Floor washing and sucking-drying equipment

An equipment and floor washing technology, applied in cleaning equipment, carpet cleaning, floor cleaning, etc., can solve the problem that the brush plate and squeegee cannot adapt to different ground conditions, and the brush plate and squeegee cannot adapt to different ground conditions. The cleaning performance of the brush plate, the water absorption performance of the squeegee, etc., can ensure the effect of washing the floor, improve the anti-seismic effect, and optimize the space layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

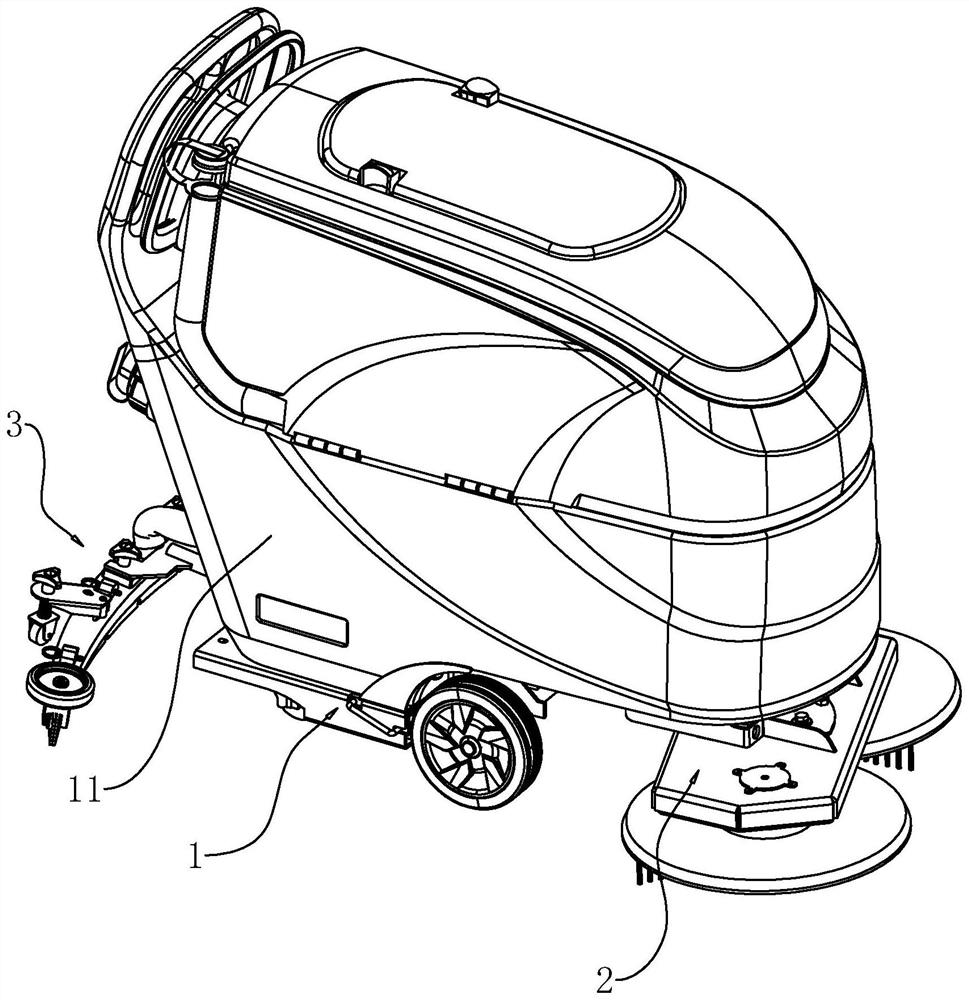

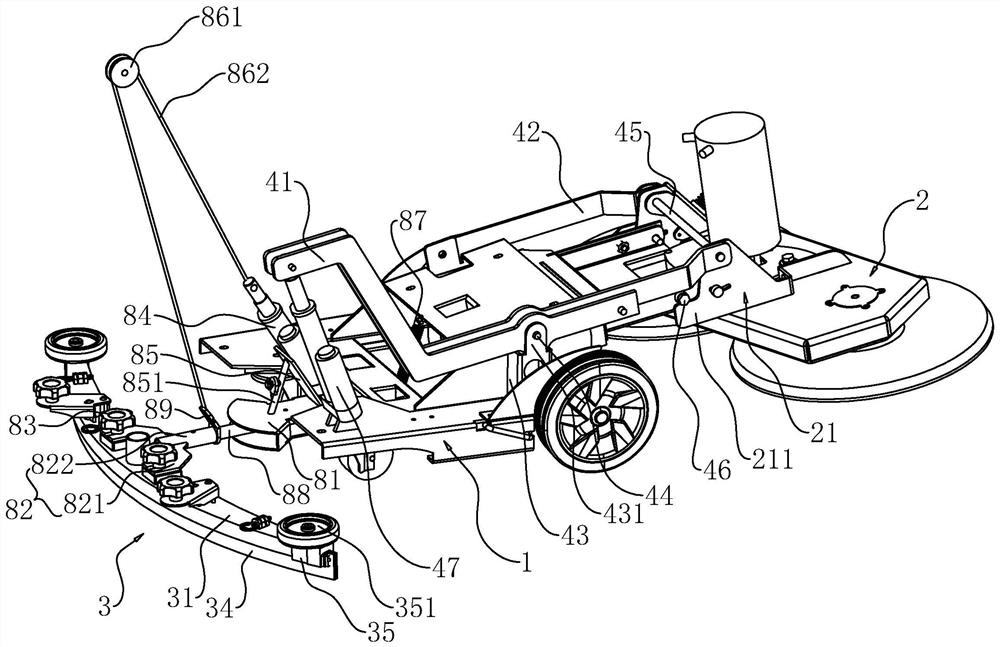

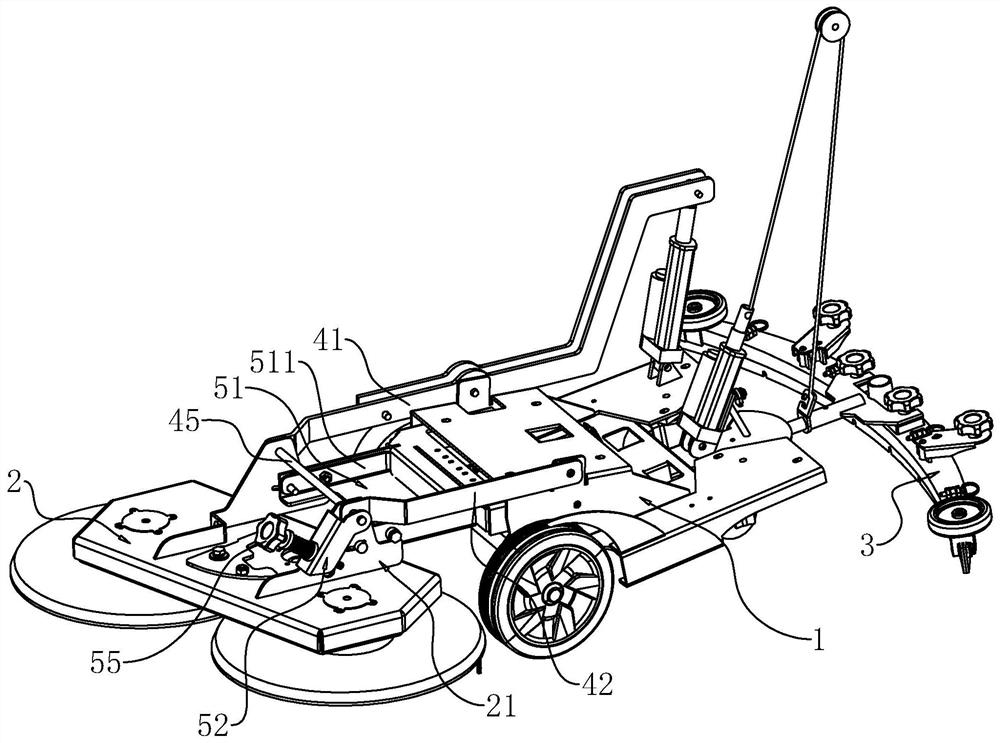

[0056] Embodiment one, with reference to figure 1 with figure 2 , the floor scrubbing and drying equipment includes frame 1, brush plate 2 and squeegee 3, frame 1 is a sheet metal part, and sheet metal has the characteristics of light weight and high strength, so frame 1 can maintain low weight For better strength, a water tank 11 is fixedly arranged on the frame 1 . refer to figure 2 The frame 1 is provided with a first lifting structure for controlling the lifting of the brush plate 2 and a second lifting structure for controlling the lifting of the squeegee 3 .

[0057] refer to figure 2 , the first lifting structure includes a swing arm group hinged on the left and right sides of the frame 1, and the rotation axes between the swing arm groups are collinear. In this embodiment, the swing arm group includes a first swing arm 41 and a second swing arm 42. The first swing arm 41 and the second swing arm 42 are also sheet metal parts, so that the first swing arm 41 and t...

Embodiment 2

