Patents

Literature

36results about How to "Reduce labor usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

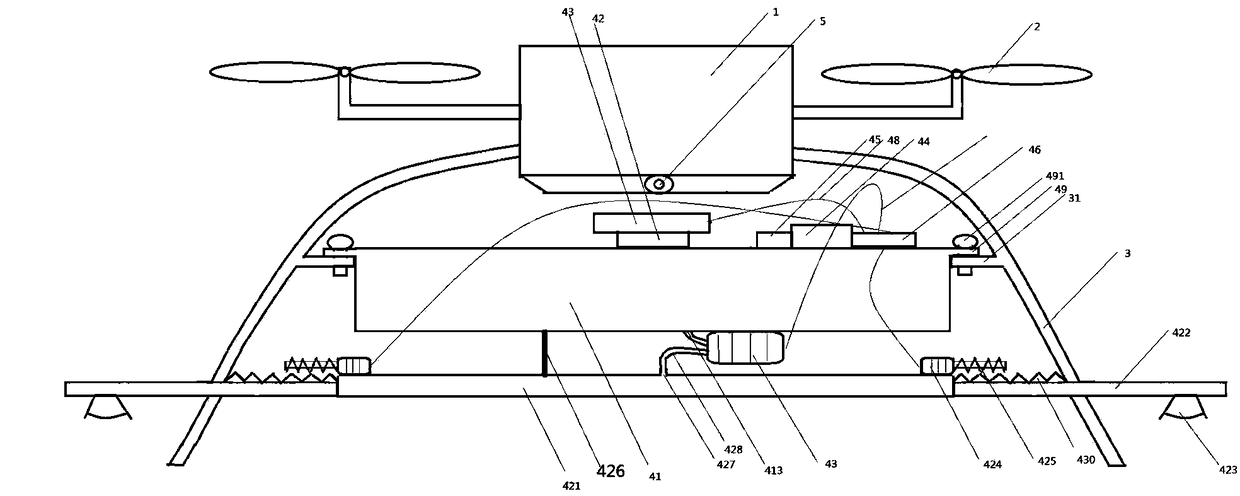

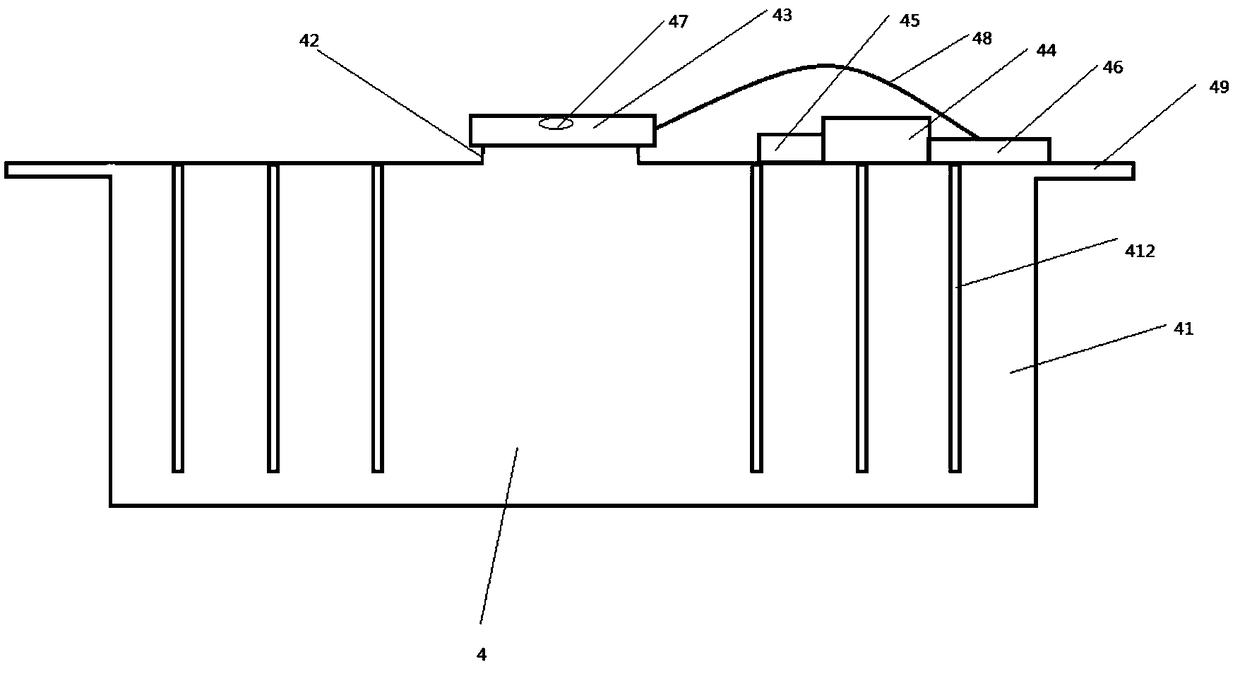

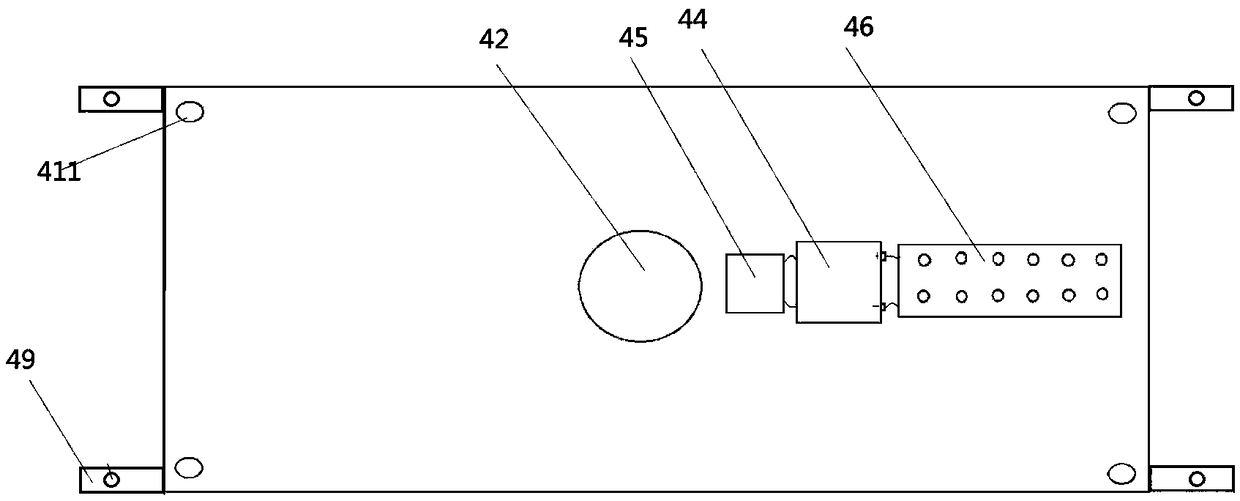

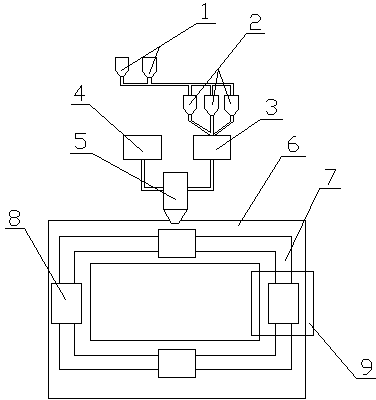

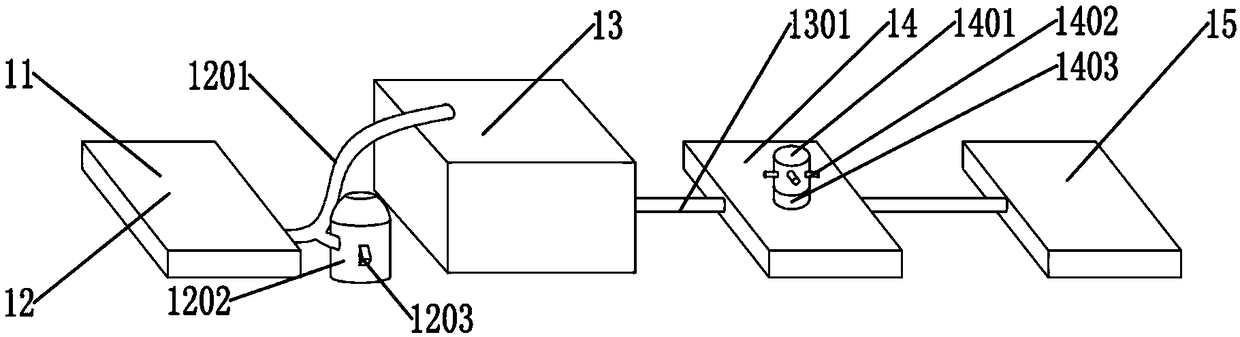

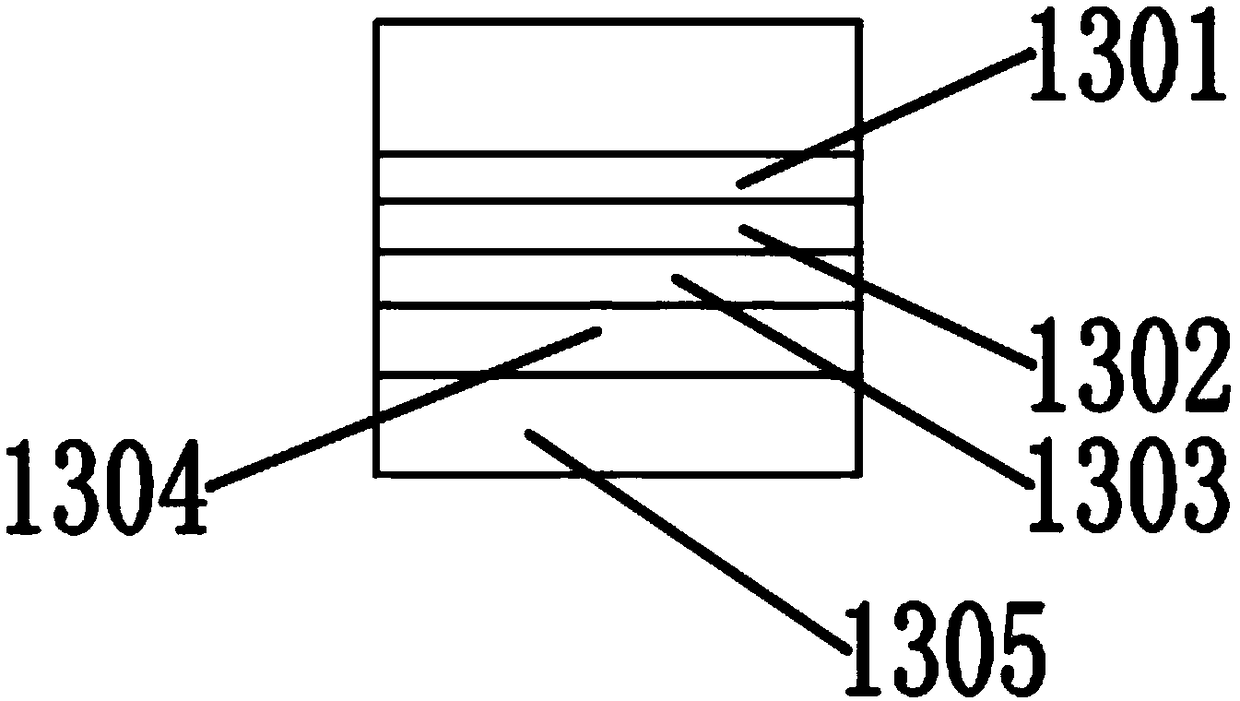

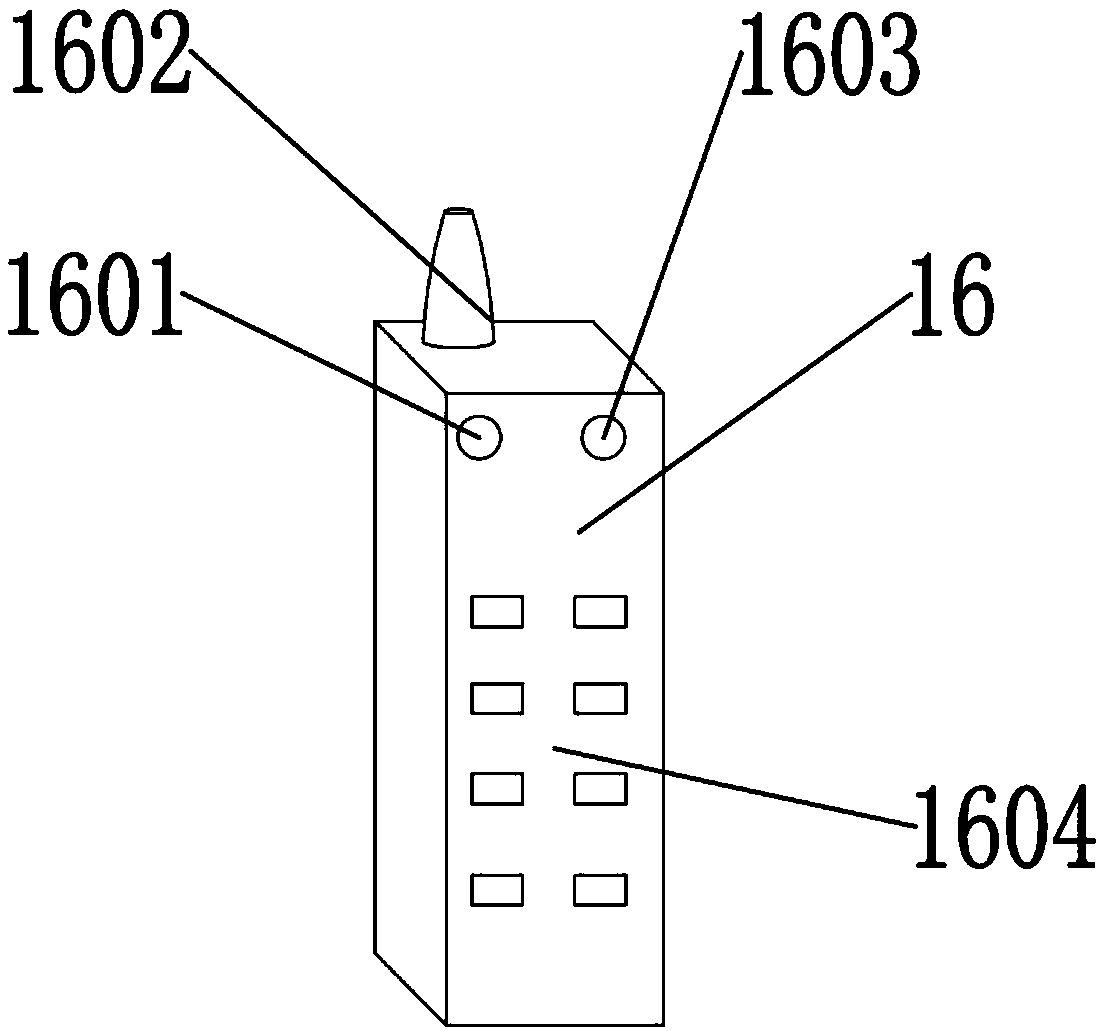

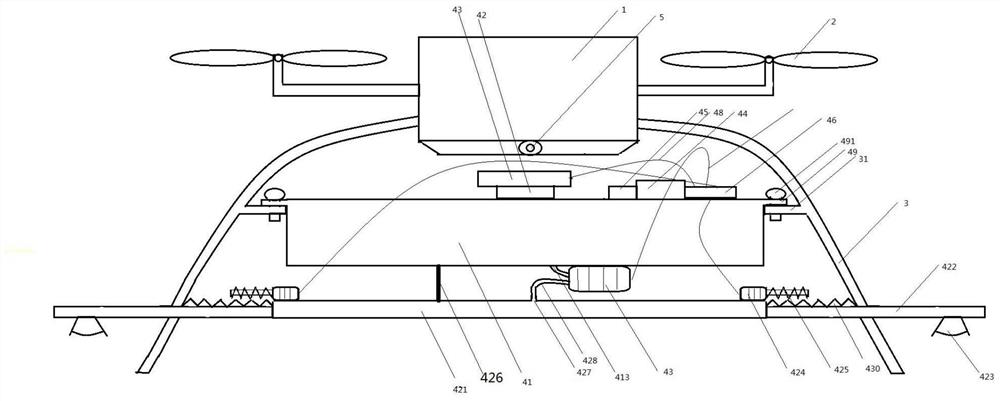

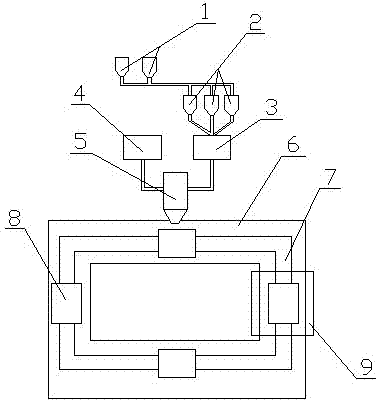

Autonomous flight pesticide spraying unmanned aerial vehicle controlled precisely

ActiveCN108791894AAvoid dangerReduce labor usageAircraft componentsPosition/course control in three dimensionsPesticideExpansion joint

The invention provides an autonomous flight pesticide spraying unmanned aerial vehicle controlled precisely and a plant protection method using the autonomous flight pesticide spraying unmanned aerialvehicle controlled precisely. The autonomous flight pesticide spraying unmanned aerial vehicle comprises a fuselage, four or more rotor wings, an undercarriage, a mounting plate, an externally-hung pesticide box, a control device and a power source. The control device of the unmanned aerial vehicle collects environment data in real time, and comprehensive dynamic adjustment is conducted accordingto the environment data, specifically, the expansion amount of expansion joints is adjusted according to the deviation angle, a wind speed empirical value is added on the basis of the expansion amount, and thus spraying precision is improved; and PWM is adjusted according to the wind speed, the spraying amount is increased, and the unmanned aerial vehicle plans a path automatically and makes a return flight automatically under the situation that the wind speed is too large. According to the autonomous flight pesticide spraying unmanned aerial vehicle controlled precisely, the spraying precision can be effectively improved, and the using safety of the unmanned aerial vehicle is improved.

Owner:NANTONG VOCATIONAL COLLEGE

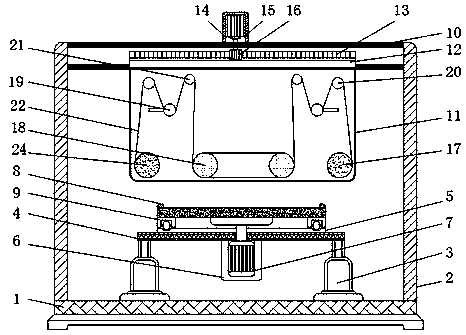

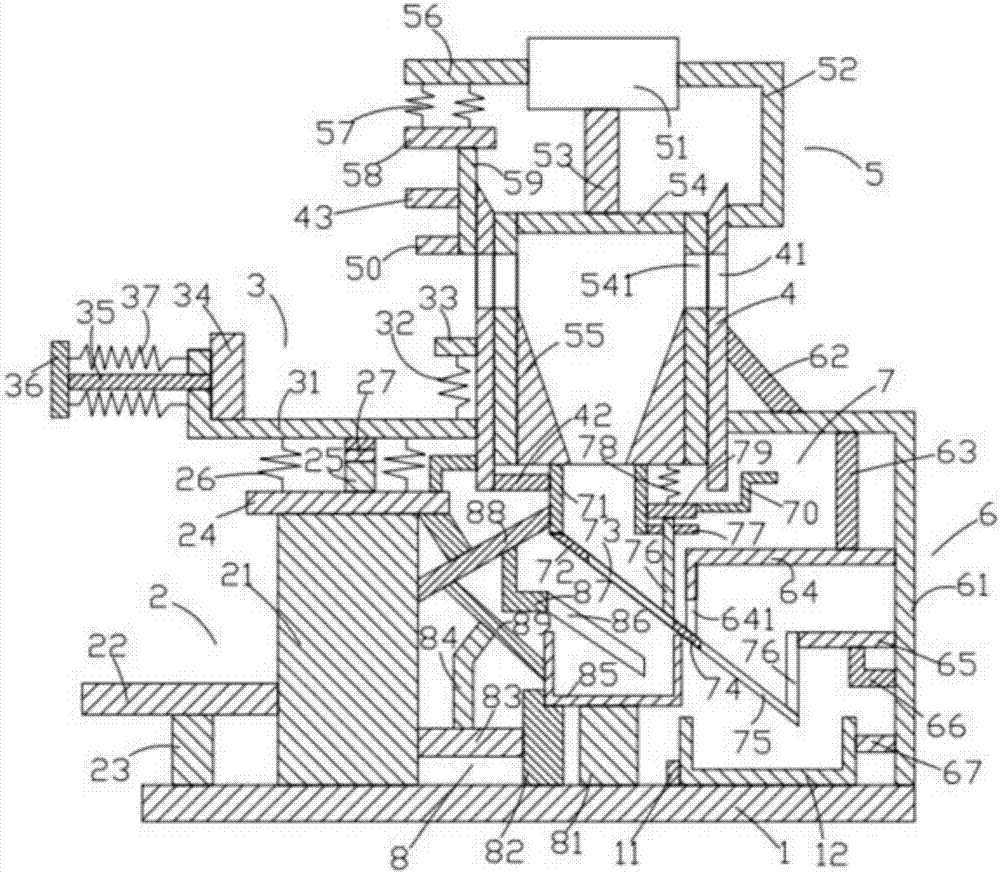

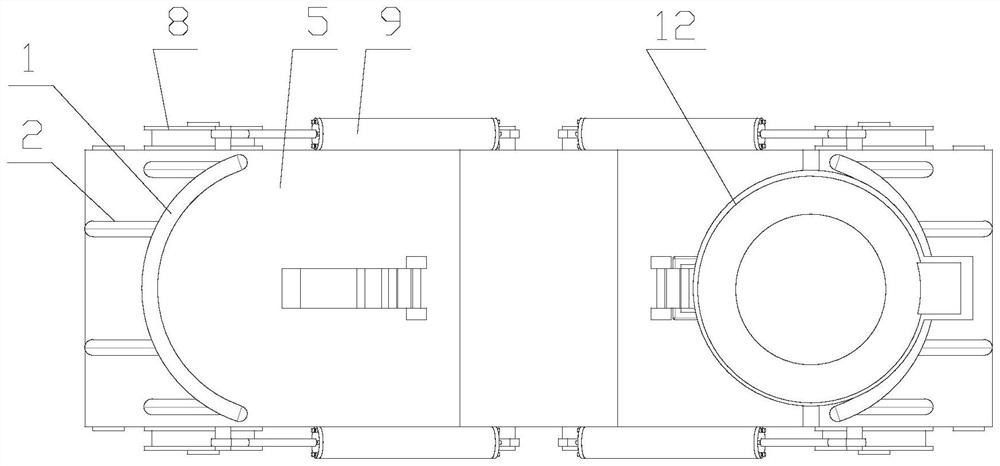

Biological feed manufacturing system

InactiveCN103653213APromote circulationPrevent degradation of fermentation qualityFeeding-stuffBiotechnologyFirst-order reaction

The invention discloses a biological feed manufacturing system which comprises first-order reaction kettles, second-order reaction kettles, a strain fermentation culture tank and a mixer. The first-order reaction kettles and the second-order reaction kettles are used for breeding various strains in a fermentation manner, the various strains are mixed and allowed to ferment by the aid of the strain fermentation culture tank, materials are inoculated with mixed strains and are mixed with one another by the mixer, inoculated and mixed materials in the mixer are loaded on a fermentation vehicle, ferment in an annular fermentation kiln, and completely ferment when the fermentation vehicle moves to a discharging platform, the materials loaded on the fermentation vehicle are unloaded, and the fermented materials can be bagged. The biological feed manufacturing system has the advantages that the inoculated materials which are mixed with one another by the mixer and are loaded on the fermentation vehicle are collected at a certain position of the annular fermentation kiln, then the fermentation vehicle slowly runs to the discharging platform along a conveying rail, the materials completely ferment in the procedure, accordingly, a fermentation procedure and a conveying procedure are combined with each other, and the manufacturing efficiency can be greatly improved; the fermentation vehicle in a unique design and the discharging platform are matched with each other, so that the materials can be automatically unloaded, the work efficiency can be greatly improved, and the degree of dependence on labor can be reduced.

