Fully assembled steel pipe concrete frame composite shear wall structure

A technology of steel pipe concrete and combined shear walls, which is applied in the direction of walls, building components, building structures, etc., and can solve the problem of imperfect structural systems, less research and application of prefabricated steel pipe concrete frames, and fully assembled combined structural systems Problems such as the lack of formal connection, etc., to achieve the effect of novel connection form, improved construction environment, and convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

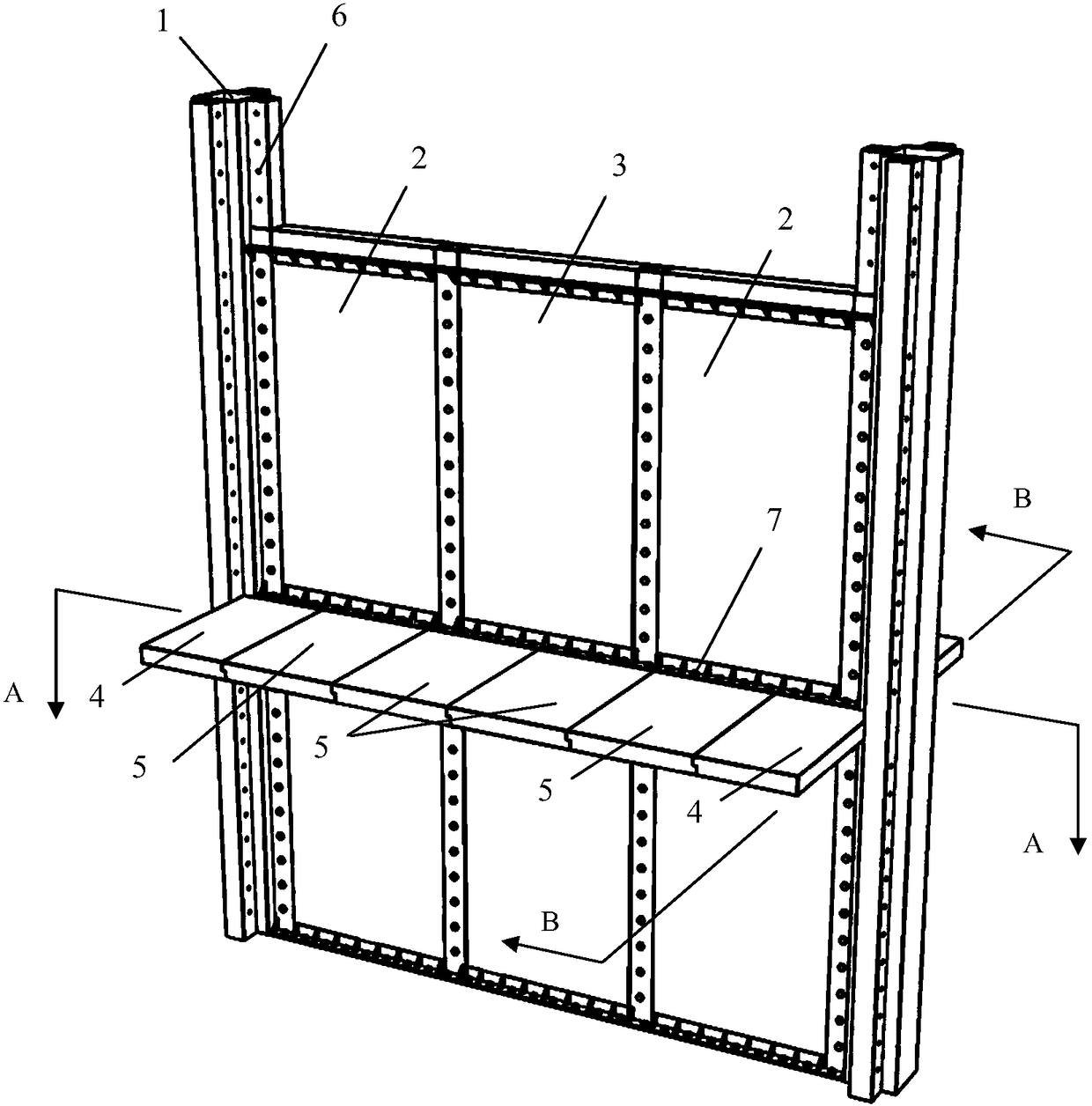

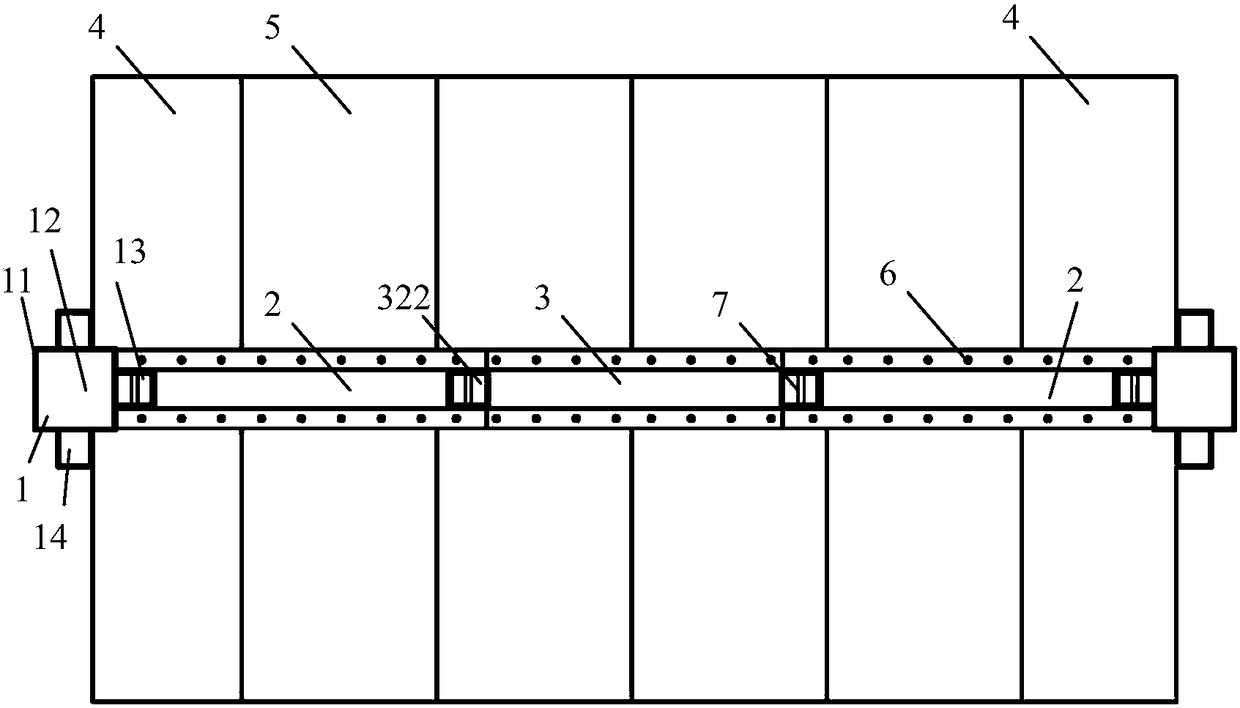

[0027] see Figure 1 to Figure 10 As shown, a specific embodiment of a novel fully assembled concrete-filled steel tube frame composite shear wall structure of the present invention includes a