Corrugated steel pipe concrete overlapped component and manufacturing method thereof

A technology of corrugated steel pipes and superimposed members, applied in the direction of building structure, construction, etc., can solve the problem of affecting the bearing capacity and seismic ductility of superimposed members, the external reinforcement of superimposed columns is prone to corrosion, and affecting the interoperability of reinforced concrete, etc. problems, to achieve the effect of improving collaborative work performance, improving restraint capacity, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

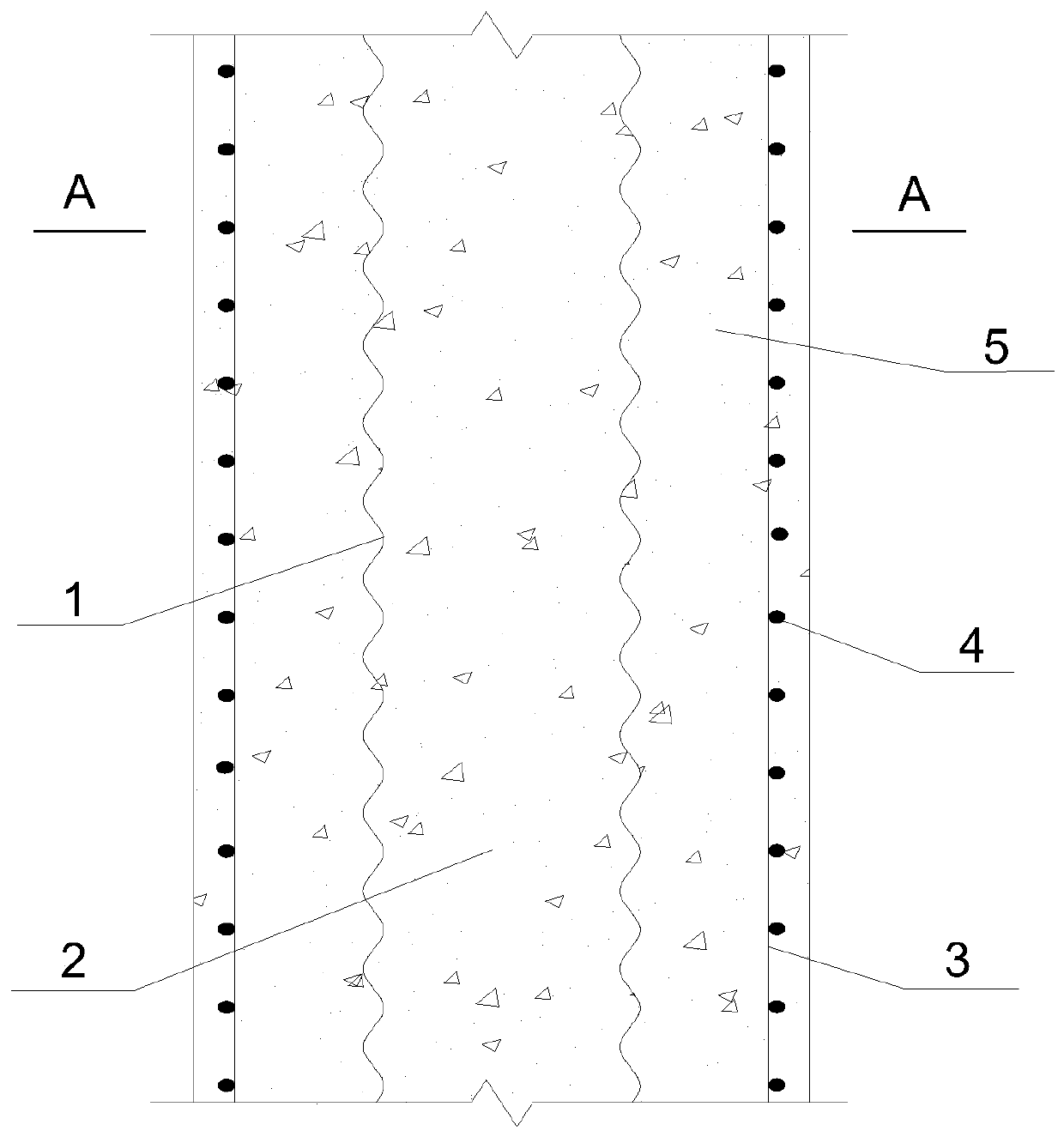

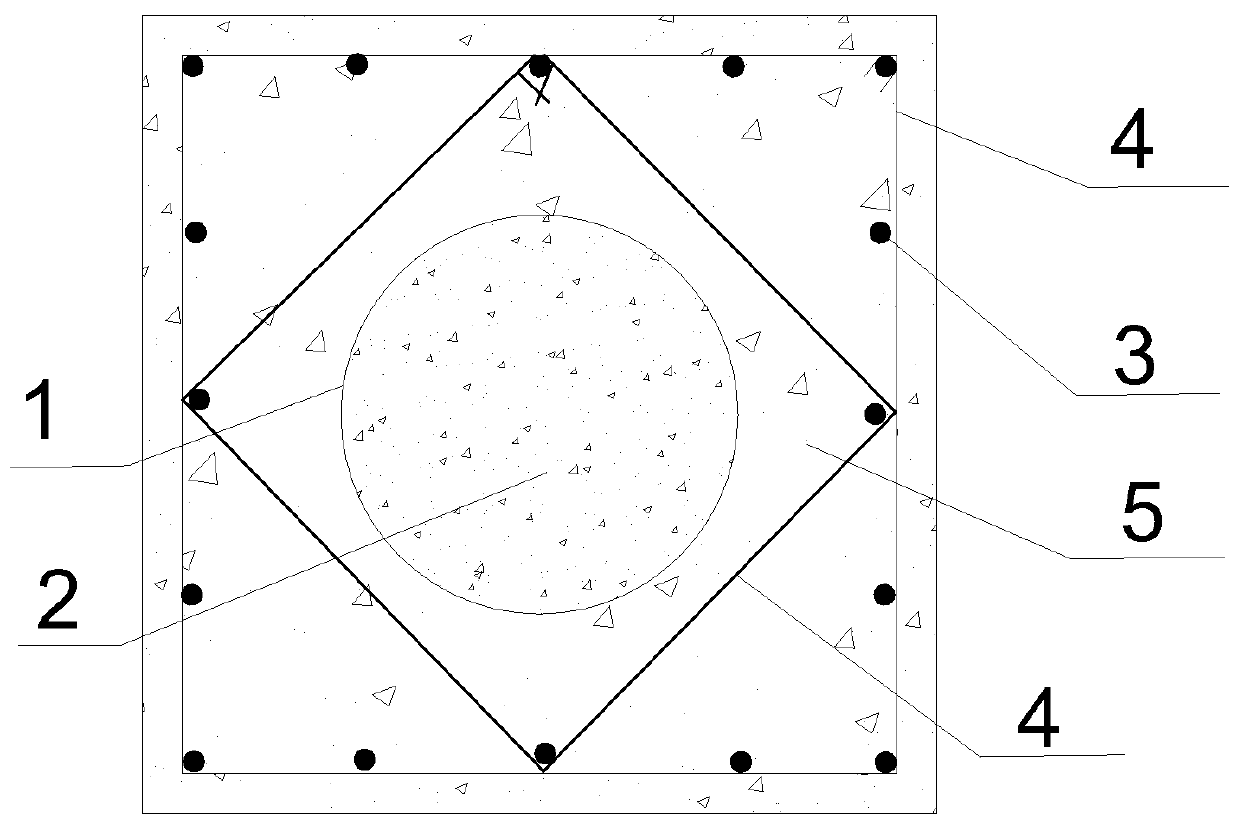

[0037] Such as figure 1 and figure 2 As shown, a corrugated steel pipe concrete composite member includes reinforced concrete and a steel pipe arranged in the center of the reinforced concrete; the steel pipe is a corrugated steel pipe 1, and the crest and trough directions of the corrugated steel pipe 1 are perpendicular to the length direction of the corrugated steel pipe 1 or are in line with the corrugated steel pipe 1. The length direction of the steel pipe 1 is oblique; the corrugated steel pipe 1 is filled with core concrete 2, the core concrete 2 in the corrugated steel pipe 1 is made of ordinary concrete, and the strength grade of the core concrete is C50; the corrugated steel pipe 1 is a circular corrugated steel pipe with galvanized surface ; The wall thickness of the steel pipe is 4mm, and the material is Q235B.

[0038] The outer periphery of the corrugated steel pipe 1 is wrapped with superimposed concrete 5 with a thickness of 200mm. The superimposed concrete ...

Embodiment 2

[0048] Such as figure 1 and image 3 As shown, a corrugated steel pipe concrete composite member includes reinforced concrete and a steel pipe arranged in the center of the reinforced concrete; the steel pipe is a corrugated steel pipe 1, and the crest and trough directions of the corrugated steel pipe 1 are perpendicular to the length direction of the corrugated steel pipe 1 or are in line with the corrugated steel pipe 1. The length direction of the steel pipe 1 is oblique; the corrugated steel pipe 1 is filled with core concrete 2, the core concrete 2 in the corrugated steel pipe 1 is made of ordinary concrete, and the strength grade of the core concrete is C45; the corrugated steel pipe 1 is a circular corrugated steel pipe with galvanized surface ; The wall thickness of the steel pipe is 3mm, and the material is Q345B.