Owner:河南宏翔生物科技有限公司

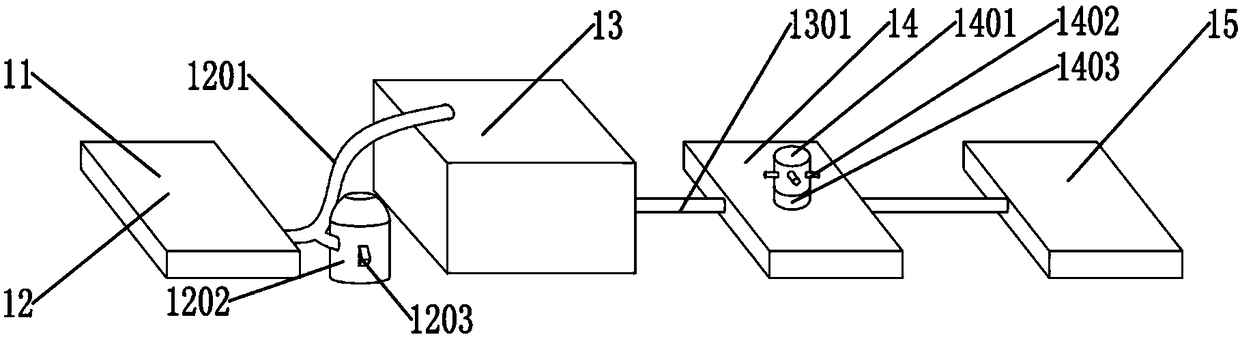

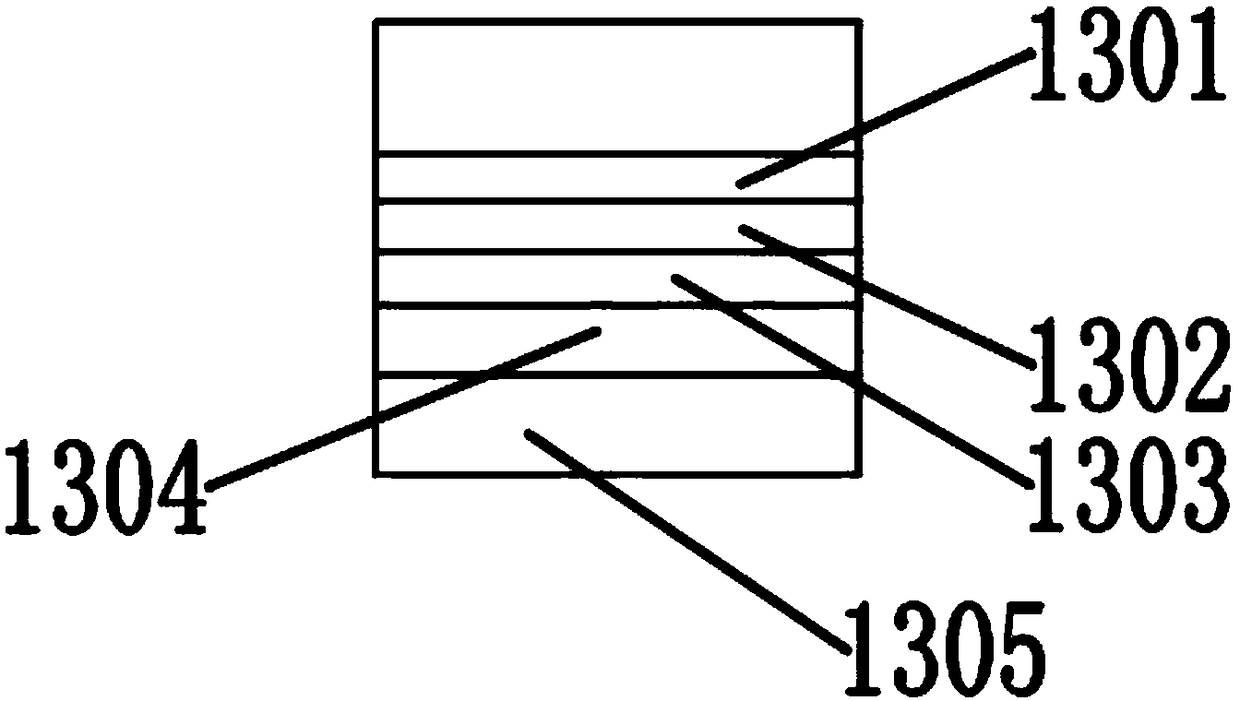

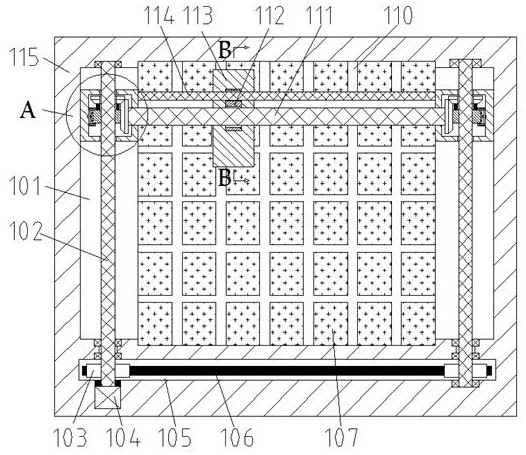

Multi-wire cutting machine with high using efficiency

InactiveCN109318386AImprove efficiencyImprove the problem that only up and down can be moved and cutWorking accessoriesGrinding machinesElectric machineWire cutting

The invention relates to the technical field of multi-wire cutting machines, and discloses a multi-wire cutting machine with high using efficiency. The multi-wire cutting machine comprises a base. Themulti-wire cutting machine with high using efficiency is characterized in that a fixing plate, a first motor and a workbench are arranged, the height of the fixing plate is adjusted through stretching and retracting of stretchable rods so that a product placed on the workbench can move up and down, then the product on the workbench can undergo wire cutting conveniently, the first motor is arranged at the bottom of the fixing plate so that the first motor can drive the workbench at the top to rotate, the product placed on the workbench can rotate, a rollers and matching blocks are arranged atthe bottom of the workbench so that the workbench can stably rotate at the top of the fixing plate, then the product can be cut more stably, the problem that a traditional multi-wire cutting machine can be only used for cutting in an up-down moving mode is solved, then the multi-wire cutting machine can achieve a more intelligent effect, the cut product can be cut more finely, and the effect of stable rotary cutting is achieved.

Owner:江苏科成电子有限公司

Treatment method for cleaning black-odor river

InactiveCN108249695ABest antivirus levelSimple structureWater aerationTreatment involving filtrationWastewaterSewage

The invention relates to a treatment system for cleaning a black-odor river. The system comprises a primary wastewater cleaning system, a secondary precipitating and biological treating device, a third precipitating and sterilizing and disinfecting device, an aerating and wastewater recycling device and a final cleaning device. According to the system, all parts coordinately work to quickly and effectively clean the black-odor river, so that the cleaning effect is good.

Owner:湖南道同消防工程有限公司

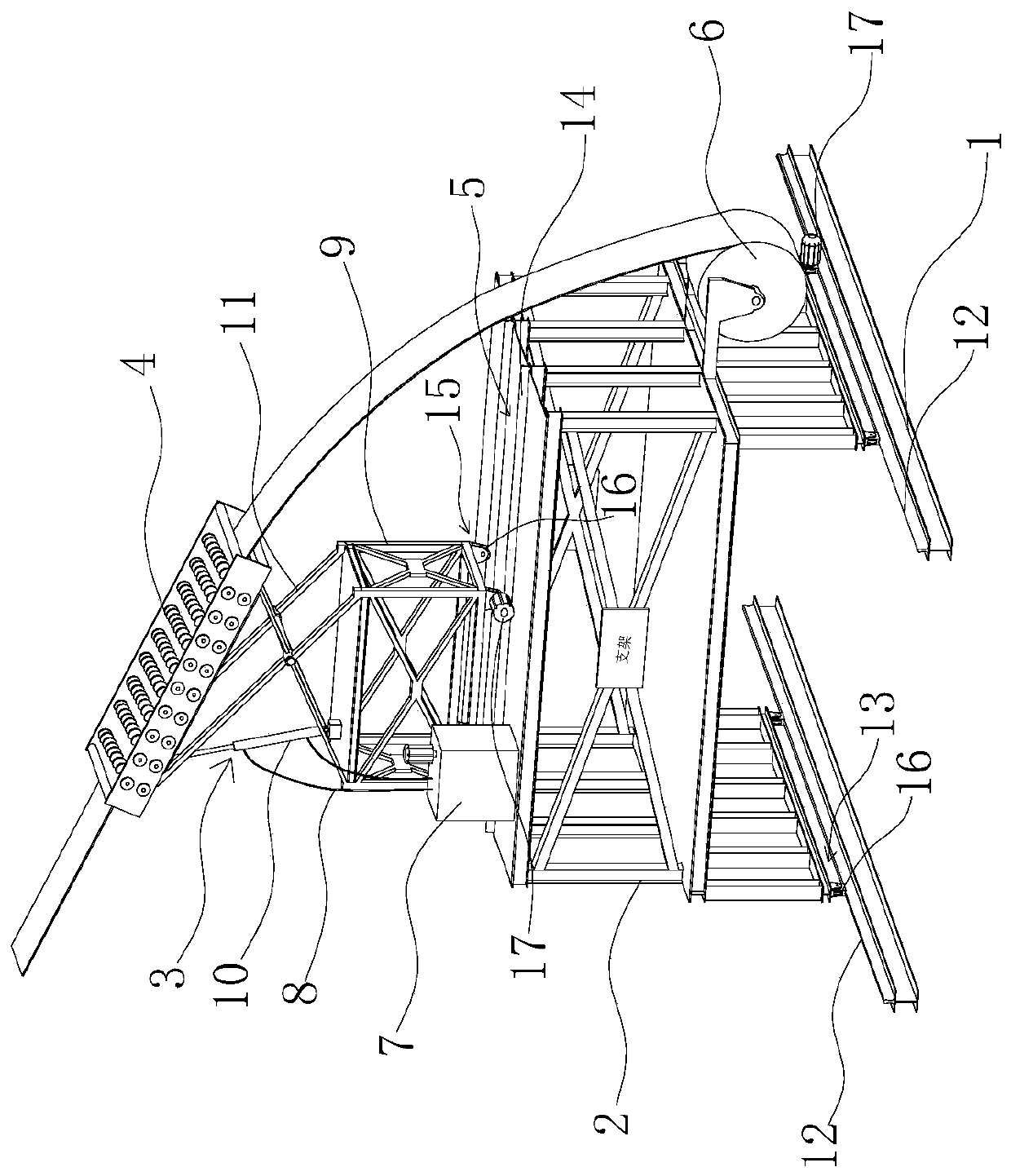

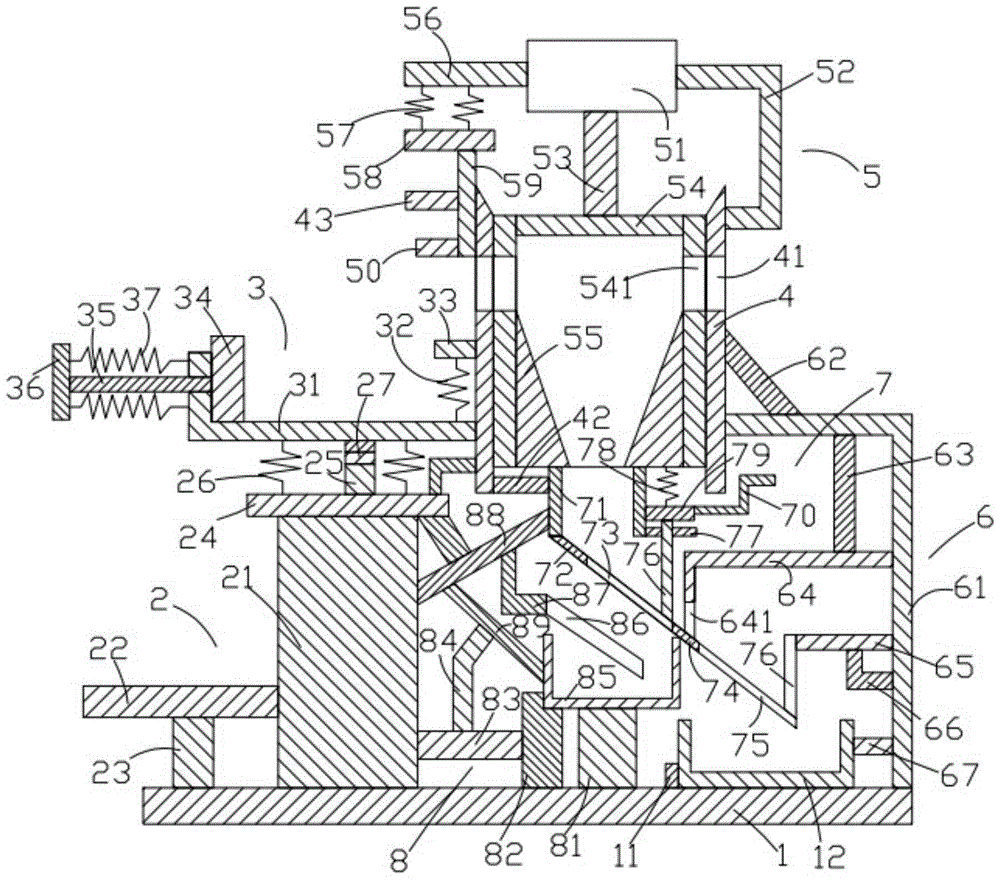

Sand screening device used for building construction

InactiveCN107511320ASimple structureEasy to useSievingGas current separationElectric machineryArchitectural engineering

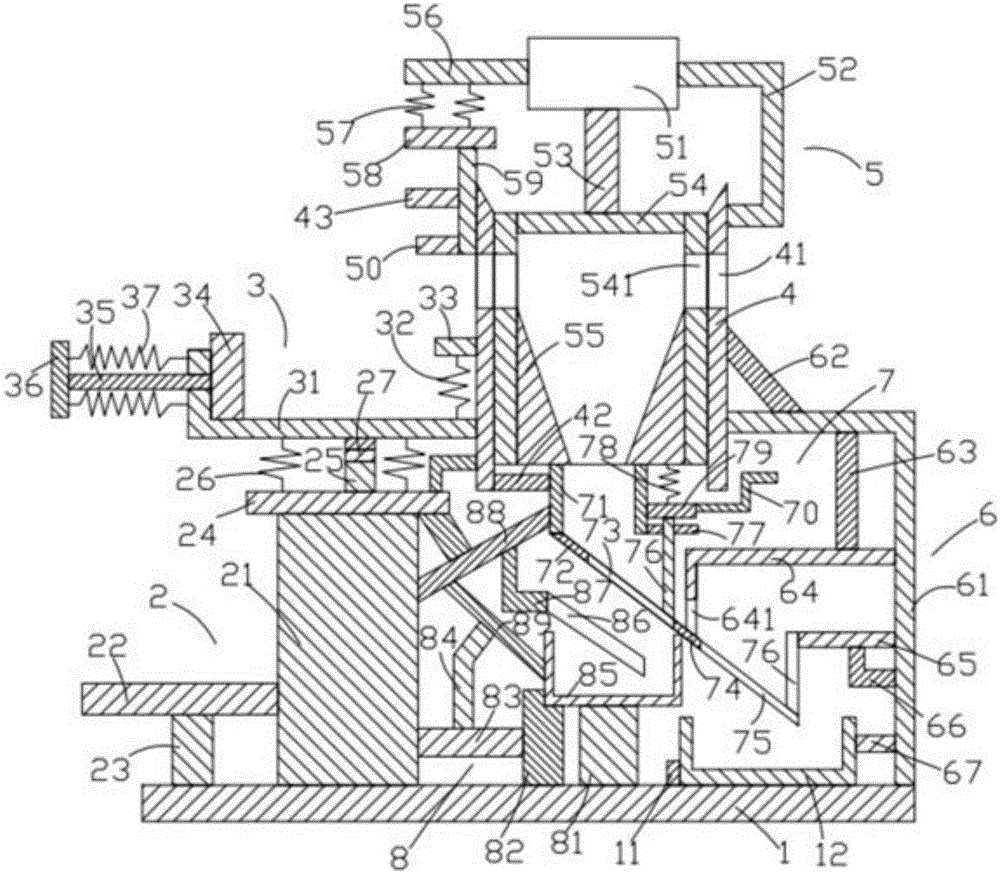

The invention relates to a sand screening device used for building construction. The sand screening device comprises a base plate, a support device, a discharging device, a frame body, a rotating device, a support frame device, a filtering device and a material collecting device, wherein a first fixing block and a first material collecting box are arranged on the base plate; the support device comprises a first support block, a pedal plate, a first support rod, a transverse plate, first springs, a second support block and a first magnet; the discharging device comprises a discharging frame, a second spring, a first jacking and propping block, a push block, a push rod, a vertical plate and third springs; a first through hole, a first transverse rod and a fixing rod are arranged on the frame body; the rotating device comprises a motor, a first support frame, a rotating shaft, a rotating frame, a concentrated ring, a second transverse rod, fourth springs, a third transverse rod, a first vertical rod and a fourth transverse rod; and the support frame device comprises a second support frame, a first oblique rod, a second vertical rod, a third support frame, a fifth transverse rod, a fourth support frame, a sixth transverse rod and a third filter net. The sand screening device used for building construction has the benefits as follows: sand needing to be screened can be fully screened, and the screening efficiency is high.

Owner:乌鲁木齐九品芝麻信息科技有限公司

Intelligent speed adjusting system and method for wine filling machine

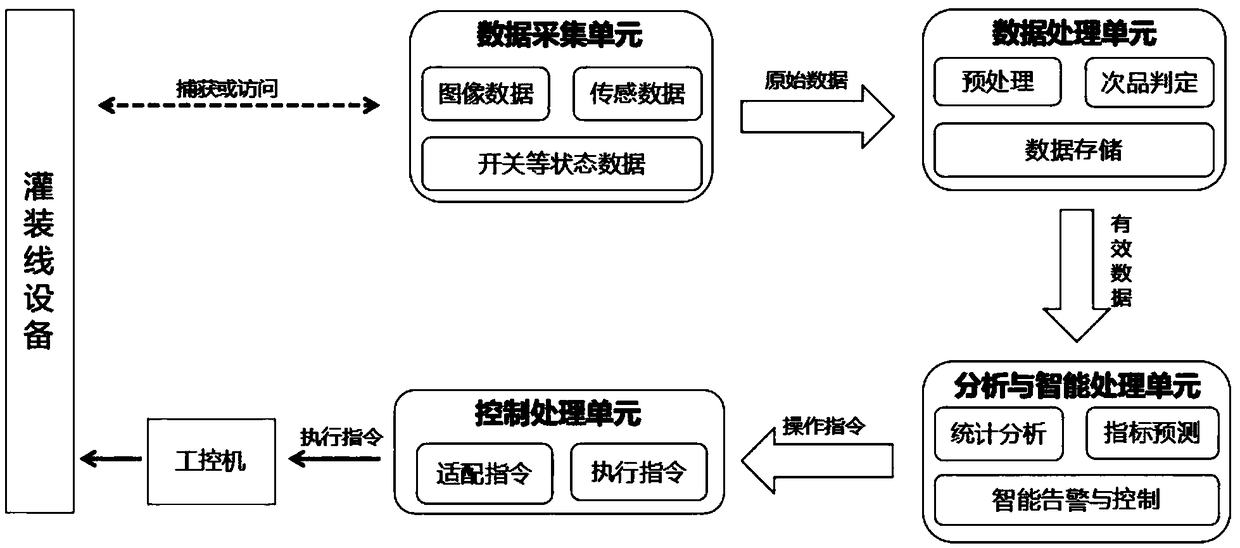

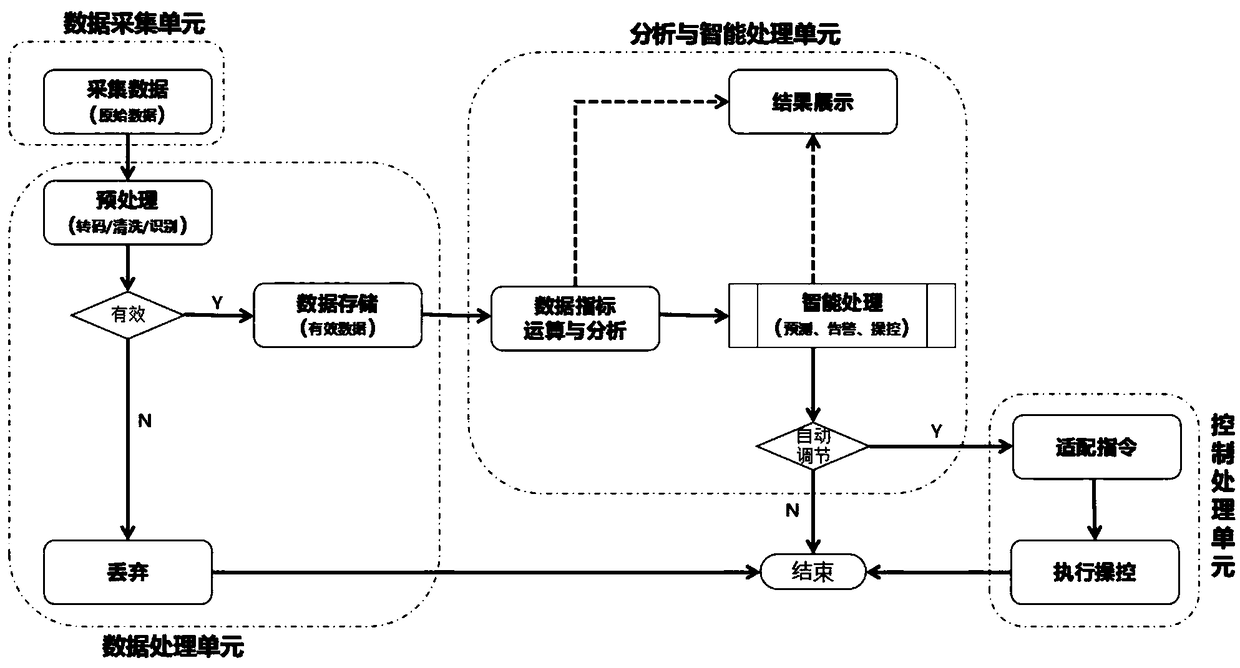

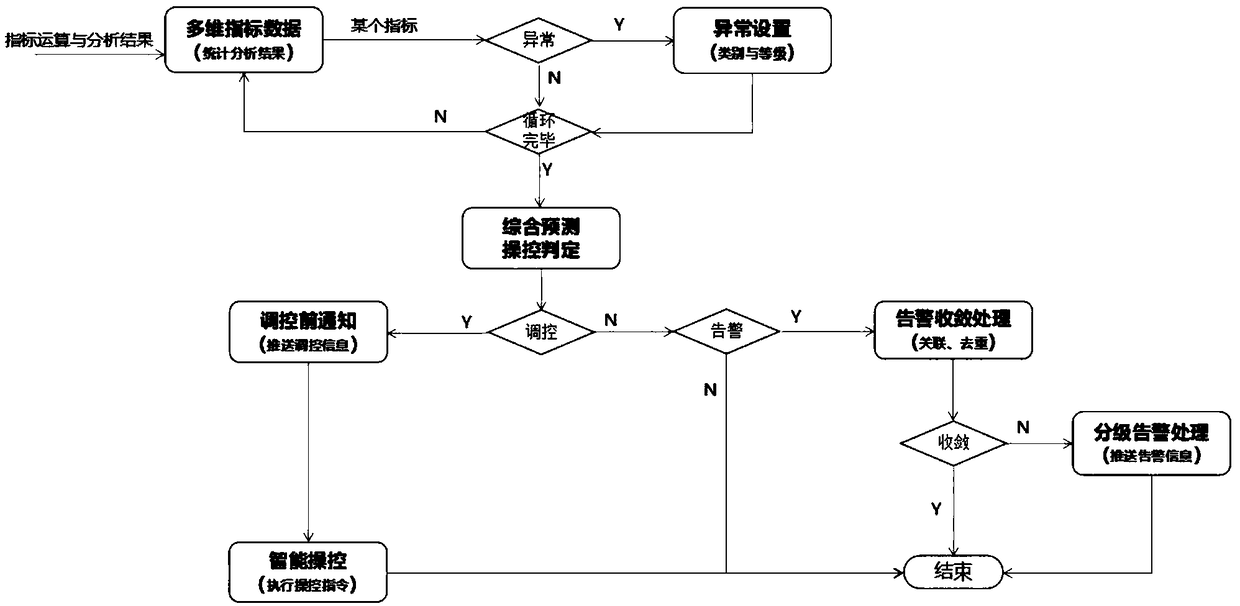

InactiveCN108803517ABest production efficiencyCurb exception costsProgramme total factory controlManagement toolOriginal data

The invention discloses an intelligent speed adjusting system and method for a wine filling machine. The system comprises a data acquisition module, a data processing module, an analysis and intelligent processing module and a control processing module. The data acquisition module is used for acquiring and collecting real-time operating state data of various types of equipment on a filling line and wine bottle image data to form original data. The data processing module is used for preprocessing the original data, recognizing and judging defective products, storing and outputting effective data. The analysis and intelligent processing module is used for effective data statistics and index data analysis, further judges production index abnormality or equipment abnormality and executes corresponding actions according to index analysis results. The control processing module sends execution instructions to an industrial personal computer to control the equipment on the filling line. By theintelligent speed adjusting system and method for the wine filling machine, the defective product rate and the labor rate under abnormal conditions can be effectively decreased, and an efficient management tool is provided for producers and managers of enterprises.

