Intelligent speed adjusting system and method for wine filling machine

A technology for regulating systems and filling machines, applied in control/regulation systems, general control systems, instruments, etc., to achieve the effects of efficient management tools, less energy consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

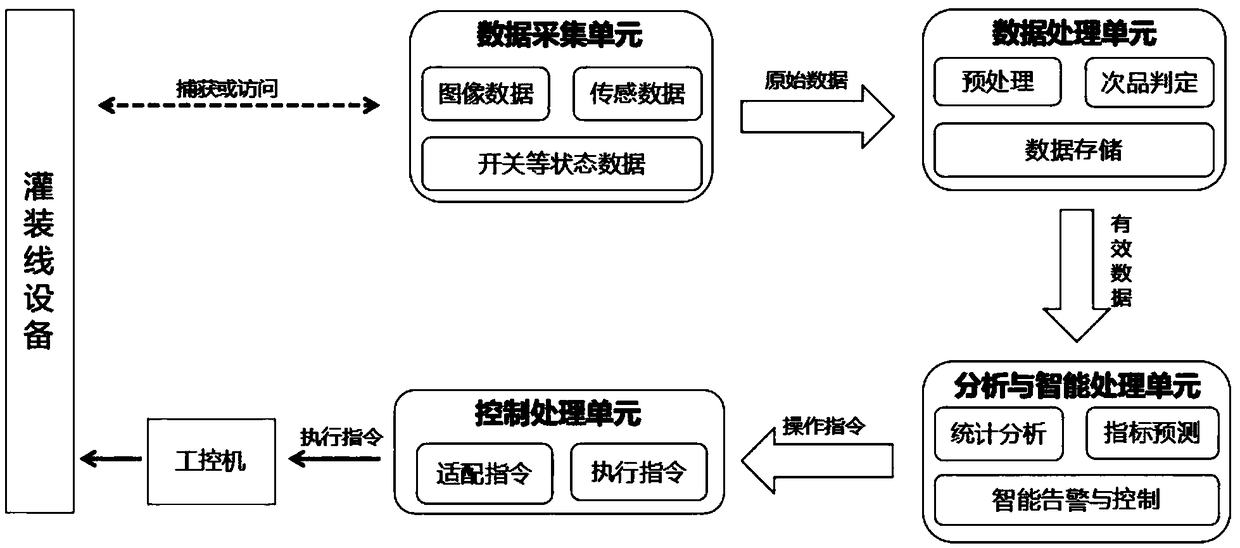

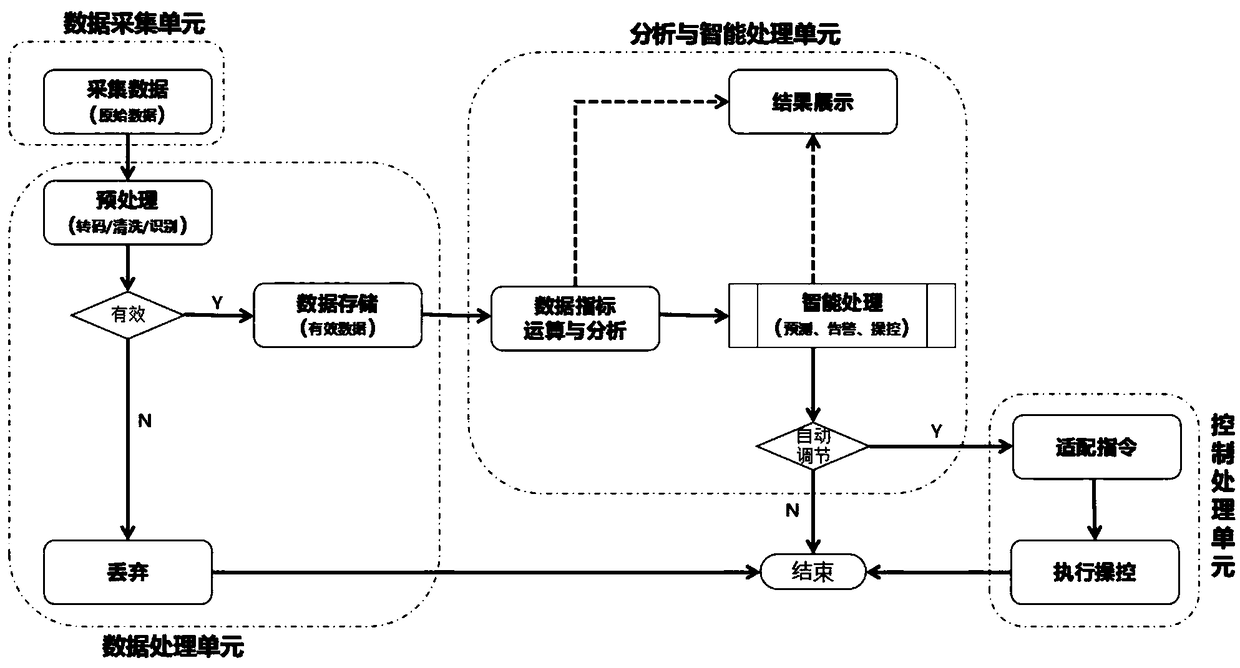

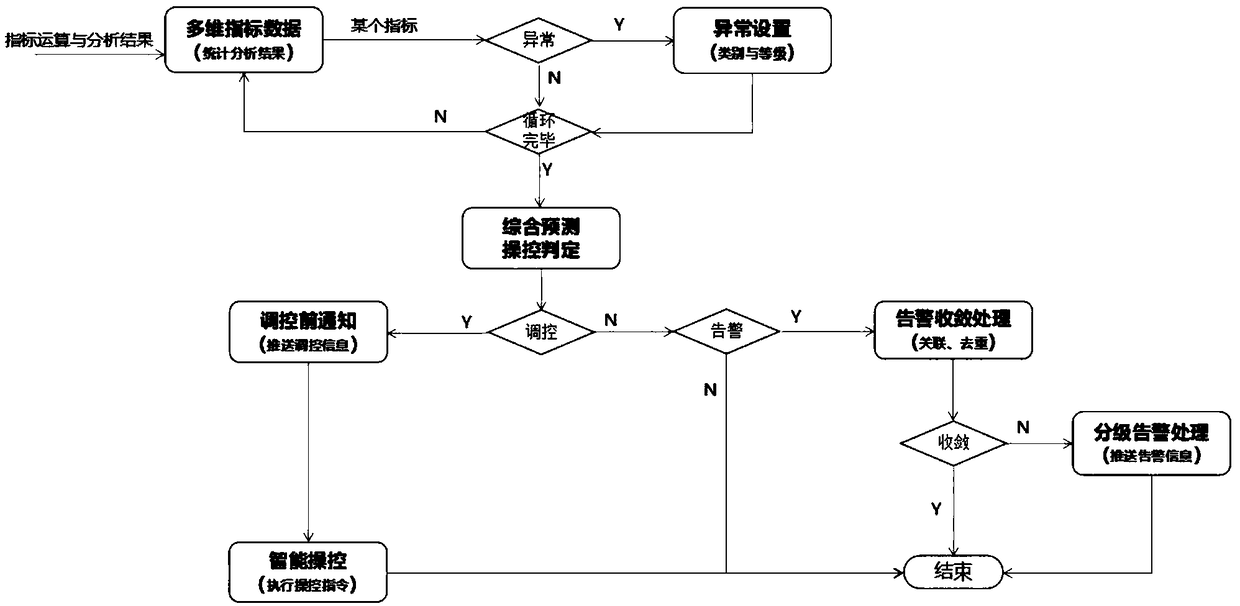

[0034] The system structure of the intelligent adjustment system of the production speed of the wine filling machine of the present invention is as follows: figure 1 As shown, it is composed of four core modules: data acquisition module (unit), data processing module (unit), analysis and intelligence module (unit), and control processing module (unit). The functions of each module are as follows:

[0035] Data acquisition unit: responsible for collecting and collecting the current operating status data and bottle image data of various equipment on the filling line, including data such as pressure load, speed, temperature, empty bottle image after bottle washing, and bottle image after filling;

[0036] Data processing unit: responsible for processing and storing original data, identifying and judging defective products, and outputting valid data required by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com