[0049] The outer periphery of the corrugated steel pipe 1 is wrapped with a composite concrete 5 with a thickness of 150mm. The composite concrete 5 is ...

Embodiment 3

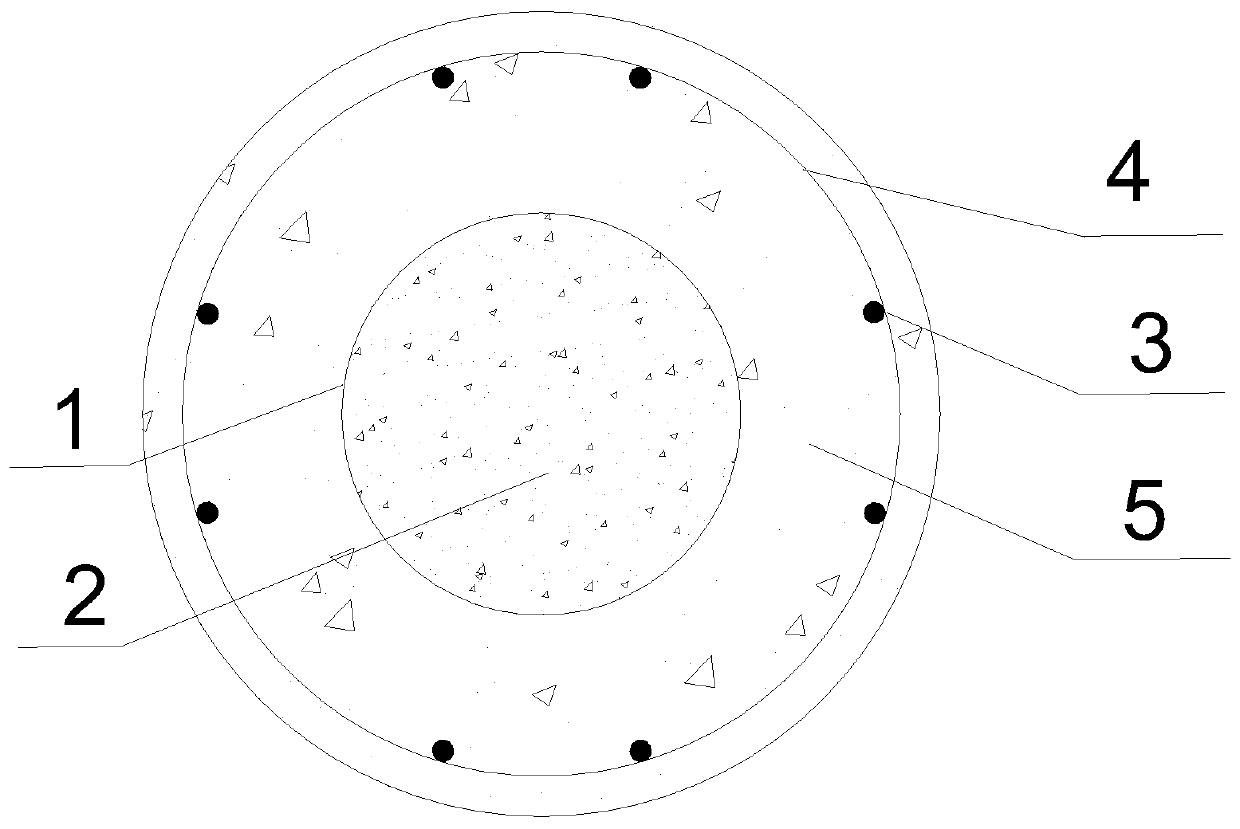

[0059] Such as figure 1 and Figure 4 As shown, a corrugated steel pipe concrete composite member includes reinforced concrete and a steel pipe eccentrically arranged inside the reinforced concrete; the steel pipe is a corrugated steel pipe 1, and the direction of the crest and trough of the corrugated steel pipe 1 is perpendicular to the length direction of the corrugated steel pipe 1 or is in line with the corrugated steel pipe 1. The length direction of the steel pipe 1 is oblique; the core concrete 2 is filled in the corrugated steel pipe 1, and the core concrete 2 in the corrugated steel pipe 1 is made of high-strength concrete, and the strength grade of the core concrete is C60; A steel pipe welded by steel plates with a rectangular cross-section; the wall thickness of the steel pipe is 6mm, and the material is Q345C.

[0060] The outer periphery of the corrugated steel pipe 1 is wrapped with laminated concrete 5 with a thickness of not less than 80mm. The laminated con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com