Partial prefabricated reinforcing structure of existing H-shaped steel column and construction process thereof

A technology for strengthening structures and construction techniques, which is applied in the direction of columns, pillars, pier columns, etc., and can solve problems such as long periods, changes in building shapes, and limited increase in column bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

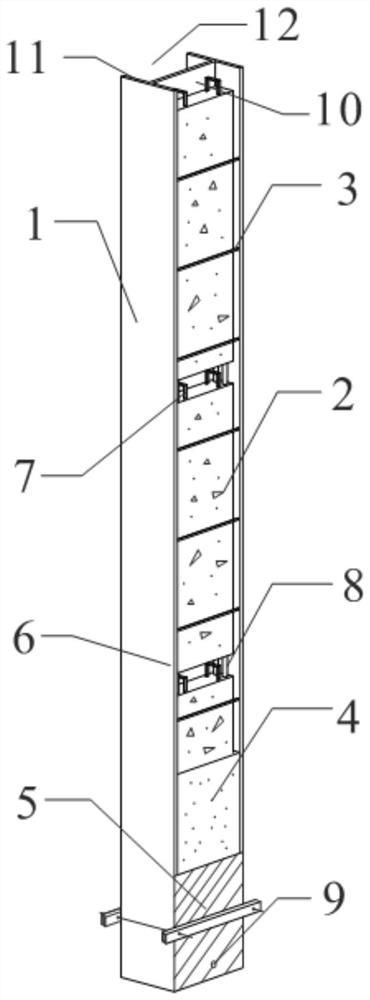

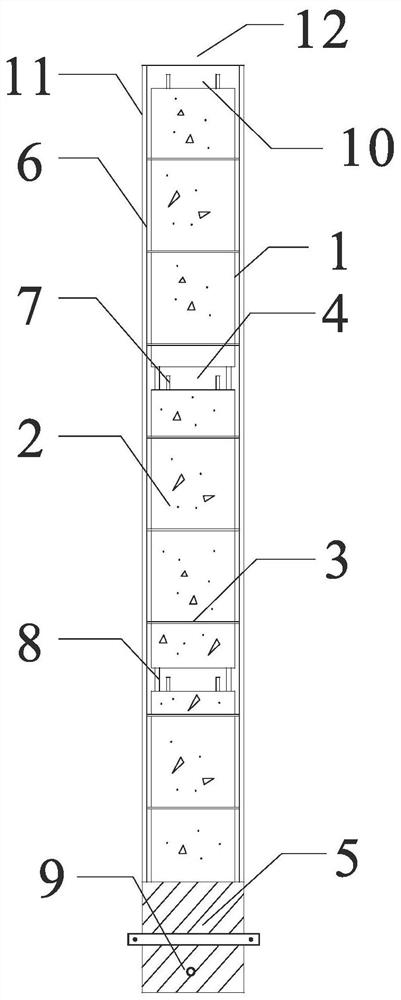

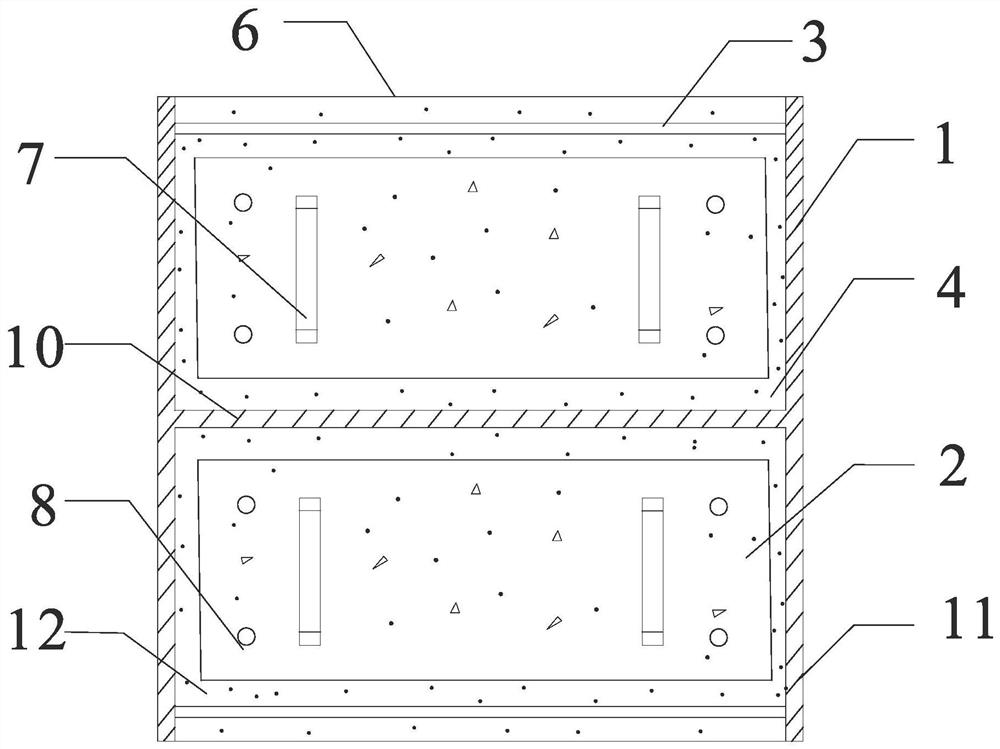

[0037] like Figure 1 to Figure 3 As shown, this embodiment provides a partially prefabricated reinforced structure with existing H-shaped steel columns, including: existing H-shaped steel columns 1 , several prefabricated concrete segments 2 , several horizontal tie rods 3 and grouting material 4 .

[0038] The length of the existing H-shaped steel column 1 is 3800 mm (the standard story height of a multi-storey steel structure building), the cross-sectional size is 600 mm × 600 mm, and the width of the web and flange is 16 mm. Steel grade Q345. The existing H-shaped steel column 1 includes a web 10 and two flanges 11 relatively fixedly arranged on both sides of the web 10 , two semi-closed cavities 12 are enclosed by the two surfaces of the web 10 and the two flanges 11 .

[0039] Several prefabricated concrete segments 2 are stacked one by one in two semi-closed cavities 12 along the length direction of the existing H-shaped steel column 1 . The tops of the prefabricated ...

Embodiment 2

[0046] It is basically the same as Embodiment 1, except that this embodiment also provides a construction process of a partially prefabricated reinforced structure with H-shaped steel columns in Embodiment 1.

[0047] This embodiment is also equipped with a template 5, which is used to fill the two semi-closed spaces of the existing H-shaped steel column 1 before pouring the grouting material 4 into the gap between the existing H-shaped steel column 1 and the prefabricated concrete segment 2. Chamber 12 is closed. The template 5 includes two long slats, the length of the long slats is not less than the length of the existing H-shaped steel column 1, and the width is not less than the distance between the two flanges 11 of the existing H-shaped steel column 1. Bottoms of the two strips are provided with grouting holes 9 .

[0048] A construction process for a partially prefabricated reinforced structure with existing H-shaped steel columns, comprising the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com