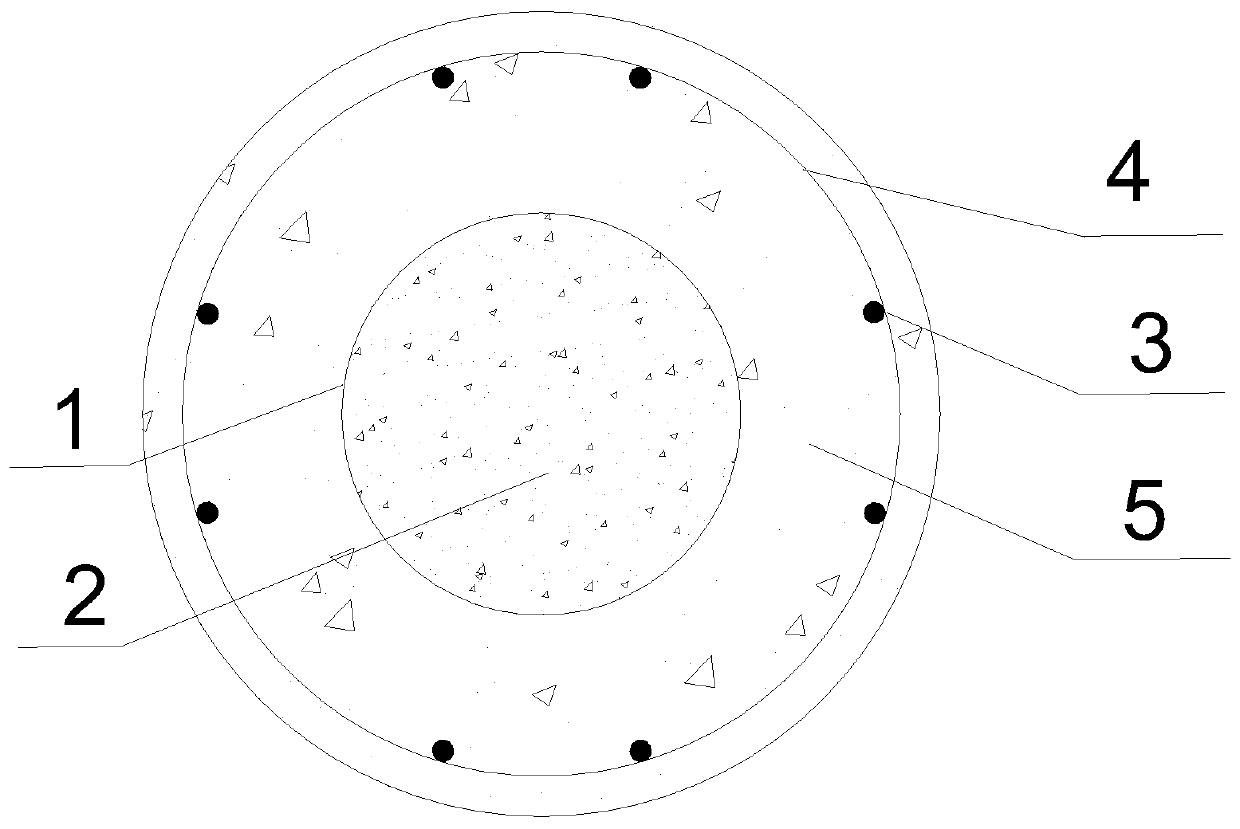

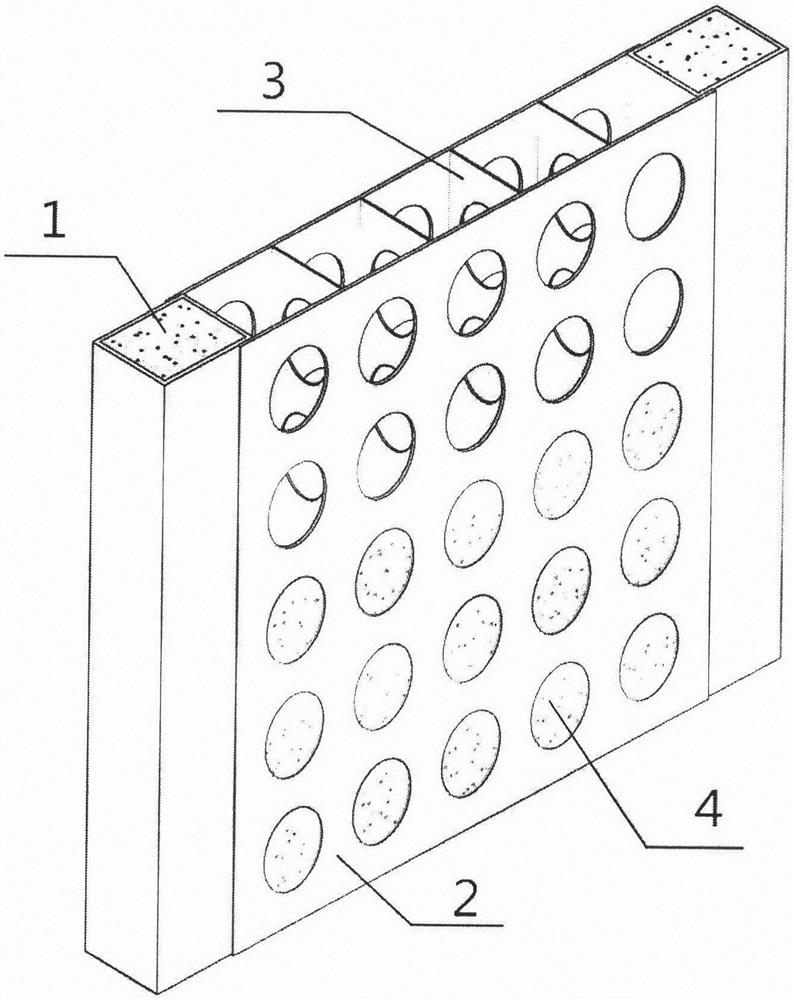

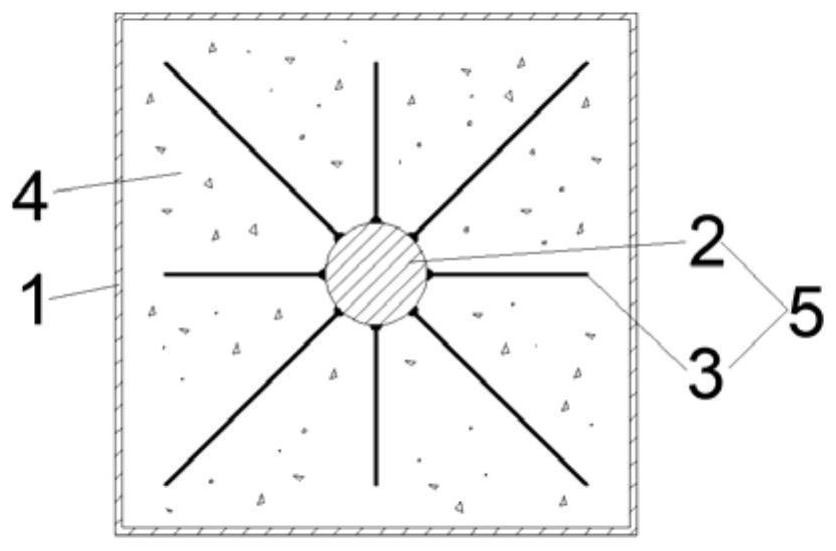

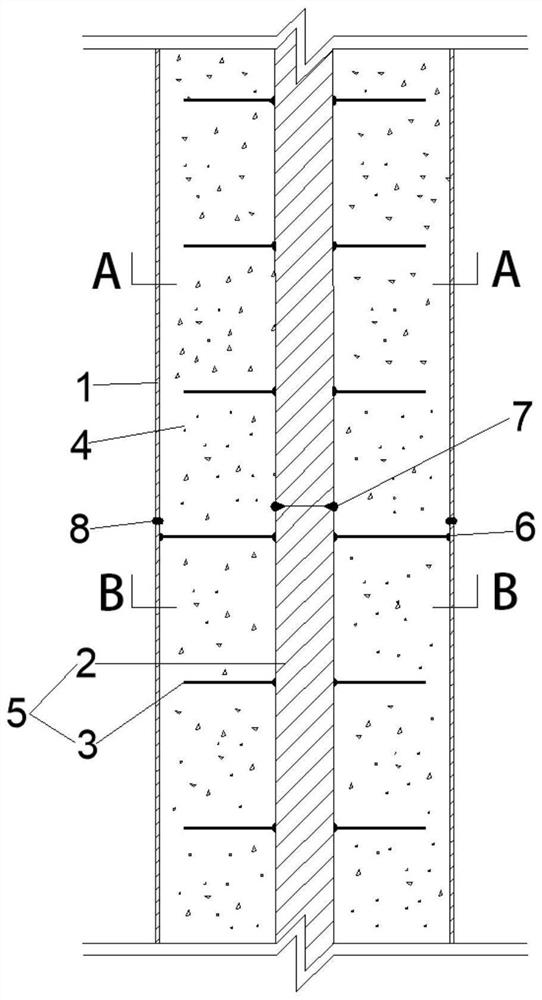

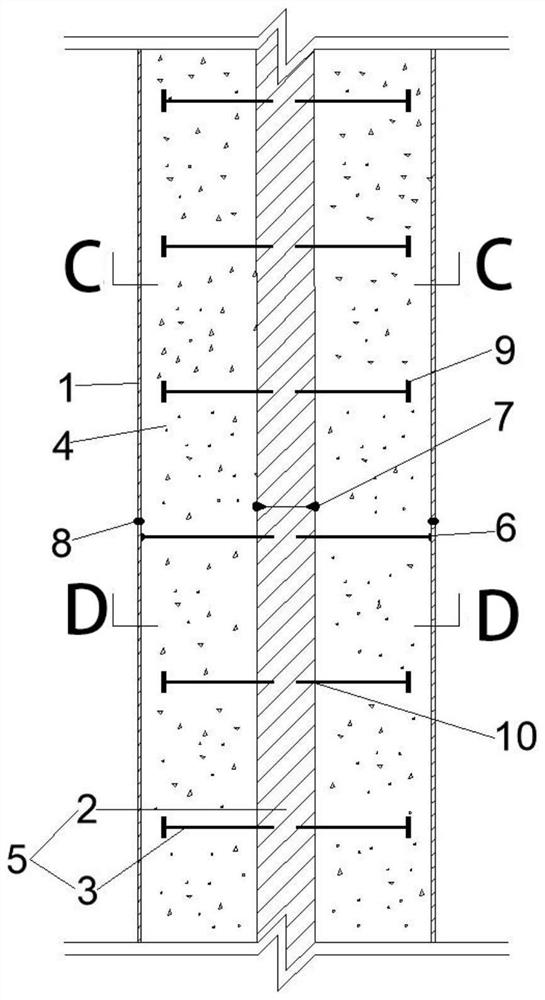

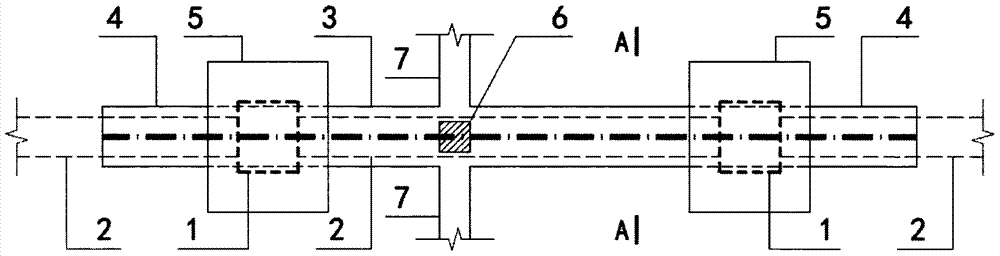

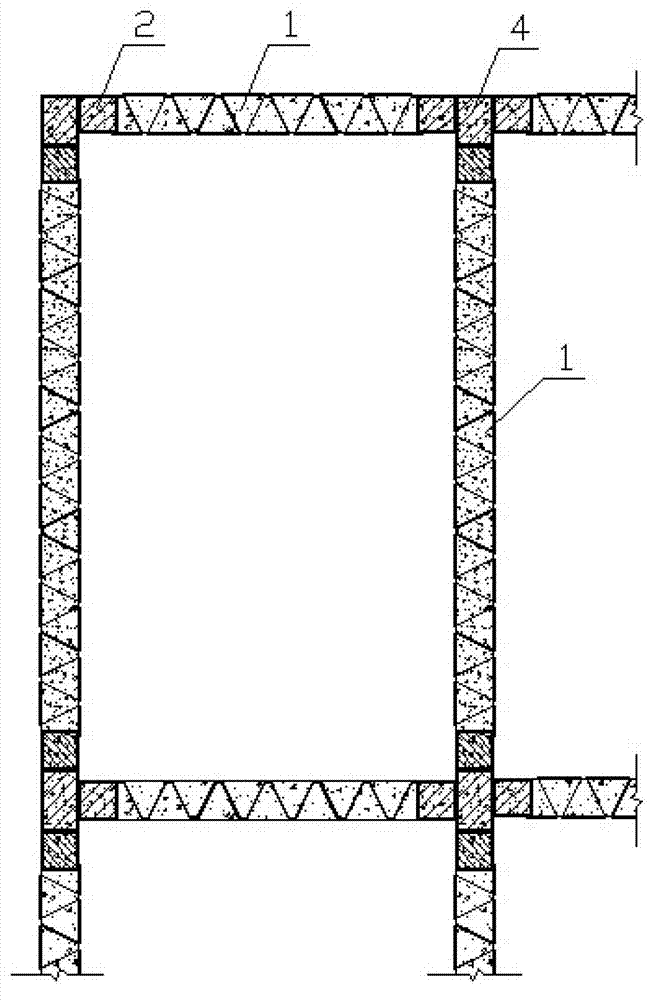

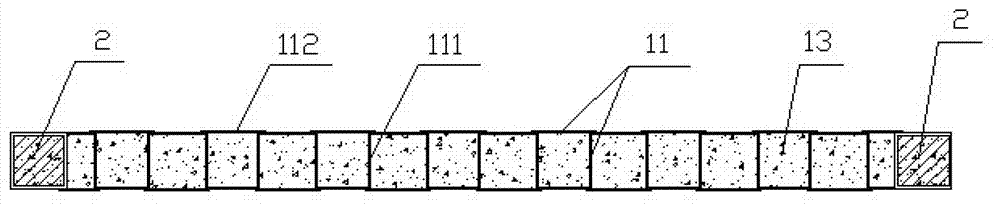

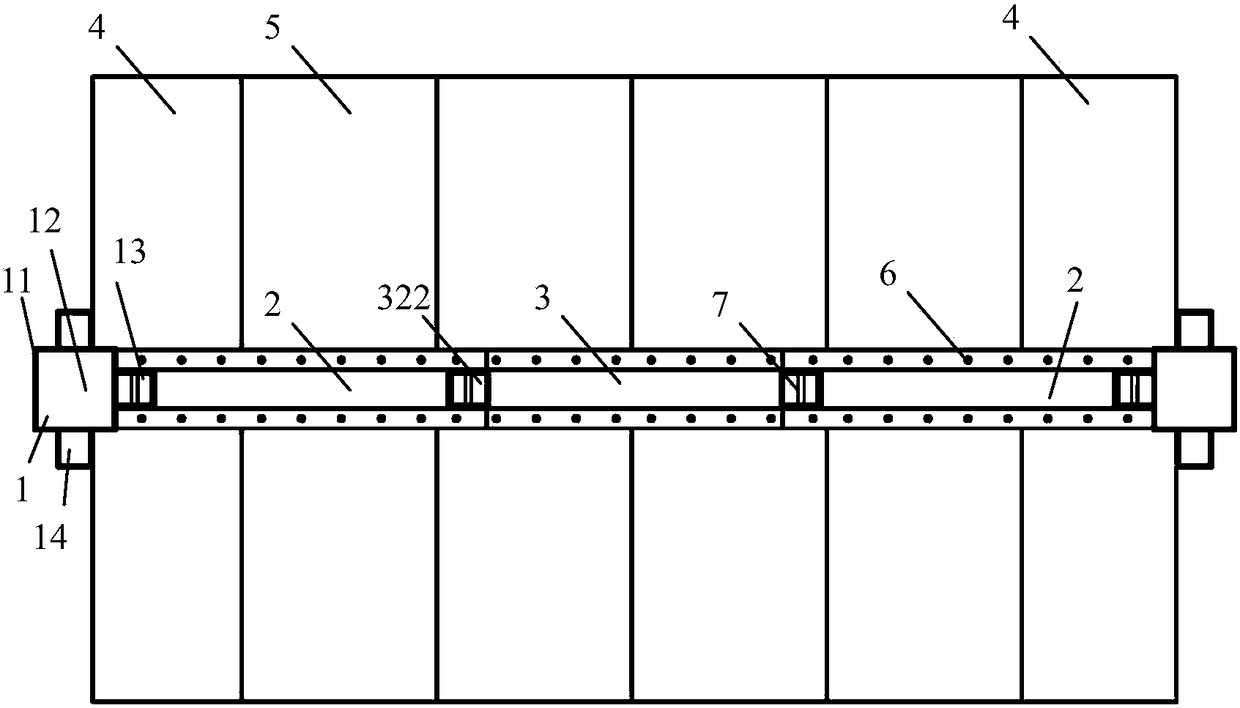

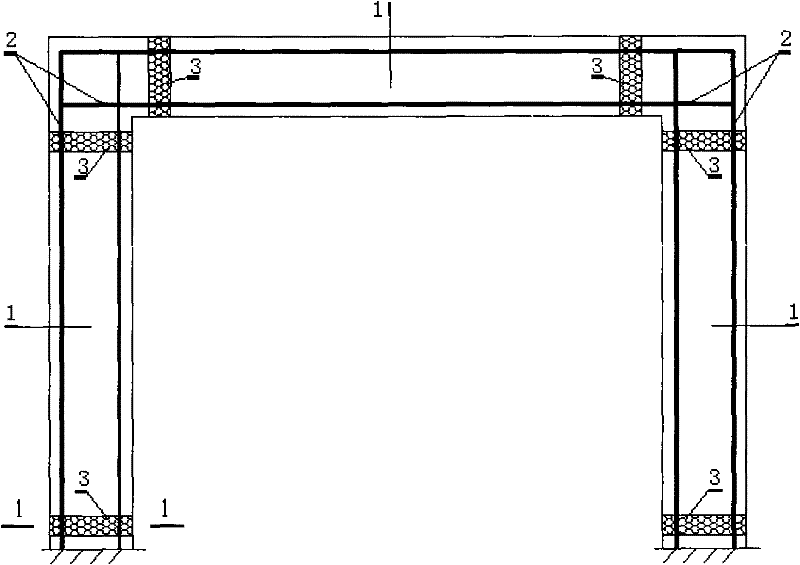

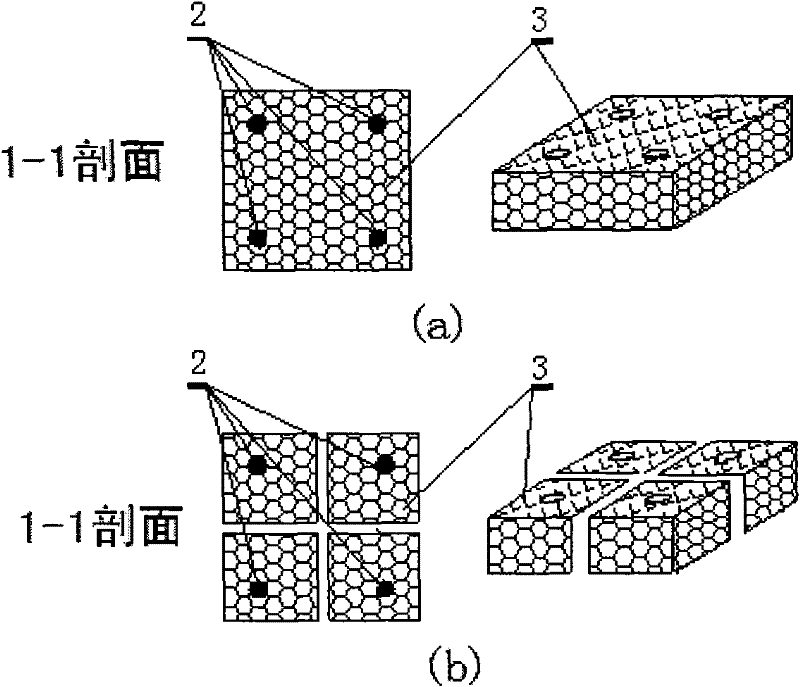

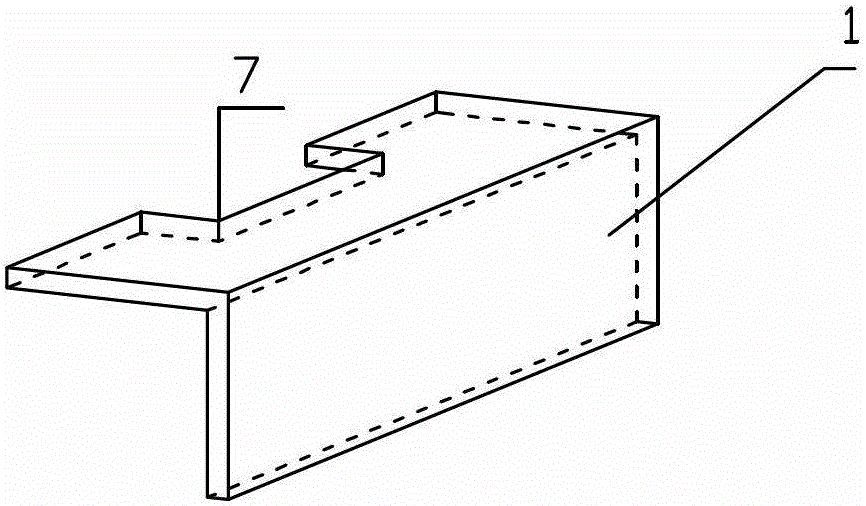

Lattice type single-row reinforcement T-shaped cross section concrete column and construction method thereof

InactiveCN102518258AReduce dosageImprove shear resistanceStrutsPillarsStructural engineeringShear resistance

The invention relates to a lattice type single-row reinforcement T-shaped cross section concrete column and a construction method thereof, and belongs to the field of damping and disaster prevention. The lattice type single-row reinforcement T-shaped cross section concrete column of the invention comprises concrete (1), a ladder lattice-shaped common reinforcing steel bar net (2), lattice single-row reinforcement