Vehicle hybrid power system achieving multi-power-source coupling

A hybrid power system and multi-power technology, which is applied to the arrangement of multiple different prime movers, power plants, pneumatic power plants, etc. low problems, to achieve the effect of improving fuel economy, low cost and low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

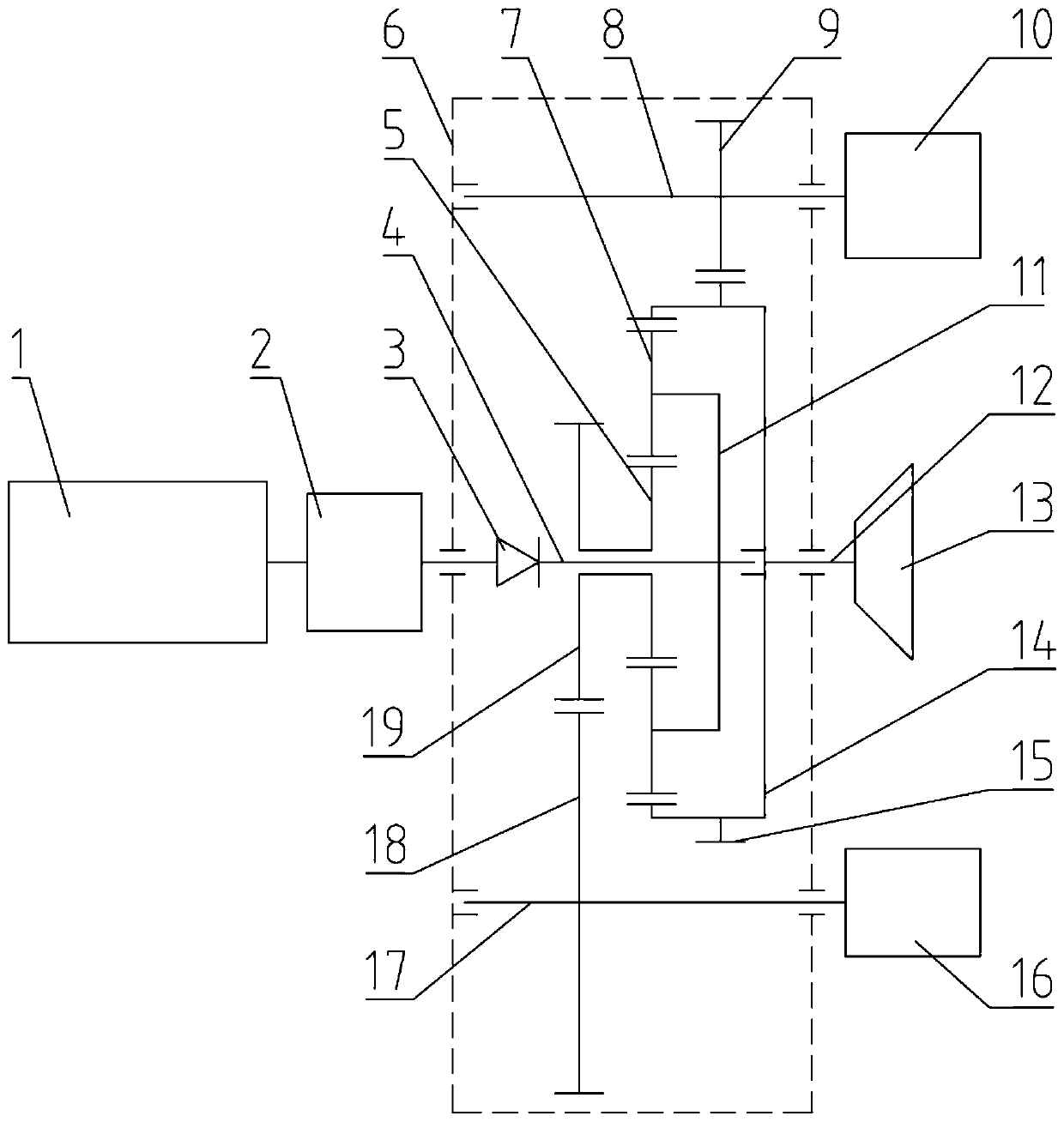

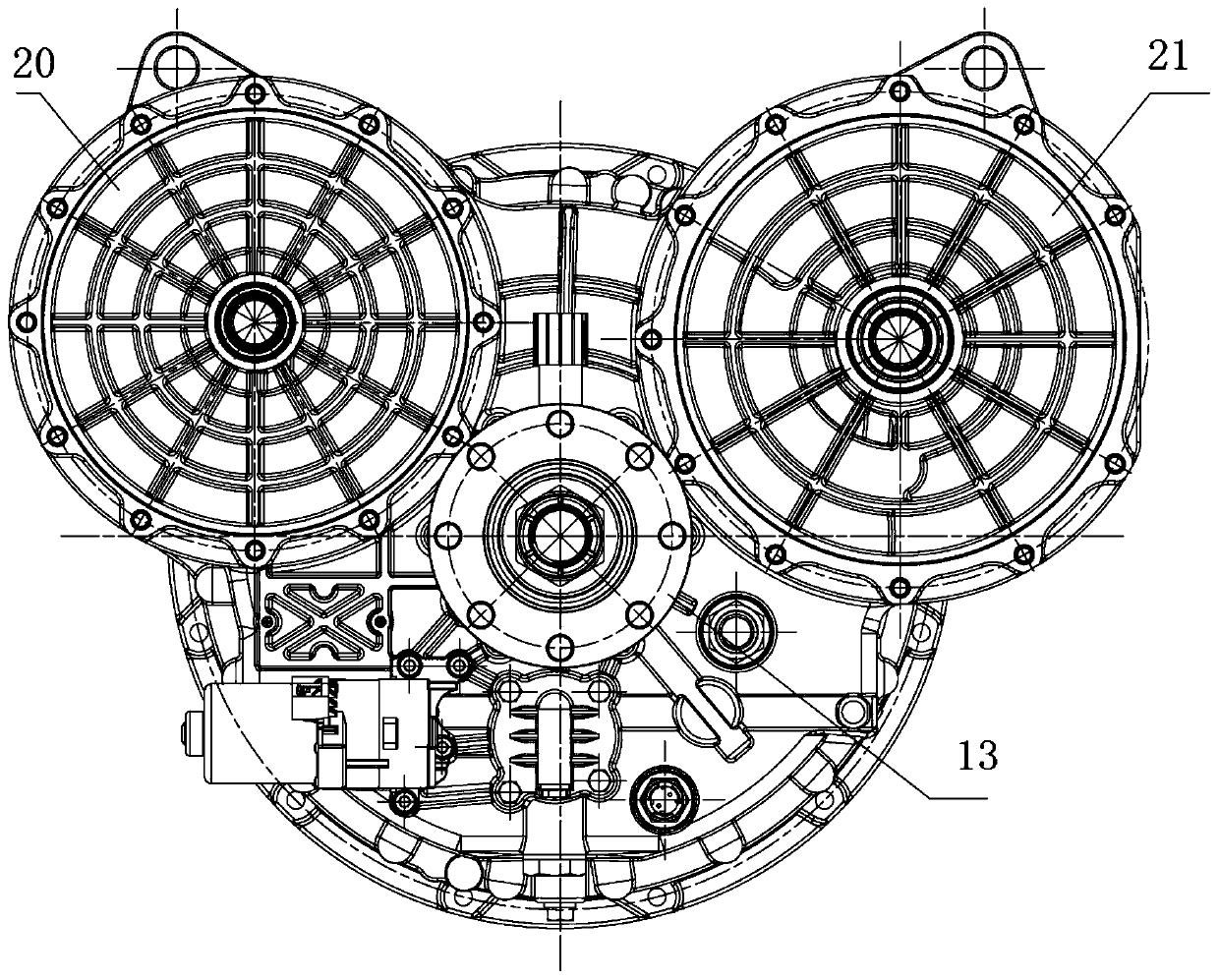