Owner:方汝松

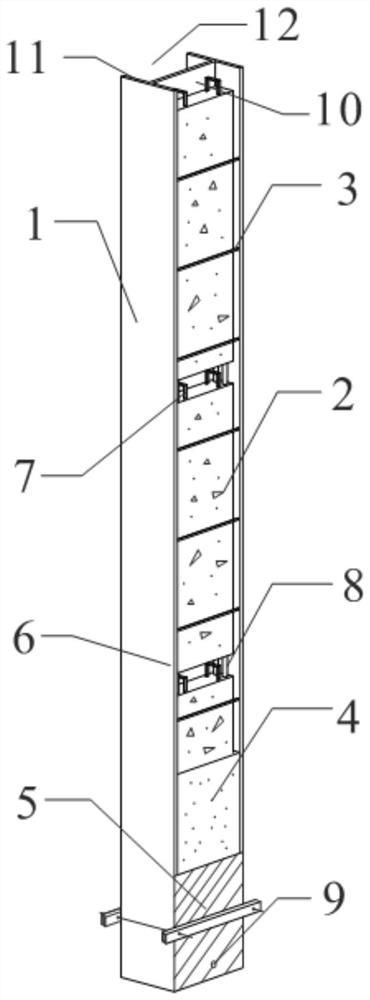

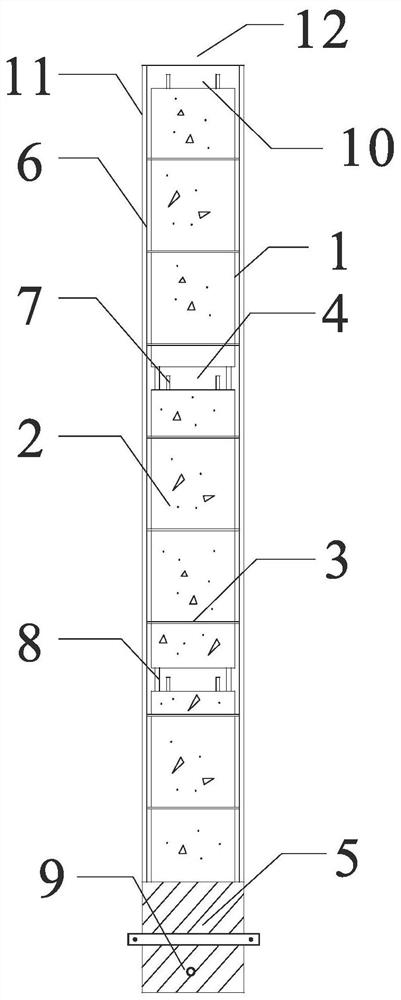

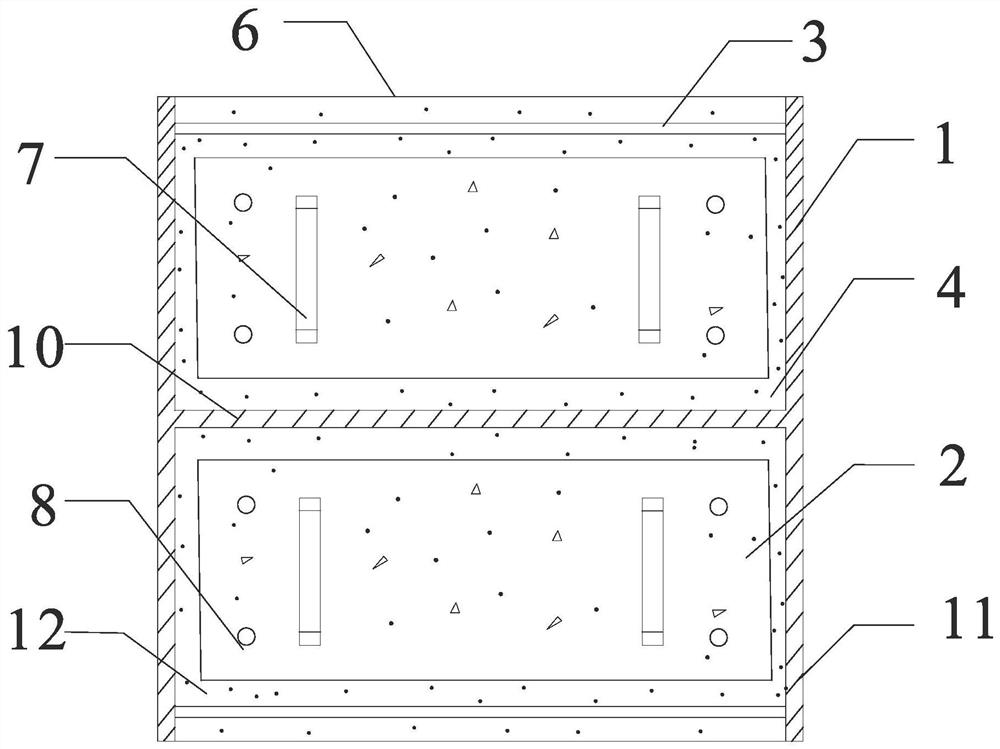

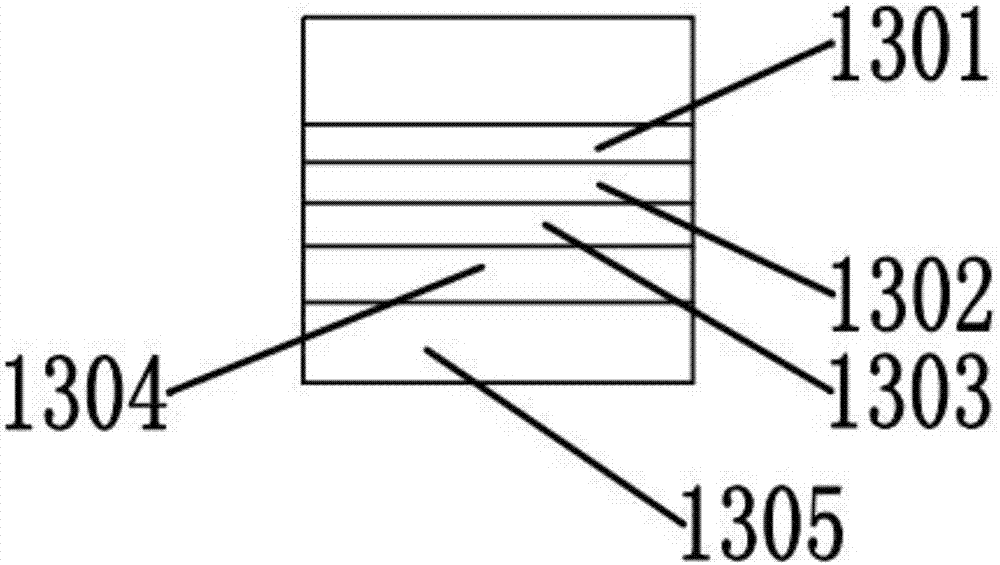

Partial prefabricated reinforcing structure of existing H-shaped steel column and construction process thereof

PendingCN111851861AImprove carrying capacityImprove the bearing capacity of axial pressureStrutsPillarsArchitectural engineeringSteel columns

The invention discloses a partial prefabricated reinforcing structure of an existing H-shaped steel column. The structure comprises the existing H-shaped steel column, prefabricated concrete sections,horizontal pull rods and a grouting material. The plurality of prefabricated concrete sections are stacked one by one in two semi-closed cavities defined by flanges and a web of the existing H-shapedsteel column; the horizontal pull rods are arranged in the longitudinal direction of the existing H-shaped steel column at a certain interval, and the two ends of the horizontal pull rods are respectively welded with the two flanges of the existing H-shaped steel column; a formwork is adopted to wrap the existing H-shaped steel column, and then the grouting material is filled with the gaps between the H-shaped steel column and the prefabricated concrete sections; and after the formwork is removed, partial prefabricated reinforcing columns are formed. The invention further discloses a construction process of the partial prefabricated reinforcing structure of the existing H-shaped steel column. The prefabricated concrete sections are convenient for industrial production and high in construction efficiency; and the grouting material can combine the prefabricated concrete sections and the existing H-shaped steel column into a whole, so that the bearing capacity of an original component isremarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

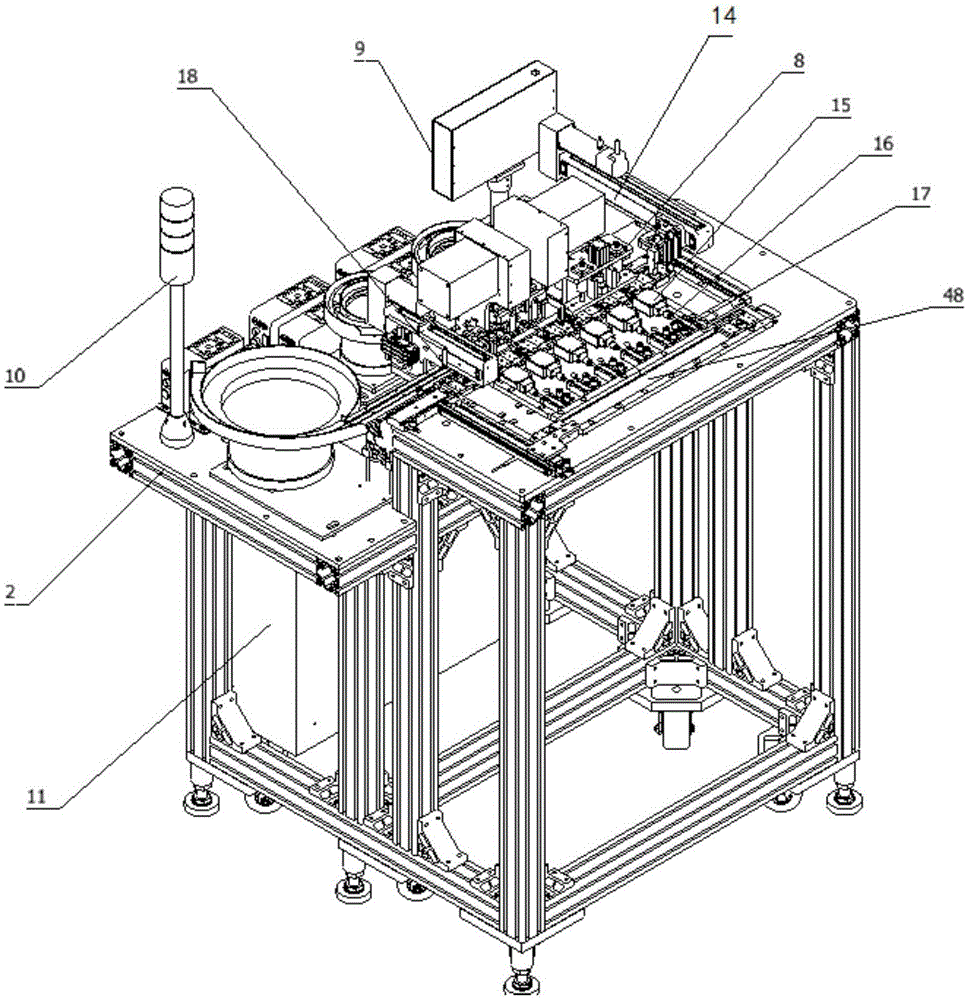

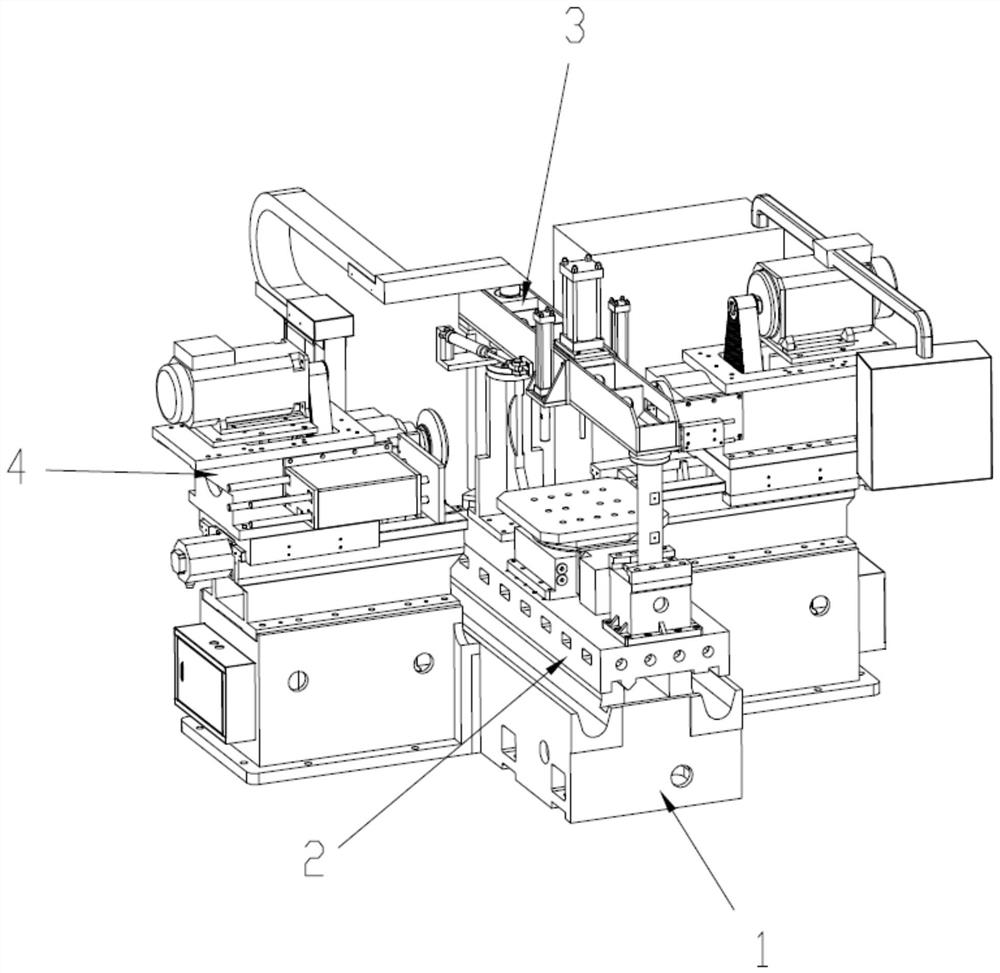

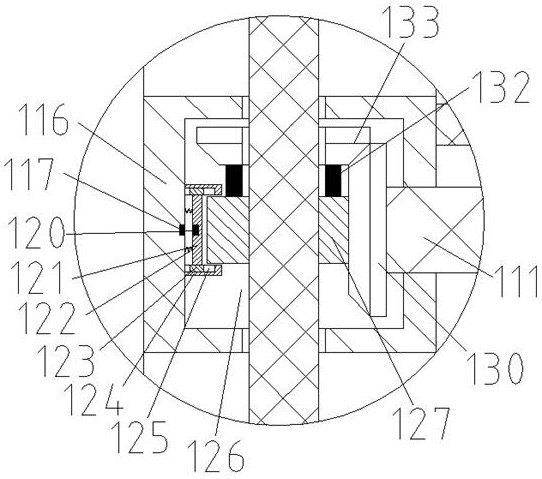

Automatic terminal insertion hinge device

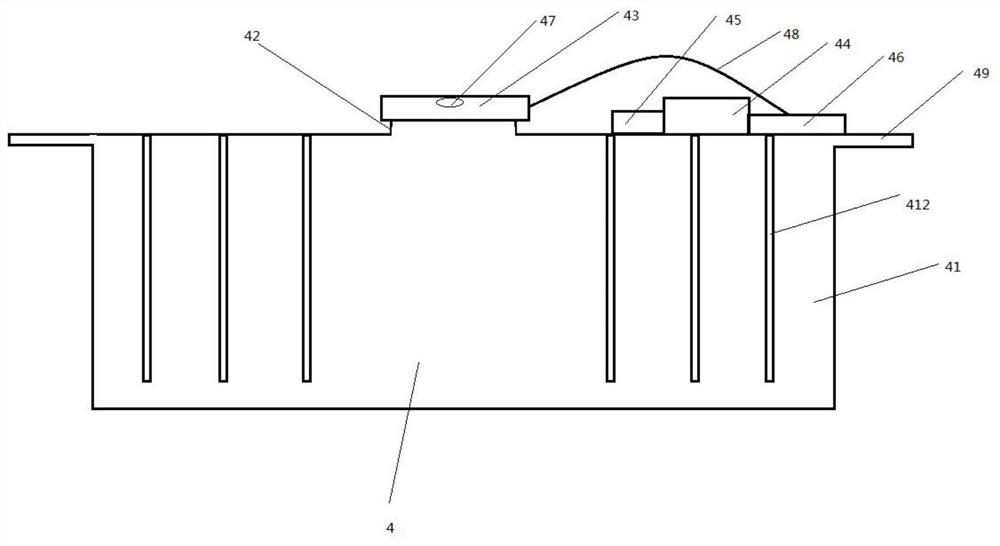

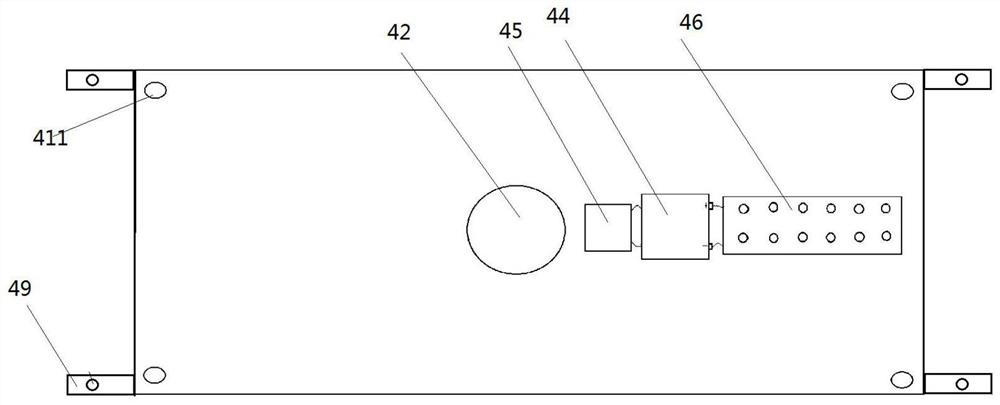

ActiveCN105428249AImprove integrityGuaranteed to workSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingRejection rateEngineering

The invention provides an automatic terminal insertion hinge device. The device comprises a workbench, a circulation carrying system fixed on the workbench, six stations arranged on the circulation carrying system, a station positioning compression mechanism arranged on each station, a workpiece carrying mechanism used for carrying a workpiece to a first station, a left terminal inserting mechanism used for inserting a terminal into the left end of the workpiece at a second station, a right terminal inserting mechanism used for inserting the terminal into the right end of the workpiece at a third station, a pressing hinge mechanism positioned above the fourth station to the six station, a lifting mechanism used for lifting the pressing hinge mechanism, and a workpiece compression mechanism positioned above the pressing hinge mechanism and used for compressing the workpiece. According to the device, the usage quantity of labor force can be effectively reduced, the productivity is increased, the qualified rate of product is guaranteed, and the rejection rate is greatly reduced.