nets (3), and binding reinforcing steel bars (4). The T-shaped column reinforcing steel bar framework is the T-shaped structure. The three pieces of the lattice single-row reinforcement nets (3) are welded into the three limbs of the T-shaped structure. The ladder lattice-shaped common reinforcing steel bar net (2) is vertically welded on the end parts of the three limbs of the T-shaped lattice single-row reinforcement net. The binding reinforcing steel bars (4) are vertically welded on the horizontal level reinforcing steel bar center position of the common reinforcing steel bar net (2), and are arranged equidistantly along the column height direction. According to the present invention, the lattice type single-row reinforcement T-shaped cross section concrete column adopts the single-row reinforcement, such that the construction is simple, and the use amount of the reinforcing steel bars is less; the lattice reinforcing steel bar sheets are welded to form the reinforcement, such that the industrial production is easily achieved; the lattice reinforcement is adopted, and the shear resistance of the diagonal web reinforcement is good, such that the brittle shear failure of the special-shaped cross section short column can be prevented, and the seismic ductility of the column is improved.

Owner:BEIJING UNIV OF TECH

Method for reinforcing steel pipe joints by upward movement of groove-shaped collar plate

InactiveCN105888286AHigh static strengthImproves seismic ductilityBuilding repairsStatic strengthSteel tube

The invention provides a method for reinforcing steel pipe joints by upward movement of a groove-shaped collar plate. A branch pipe is perpendicularly welded at the middle position of the top surface of a main pipe with the reinforced joints; the groove-shaped collar plate is welded on a pipe body of the branch pipe in a sleeving manner and is welded on two sides of the main pipe with the reinforced joints in the direction of the axis of the main pipe or in the direction perpendicular to the axis of the main pipe or welded on the upper surface of the main pipe with the reinforced joints, so that a surrounding welded joint, a center connecting welded joint and a double-side connecting welded joint are formed; and when the groove-shaped collar