Anti-pulling steel pipe pile structure supplemented on existing structure foundation slab and construction method of anti-pulling steel pipe pile structure

A technology for foundation floor and existing structures, which is applied in foundation structure engineering, building construction, building maintenance, etc., can solve the problems of large impact of environmental conditions, reduced seismic performance, poor anti-floating effect, etc., and achieves low construction cost and low load bearing capacity. The effect of high force and small volume of squeezed soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

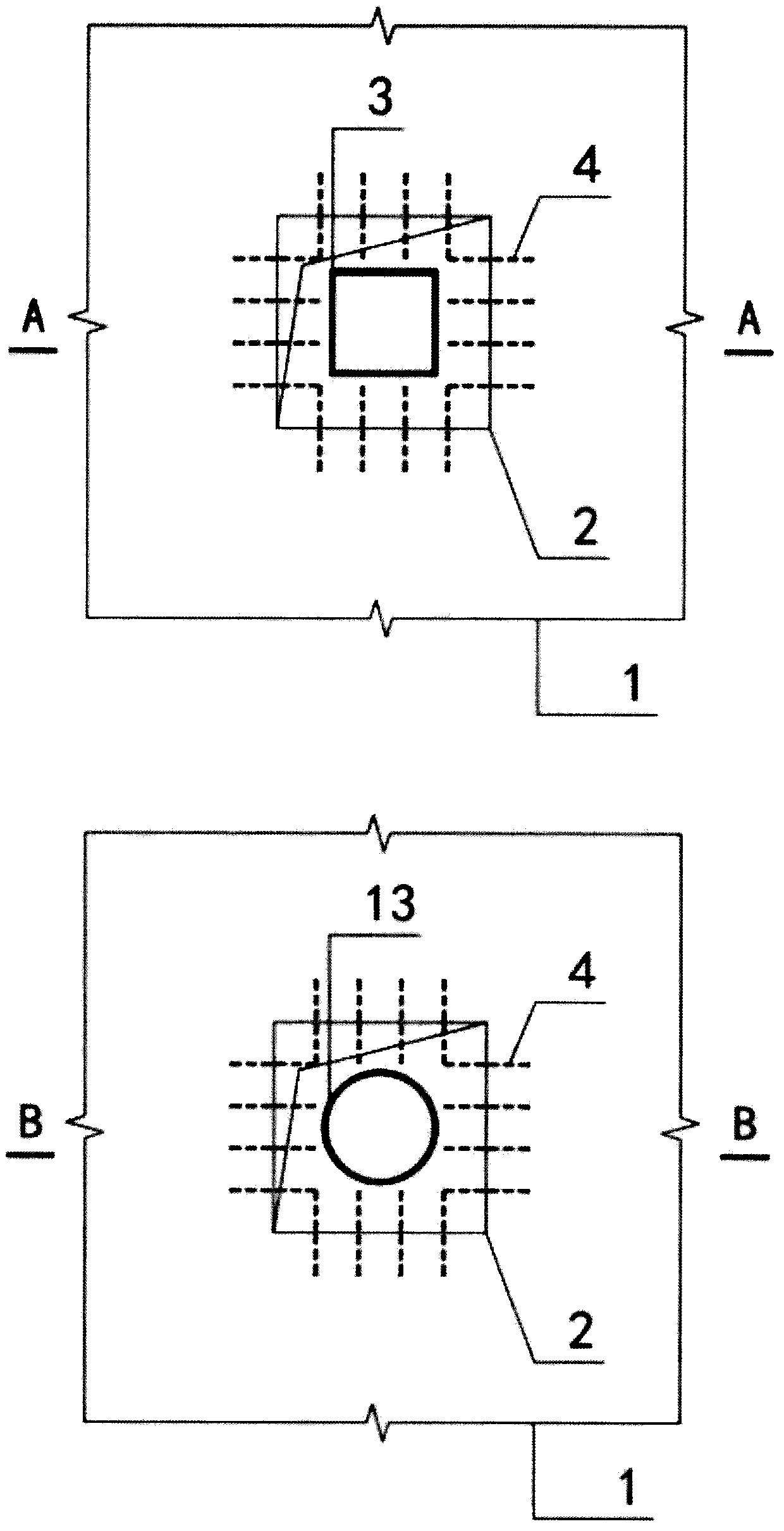

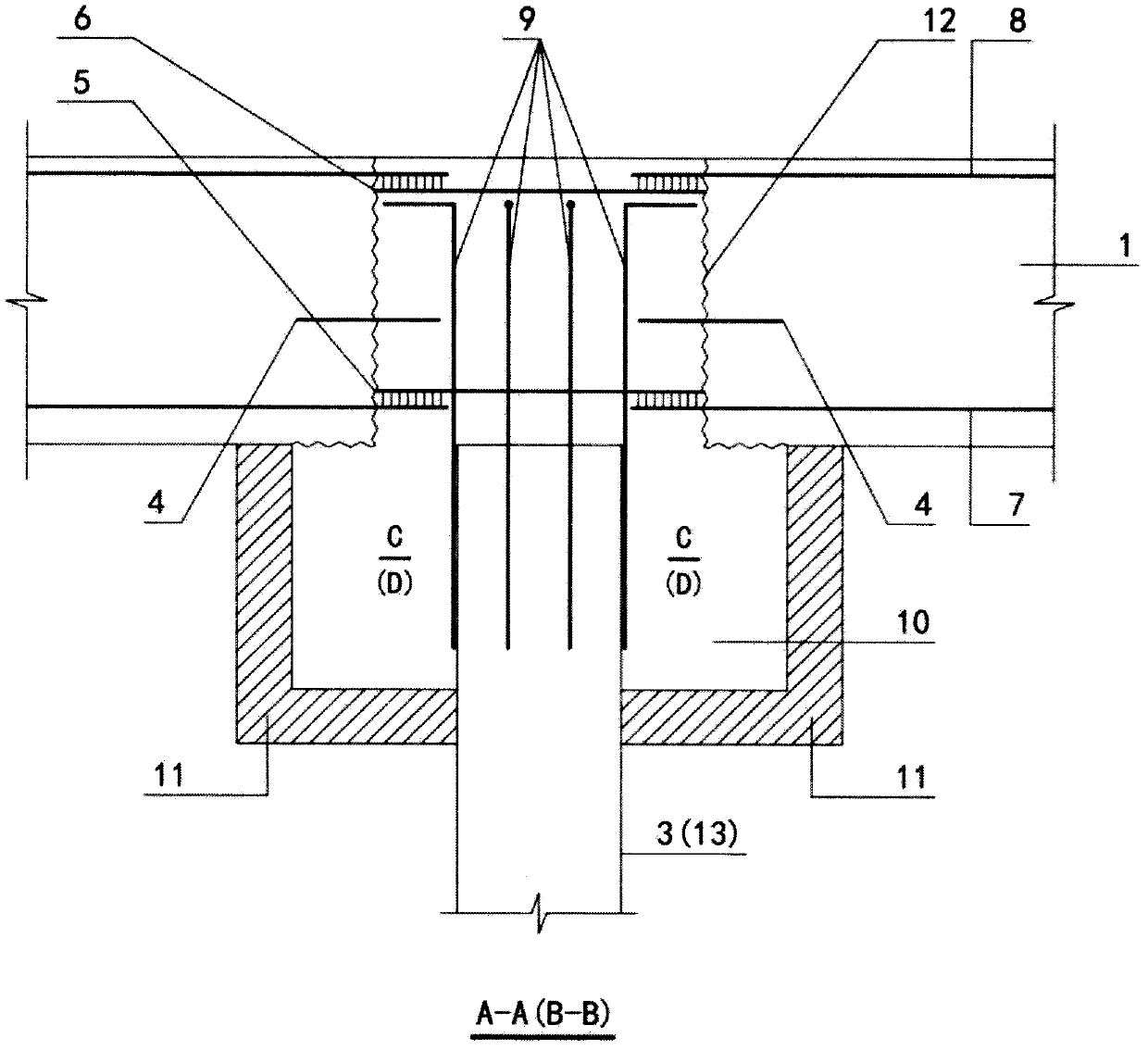

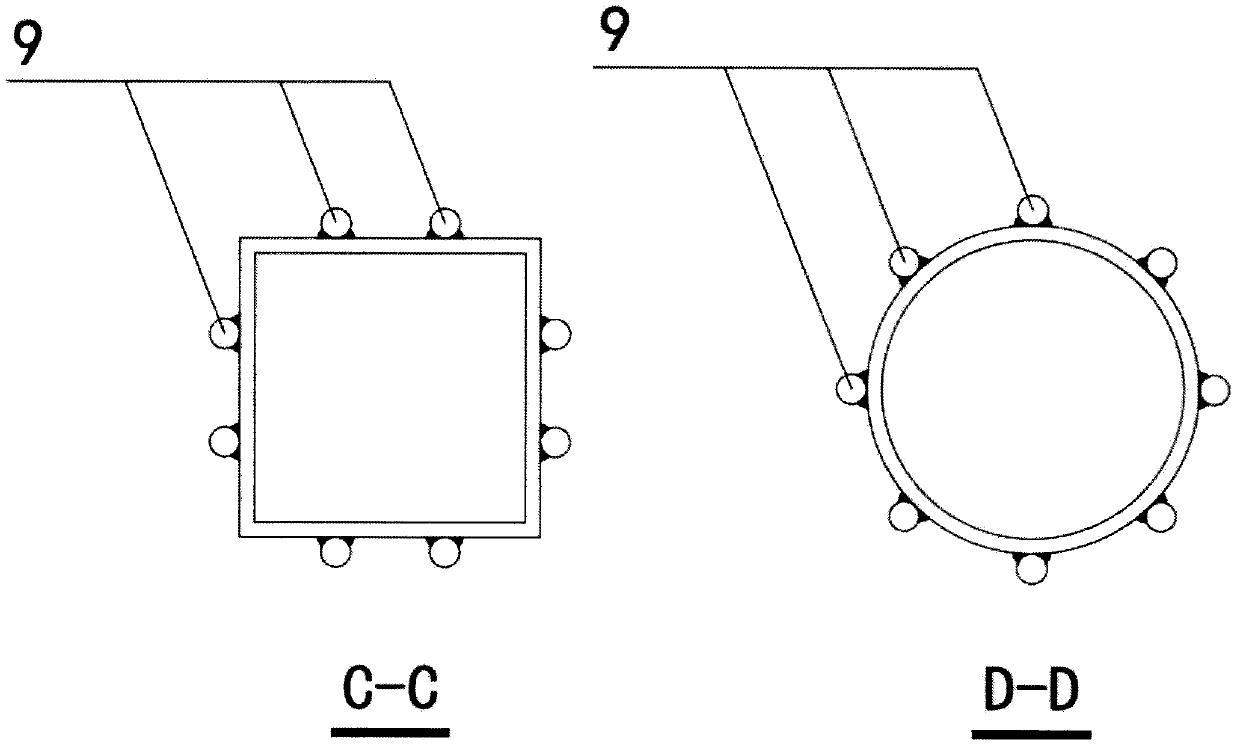

[0032] Such as Figure 1 to Figure 3 As shown, the uplift-resistant steel pipe pile structure is supplemented on the foundation floor of the existing structure, including: the foundation floor 1 of the existing structure, the pile pressure hole 2 is set on the foundation floor 1 of the existing structure, and the pile pressure hole 2 is located on the foundation floor of the existing structure The bottom reinforcement 7 of the foundation floor of the existing structure and the top reinforcement 8 of the foundation floor of the existing structure are cut off, and the steel pipe piles (including the rectangular steel pipe pile 3 and the circular steel pipe pile 13, the same below) are pressed in through the pile hole 2 In the foundation soil under the foundation floor 1 of the existing structure, the top surface of the steel pipe pile enters the foundation floor 1 of the existing structure at a distance of 50mm, and the top of the steel pipe pile is provided with a pile top conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com