Owner:龙口市埃迪克自动化设备有限公司

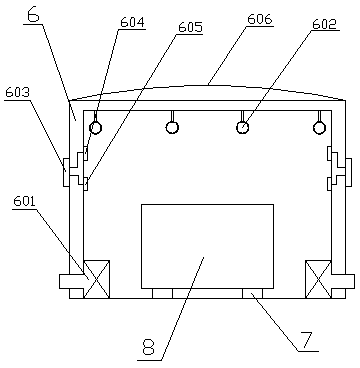

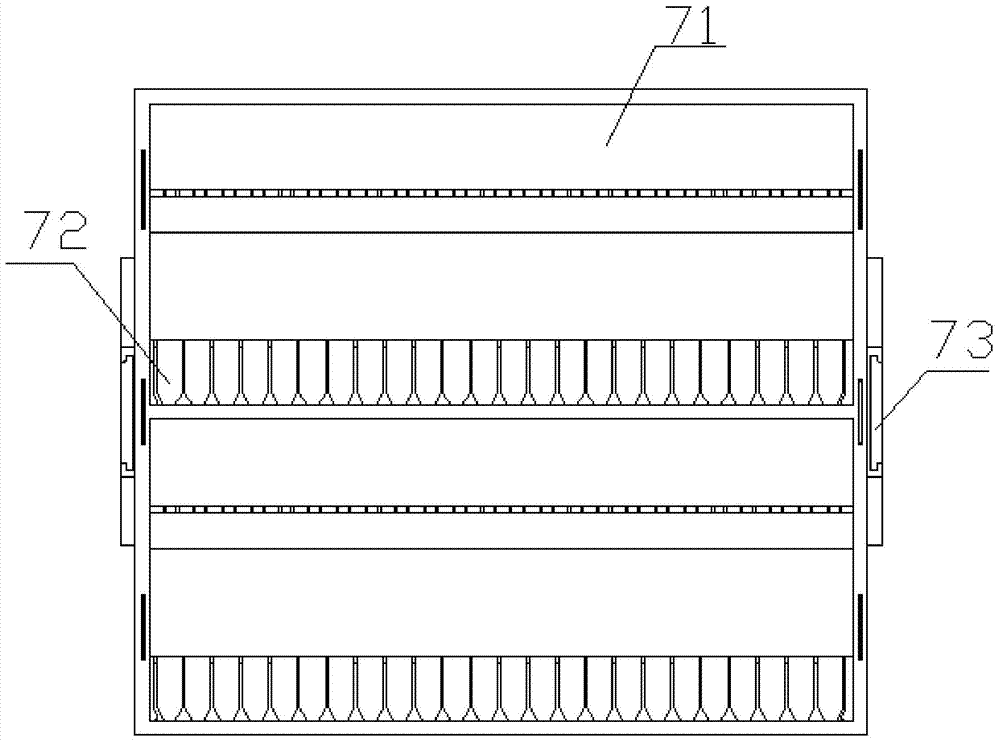

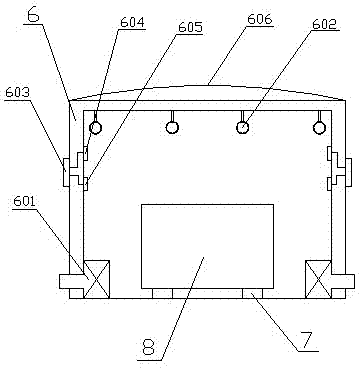

Deck type color plate molding press

PendingCN110884193AReduce loss rateGuaranteed forming qualityMetal-working feeding devicesPositioning devicesHydraulic cylinderBreakage rate

The invention belongs to the field of constructional engineering construction and provides a deck type color plate molding press. The deck type color plate molding press comprises a longitudinal railgroup, a first rack, a swing block mechanism and a plate pressing machine. The first rack is arranged on the longitudinal track group, the first rack is movably connected with the longitudinal rail set, a transverse rail set, a color steel coil hanging frame and a hydraulic station are installed on the first rack, a second rack is installed on the transverse rail set, the transverse rail set is movably connected with the second rack, and the swing block mechanism is provided with a jacking hydraulic cylinder. Compared with the prior art, the deck type color plate molding press has the advantages that the equipment can longitudinally move, the continuous construction of the equipment is maintained, the second rack transversely moves on a second sliding groove, the swing block mechanism canadjust the inclination angle of the plate pressing machine, the construction requirements of different positions are met, the breakage rate of color plates is reduced, the forming quality of the colorplates is guaranteed, the manual use rate is reduced, the construction machine team and labor cost are greatly saved, and the safety of personnel during construction is guaranteed.

Owner:浙江二十冶建设有限公司 +1

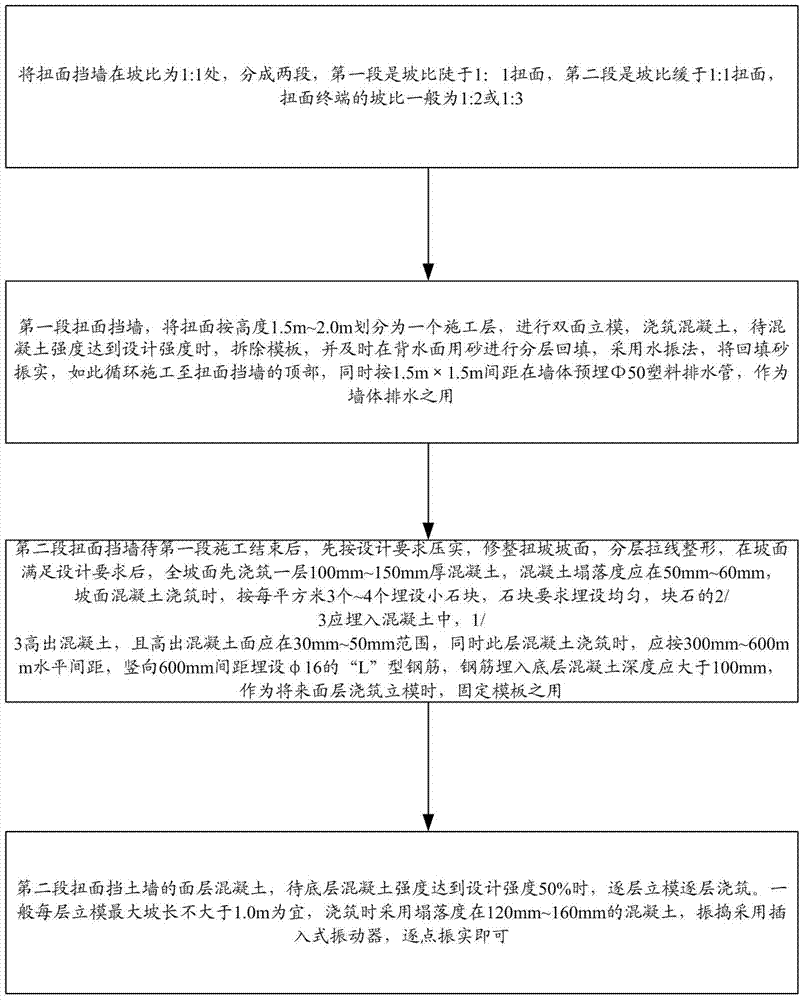

Construction method of plain concrete twisted face retaining wall

ActiveCN103882830AReduce construction costsSolve the problems of high construction cost and complicated operationCoastlines protectionSlope ratioRetaining wall

The invention discloses a construction method of a plain concrete twisted face retaining wall. According to the construction method, a twisted face is constructed in a segmented and layered mode according to difference of slope ratios; when layered casting is carried out and a die is removed in the first segment, sand is refilled in time, and the twisted face is not damaged by tension; in the second segment, the concrete of the slope is constructed according to a two-layer casting method. The method is simple, operation is easy, high-quality rock blocks are not used, neither excellent stone-laying workers nor M10 mortar is required, construction cost of the plain concrete twisted face retaining wall is lowered greatly, manpower is reduced, and the twisted face is protected against damage caused by tension.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

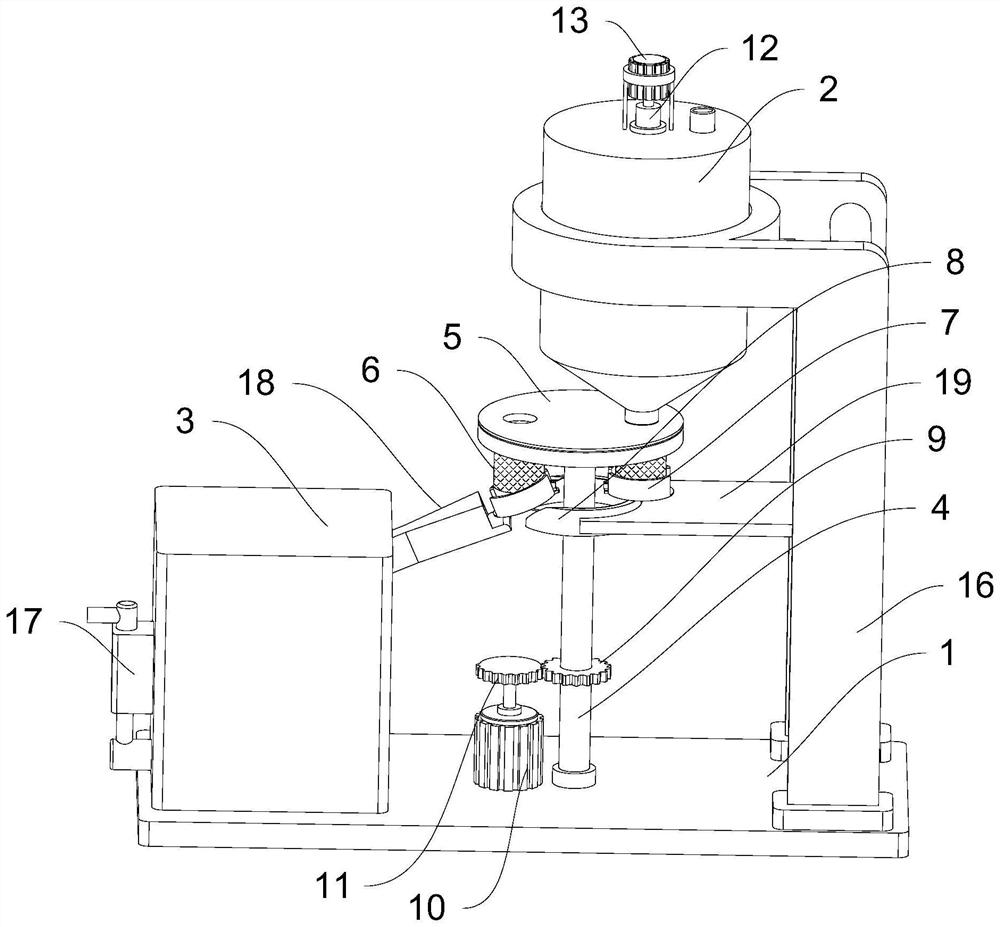

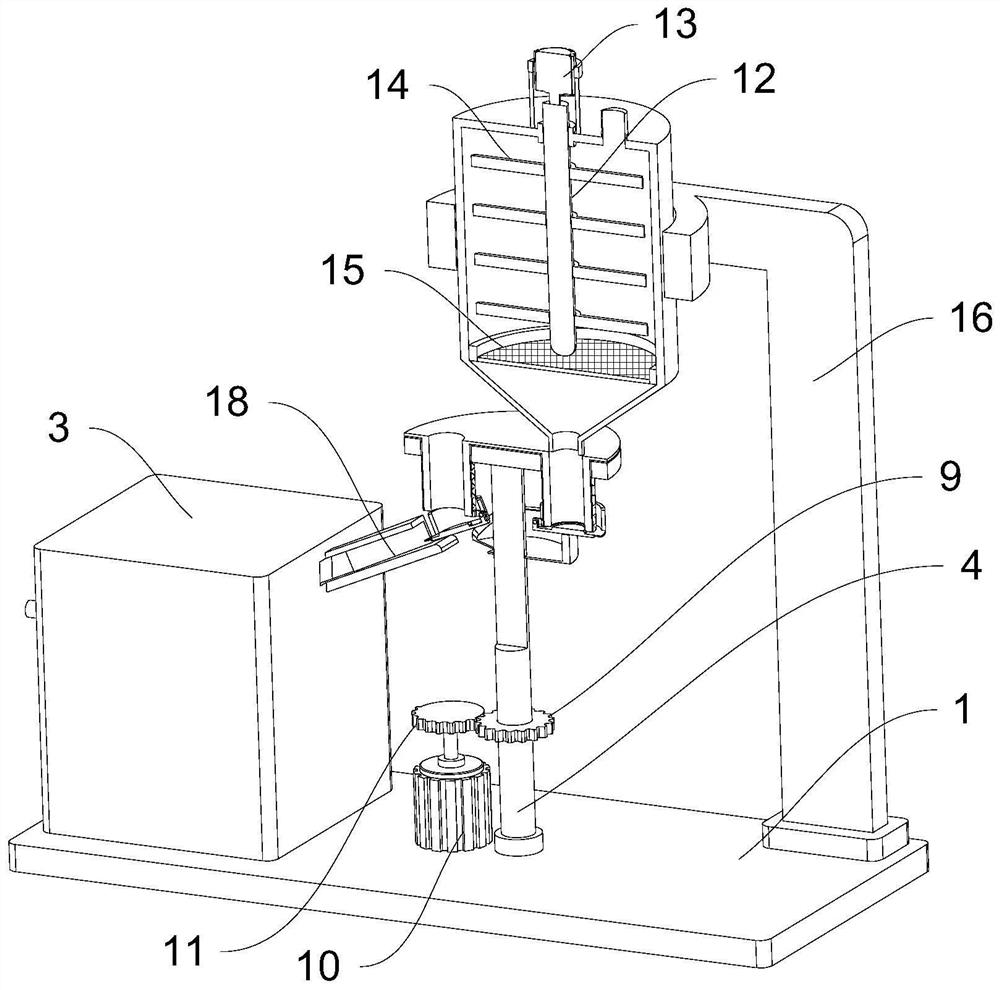

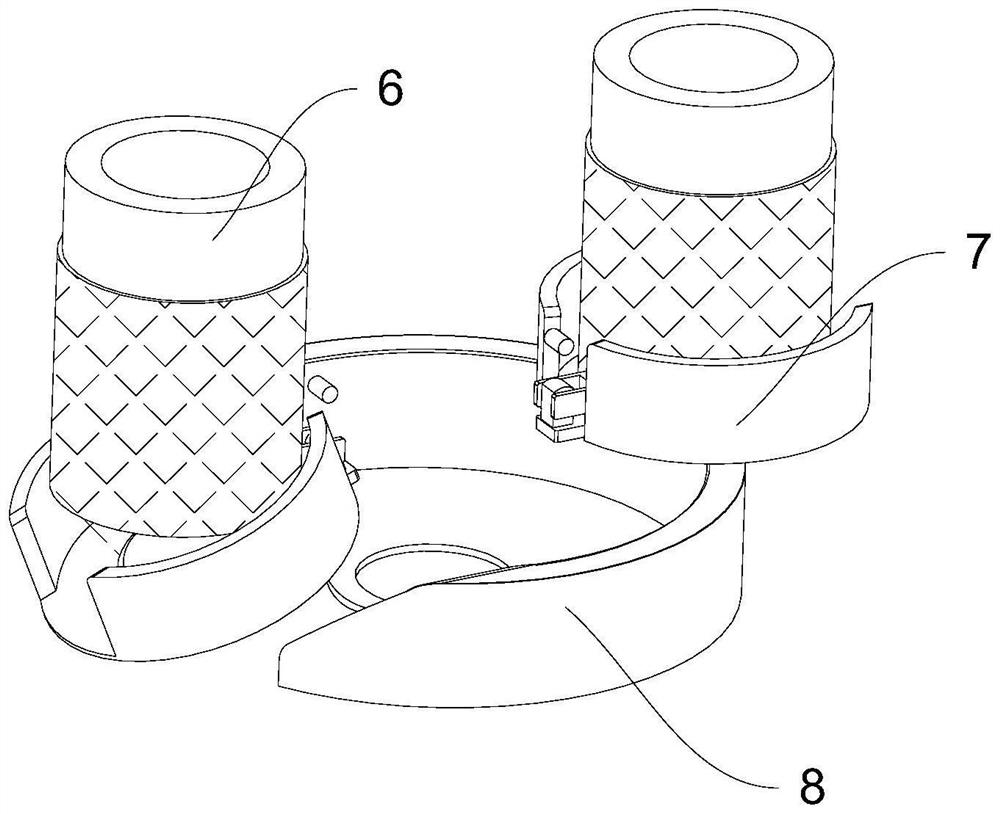

Integrated equipment for processing nano calcium carbonate of polyurethane adhesive

The integrated equipment comprises a base, a drying device and a grinding device are arranged above the base, a stand column is rotationally connected to the side, close to the grinding device, of the top of the base, and a rotating disc is fixedly connected to the top of the stand column; two symmetrically-distributed material collecting barrels are arranged at the bottom of the rotary disc, a protrusion is fixedly connected to one side of the bottom of each material collecting barrel, a material blocking cover matched with the material collecting barrels is arranged at the ends, away from the rotary disc, of the material collecting barrels, and the material blocking covers are rotationally connected with the protrusions. According to the nano calcium carbonate raw material drying device, through mutual cooperation of the arranged shaft rod, a second motor, a stirring piece and a filter screen, the drying efficiency can be effectively improved, the problem that a nano calcium carbonate raw material is agglomerated in the drying process is solved through the arranged stirring piece, and the arranged filter screen can effectively prevent the agglomerated nano calcium carbonate raw material from entering and exiting the material collecting barrel; and the discharging quality of the dried raw materials is ensured.