plate is arranged in the direction of the axis of the main pipe with the reinforced joints and the width of the surface of the main pipe with the reinforced joints difficultly guarantees welding of the double-side connecting welded joint, a flange of the groove-shaped collar plate can be welded with the side wall of the main pipe with the reinforced joints. The method for reinforcing the steel pipe joints by upward movement of the groove-shaped collar plate is not only suitable for reinforcement, repairing and strengthening of the steel pipe joints during service period, but also is suitable for machining the reinforced joints of steel pipe structures in the design stage. In the method, the collar plate and the welded joints of the branch pipe move upwards, the static strength of the joints can be improved, the welded joints of the main pipe and the branch pipe can be protected, brittle failure of the welded joints is avoided, and therefore, the anti-seismic ductility performance of the welding joints is improved.

Owner:CHINA UNIV OF MINING & TECH

Corrugated steel pipe concrete overlapped component and manufacturing method thereof

InactiveCN111005452AIncrease contact areaImprove adhesionBuilding constructionsReinforced concreteRebar

The invention discloses a corrugated steel pipe concrete overlapped component and a manufacturing method thereof. The component comprises reinforced concrete and a steel pipe arranged inside the reinforced concrete and is characterized in that the steel pipe is a corrugated steel pipe, the directions of the wave crest and the wave trough of the corrugated steel pipe are perpendicular to the lengthdirection of the corrugated steel pipe or skew to the length direction of the corrugated steel pipe, core concrete fills the corrugated steel pipe, overlapped concrete with the thickness of 80 mm orabove is wrapped around the outer circumference of the corrugated steel pipe, and a reinforcement framework cage is arranged inside the overlapped concrete. According to the component, the bonding performance and the anti-seismic ductility of the steel pipe and the overlapped concrete can be improved, the bearing capacity of the component is improved, and the overlapped component can better adaptto the corrosion environment.

