Post-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and construction method thereof

A high-strength concrete and construction method technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as disaster relief and rescue and post-disaster repair and reconstruction work, reinforced concrete pier damage, and earthquake damage that is difficult to repair, etc., to improve seismic performance and Seismic safety, prevention of severe damage and collapse, effect of avoiding severe damage and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: High-strength concrete composite bridge pier with single core column prestressed steel tube with circular cross section

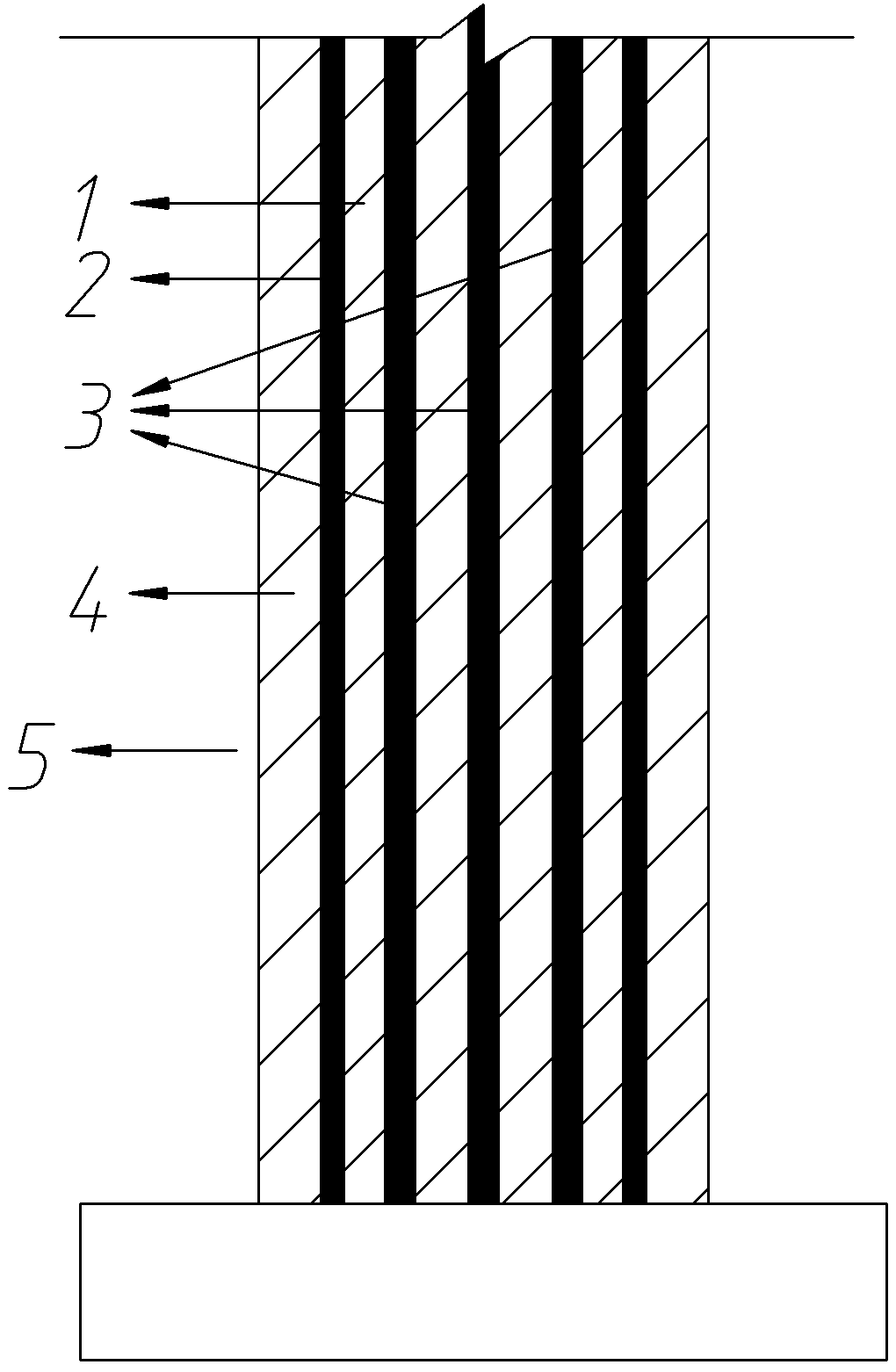

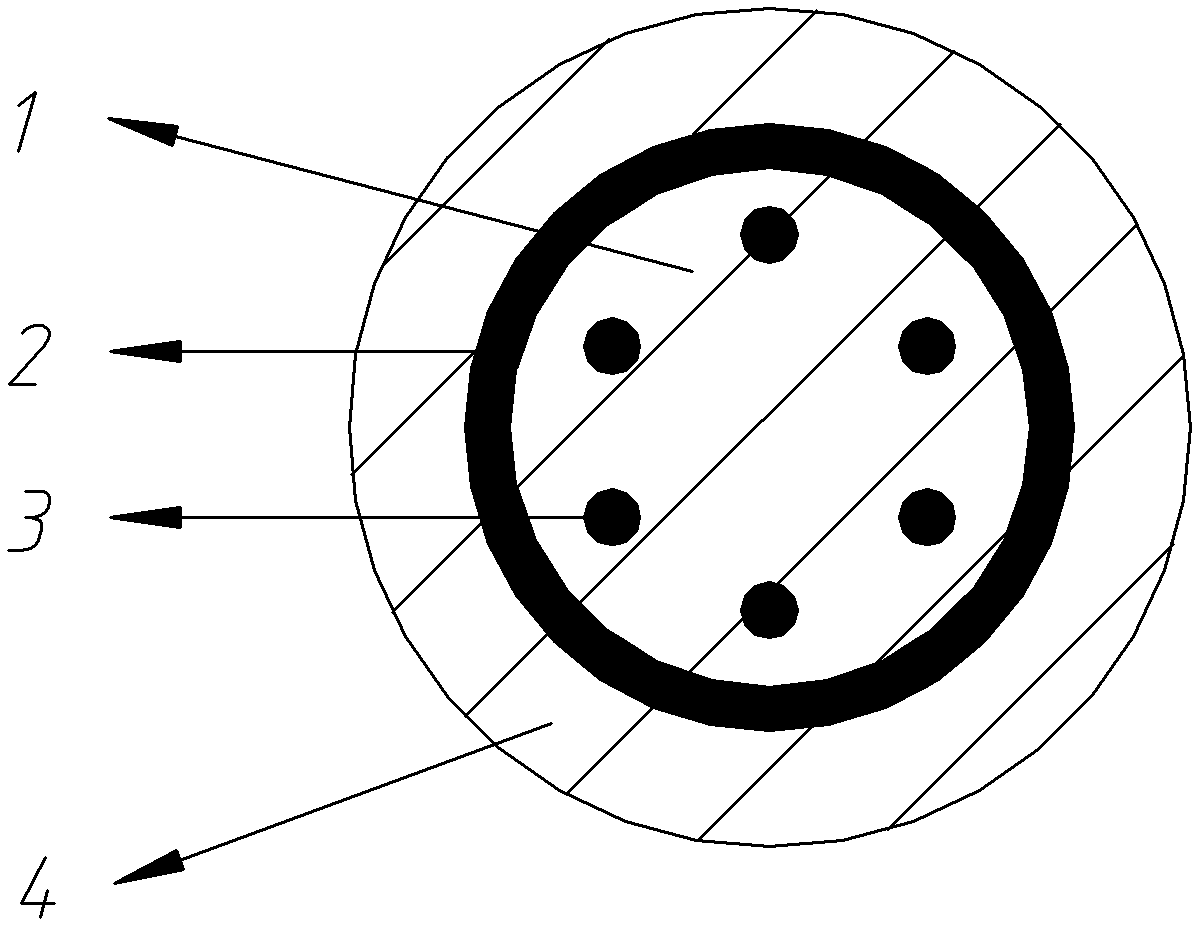

[0031] see figure 1 and figure 2 , a post-tensioned prestressed steel pipe high-strength concrete composite bridge pier, comprising a steel pipe 2, six pre-unbonded prestressed tendons 3 arranged in the steel pipe 2, and pouring water between the inner wall of the steel pipe 2 and the pre-unbonded prestressed tendons 3 In-pipe concrete 1, steel pipe 2, pre-unbonded prestressed tendons 3 and in-pipe concrete 1 form a core column 5, and external concrete 4 is poured outside the core column 5 to form a superimposed pier, and the cross-section of the superimposed pier is circular.