Owner:FUJIAN HONGFENG NANO TECH

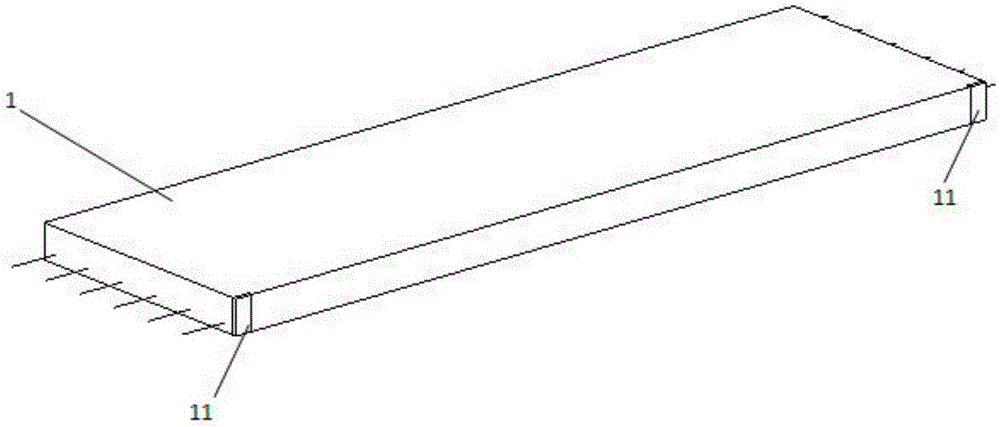

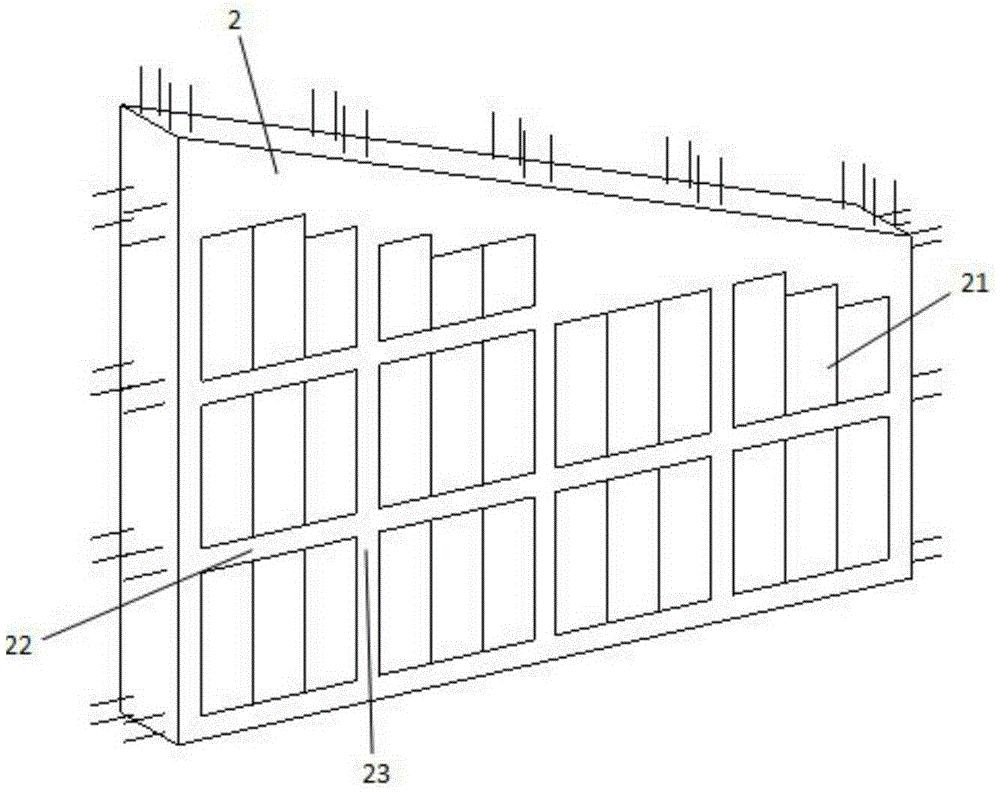

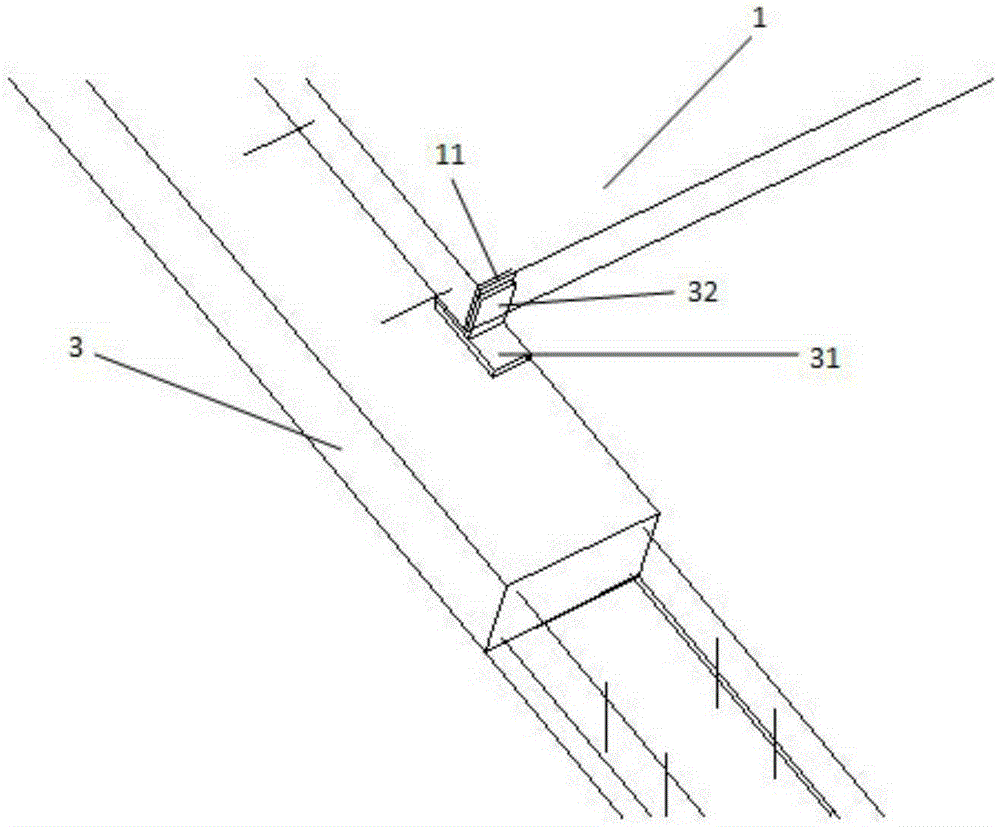

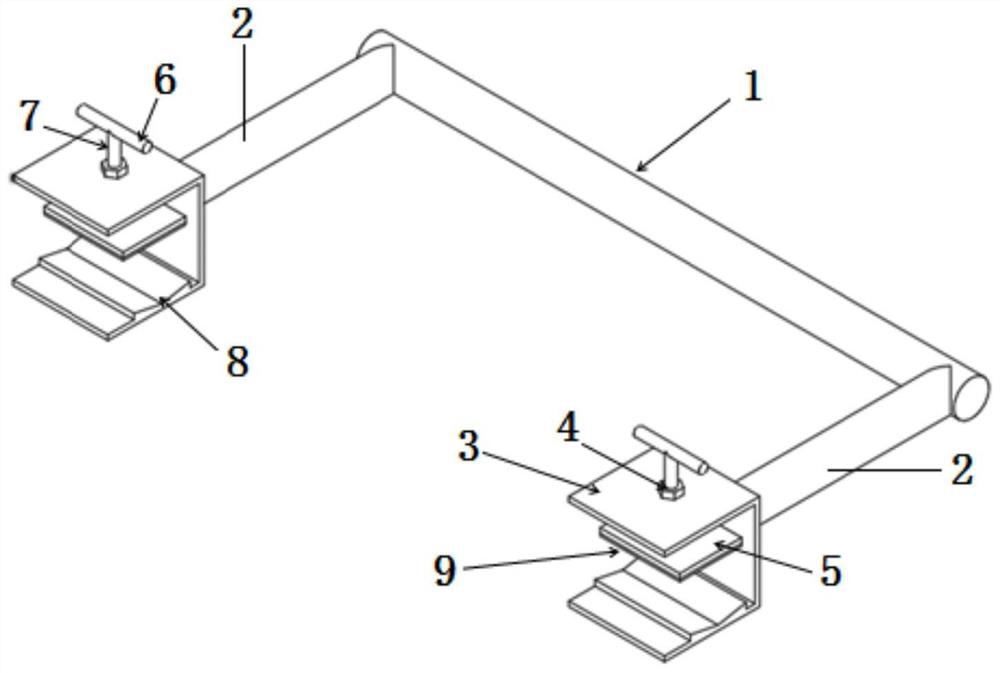

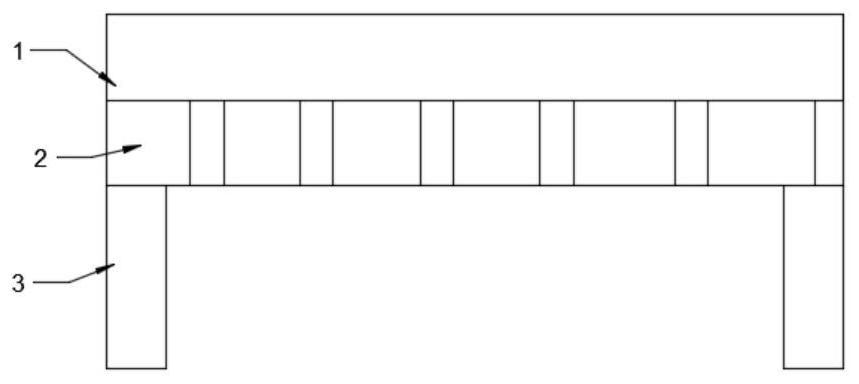

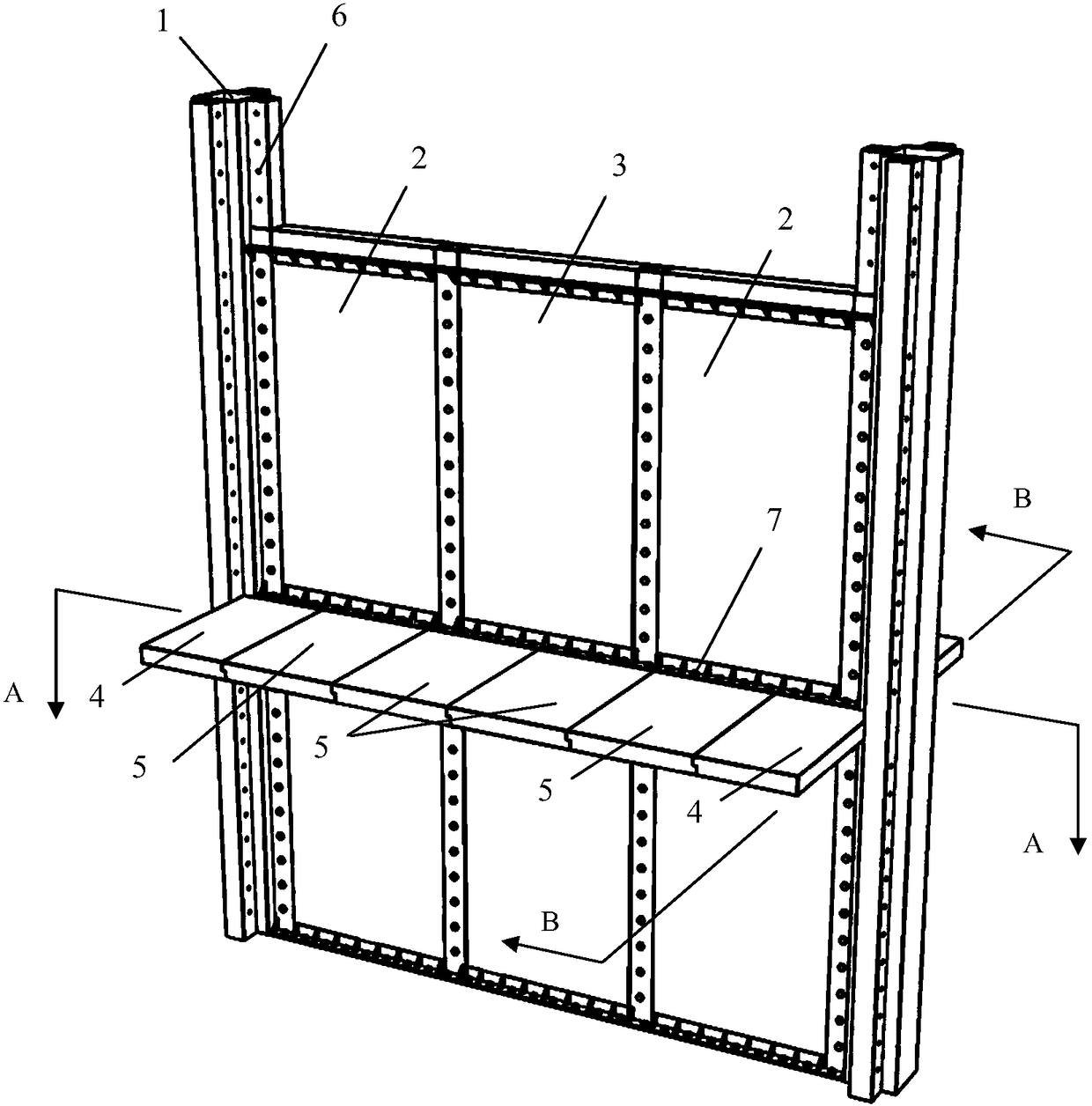

Quick assembled type sloping roof based on assembled type composite wall structural system and construction method of quick assembled type sloping roof

ActiveCN105401681AReduce labor usageLabor use precisionBuilding roofsStructural systemAgricultural engineering

The invention relates to a quick assembled type sloping roof based on an assembled type composite wall structural system and a construction method of the quick assembled type sloping roof. The sloping roof comprises a prefabricated sloping roof board and a prefabricated assembled type composite ridge wall board, wherein angle steel I is pre-buried on the lower surface of the prefabricated sloping roof board, and a hidden girder is arranged at the upper part of the prefabricated assembled type composite ridge wall board; a welding board is pre-buried in the top surface of the hidden girder, and angle steel II is welded to the welding board; the angle steel I and the angle steel II are welded, so that the connection of the hidden girder and the prefabricated sloping roof board is realized; concrete is poured to the hidden girder, so that the connection of the hidden girder and the prefabricated assembled type composite ridge wall board is realized. The construction method of the quick assembled type sloping roof comprises the following steps of preparing the prefabricated sloping roof board, preparing the prefabricated assembled type composite ridge wall board and the assembly of prefabricated components. The quick assembled type sloping roof is reasonable in design, convenient to construct and low in investment cost, and the problems existing in the construction process of a conventional cast-in-place sloping roof are solved. The industrialized production is realized, the mechanized construction is realized, and resources are saved. The quick assembled type sloping roof is environment-friendly and conforms to developing direction of housing industrialization at present.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Purification treatment system for black-colored and odorous rivers

InactiveCN108164089ASimple structureEasy to operateWater treatment parameter controlSpecific water treatment objectivesWastewaterSewage

The invention relates to a purification treatment system for black-colored and odorous rivers. The purification treatment system comprises a sewage preliminary-purification device, a secondary-precipitation and biological treatment device, a thrice-precipitation and sterilization disinfection device, aeration and wastewater reutilization equipment and a final purifier. According to the purification treatment system, through the cooperation of all parts, the black-colored and odorous rivers are rapidly and effectively purified, and the purification effect is good.

Owner:湖南道同消防工程有限公司

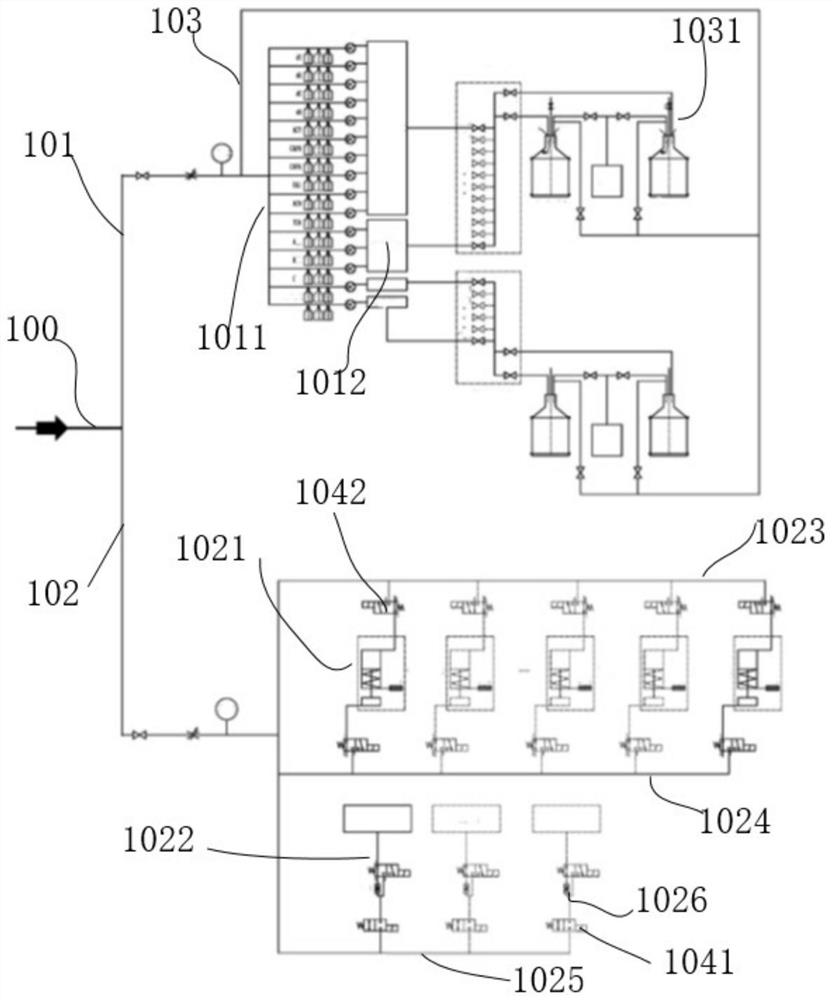

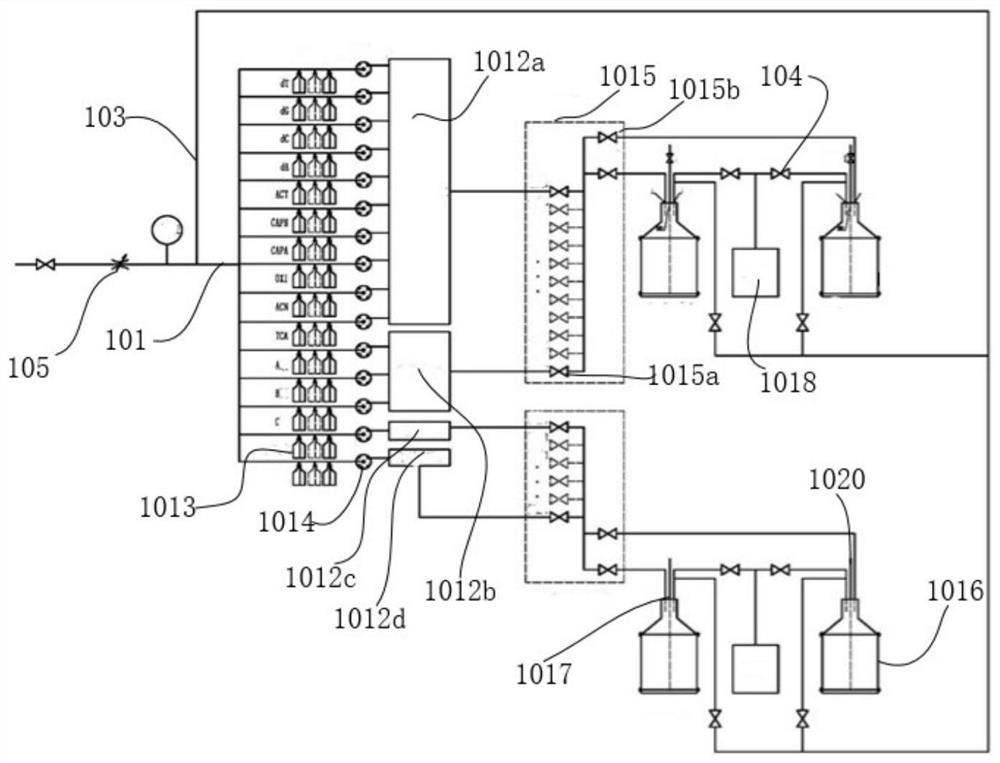

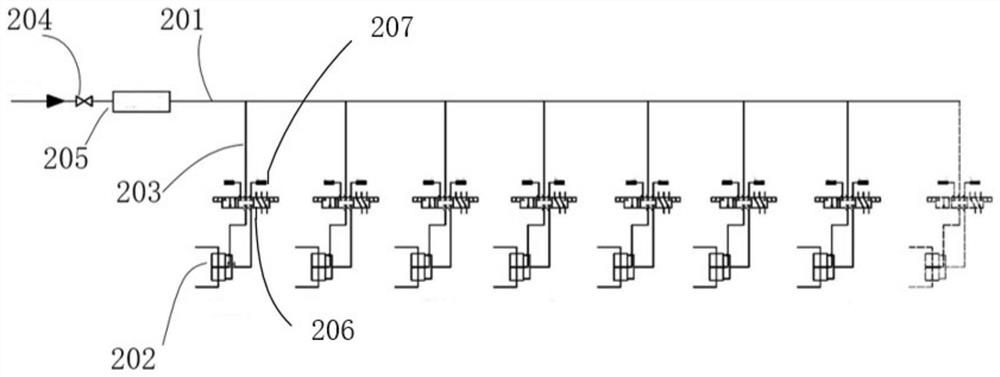

Gas and liquid path system for automatic synthesis of nucleic acid and synthesis system

PendingCN114573653AImprove delivery accuracyWill not affect normal workSugar derivativesSugar derivatives preparationProcess engineeringOrganic chemistry

The invention provides a gas and liquid path system for automatic synthesis of nucleic acid and a synthesis system, and belongs to the technical field of biology. The gas and liquid path system comprises a main pipeline, a first pipeline and a second pipeline, wherein the first pipeline and the second pipeline are arranged at one end of the main pipeline in parallel; the downstream of the first pipeline is provided with a reagent conveying module, the downstream of the reagent conveying module is provided with a plurality of nucleic acid automatic synthesis devices, and the nucleic acid automatic synthesis devices are communicated with waste liquid recovery modules; a gas path supply module is arranged at the downstream of the second pipeline and comprises a gas supply unit and a blowing and pressing unit which are arranged in parallel and can be communicated with the automatic nucleic acid synthesis equipment. The gas and liquid path system for reagent adding, cleaning and waste liquid recycling is provided in the automatic nucleic acid synthesis process, important guarantee is provided for building an automatic nucleic acid synthesis production line, and the gas and liquid path system has important practical significance.

Owner:北京擎科生物科技股份有限公司

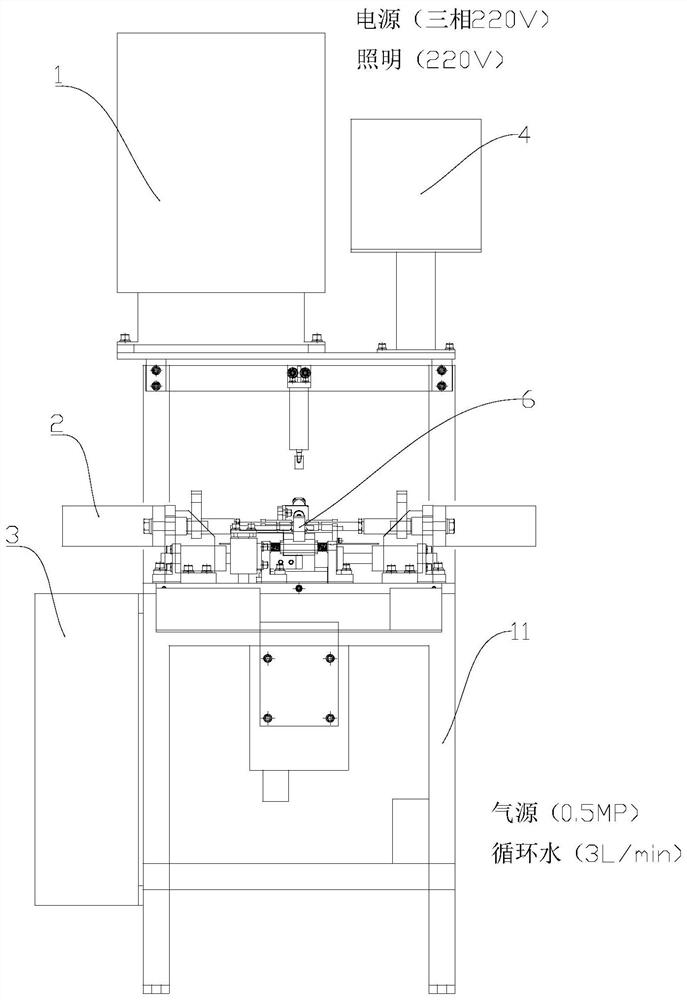

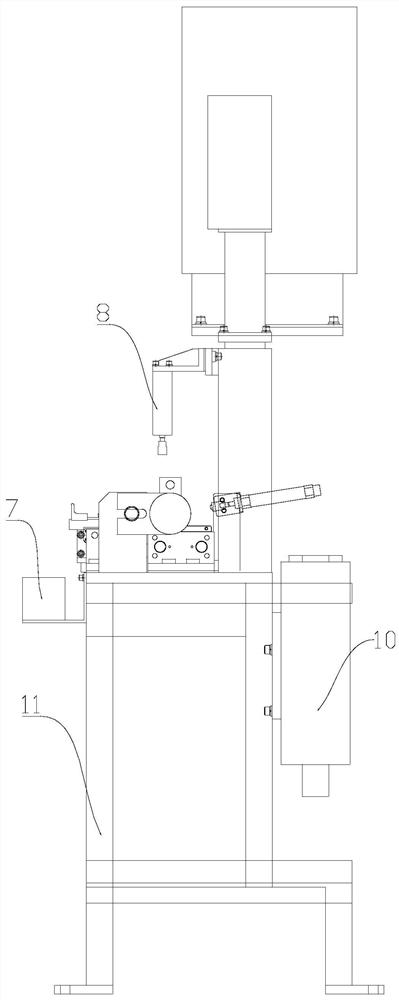

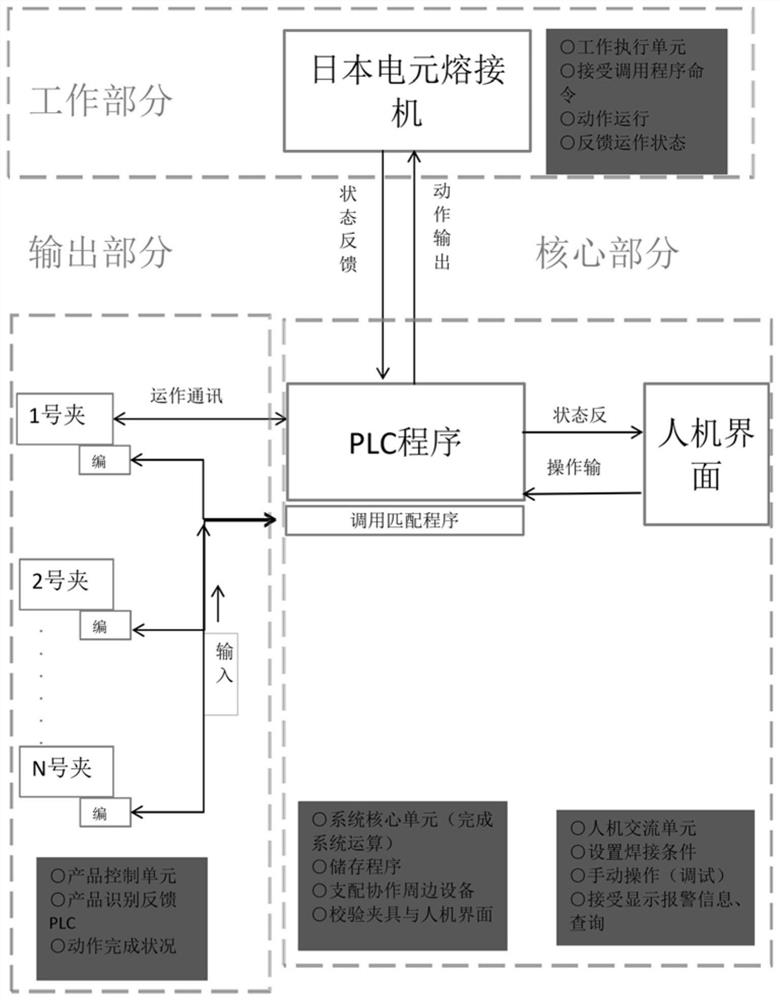

Double-point type lateral spot welding device

PendingCN112692416AImprove securityImprove Spot Welding Work EfficiencyWelding/cutting auxillary devicesWelding monitoring devicesControl engineeringElectric machinery

The invention relates to a double-point type lateral spot welding device which comprises a machine seat, a product clamp installed on the machine seat and a spot welding device body. A control device is arranged, the control device controls operation of the spot welding device body, and the control device comprises a storage part used for storing action conditions and action programs. The control device is formed to be capable of detecting state values including current and torque of a motor driven by the spot welding device body, and the control device is formed to perform the following detection control: setting parameter control for each dotting of the spot welding device body and driving the spot welding device body to stop and providing an alarm when the state value of the motor driven by the spot welding device, the workpiece detection parameters and the state value of a workpiece operator are out of a predetermined range; and the product clamp comprises a clamp positioning base at the lower end and a product clamp body, the clamp positioning base is provided with a plurality of sets of product clamp bodies in a matched mode, the product clamp bodies are coded according to the FDTI1248 protocol, and the reserved port of the control device receives signals of the 1248 protocol so as to regulate and control the different product clamp bodies to clamp different products. The double-point type lateral spot welding device can automatically operate, automatically detect and automatically report errors.