Owner:CHINA UNIV OF MINING & TECH

Honeycomb hollowed-out grating tubular double-steel-plate concrete composite shear wall and preparation method thereof

PendingCN112832417AThe same principles of structural mechanicsEnhanced capacity for out-of-plane buckling failureWallsFloorsFloor slabRebar

A honeycomb hollowed-out type grating tubular double-steel-plate concrete composite shear wall comprises steel pipe concrete end columns, honeycomb hollowed-out steel plates and honeycomb hole tie steel plates, the honeycomb hollowed-out steel plates are thin steel plates provided with holes arranged in an orthogonal array mode, and the two honeycomb hollowed-out steel plates are arranged in front of and behind the left steel pipe concrete end column and the right steel pipe concrete end column. A plurality of honeycomb hole tie steel plates are arranged between the two honeycomb hollowed-out steel plates, the honeycomb hollowed-out steel plates, the honeycomb hole tie steel plates and the honeycomb hollowed-out steel plates are welded to form honeycomb hollowed-out grating tubular wallboards, the wallboards are welded and spliced to form L-shaped, T-shaped and cross-shaped shear walls, concrete is poured into the pipes, and the honeycomb hollowed-out grating tubular double-steel-plate concrete composite shear wall system is formed. The honeycomb hollow-out steel plate is adopted, a large amount of steel is saved, the hoisting weight is reduced, the problem that welding construction of an internal tie steel plate is difficult is solved, the steel bar truss floor bearing plate is placed in a hole of the honeycomb hollow-out steel plate, the problem of bearing connection of a reinforced concrete floor is solved, and the honeycomb hollow-out grating tubular wallboard is also used as a vertical temporary support. A plurality of floors are constructed at the same time, and a super high-rise building can be rapidly built.

Owner:张家港保税区金港建设工程质量检测有限公司

Superimposed reinforcement structure and method for additionally arranging column grid on existing long-span structure

The invention belongs to the field of constructional engineering and particularly relates to a superimposed reinforcement structure for additionally arranging a column grid on an existing long-span structure. The superimposed reinforcement structure comprises existing structure columns and an existing long-span structure beam which is supported on the existing structure columns. An additional beam superimposed layer is arranged on the existing long-span structure beam, profile steel is arranged inside the additional beam superimposed layer, and the existing long-span structure beam and the additional beam superimposed layer are provided with shear-resistant connection steel bars and junction surface constructional steel bars in the position of an old and new concrete junction surface. By means of the superimposed reinforcement structure, components of the existing structure do not need to be dismantled, the damage to the existing structure is small, and normal functional application of an existing building does not need to be interrupted; the characteristic that the existing structure possesses certain bearing capacity is fully utilized, and temporary construction safety supporting measures are not needed, so that the construction cost is reduced and the construction efficiency is improved; and the shear-resistant bearing capacity of the superimposed structure in the position of the junction surface is guaranteed, and finally, the overall anti-bending bearing capacity of the superimposed structure is guaranteed.

Owner:ZHEJIANG GAD

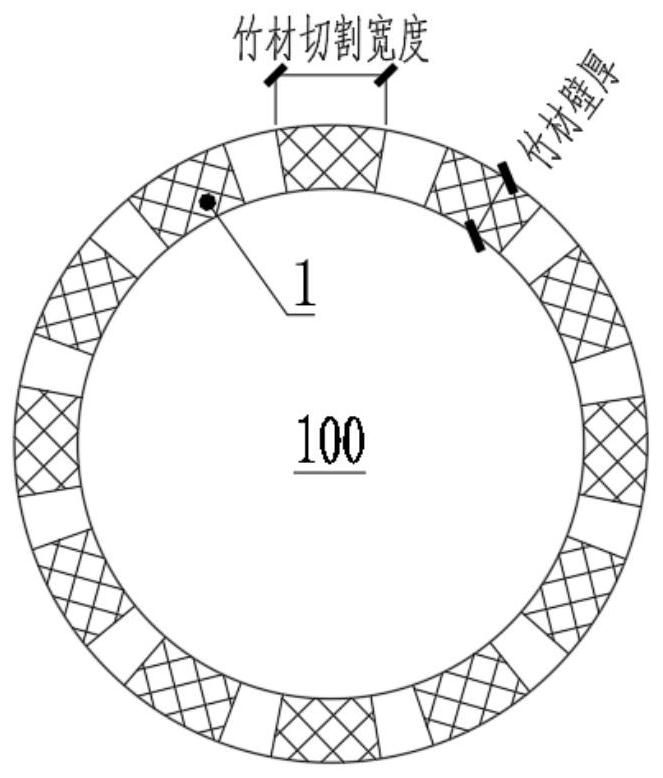

Concrete filled steel tubular column with wolf tooth core column

PendingCN114809452AImprove Constraint PerformanceImprove load carrying capacity and seismic ductilityStrutsPillarsSteel tubeRebar

