Connecting method of steel beam and existing reinforced concrete column

A technology for reinforced concrete columns and connection methods, which is applied in building maintenance, construction, building construction, etc., can solve problems such as poor reliability of force transmission in node areas, large concrete damage in core areas, and difficulty in ensuring quality, avoiding crack exposure, Superior seismic ductility and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure, processing and use of the present invention will be further described below in conjunction with the accompanying drawings.

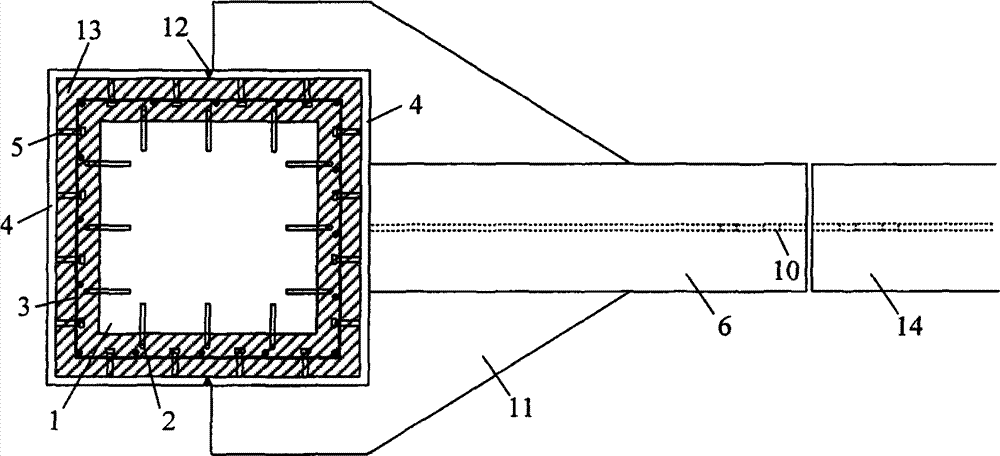

[0021] figure 1 Shown is the overall schematic diagram of the present invention. The specific construction steps are as follows:

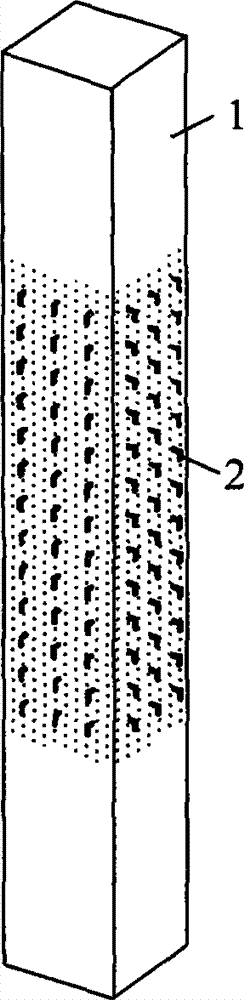

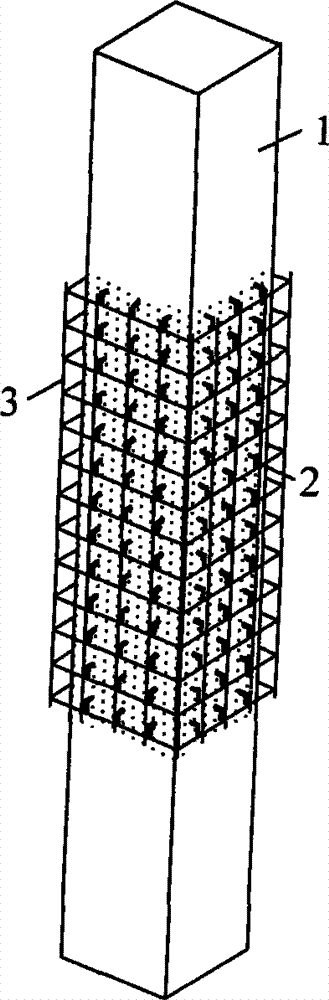

[0022] 1) Chiseling the surface around the connection area of the original reinforced concrete column 1 node, and planting L-shaped short steel bars 2 in the chiseled area, such as figure 2 As shown, the steel mesh sheet 3 is bound on the periphery of the L-shaped short steel bar, such as image 3 shown.

[0023] 2) if Figure 4 As shown, two channel steels 4 are processed, and stud connectors 5 are welded on the inner side of the channel steel; the outer side of the channel steel 4 that needs to be connected to the steel beam 14 side is welded with an outstretched corbel 6, and the outrigger 6 Composed of upper flange plate 7, lower flange plate 8 and web 9, holes are punched at the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com