Owner:浙江永田汽车配件有限公司

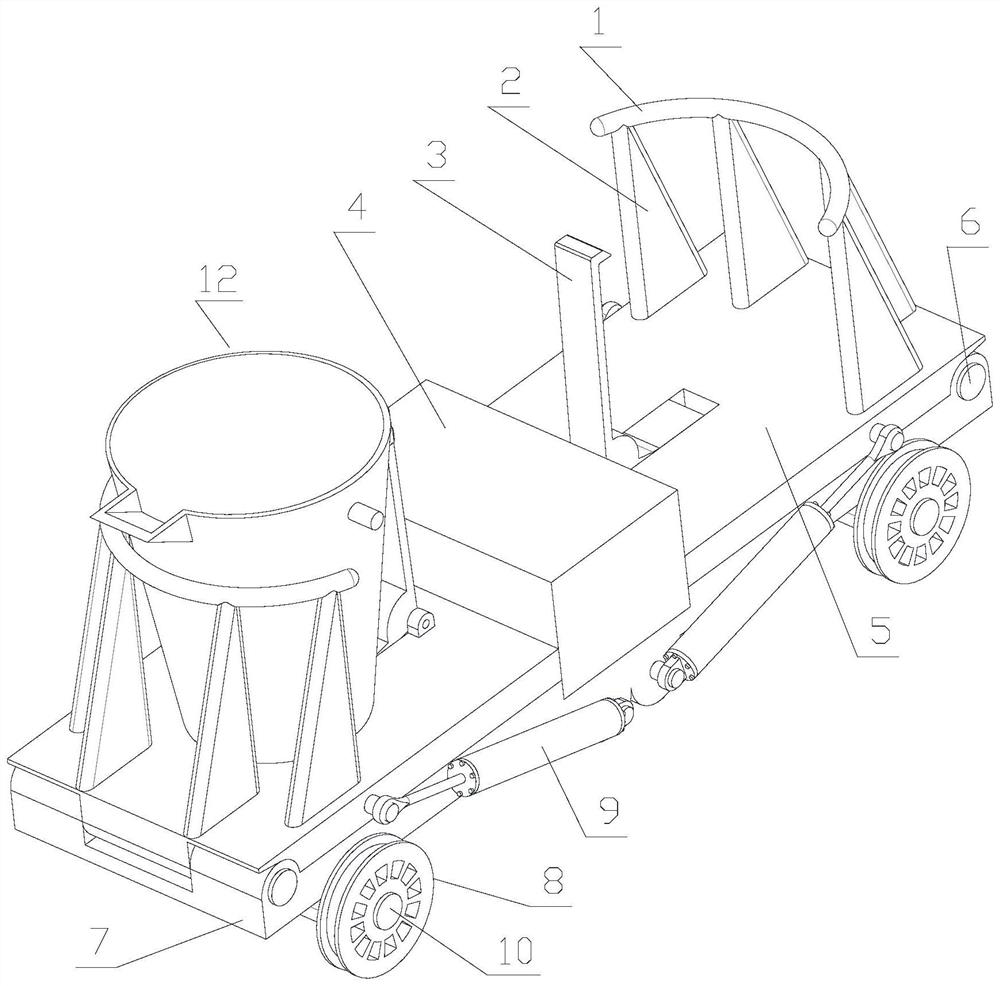

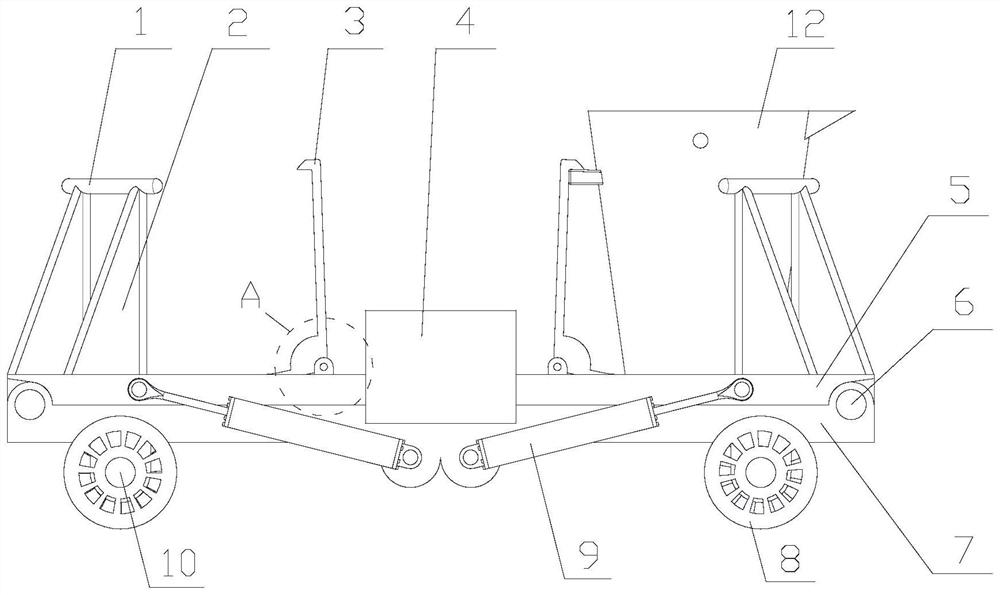

Steel slag tipping carrier loader

InactiveCN114292972ARealize two-way dumpingHigh degree of automationProcess efficiency improvementVehicle frameSlag

The invention discloses a steel slag tipping carrier loader. The invention relates to a slag ladle overturning device which comprises slag ladles, slag ladle overturning plates and a frame, two ladle bodies are arranged on the two slag ladle overturning plates respectively, the two slag ladle overturning plates are hinged to the two sides of the frame respectively and can be driven by power to overturn in opposite directions, and wheels are arranged on the lower portion of the frame. According to the device, automatic slag tank locking and automatic unlocking can be achieved, the automation degree of slag tank tipping and transferring is improved, and therefore the utilization rate and the loss rate of other matched equipment such as a running crane are obviously reduced, the manual utilization rate is reduced, and the carrying efficiency is improved. In addition, the separation rate of tailings and heavy slag is increased, the utilization rate of steel is increased, and material loss is reduced.

Owner:武汉思赛力新材料科技有限公司

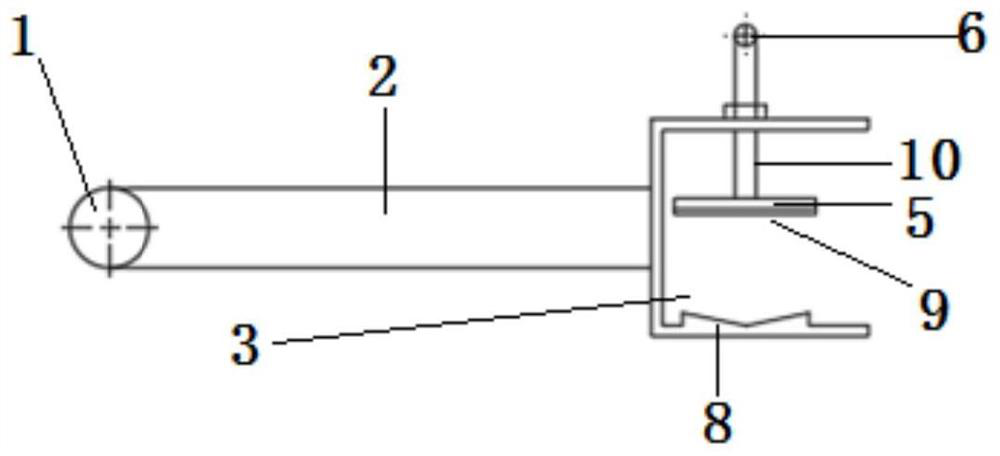

Auxiliary device for welding main reinforcement of reinforcement cage and using method

PendingCN114571174AProtect healthEnsure safetyWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringRebar

The invention belongs to the field of building construction, and particularly relates to an auxiliary device for welding a main reinforcement of a reinforcement cage. Comprising a holding rod, supporting rods, an adjusting device and a fixing device, the supporting rods are symmetrically arranged at the two ends of the holding rod, the supporting rods are perpendicular to the holding rod, the fixing device is installed on the supporting rods and arranged at the ends, away from the holding rod, of the supporting rods, and the adjusting device is arranged on the fixing device. The main reinforcement of the reinforcement cage can be placed in the fixing device in a segmented mode, and the main reinforcement of the reinforcement cage is fixed and welded through the adjusting device. The device has the beneficial effects that operation is easy, time and labor are saved, reinforcing steel bar installation can be completed quickly with less labor and less time, meanwhile, it is guaranteed that upper and lower main reinforcing steel bars are overlapped and aligned to be in a concentric state, the labor utilization rate is greatly reduced, meanwhile, personnel safety is guaranteed, and the working efficiency is improved. The construction efficiency is effectively improved, pile foundation engineering is promoted to be harmoniously, uniformly and rapidly developed, cost optimization is achieved, and high economic and social values are achieved.

Owner:MCC TIANGONG GROUP

Sand screening device for construction

The invention discloses a sand screening device for construction. The device comprises a baseplate, a support device, an emptying device, a frame body, a rotating device, a bracket device, a filter device and a collecting device; a first fixed block and a first collecting box are arranged on the baseplate; the support device comprises a first support block, a pedal plate, a first support rod, a transverse plate, a first spring, a second support block and a first magnet; the emptying device comprises an emptying frame, a second spring, a first ejection block, a pushing block, a pushing rod, a vertical plate and a third spring; the frame body is provided with a first through hole, a first cross bar and a fixed rod; the rotating device comprises a motor, a first bracket, a rotating shaft, a rotating frame, a centralizing ring, a second cross bar, a fourth spring, a third cross bar, a first vertical rod and a fourth cross bar; and the bracket device comprises a second bracket, a first inclined rod, a second vertical rod, a third bracket, a fifth cross bar, a fourth bracket, a sixth cross bar and a third filter screen. The device can fully screen sand needing to be screened, and is high in screening efficiency.

Owner:URUMQI JIUPIN SESAME INFORMATION TECH CO LTD

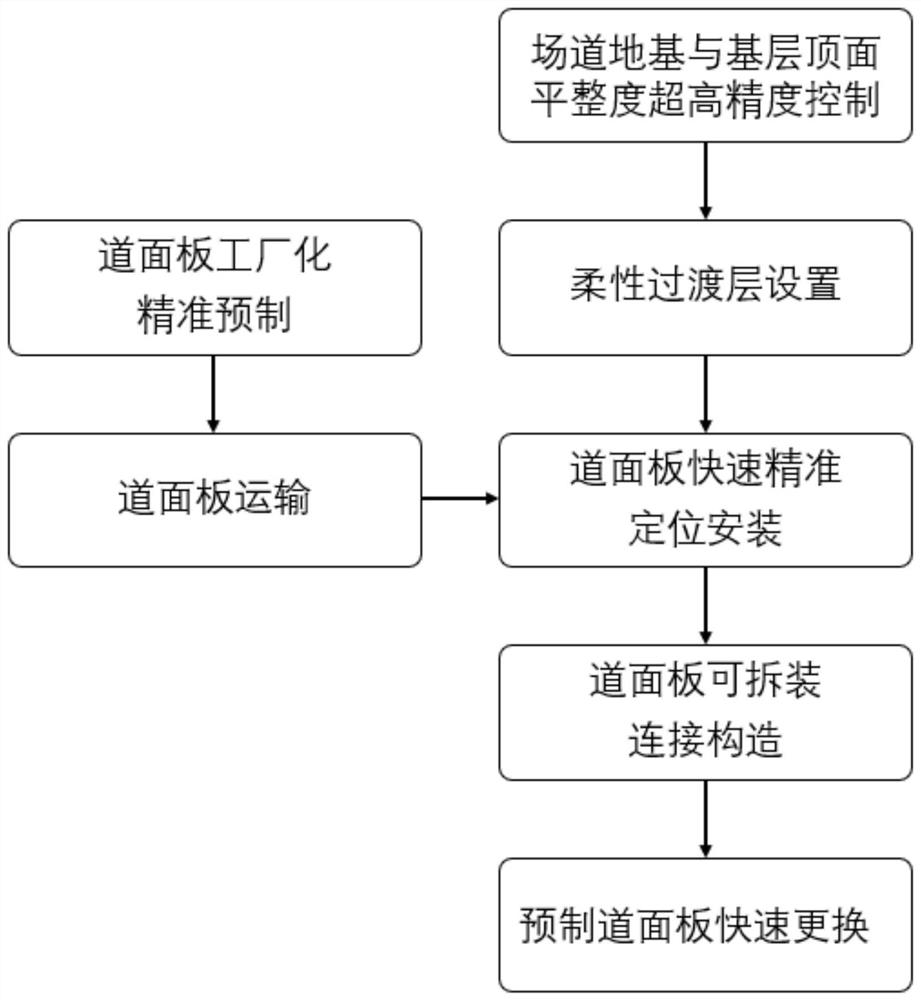

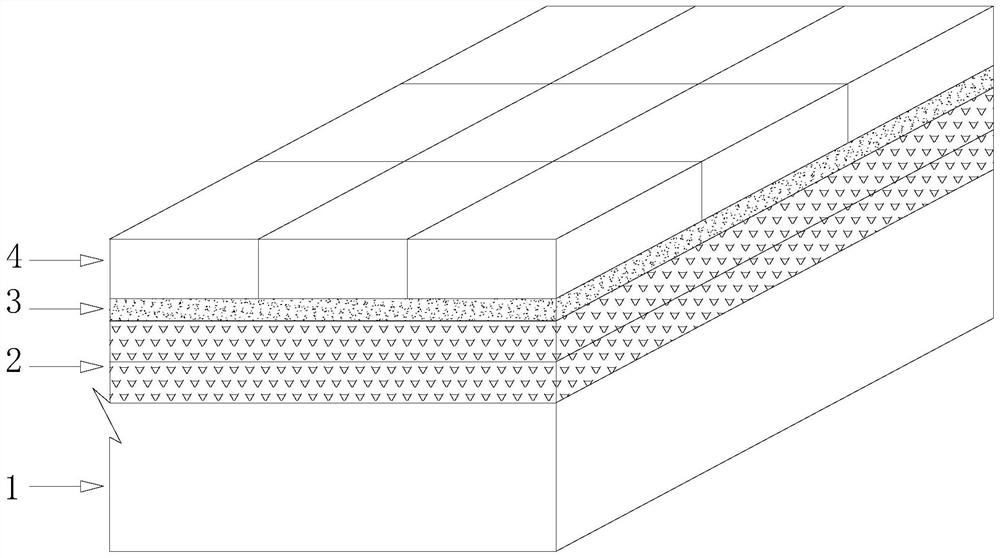

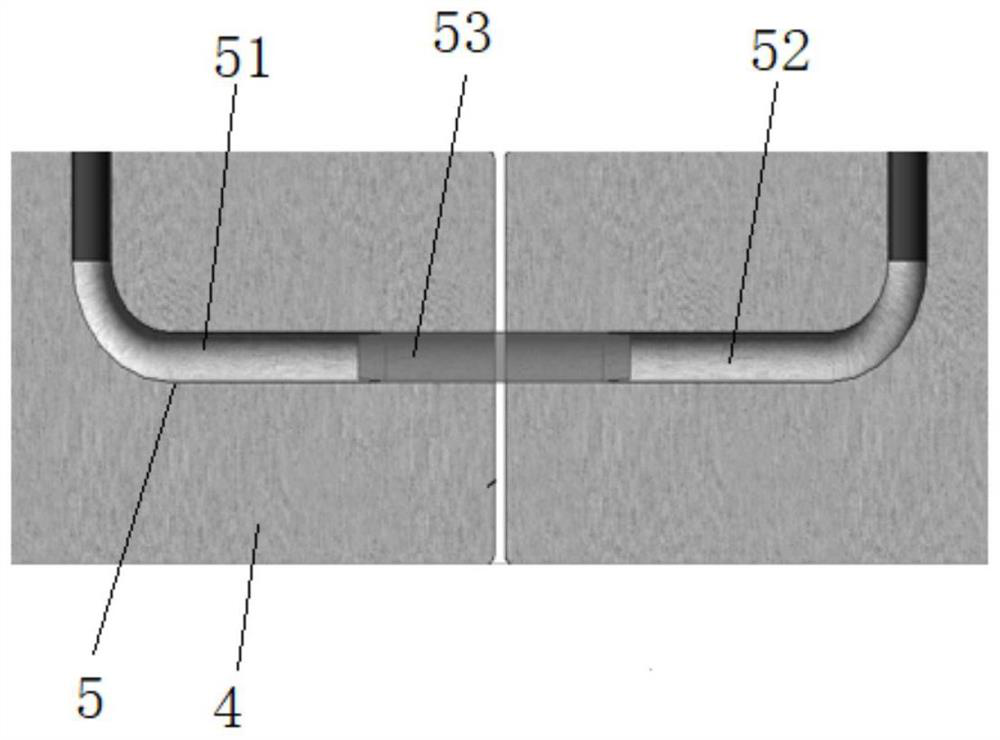

A new type of airport prefabricated pavement system

ActiveCN112746543BQuality improvementIncreased durabilityTemporary pavingsRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a novel airport assembly pavement system, which includes a field foundation, a base layer arranged on the foundation, a flexible transition layer, and a prefabricated road panel; a method for controlling the flatness precision of the field foundation and the top surface of the base layer, and a flexible transition layer The construction control method, the precise positioning and installation method of the prefabricated pavement, the detachable connection structure of the pavement and the rapid replacement method of the prefabricated pavement realize the accurate and rapid installation, replacement and maintenance of the airport pavement. This system and method improves the quality and durability of the airport pavement, avoids the wet operation of concrete in the construction of the airport pavement, greatly improves the mechanization and intelligence level of construction, effectively reduces the amount of labor, and significantly shortens the on-site pavement construction period. In order to greatly improve the efficiency and convenience of airport track construction, operation and maintenance in areas with poor weather conditions, short construction period and resource scarcity. At the same time, the time required for maintenance and replacement of road panels is greatly reduced, which better meets the needs of high-efficiency operation of busy transport airports.

