Double-point type lateral spot welding device

A spot welding device and spot technology, used in welding monitoring devices, auxiliary devices, welding power sources, etc., can solve problems such as operation safety and operation errors, improve safety, reduce spot welding error rate, and improve spot welding. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

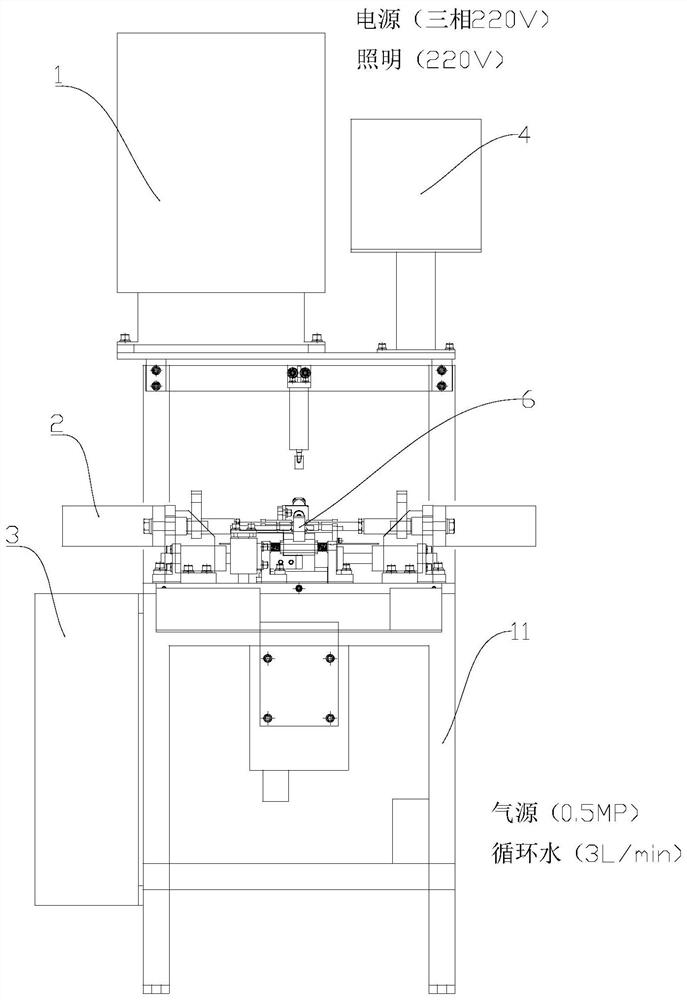

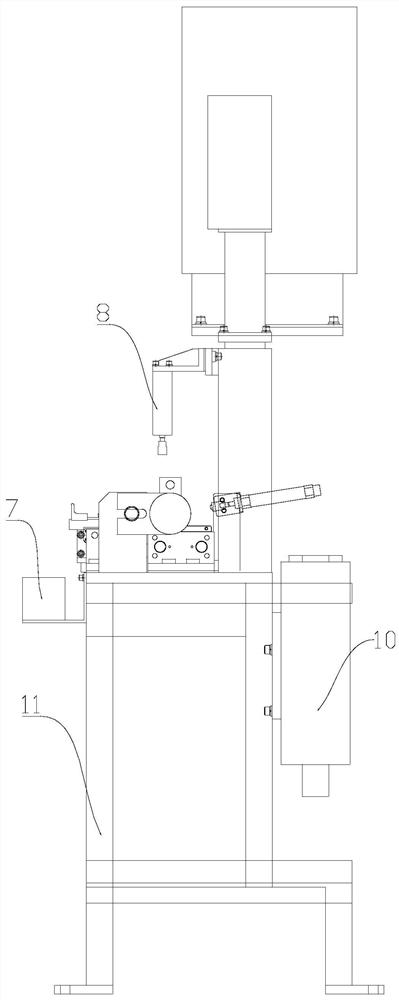

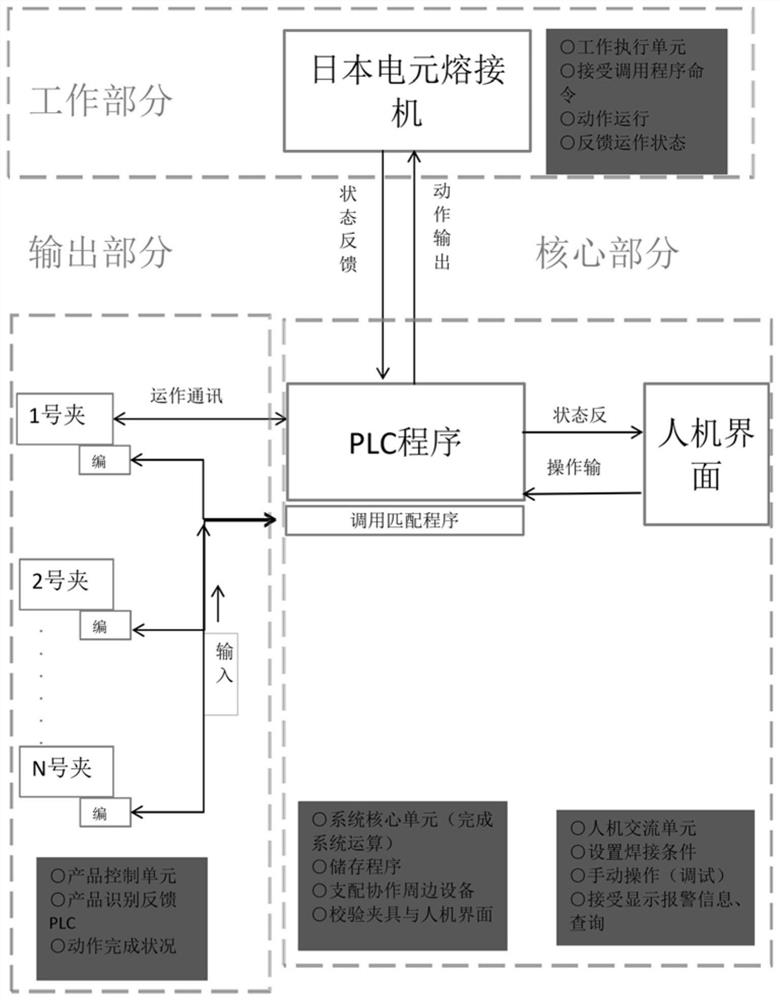

[0021]Such asFigure 1-3As shown, a two-point lateral spot welding device of the present invention includes a base 11, a product jig 6 and a spot welding device mounted to the seat 11, and a control device, the control device controlling a spot welding device. Operation, the control device includes a storage unit for storing actions and an operation procedure, a state value of a current, torque, including a motor, a torque including a spot welding device, and formed to implement the following detection control: The various points of the spot welding device set parameter control, based on the state value of the electric welding device drives the motor, the workpiece detection parameter, the workpiece operator status value is disengaged from the predetermined range; the product clamp 6 includes The lower entry positioning seat 601 and the product clamp 602, the clamp positioning seat 601, is equipped with a plurality of sets of product clamps 602, which encodes the FDTI 1248 protocol e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com