An energy-saving and environment-friendly intermediate frequency heating automatic temperature control concrete curing system

A curing system and automatic temperature control technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of uncontrollable temperature and humidity, pollution of the environment, high energy consumption for concrete curing, etc., to achieve outstanding quality, simple equipment, temperature and The effect of uniform and controllable humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

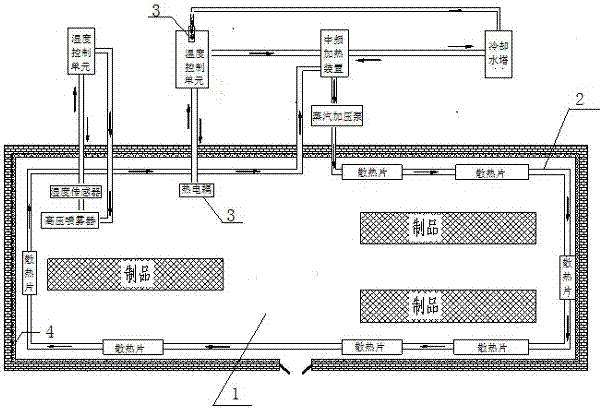

[0033] An energy-saving and environment-friendly medium-frequency heating automatic temperature-controlled concrete curing system, including a curing room 1, a temperature control device and a humidity control device that respectively control the temperature and humidity in the curing room 1, and the curing system cures concrete products by injecting steam, The steam is made by heating water with an intermediate frequency heating device connected to the curing room 1 .

[0034] Further, the intermediate frequency heating device is connected to the steam pipe 2 arranged along the inner wall of the curing room 1 , and the steam produced by the intermediate frequency heating device enters the curing room 1 through the steam pipe 2 .

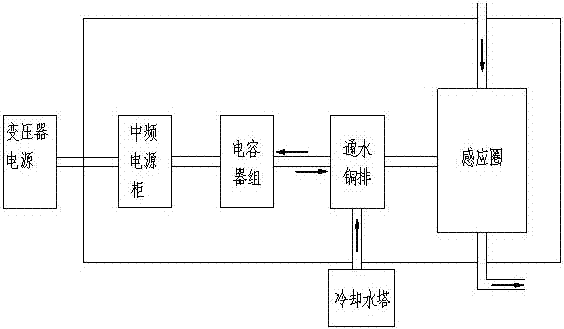

[0035] The intermediate frequency heating device includes an intermediate frequency power supply cabinet, a capacitor bank, a water copper bar and an induction coil connected in sequence, and the induction coil is connected to the steam pipeline 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com