Owner:NO 4 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY +1

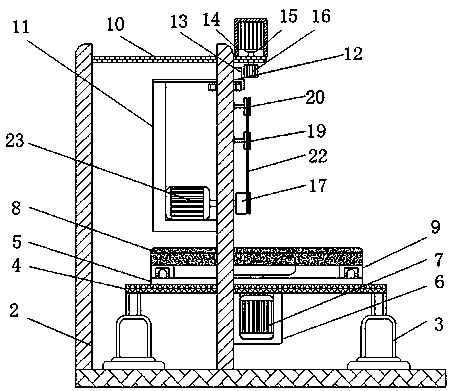

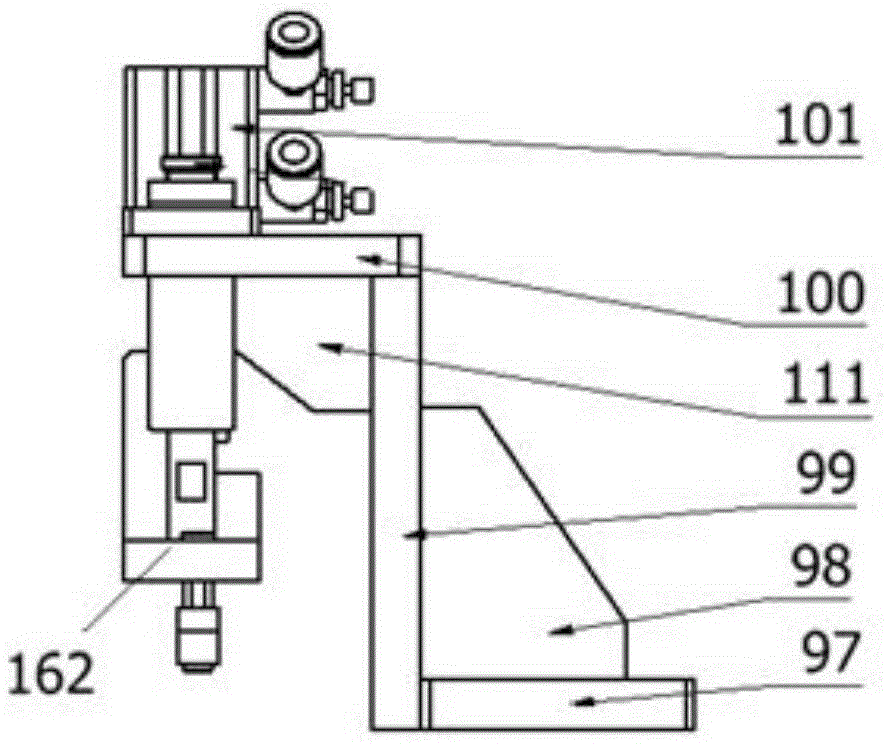

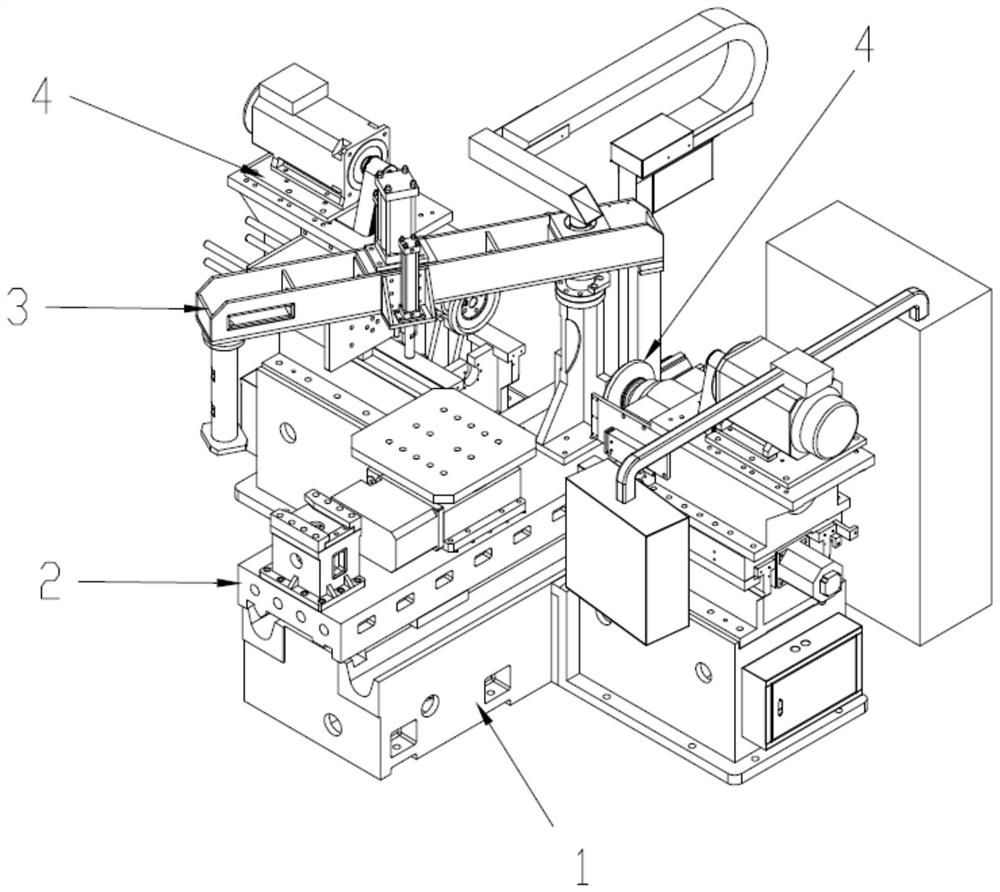

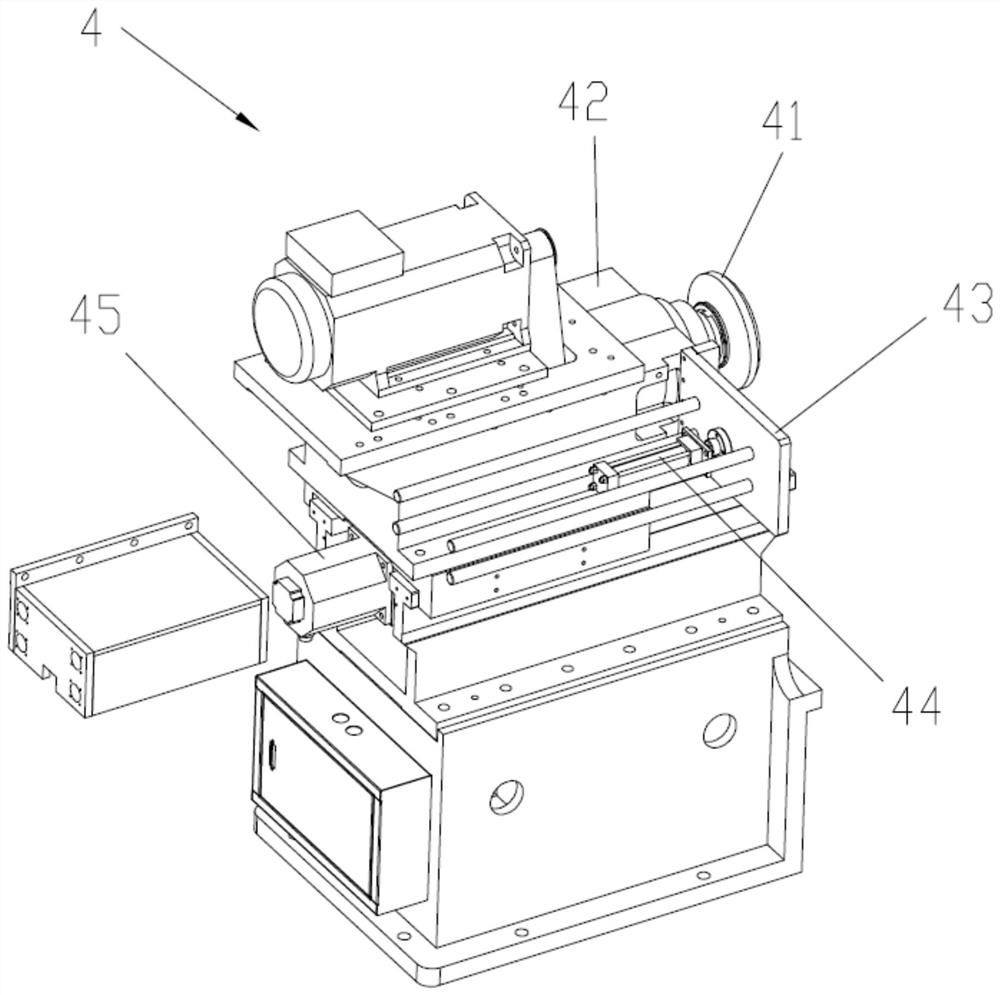

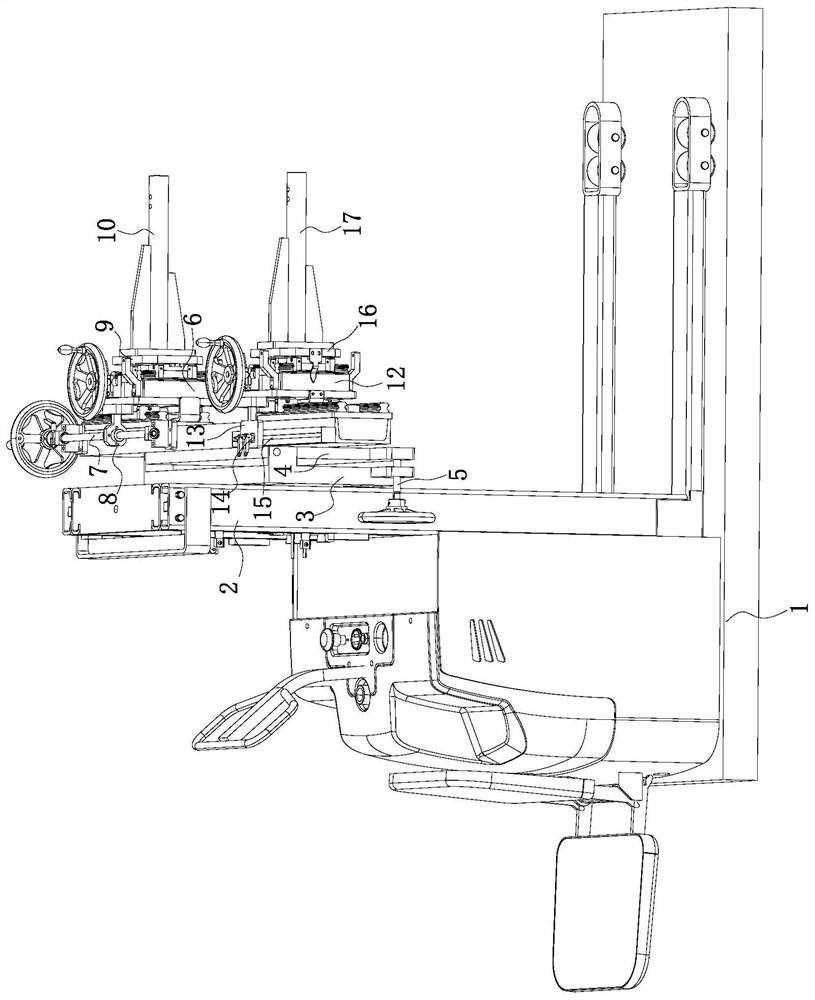

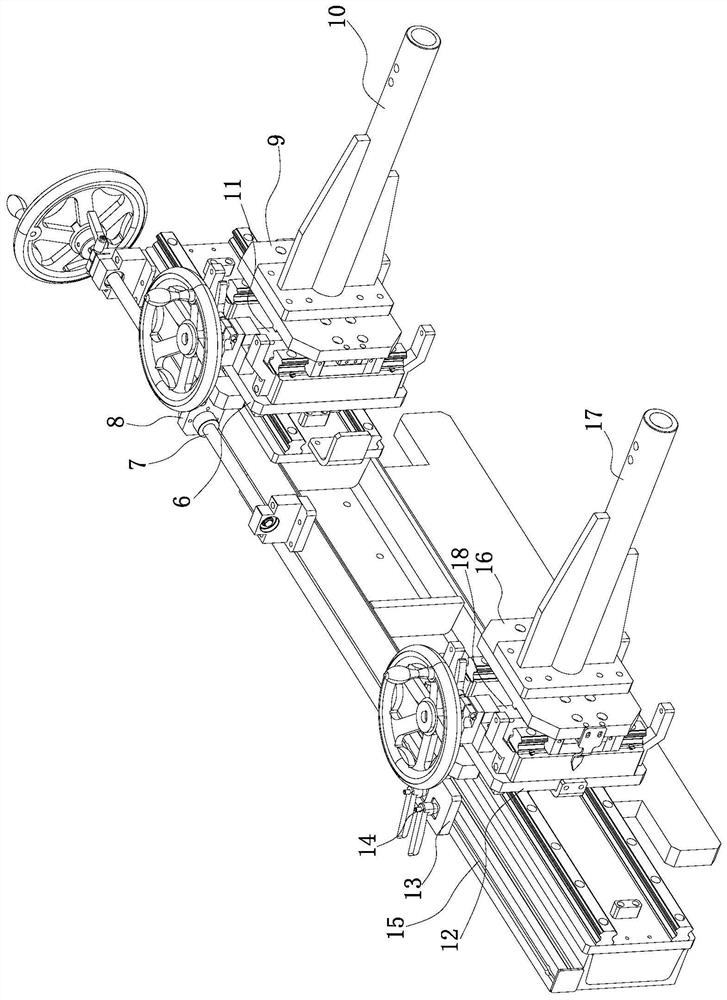

Planer type milling machine

PendingCN112935351AReduce labor usageIncrease productivityMeasurement/indication equipmentsMilling machinesPhysicsEngineering

The invention relates to the technical field of milling machines, in particular to a planer type milling machine. The machine comprises a base, a workbench arranged on the base, an automatic opening and closing portal frame arranged on the workbench and a cutter machining device; the automatic opening and closing portal frame comprises a seat body arranged on the workbench, a cross beam rotationally connected to the seat body, a cross beam driving assembly used for driving the cross beam to rotate, an induction piece arranged on the cross beam driving assembly and a jacking device arranged on the cross beam, the cross beam driving assembly comprises a first driving source, a piston rod and a shell, the shell is arranged on the seat body, the first driving source is contained in the shell and drives the piston rod to stretch out and draw back, and the piston rod is fixedly connected with the cross beam; the induction piece is arranged in the shell and used for inducting the piston rod; and the automatic opening and closing portal frame is arranged on the workbench of the milling machine, the automatic opening and closing portal frame comprises the cross beam driving assembly and the induction piece, the purpose that the cross beam driving assembly drives the cross beam to rotate automatically is achieved, the labor use amount is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:东莞市固达机械制造有限公司

A precisely controlled autonomous flying pesticide spraying drone

ActiveCN108791894BAvoid operational hazardsReduce lossAircraft componentsPosition/course control in three dimensionsDroneControl theory

The invention provides a precisely controlled autonomous flying pesticide spraying unmanned aerial vehicle and its plant protection method. The unmanned aerial vehicle includes a body, four or more rotors, landing gear, a mounting plate, an external medicine box, a control device, and a power supply. . The UAV control device collects environmental data in real time, and performs comprehensive dynamic adjustment based on the environmental data, including adjusting the expansion and contraction of the expansion joint according to the offset angle, and adding the wind speed experience value to the expansion and contraction to improve the spraying accuracy; and adjusting the PWM according to the wind speed. , to increase the amount of spraying, the UAV automatically performs path planning, and automatically returns when the wind speed is too high. The invention can effectively improve the spraying precision and enhance the safety of the drone.

Owner:NANTONG VOCATIONAL COLLEGE

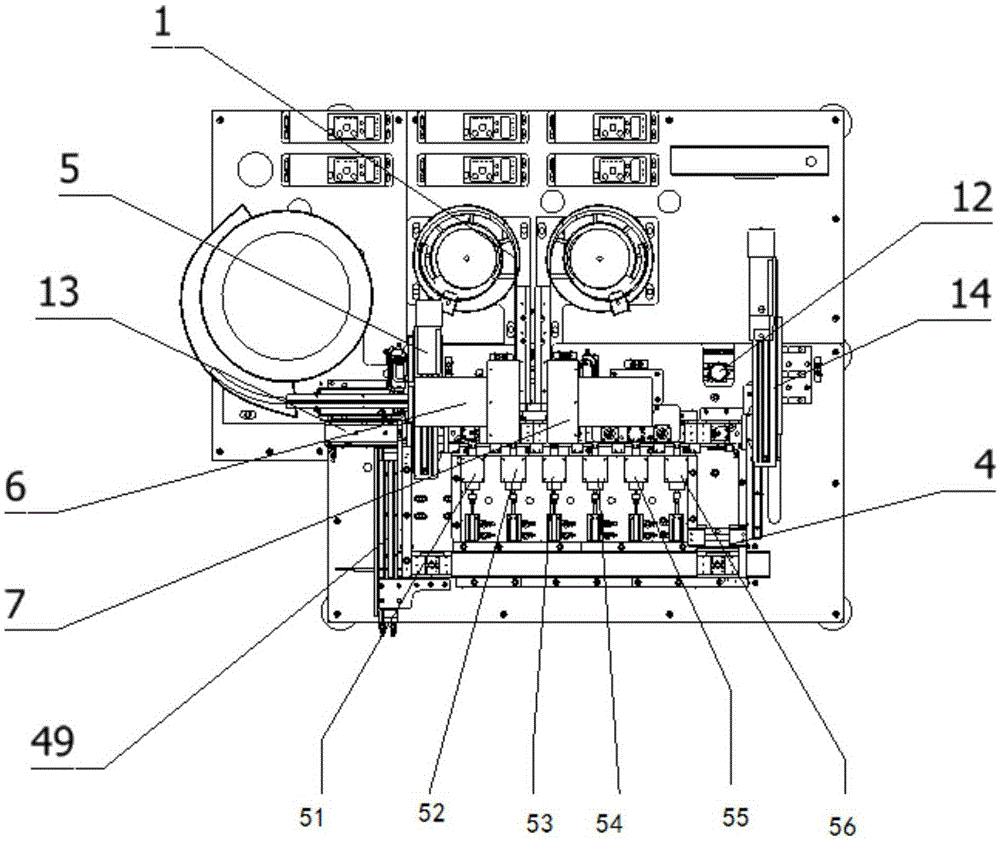

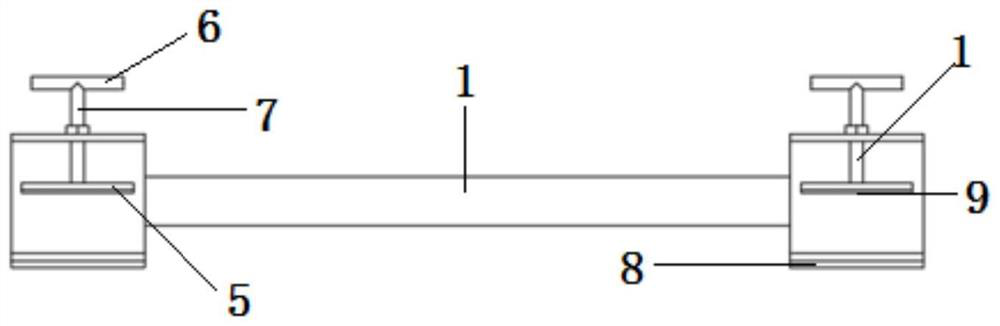

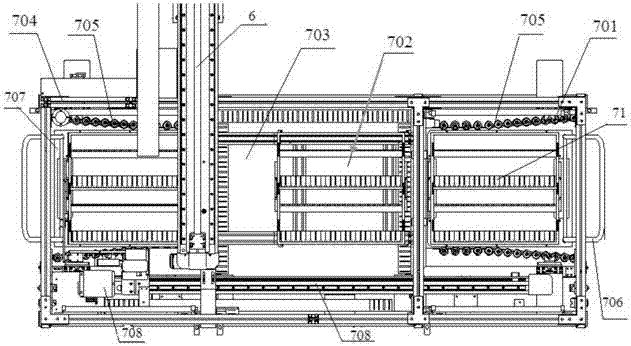

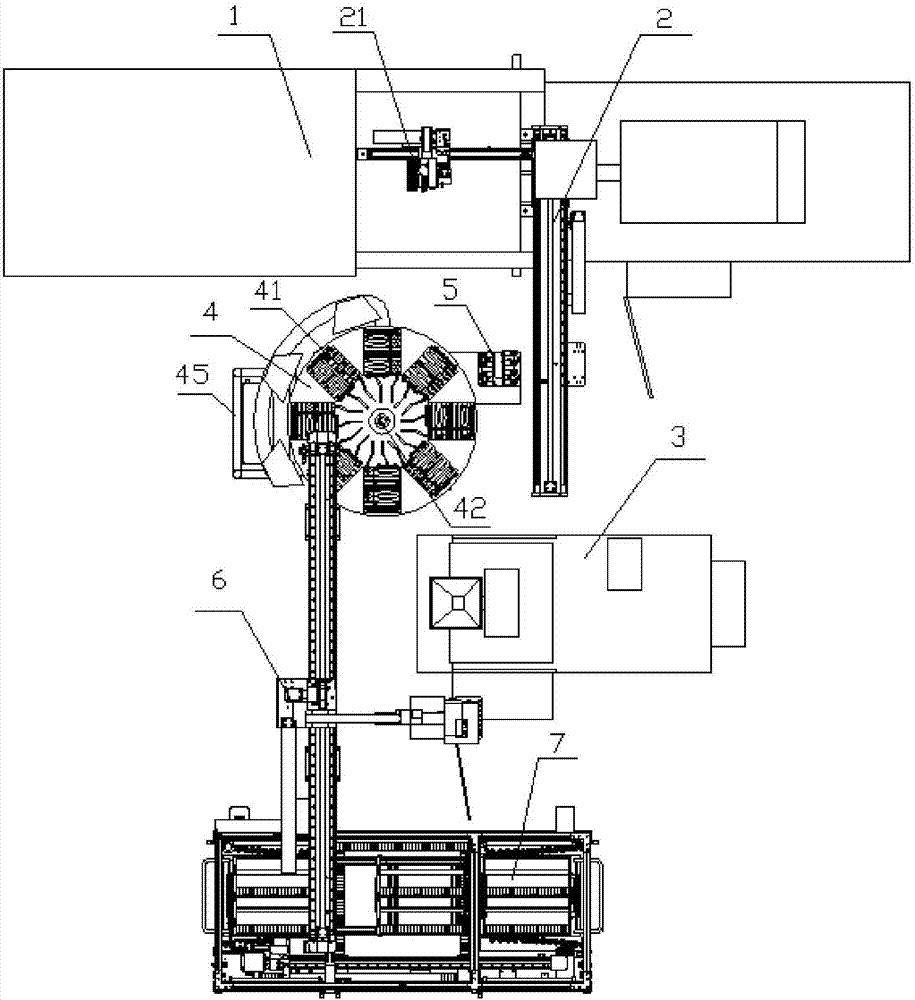

The shank is taken and cut by the horizontal machine and put into the vertical machine for secondary glue injection and packing system

The invention relates to system for taking toothbrush handles from a horizontal machine, shearing the toothbrush handles, placing the toothbrush handles into a vertical machine for secondary glue injection, and conducting casing. The system comprises a three-axis full-servo mechanical arm, an air shear jig, a rotating conveyer, a vertical injection molding machine, a three-axis full-servo truss robot and an automatic stacker. A plurality of toothbrush handles are grabbed through the three-axis full-servo mechanical arm from the interior of a mold opening die and then moved onto the air shear jig, stub bars of the toothbrush handles are sheared off through an air shear, and then the sheared toothbrush handles are placed on the rotating conveyer, cooled on the rotating conveyer and conveyed to an automatic feeding standby position of the vertical injection molding machine in the rotating process of the rotating conveyer; then, the toothbrush handles are grabbed and sent into a cavity of the vertical injection molding machine through the three-axis full-servo truss robot, and after injection molding is completed, the toothbrush handles are taken out and sent into a tray of the automatic stacker through the three-axis full-servo truss robot; automatic tray exchange is achieved through the automatic stacker, and then automatic casing is achieved. The system is high in automation degree, the usage rate of manpower is reduced, production efficiency is improved, and production cost is reduced relatively.

Owner:SUZHOU IND PARK CHAOQUN AUTOMATION EQUIP

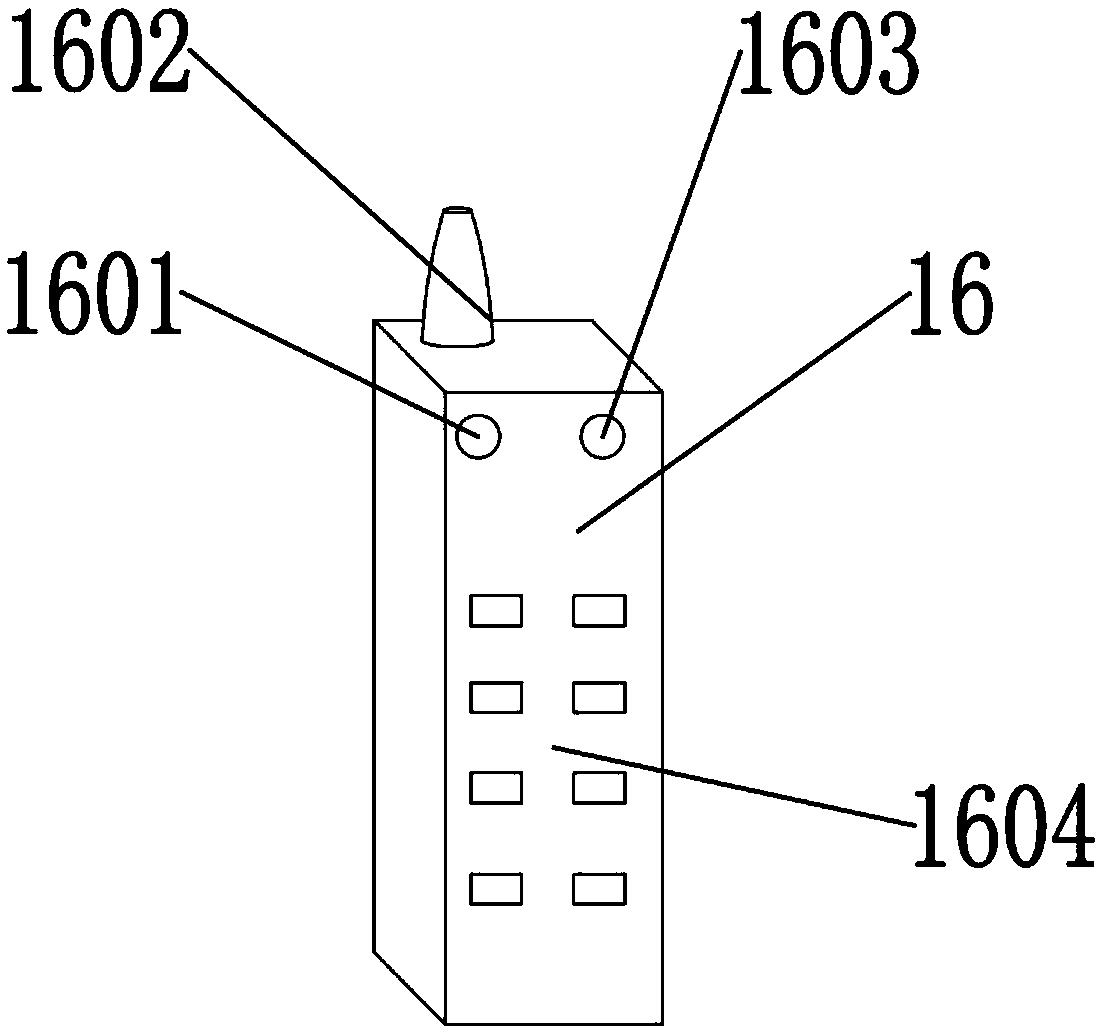

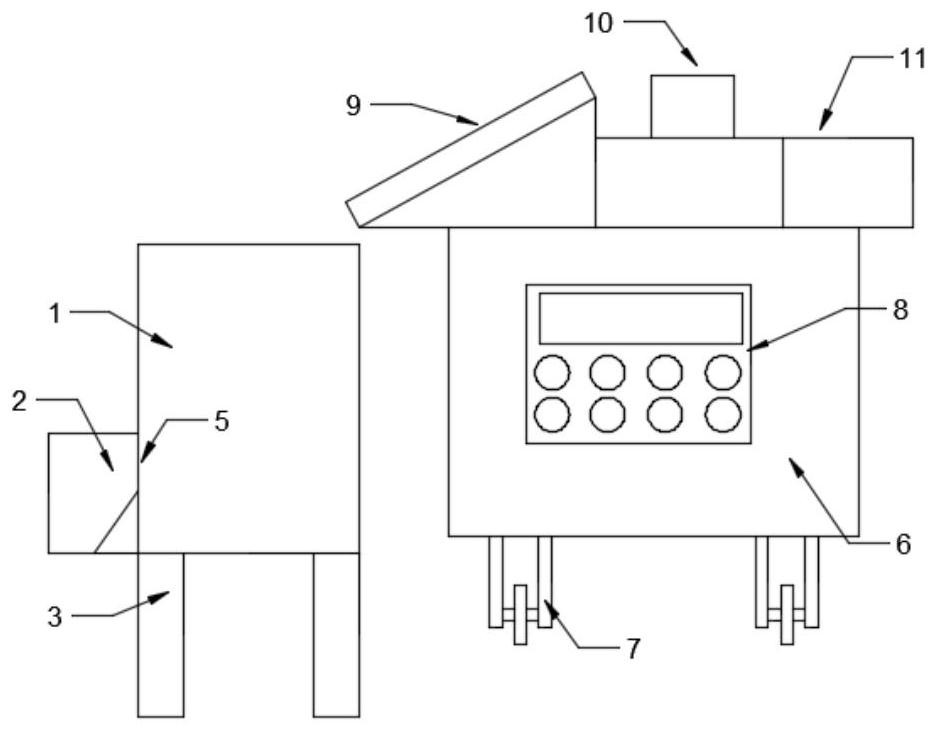

Automatic feed feeding machine for livestock breeding

InactiveCN112868557AReduce manual labor intensityReduce labor usageAnimal feeding devicesAvicultureTransfer mechanismAnimal science

The invention relates to the related technical field of livestock breeding equipment, in particular to an automatic feed feeding machine for livestock breeding. The automatic feed feeding machine comprises a feed trough; a feed box is fixed on one side of the feed trough; support legs are fixed at the bottom of the feed trough; a feed passing port is formed in a trough body of the feed trough on one side of the feed box; a baffle mechanism is fixedly mounted on the feed trough on the feed passing port; a movable box is arranged on the other side of the feed trough; universal wheels are installed at the bottom of the movable box; a control panel is arranged on a box body of the movable box; a material pouring mechanism is fixedly installed on the top of the movable box; a transferring mechanism is fixedly installed on one side of the material pouring mechanism; and a feed stirring mechanism is fixed to the position, on the other side of the transferring mechanism, of the top of the movable box. According to the device, mechanical automatic operation is utilized, stirring processing and timed and quantitative adding of feed are achieved, the labor intensity of workers is reduced, the use amount of the workers is reduced, and meanwhile, the waste use amount of the feed is reduced, and the breeding benefits are greatly improved.

