Infrared temperature measurement and variable emittance based laser welding safety control method and system

A technology of laser welding and infrared temperature measurement, which is applied in welding equipment, manufacturing tools, electric heating devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The system and method of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the technical solution of the present invention, and are not used to limit the protection scope of the present invention.

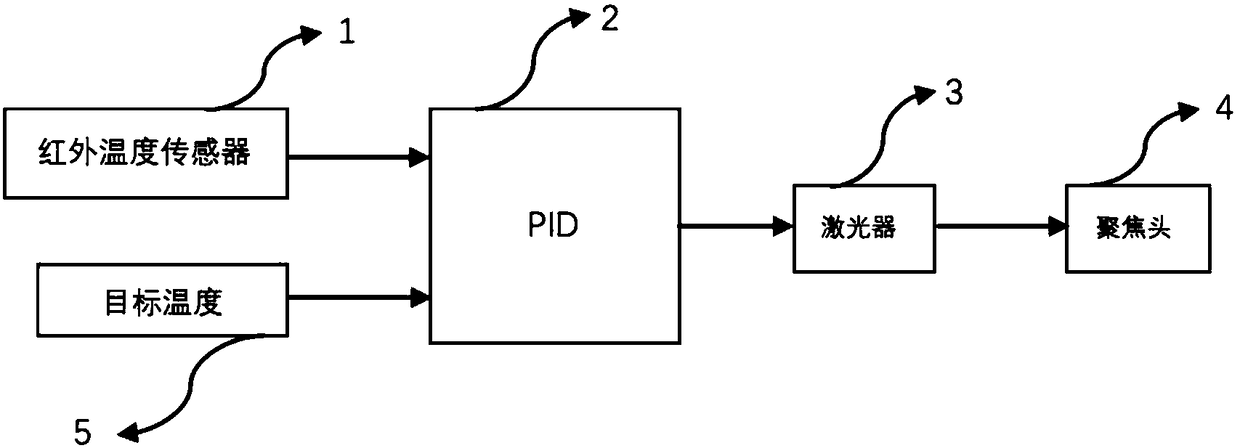

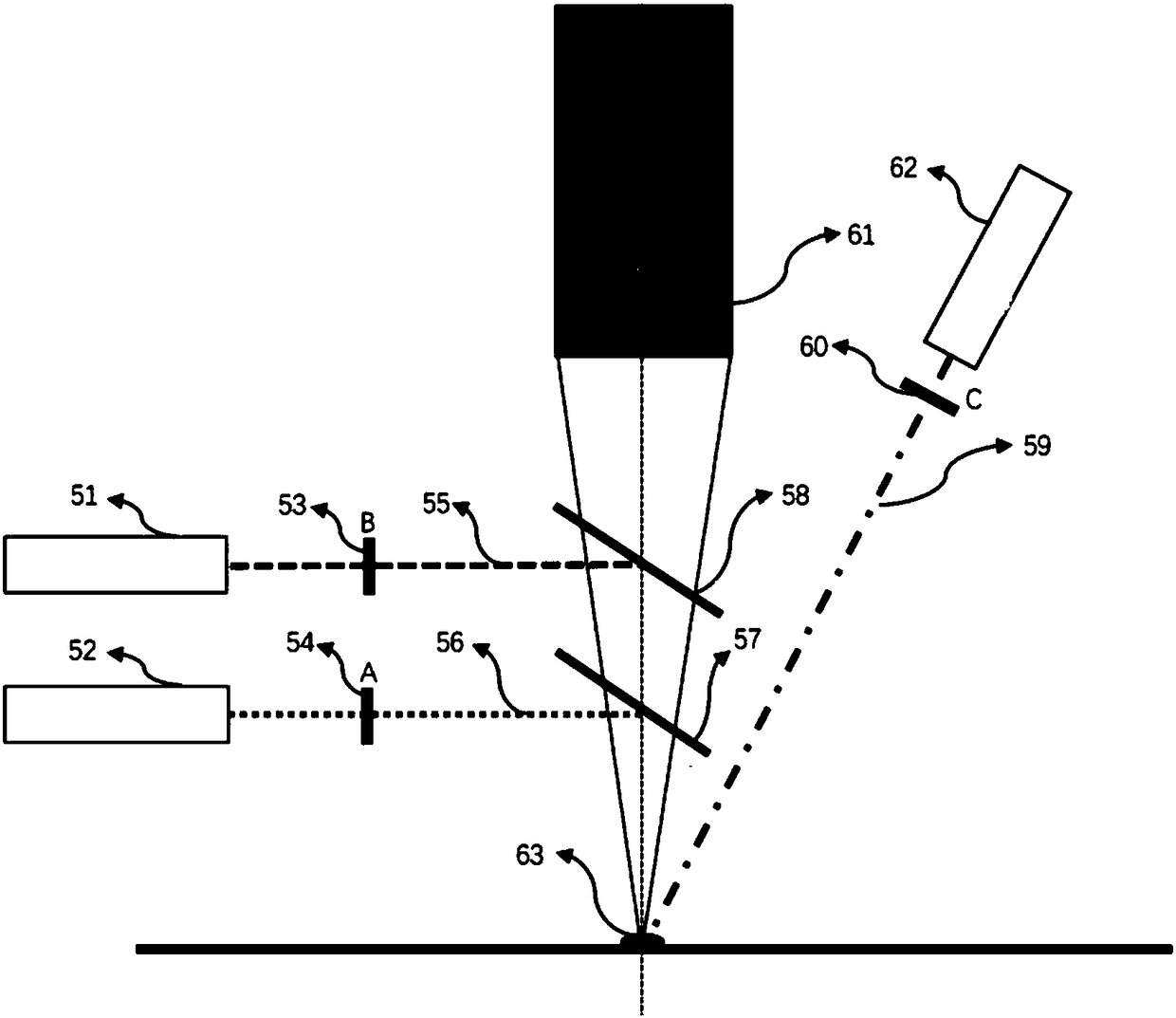

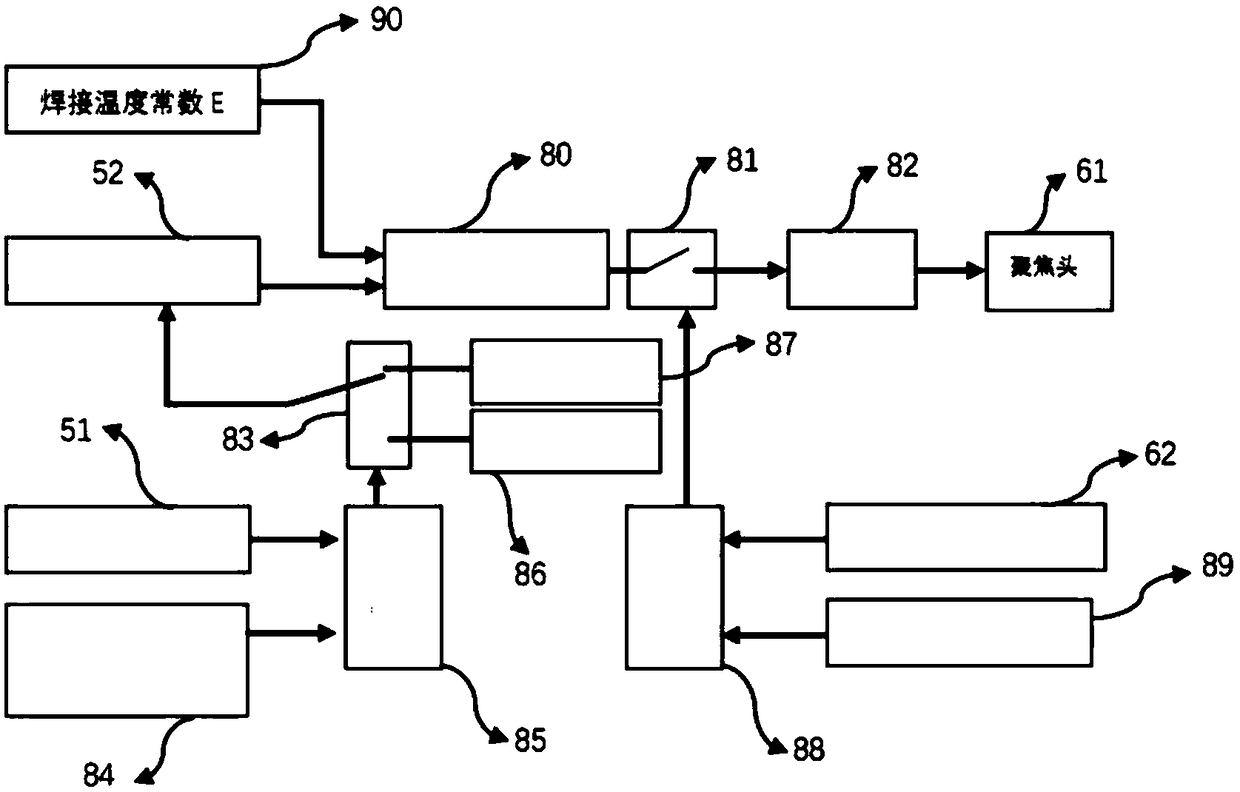

[0042] Such as figure 2 As shown, the technical solution system of the present invention includes

[0043] The optical paths of the three detection units are, respectively,

[0044] The infrared temperature detection optical path (infrared temperature detection at the laser welding point) includes a reflector A 57 , an optical filter A 54 and an infrared temperature sensor 52 arranged in sequence along the optical path 56 .

[0045] The laser reflected light intensity detection optical path at the laser welding point includes a filter C60 and a reflected light laser sensor 51 arranged in sequence along the optical path 59 .

[0046] The optical path for detecting visible light when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com