The concrete-filled steel tube column comprises an outer steel tube, the wolf tooth core column located in the outer steel tube and concrete filled in the outer steel tube, the wolf tooth core column comprises a solid steel column and ribbed steel bars, the internally-arranged wolf tooth core column longitudinally penetrates through a column body, and the center of the wolf tooth core column coincides with the center of the outer steel tube; wherein the wolf tooth core column is connected with the ribbed steel bars. The solid steel columns and the ribbed steel bars connected with the solid steel columns are collectively called wolf tooth core columns. The ribbed steel bars are evenly distributed on the periphery of the built-in steel column in the mode of being perpendicular to the built-in steel column to form a wolf tooth-shaped core column. The core column is located in the center of the steel pipe and at least tightly connected with the eight ribbed steel bars with certain lengths, and the core column and the outer steel pipe form a whole after concrete is poured. The structural design is improved, the constraint performance of core concrete is improved, the bearing capacity of the column is improved, the plastic deformation of the column is reduced, the section size and material consumption of the concrete-filled steel tube column are reduced, and the column is economical and environmentally friendly.

Owner:GUANGZHOU UNIVERSITY

An assembly method of a steel pipe column and a steel beam

InactiveCN105839788BNo brittle failureSolve the inconvenience of assemblyBuilding constructionsSteel frameFlange

The invention discloses a novel steel pipe column and shaped steel beam assembling method. Top flange U-shaped steel or channel steel provided with multiple bolt holes is vertically welded to the two sides faces of a steel pipe column with the section closed and is symmetrical about the axis, lower flange U-shaped steel or channel steel provided with multiple bolt holes is correspondingly welded to the lower portion of the steel pipe column, and a shear web provided with bolt holes is welded to the gap between the top flange U-shaped steel or channel steel and the lower flange U-shaped steel or channel steel; an open type steel beam has an open section, a beam end plate is welded to the end of one side of the open type steel beam, a beam end lug plate is welded to the middle of the beam end plate, bolt holes in the beam end plate correspond to those in the top flange U-shaped steel or channel steel and the lower flange channel steel, and the beam end lug plate corresponds to the bolt holes in the shear web. The method is suitable for assembly and connection between the steel pipe column with the closed section and the steel beam with the open section, the anti-seismic property and ductility of a joint can be improved, the bearing capacity of the joint can be improved, brittle failure of the steel pipe column under static force or earthquake action is avoided, and then high earthquake-resistant ductility of a steel frame structure is guaranteed.

Owner:CHINA UNIV OF MINING & TECH

A construction method of superimposed reinforcement structure with newly added column network on the existing long-span structure

ActiveCN106401208BAvoid damageNo need to interrupt normal functional useBuilding repairsRebarLong span

The invention belongs to the field of constructional engineering and particularly relates to a superimposed reinforcement structure for additionally arranging a column grid on an existing long-span structure. The superimposed reinforcement structure comprises existing structure columns and an existing long-span structure beam which is supported on the existing structure columns. An additional beam superimposed layer is arranged on the existing long-span structure beam, profile steel is arranged inside the additional beam superimposed layer, and the existing long-span structure beam and the additional beam superimposed layer are provided with shear-resistant connection steel bars and junction surface constructional steel bars in the position of an old and new concrete junction surface. By means of the superimposed reinforcement structure, components of the existing structure do not need to be dismantled, the damage to the existing structure is small, and normal functional application of an existing building does not need to be interrupted; the characteristic that the existing structure possesses certain bearing capacity is fully utilized, and temporary construction safety supporting measures are not needed, so that the construction cost is reduced and the construction efficiency is improved; and the shear-resistant bearing capacity of the superimposed structure in the position of the junction surface is guaranteed, and finally, the overall anti-bending bearing capacity of the superimposed structure is guaranteed.

Owner:ZHEJIANG GAD

A method of moving and strengthening steel pipe joints on grooved ring mouth plate

InactiveCN105888286BImprove static strengthImproves seismic ductilityBuilding repairsEngineeringDesign stage

The invention provides a method for reinforcing steel pipe joints by upward movement of a groove-shaped collar plate. A branch pipe is perpendicularly welded at the middle position of the top surface of a main pipe with the reinforced joints; the groove-shaped collar plate is welded on a pipe body of the branch pipe in a sleeving manner and is welded on two sides of the main pipe with the reinforced joints in the direction of the axis of the main pipe or in the direction perpendicular to the axis of the main pipe or welded on the upper surface of the main pipe with the reinforced joints, so that a surrounding welded joint, a center connecting welded joint and a double-side connecting welded joint are formed; and when the groove-shaped collar plate is arranged in the direction of the axis of the main pipe with the reinforced joints and the width of the surface of the main pipe with the reinforced joints difficultly guarantees welding of the double-side connecting welded joint, a flange of the groove-shaped collar plate can be welded with the side wall of the main pipe with the reinforced joints. The method for reinforcing the steel pipe joints by upward movement of the groove-shaped collar plate is not only suitable for reinforcement, repairing and strengthening of the steel pipe joints during service period, but also is suitable for machining the reinforced joints of steel pipe structures in the design stage. In the method, the collar plate and the welded joints of the branch pipe move upwards, the static strength of the joints can be improved, the welded joints of the main pipe and the branch pipe can be protected, brittle failure of the welded joints is avoided, and therefore, the anti-seismic ductility performance of the welding joints is improved.