Owner:钟离平

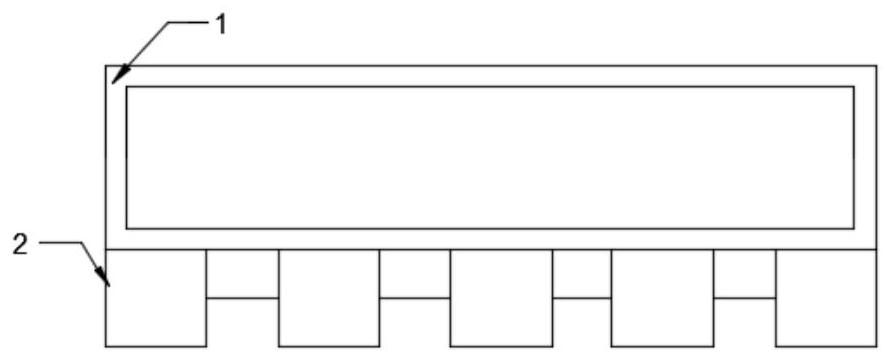

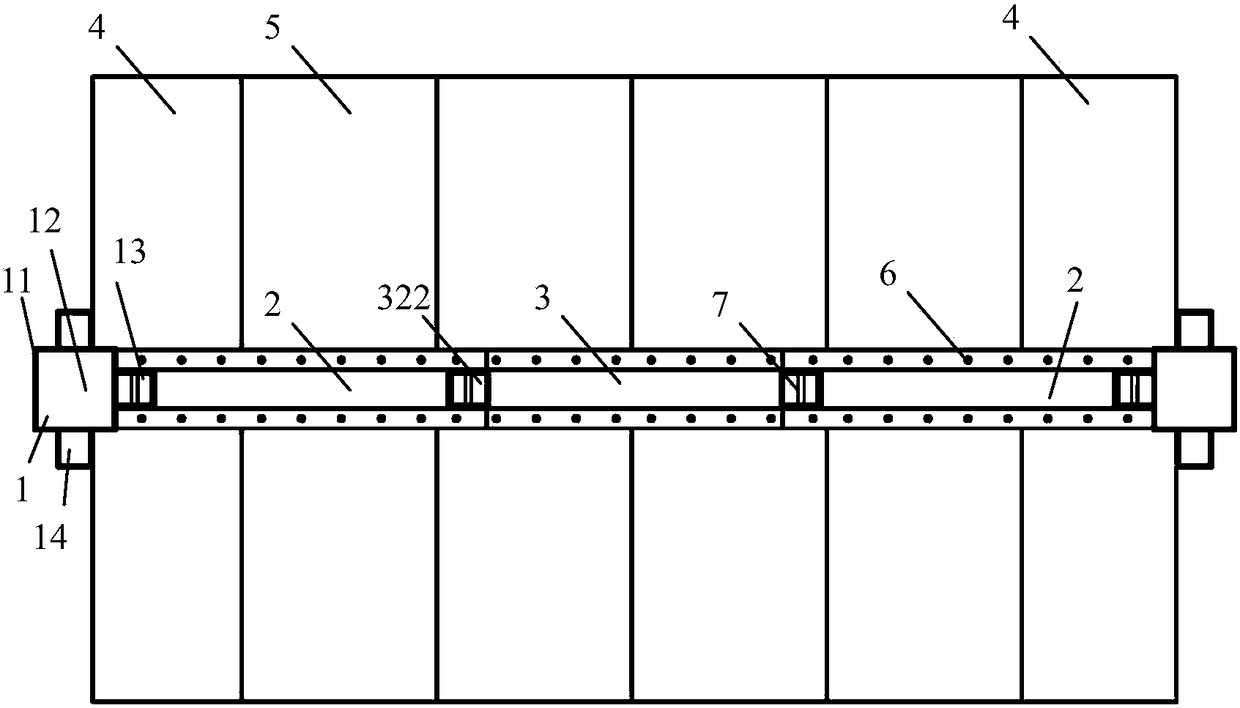

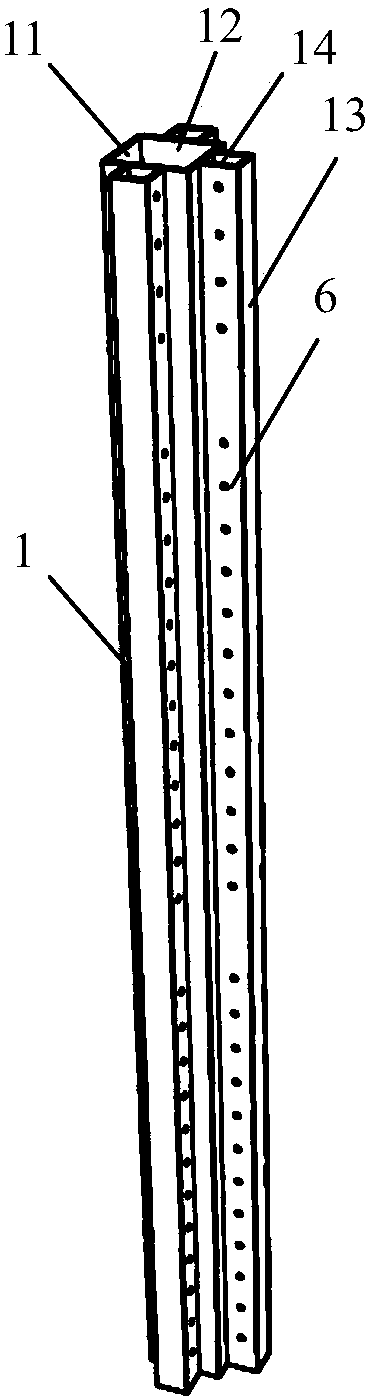

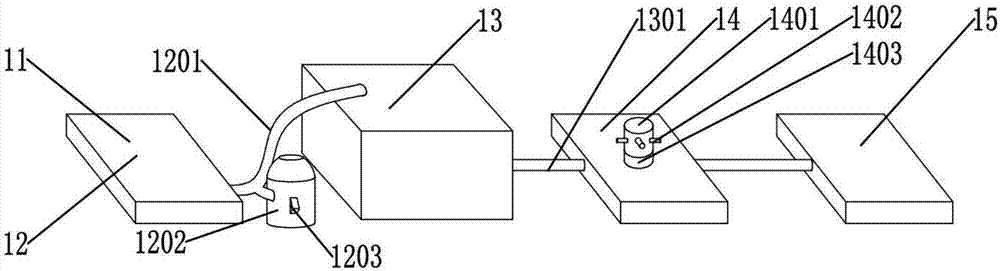

Fully assembled steel pipe concrete frame composite shear wall structure

The invention provides a full assembly type steel pipe concrete side frame combined shear wall structure, which comprises a steel pipe concrete post, a prefabricated shear wall and a floor slab, wherein the steel pipe concrete post comprises a steel pipe post and post wall connecting sectional steel welded on the periphery of the steel pipe post; concrete is cast in the steel pipe post; a plurality of screw bolt holes are formed in two sides of the post wall connecting sectional steel, and are used for connecting the prefabricated shear wall; the prefabricated shear wall comprises a reinforced concrete shear wall and embedded sectional steel positioned on the periphery of the reinforced concrete shear wall; a plurality of screw bolt holes are formed in the left side and the right side of the embedded sectional steel, and are used for connecting the post wall connecting sectional steel or the embedded sectional steel of the other prefabricated shear wall; the upper side and the lower side of the embedded sectional steel are provided with end plates; a plurality of screw bolt holes are formed in the end plates and are used for connecting floor slabs. The full assembly type steel pipe concrete side frame combined shear wall structure has the advantages that the joint connection is fast and reliable; the construction is convenient; the construction quality is good; the bearing force is high; the quake-proof performance is good; the construction period is short; components can realize standardized production.

Owner:FUJIAN UNIV OF TECH

Purifying treatment system and purifying treatment method of black-odor rivers

InactiveCN108002662ABest antivirus levelSimple structureWater treatment parameter controlSpecific water treatment objectivesWastewaterSewage

The invention relates to a purifying treatment system of black-odor rivers. The purifying treatment system comprises a sewage primary purifying apparatus, a secondary precipitation and biological treatment apparatus, a tertiary precipitation and sterilization and disinfection apparatus, an aeration and waste water reutilization device and a final purifying apparatus. By virtue of the cooperative work of different parts, the black-odor rivers can be rapidly and effectively purified, and the purifying effect is good.

Owner:湖南道同消防工程有限公司

A sand screening device for building construction

ActiveCN105289984BSimple structureEasy to useSievingGas current separationArchitectural engineeringElectric machinery

A sand screening device for building construction comprises a bottom plate, a supporting device, a discharging device, a frame, a rotating device, a support device, a filtering device and a material collecting device. The bottom plate is provided with a first fixing block and a first material collecting box. The supporting device comprises a first supporting block, a pedal plate, a first supporting rod, a cross plate, first springs, a second supporting block and a first magnet. The discharging device comprises a discharging frame, a second spring, a first abutting block, a push block, a push rod, a vertical plate and third springs. The frame is provided with first through holes, a first cross rod and a fixing rod. The rotating device comprises a motor, a first support, a rotating shaft, a rotating frame, a centralizing ring, a second cross rod, fourth springs, a third cross rod, a first vertical rod and a fourth cross rod. The support device comprises a second support, a first inclined rod, a second vertical rod, a third support, a fifth cross rod, a fourth support, a sixth cross rod and a third filtering net. By means of the sand screening device, sand needing to be screened can be sufficiently screened, and the screening efficiency is high.

Owner:JIANGSU TIANYUAN ZHONGKE BIOTECHNOLOGY CO LTD

A production system for biological feed

InactiveCN103653213BPromote circulationPrevent degradation of fermentation qualityFeeding-stuffBiotechnologyFirst-order reaction

The invention discloses a biological feed manufacturing system which comprises first-order reaction kettles, second-order reaction kettles, a strain fermentation culture tank and a mixer. The first-order reaction kettles and the second-order reaction kettles are used for breeding various strains in a fermentation manner, the various strains are mixed and allowed to ferment by the aid of the strain fermentation culture tank, materials are inoculated with mixed strains and are mixed with one another by the mixer, inoculated and mixed materials in the mixer are loaded on a fermentation vehicle, ferment in an annular fermentation kiln, and completely ferment when the fermentation vehicle moves to a discharging platform, the materials loaded on the fermentation vehicle are unloaded, and the fermented materials can be bagged. The biological feed manufacturing system has the advantages that the inoculated materials which are mixed with one another by the mixer and are loaded on the fermentation vehicle are collected at a certain position of the annular fermentation kiln, then the fermentation vehicle slowly runs to the discharging platform along a conveying rail, the materials completely ferment in the procedure, accordingly, a fermentation procedure and a conveying procedure are combined with each other, and the manufacturing efficiency can be greatly improved; the fermentation vehicle in a unique design and the discharging platform are matched with each other, so that the materials can be automatically unloaded, the work efficiency can be greatly improved, and the degree of dependence on labor can be reduced.

Owner:河南宏翔生物科技有限公司

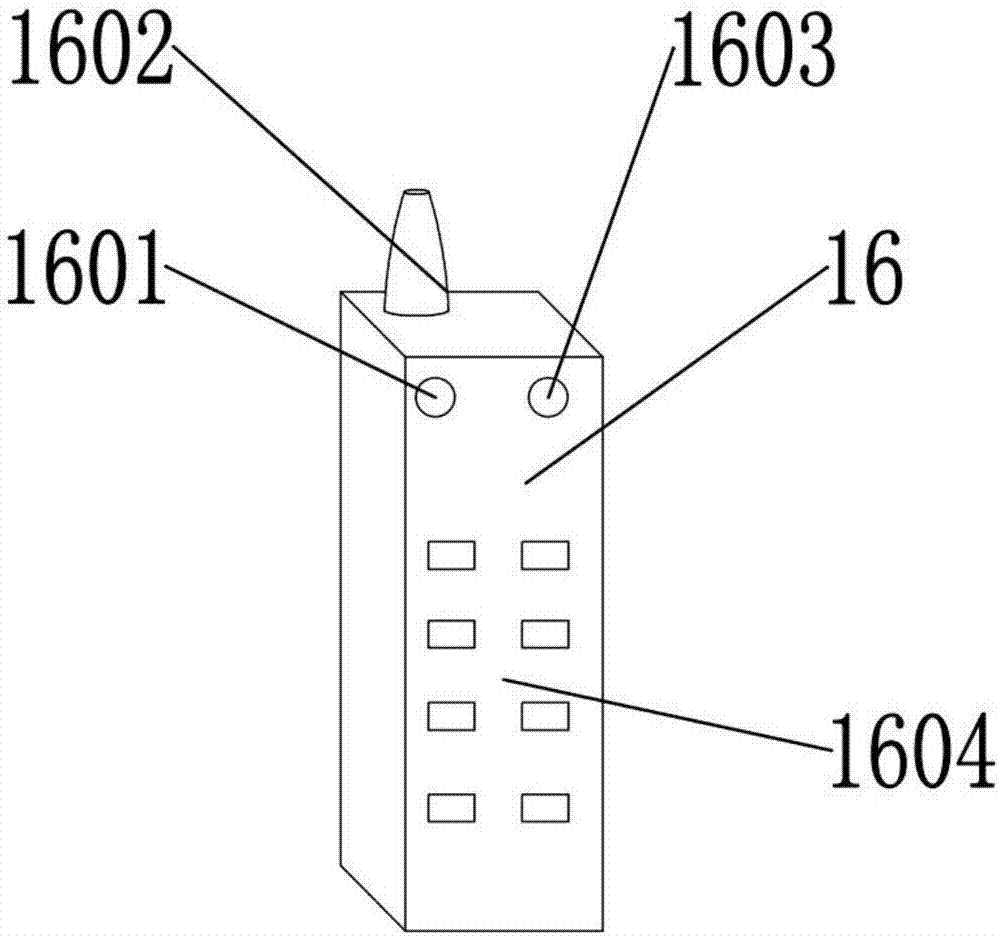

A kind of logistics sorting equipment

ActiveCN109967405BImprove user experienceShorten the timeSortingLogistics managementIndustrial engineering

The invention discloses a kind of logistics sorting equipment, which comprises a logistics cabinet and an installation space arranged in the logistics cabinet. A plurality of mailboxes are arranged in the installation space through installation brackets. Lifting devices located on both sides of the mailboxes are arranged in the logistics cabinet. The lifting device Including the lifting chamber connected to the left and right end walls of the installation space and located on the front side of the mailbox, and the logistics cabinet is provided with a power chamber located on the lower side of the installation space. The invention has a simple structure and completes the mail sorting process for different households. The linkage of device operation reduces the time for sorting mail and reduces the labor utilization rate. When facing high logistics cabinets, mail can be sorted without the use of ladders, reducing potential safety hazards. The community sorts through the device to avoid the possibility of sending the wrong mailbox due to the negligence of the courier, and improve the user experience of the residents.

Owner:至美通供应链管理(深圳)有限公司

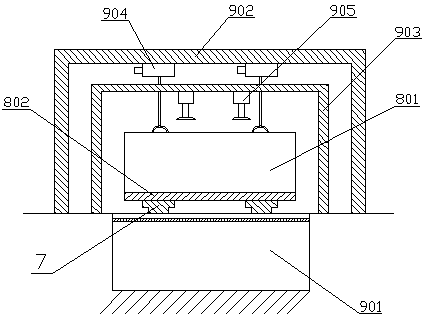

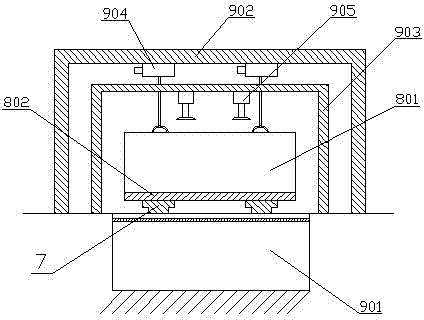

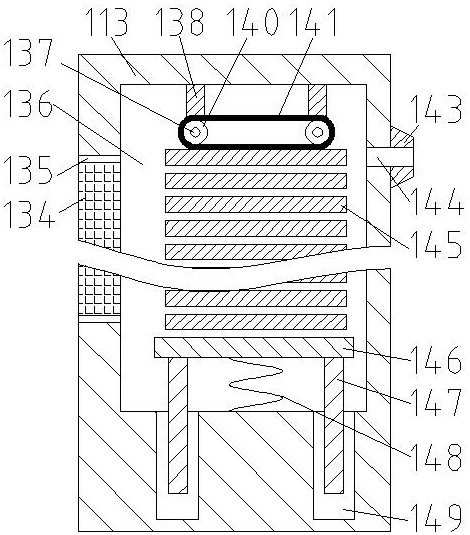

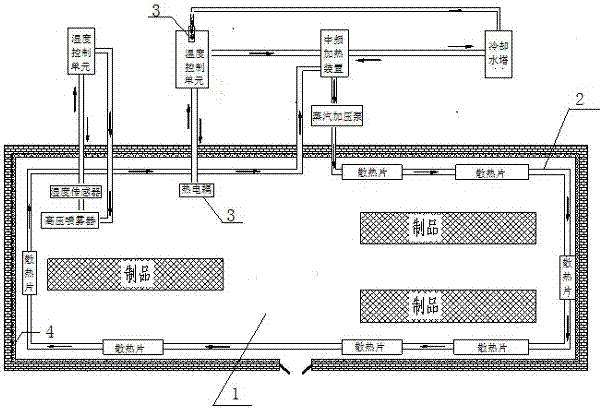

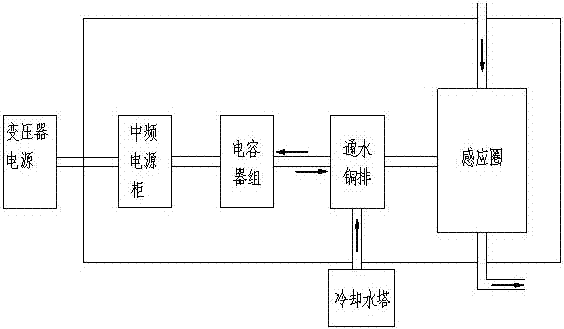

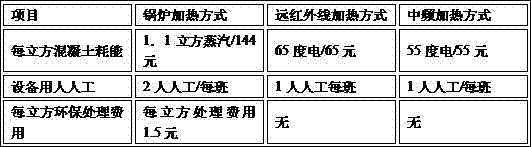

An energy-saving and environment-friendly intermediate frequency heating automatic temperature control concrete curing system

ActiveCN104827553BControl liftStable temperatureCeramic shaping apparatusTemperature controlAutomatic train control

The invention discloses an energy-saving environment-protection medium-frequency heating automatic temperature control concrete curing system, which comprises a curing room, a temperature control device and a humidity control device, wherein the temperature control device and the humidity control device are respectively used for controlling the temperature and the humidity in the curing room; the curing system realizes concrete product curing through injected steam; the steam is prepared from water heated by a medium-frequent heating device connected with the curing room. The energy-saving environment-protection medium-frequency heating automatic temperature control concrete curing system has the advantages that the concrete curing is realized through the steam generated by circulation water heating by a medium-frequency heating controller, the energy is saved, and the environment is protected. Meanwhile, the temperature and the humidity in the curing room are uniform and controllable, and the quality of concrete products is greatly improved.

Owner:黄贺明

Die change transport cart

PendingCN111960336AEasy to assemble and disassembleReduce labor usageLifting devicesClassical mechanicsEngineering

The invention belongs to the field of moving carriers, and particularly relates to a die change transport cart. The die change transport cart comprises a die change cart body, a connecting block, a Y-axis angle adjuster, a first positioning assembly, a second positioning assembly and a Z-axis angle adjuster; a supporting frame is arranged at the end of the die change cart body, and a connecting plate is movably arranged on the supporting frame; the upper end of the connecting block is rotationally connected with the upper end of the connecting plate; the Y-axis angle adjuster is rotationally inserted into the connecting plate, and the end part of the Y-axis angle adjuster is propped against the connecting block; the first positioning assembly is arranged on the connecting block, and a first connector clip is arranged on the first positioning assembly; the second positioning assembly is transversely arranged on the connecting block in a sliding mode, and a second connector clip is arranged on the second positioning assembly in a sliding mode; and the Z-axis angle adjuster is arranged on the second positioning assembly and is connected with the second connector clip. Compared with the prior art, the die change transport cart has the advantages that the height and the angle of a jig can be adaptively adjusted according to the mounting position of the jig, so that the jig is convenient to disassemble and assemble, the labor occupation is reduced, and the replacement is more convenient and quicker.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com