Biological feed manufacturing system

A production system and biological feed technology, applied in the field of biological feed production systems, can solve the problems of poor fermentation air, low fermentation quality and fermentation efficiency, and achieve the effects of improving production efficiency, improving air circulation, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

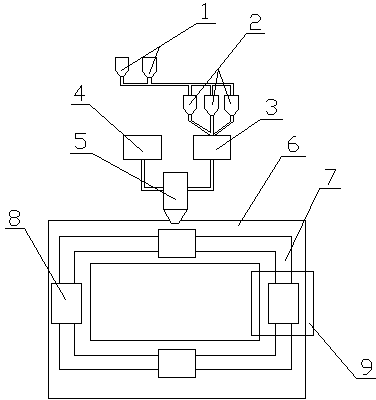

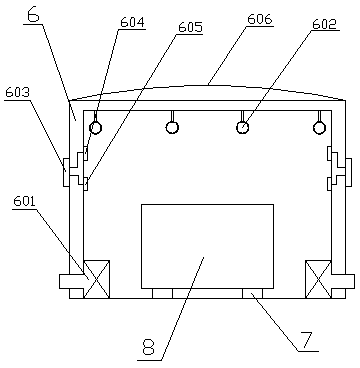

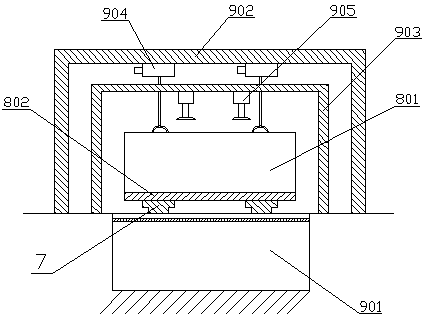

[0021] As shown in the figure, a production system of biological feed includes a first-stage reactor 1 and a second-stage reactor 2 for fermenting and propagating various strains, a strain fermentation culture tank 3 for mixing and fermenting various strains, and inoculating and mixing materials. The mixing machine 5 for bacteria and mixing. The mixed material inoculated in the mixing machine 5 is loaded by the fermentation car 8 and fermented in the ring-shaped fermentation kiln 6. After the fermentation car 8 moves to the unloading platform 9 to complete the fermentation and unload The material loaded by the fermentation car 8, the circular fermentation kiln 6 is provided with a conveying track 7 supporting the fermentation car 8, the top of the kiln is provided with a heat delivery pipe 602 for maintaining the temperature in the kiln, and the outer wall of the kiln is provided for displaying kiln temperature. A display screen 603 for temperature and humidity in the kiln,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com