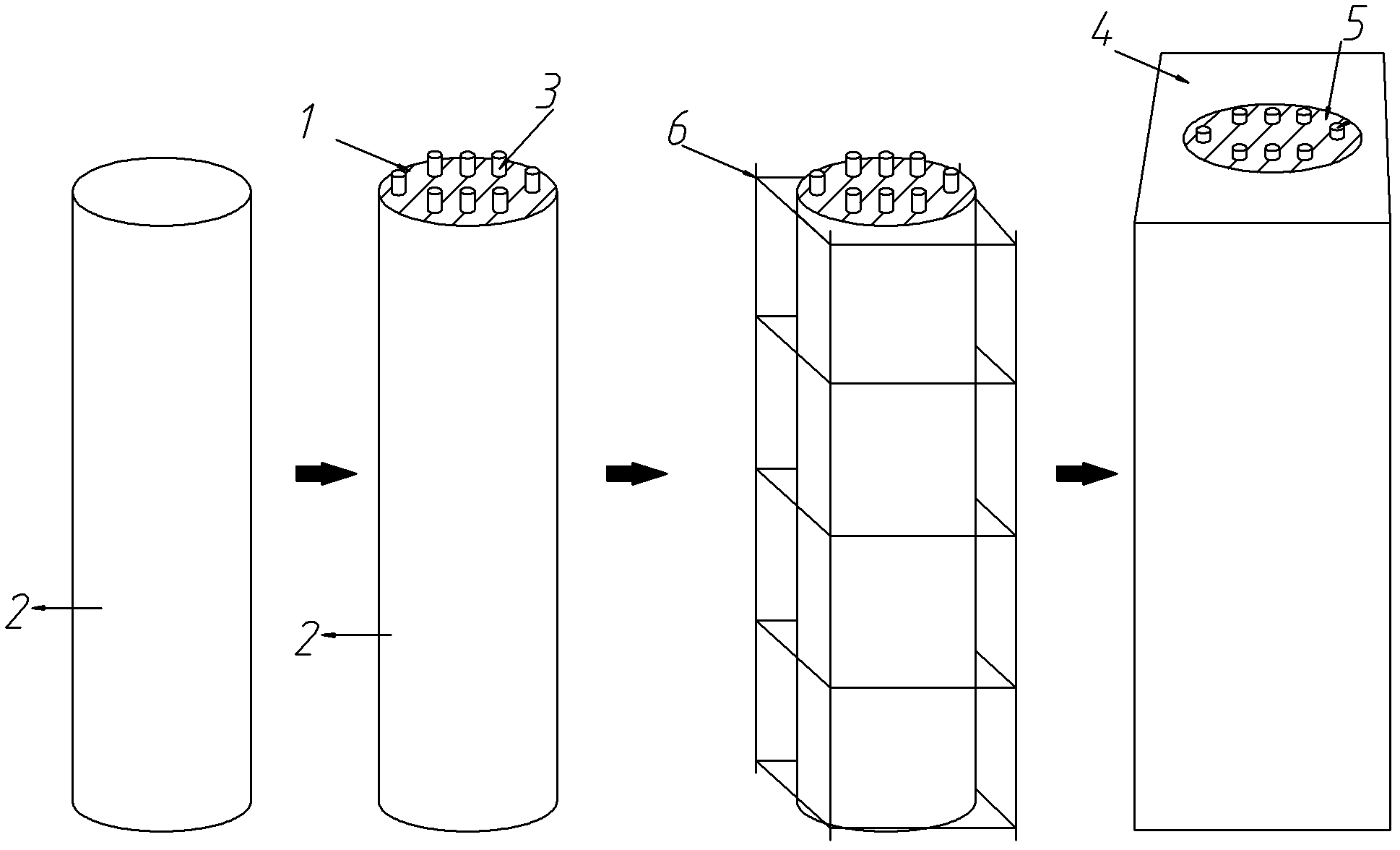

[0032] For the construction steps of the laminated pier, see image 3 ,as follows:

[0033] Step 1, determine the diameter and wall thickness of the steel pipe 2, the diameter, quantity and arrangement position of the unbonded prestressed tendons 3, and the str...

Embodiment 2

[0040] Example 2: High-strength concrete composite bridge pier with square cross-section single core column prestressed steel pipe

[0041] see Figure 4 and Figure 5 , a post-tensioned prestressed steel pipe high-strength concrete composite bridge pier, comprising a steel pipe 2, six pre-unbonded prestressed tendons 3 arranged in the steel pipe 2, and pouring water between the inner wall of the steel pipe 2 and the pre-unbonded prestressed tendons 3 In-pipe concrete 1, steel pipe 2, pre-unbonded prestressed tendons 3 and in-pipe concrete 1 form a core column 5, and external concrete 4 is poured outside the core column 5 to form a superimposed pier, and the cross-section of the superimposed pier is circular.

[0042] For the construction steps of the laminated pier, see image 3 , consistent with the method in Example 1.

[0043] A kind of prestressed steel tube high-strength concrete composite pier with rectangular cross-section single core column is prepared as follows: ...

Embodiment 3

[0044] Example 3: High-strength concrete composite bridge pier with multi-core columns and prestressed steel pipes with elliptical cross-section

[0045] see Image 6 and Figure 7 , there are three core columns 5, the concrete 4 in the pipe is poured outside the core columns 5 and between the adjacent core columns 5 to form a multi-core column laminated pier, and the cross section of the laminated pier is elliptical.

[0046] The construction steps are as follows:

[0047] Step 1, determine the diameter, wall thickness and quantity of the steel pipe 2 according to the design requirements, the diameter, quantity and arrangement position of the unbonded prestressed tendons 3, and the strength and mix ratio of the concrete 1 inside the pipe and the concrete 4 outside the pipe;

[0048] Step 2, fixing the steel pipe 2, and arranging unbonded prestressed tendons 3 inside the steel pipe 2 according to design requirements;

[0049] Step 3: Concrete 1 in the pipe is poured by pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com