Automatic feed feeding machine for livestock breeding

A technology of automatic feeding and feeding, applied in animal husbandry, application, poultry industry, etc., can solve the problems of raising the cost of breeding, affecting the appetite of livestock, affecting the next consumption, etc., so as to reduce the amount of labor used and the intensity of labor. , the effect of reducing the amount of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

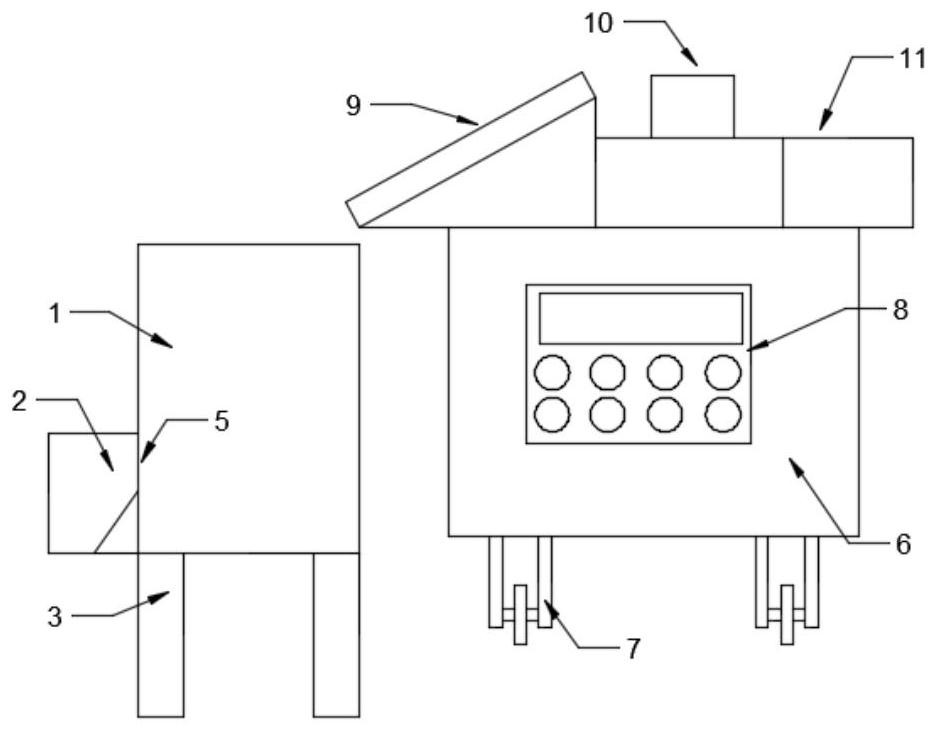

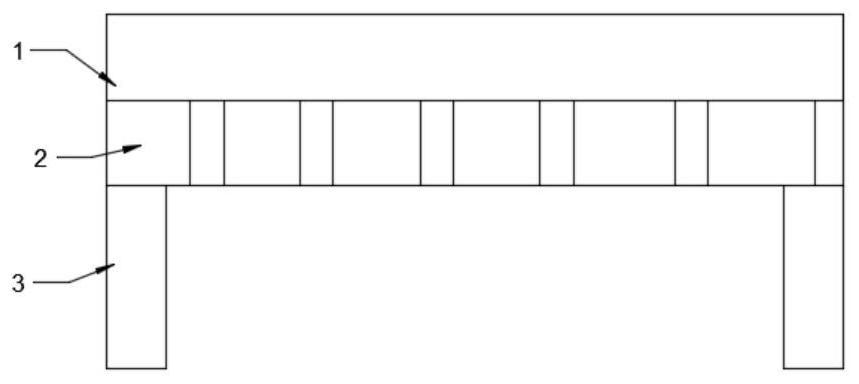

[0032] see Figure 1-12 , in the embodiment of the present invention, an automatic feed feeder for animal husbandry, comprising: a trough 1, a food box 2 is fixed on one side of the trough 1, and a leg 3 is fixed on the bottom of the trough 1, so that The trough body of the hopper 1 on one side of the food box 2 is provided with a feed opening 4, and a baffle mechanism 5 is fixedly installed on the feed chute 1 on the feed opening 4, and the other side of the feed trough 1 is provided with There is a mobile box 6, the bottom of the mobile box 6 is equipped with universal wheels 7, the casing of the mobile box 6 is provided with a control panel 8, and the top of the mobile box 6 is fixedly equipped with an unloading mechanism 9. A transfer mechanism 10 is fixedly installed on one side of the feed mechanism 9, and a feed stirring mechanism 11 is fixed on the top of the moving box 6 on the other side of the transfer mechanism 10.

Embodiment 2

[0034] see Figure 1-12, in this embodiment, the baffle plate mechanism 5 includes: a guide rail 501 fixedly installed on the trough 1 on both sides of the feed opening 4, a baffle plate 502 is slidably installed in the guide rail 501, the The upper part of the baffle plate 502 is rotatably connected with a first connecting rod 503, the other end of the first connecting rod 503 is rotatably connected with a crutch 504, and the middle part of the crutch 504 is rotatably connected with a first rocker 505, and the first rocker The end of 505 is provided with a first rotating pin 506, and the first rotating pin 506 is fixedly installed on the tank body of the trough 1, and the other end of the turning rod 504 is connected with a first crank 507 in rotation, and the first crank 507 A first rotating rod 508 is fixedly installed at the end.

[0035] In this embodiment, the size of the baffle 502 is larger than that of the feeding opening 4, and the baffle 502 is used to block the fe...

Embodiment 3

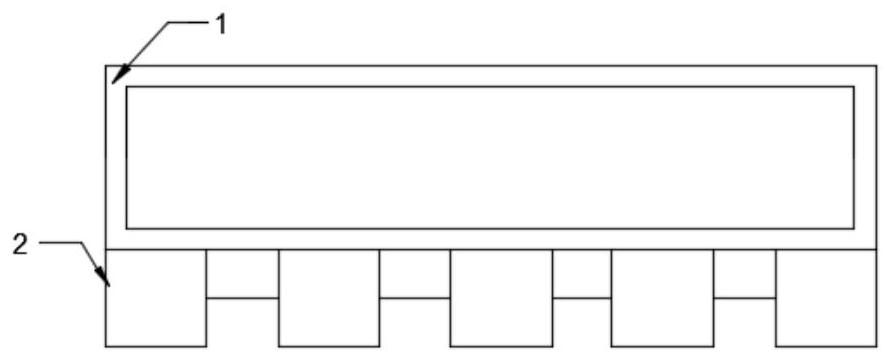

[0037] see Figure 1-12 , in this embodiment, the dumping mechanism 9 includes: a base 901, a first rotating base 902 is fixed on one side of the upper part of the base 901, and a first pole 903 is rotatably mounted on the first rotating base 902, so The middle part of the first pole 903 is provided with a second pivot pin 913, and the second pole 907 is rotated on the second pivot pin 913 at the same time, and the top of the first pole 903 and the second pole 907 are fixedly installed. There is a flat plate 908; the other side of the base 901 is fixed with a slot plate 904, and the slot plate 904 is provided with a chute 905, and a round rod 906 is slidably installed in the chute 905, and the two ends of the round rod 906 It is rotatably connected with the second pole 907, and a rolling bar 909 is rotatably installed inside the base 901, and a rotating connecting block 910 is arranged in the middle of the rolling bar 909, and a hydraulic press 911 is fixedly installed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com