Owner:CHINA UNIV OF MINING & TECH

Double-steel-sheet and concrete combined core-tube structure with built-in corrugated steel sheets

InactiveCN103233509BImprove seismic performanceImprove structural rigidityShock proofingHigh strength concreteSteel frame

Owner:SOUTHEAST UNIV

Lattice type single-row reinforcement T-shaped cross section concrete column and construction method thereof

The invention relates to a lattice type single-row reinforcement T-shaped cross section concrete column and a construction method thereof, and belongs to the field of damping and disaster prevention. The lattice type single-row reinforcement T-shaped cross section concrete column of the invention comprises concrete 1, a ladder lattice-shaped common reinforcing steel bar net 2, lattice single-row reinforcement nets 3, and binding reinforcing steel bars 4. The T-shaped column reinforcing steel bar framework is the T-shaped structure. The three pieces of the lattice single-row reinforcement nets 3 are welded into the three limbs of the T-shaped structure. The ladder lattice-shaped common reinforcing steel bar net 2 is vertically welded on the end parts of the three limbs of the T-shaped lattice single-row reinforcement net. The binding reinforcing steel bars 4 are vertically welded on the horizontal level reinforcing steel bar center position of the common reinforcing steel bar net 2, and are arranged equidistantly along the column height direction. According to the present invention, the lattice type single-row reinforcement T-shaped cross section concrete column adopts the single-row reinforcement, such that the construction is simple, and the use amount of the reinforcing steel bars is less; the lattice reinforcing steel bar sheets are welded to form the reinforcement, such that the industrial production is easily achieved; the lattice reinforcement is adopted, and the shear resistance of the diagonal web reinforcement is good, such that the brittle shear failure of the special-shaped cross section short column can be prevented, and the seismic ductility of the column is improved.

Owner:BEIJING UNIV OF TECH

Fully assembled steel pipe concrete frame composite shear wall structure

The invention provides a full assembly type steel pipe concrete side frame combined shear wall structure, which comprises a steel pipe concrete post, a prefabricated shear wall and a floor slab, wherein the steel pipe concrete post comprises a steel pipe post and post wall connecting sectional steel welded on the periphery of the steel pipe post; concrete is cast in the steel pipe post; a plurality of screw bolt holes are formed in two sides of the post wall connecting sectional steel, and are used for connecting the prefabricated shear wall; the prefabricated shear wall comprises a reinforced concrete shear wall and embedded sectional steel positioned on the periphery of the reinforced concrete shear wall; a plurality of screw bolt holes are formed in the left side and the right side of the embedded sectional steel, and are used for connecting the post wall connecting sectional steel or the embedded sectional steel of the other prefabricated shear wall; the upper side and the lower side of the embedded sectional steel are provided with end plates; a plurality of screw bolt holes are formed in the end plates and are used for connecting floor slabs. The full assembly type steel pipe concrete side frame combined shear wall structure has the advantages that the joint connection is fast and reliable; the construction is convenient; the construction quality is good; the bearing force is high; the quake-proof performance is good; the construction period is short; components can realize standardized production.

Owner:FUJIAN UNIV OF TECH

Method for improving anti-earthquake ductility of FRP tendon concrete frame structure

InactiveCN101672075BIncreased curvature ductilityOvercoming the defects of brittle failureShock proofingCompression setCompressive strength

The invention relates to a method for improving anti-earthquake ductility of FRP tendon concrete frame structure, comprising the step of building an FRP tendon concrete frame structure. When building the type of frame structure, a component with effective compressive strength and formability is installed in a zone which can produce larger bending moment under the action of earthquake loading; compression set of the component improves the formability of a construction member concrete compressive zone in the FRP tendon concrete frame structure so as to improve the anti-earthquake ductility of the frame structure. Under the condition of constant FRP tendon formability, the invention effectively increases the deformation of the concrete compressive zone and the curvature ductility of a cross section, overcomes the defect of the brittle failure of the FRP tendon concrete construction member and effectively improves the anti-earthquake ductility thereof.

Owner:SHANGHAI UNIV

A method for strengthening steel pipe joints with plates

InactiveCN102926466BImprove seismic performanceImprove ductilityBuilding constructionsMachiningPlate method

The invention relates to a method for enhancing a warp angle of a ring mouth flitch of a steel pipe node and belongs to the technical field of construction. The method for enhancing the warp angle of the ring mouth flitch of the steel pipe node is suitable for node reinforcing and repair reinforcing of an existing welded steel pipe structure and machining of an enhanced shaped node of a novel steel pipe structure. The method includes that a ring mouth flitch and the surface of an enhanced joint main pipe are attached and connected through a welding joint. One side of the ring mouth flitch is cut into a hole which is matched with a shape of a branch pipe and welded with the branch pipe. L-shaped ring mouth flitches are symmetrically arranged on both sides of an enhanced node, encircle the branch pipe, and semi-encircle the warp angle of the enhanced node main pipe. The method is suitable for the node reinforcing and repair reinforcing of the existing welded steel pipe structure and machining of the enhanced shaped node of a steel pipe structure, and capable of effectively improving earthquake resistant performance and ductility of a node, improving bearing capacity of the node, ensuring no brittle failure of the welding joint at the root of a steel pipe, and further ensuring good earthquake resistant performance and ductility performance of a space rigid frame or a truss structure.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com