Steel slag tipping carrier loader

A technology for carrying vehicles and steel slag, which is applied in the direction of improving process efficiency, etc., and can solve problems such as the inability to realize the automatic locking of the slag tank, the high utilization rate of the running vehicle, and large steel slag particles, so as to improve the efficiency of a single operation , Reduce the labor utilization rate and improve the utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following description is only used to explain the present invention, and is not intended to limit the present invention.

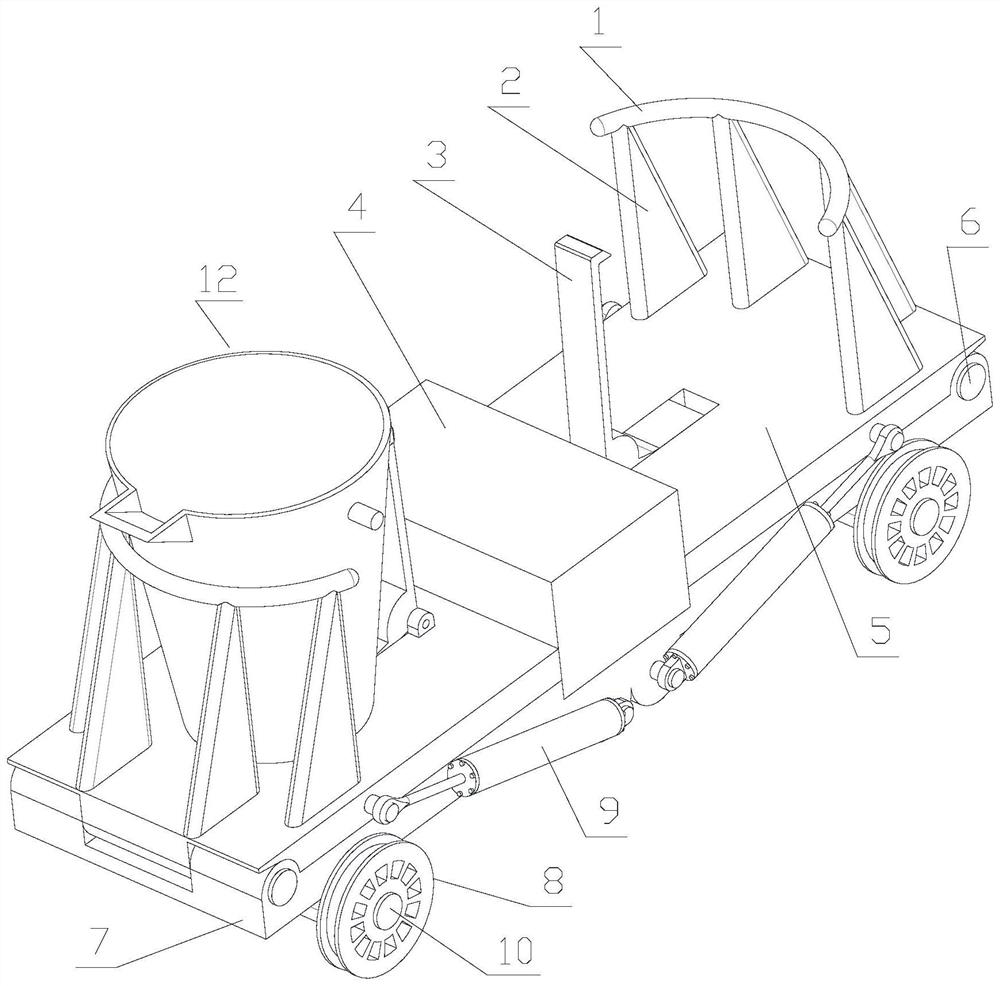

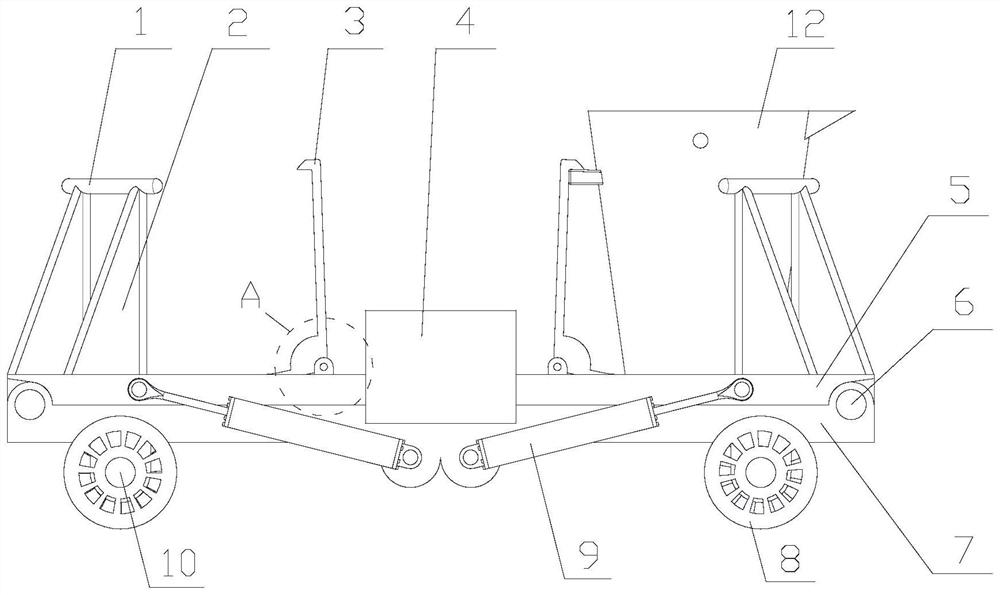

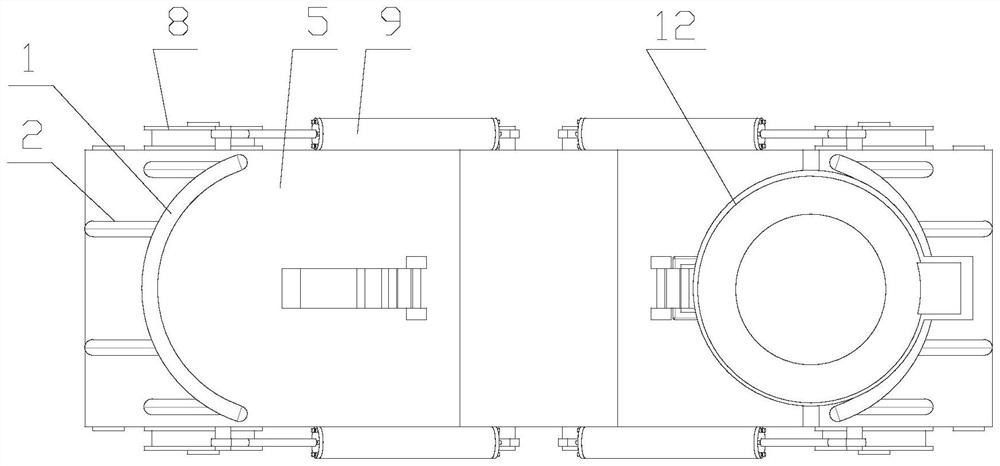

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a steel slag tipping vehicle of the present invention includes a slag tank 12, a slag tank tipping plate 5, and a vehicle frame 7, wherein two tank bodies 1201 are respectively placed on two slag tank tipping plates 5, and two The slag tank tipping plate 5 is hinged on both sides of the vehicle frame 7 and can be turned over in the opposite direction under power drive. The bottom of the vehicle frame 7 is provided with wheels 8 .

[0025] Both slag tank tipping plates 5 are provided with a slag tank guardrail 1, a guardrail bracket 2, and a self-locking hook 3. The slag tank guardrail 1 is fixed on the guardrail bracket 2, and the guardrail bracket 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com