concrete-filled steel tube column 1, a side prefabricated shear wall 2, a middle prefabricated shear wall 3, a side floor 4, Middle floor 5.

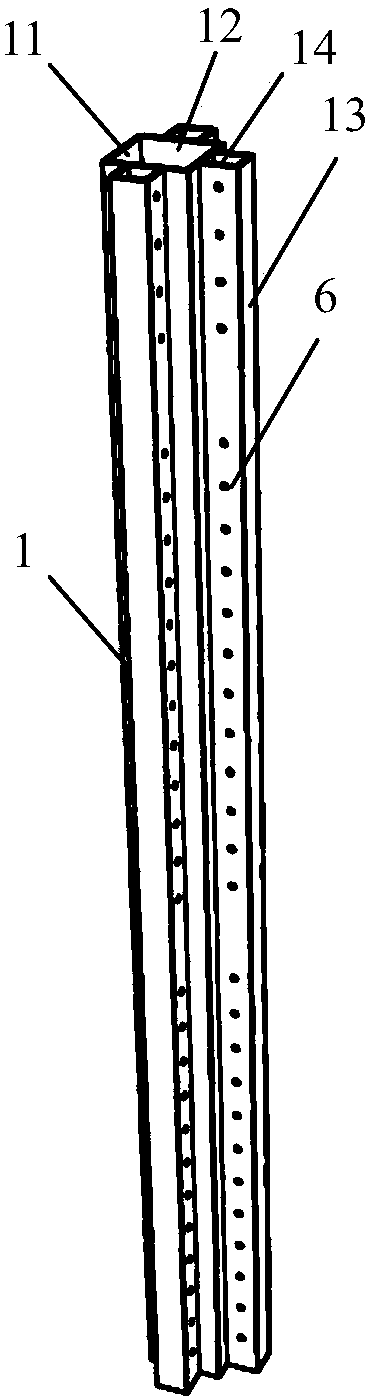

[0028] The steel tube concrete column 1 includes a steel tube column 11 , a concrete column 12 , a column wall connecting section steel 13 and a column wall connecting section steel inner concrete 14 . A plurality of bolt holes 6 are arranged on both sides of the column wall connecting section steel 13 .

[0029] The side prefabricated shear wall 2 includes a reinforced concrete shear wall 21 and prefabricated section steel 22 for the side prefabricated shear wall. Wherein the side prefabricated shear wall pre-embedded section steel 22 is pre-embedded around the reinforced concrete shear wall 21 . The prefabricated shear wall pre-embedded secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com