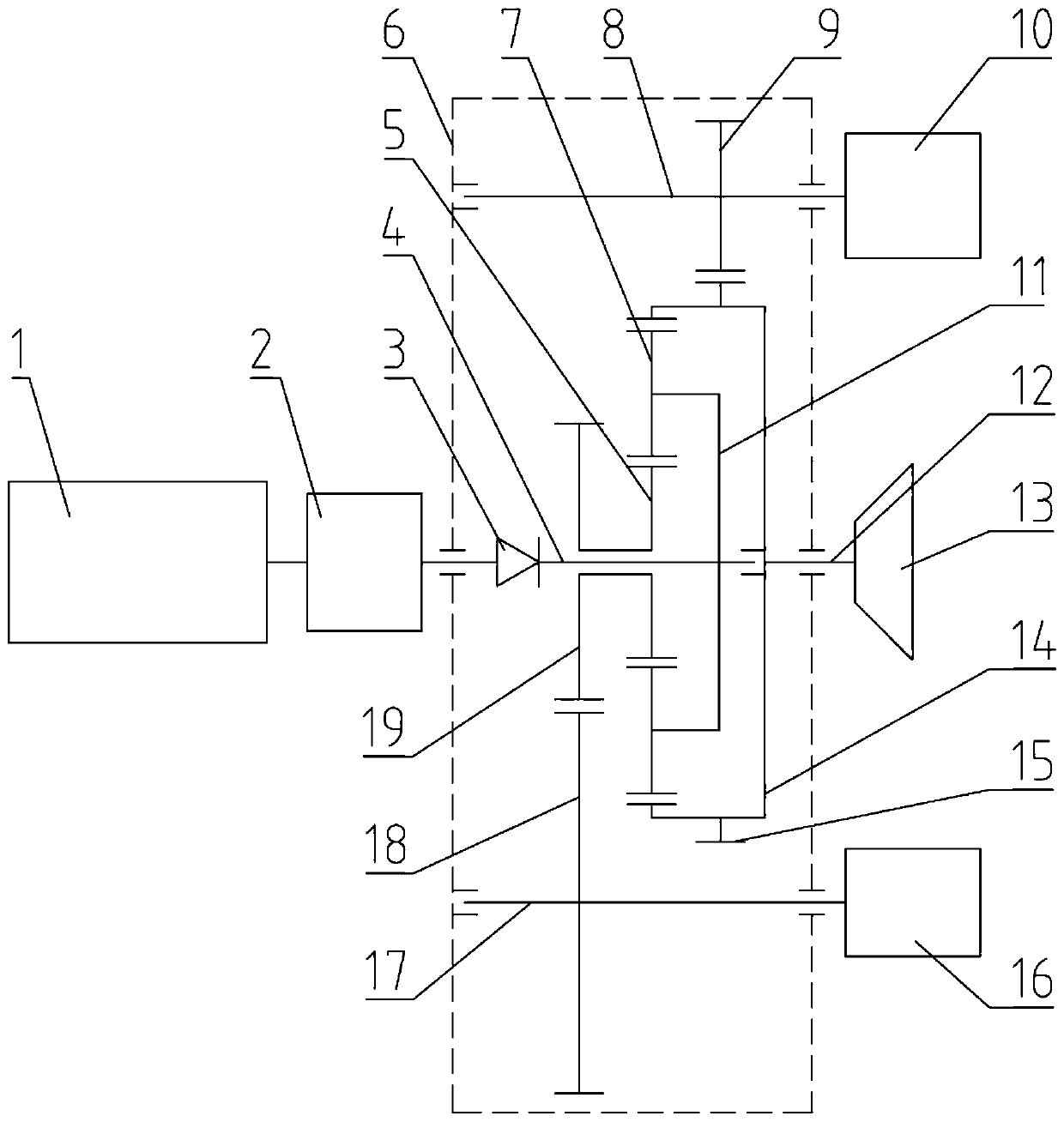

[0033] The vehicle hybrid power system that realizes the coupling of multiple power sources provided by the invention can realize the hybrid hybrid power system with the planetary differential structure as the electromechanical coupling device, realize the electronic stepless speed change function, and control the engine to always work at the best fuel Economic zone, improve the fuel economy of the whole vehicle, realize low emission, and overcome the disadvantage that the hybrid electric vehicle relies heavily on the motor and needs a large torque and low speed motor to provide sufficient driving force.

[0034] The technical scheme of the present invention is: adopting the transmission mode of "planetary differential structure + parallel shaft", the planetary row is a planetary differential structure, including a sun gear, a planetary carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com