Inner buried type circuit board and method for producing the same

A manufacturing method and circuit board technology, applied in printed circuit manufacturing, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., can solve problems such as increased load-carrying area, improve performance, reduce size, and improve overall production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

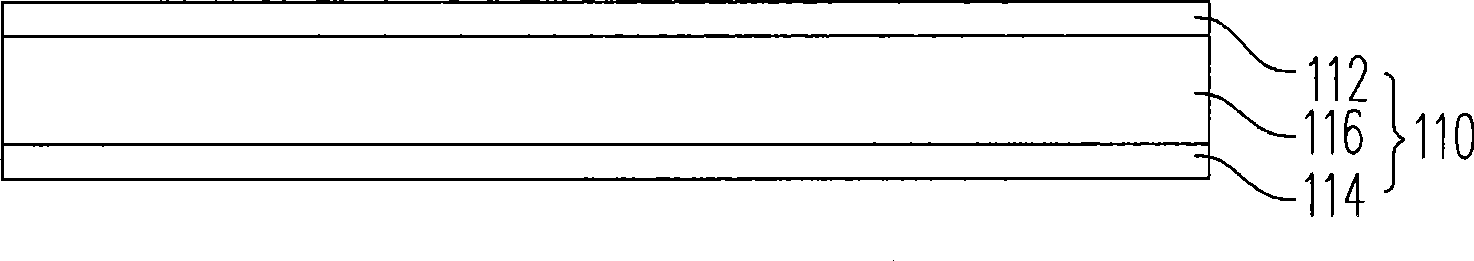

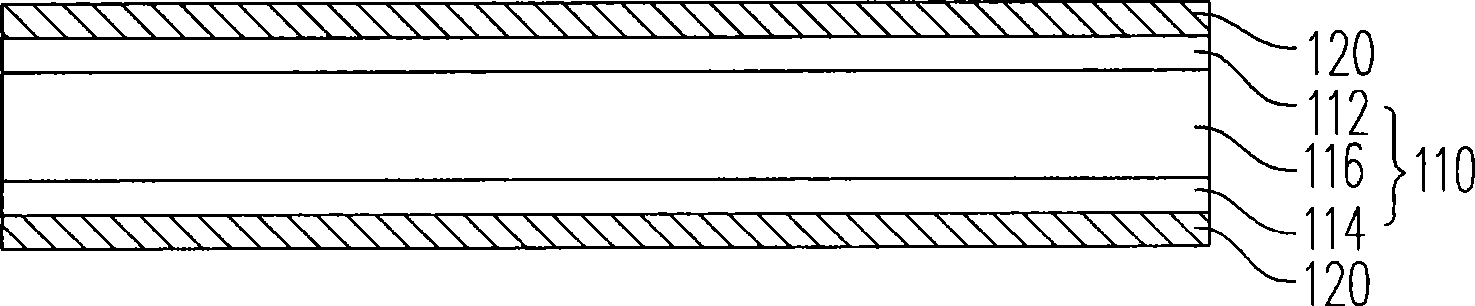

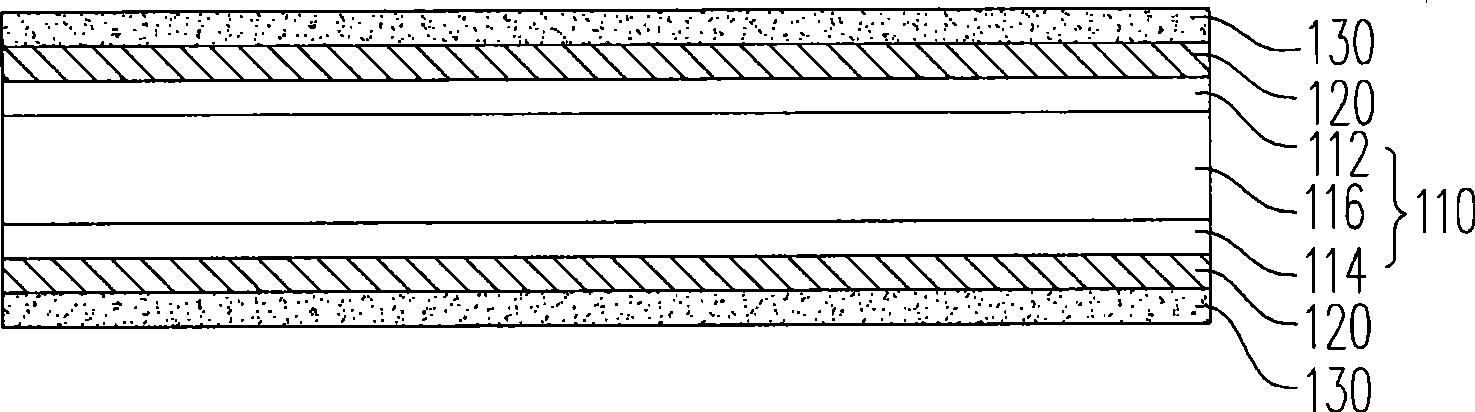

[0036] Figure 1A to Figure 1K A cross-sectional view showing the process of a method for manufacturing an embedded circuit board according to an embodiment of the present invention. The manufacturing method of the embedded circuit board of the present embodiment comprises the following steps: first, as Figure 1A As shown, a composite carrier 110 is provided. The composite carrier 110 includes a first carrier 112, a second carrier 114, and a third carrier 116. The first carrier 112 and the second carrier 114 are located on the third carrier 116 respectively. on both sides. Next, if Figure 1B to Figure 1F As shown, the circuit layer 120' is formed on the first carrier 112 and the second carrier 114 respectively. Hereinafter, this embodiment will firstly describe the formation method of the circuit layer 120' in detail.

[0037]Based on the above, in this embodiment, the method of forming the circuit layer 120 ′ on the first carrier 112 and the second carrier 114 includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com