[0099] Embodiment two, refer to Figure 12 The difference from Embodiment 1 is that the bottom of the water suction head 32 is provided with water guide grooves 91, and the water guide grooves 91 are respectively opened on both sides of the water suction hole 321, and the water guide grooves 91 on both sides are connected to the water suction hole 321, and the water guide grooves 91 corresponds to the shape of the water suction head 32 and extends in an arc, and the groove width of the water guide groove 91 gradually decreases from the end close to the water suction hole 321 to the end far away from the water suction hole 321 .

[0100] The implementation principle of a floor washing and drying equipment in the embodiment of the present application is: when the water suction head 32 absorbs water, the opening of the water guide groove 91 can guide the sewage to accelerate into the water suction hole 321, so that the sewage can be easily sucked into the water suction head 32, T...

Embodiment 3

[0101] Embodiment three, refer to Figure 13The difference from the first embodiment is that the grill seat 31 is protrudingly provided with a bump 921, and the interior of the bump 921 is hollow, and the grill seat 31 is provided with a mounting hole 922, and the mounting hole 922 runs through the grill seat 31 and communicates with the interior of the bump 921 , the suction head 32 is provided with a mounting block 923, the mounting block 923 can penetrate into the protrusion 921 through the mounting hole 922, the mounting block 923 and the protrusion 921 are fixed by a spring pin 93, and one end of the spring pin 93 is connected with a first pull Ring 931 , the first pull ring 931 is convenient for people to pull out the spring latch 93 .

[0102] The implementation principle of a floor washing and drying equipment in the embodiment of the present application is: by inserting the installation block 923 of the water suction head 32 into the protrusion 921, and passing the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com