A new type of airport prefabricated pavement system

A prefabricated, pavement technology, applied in the direction of roads, roads, special pavements, etc., can solve problems such as difficult large-scale promotion and application, difficult control, complex process, etc., to meet high-efficiency operation, high economic rationality, and reduce The effect of labor usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

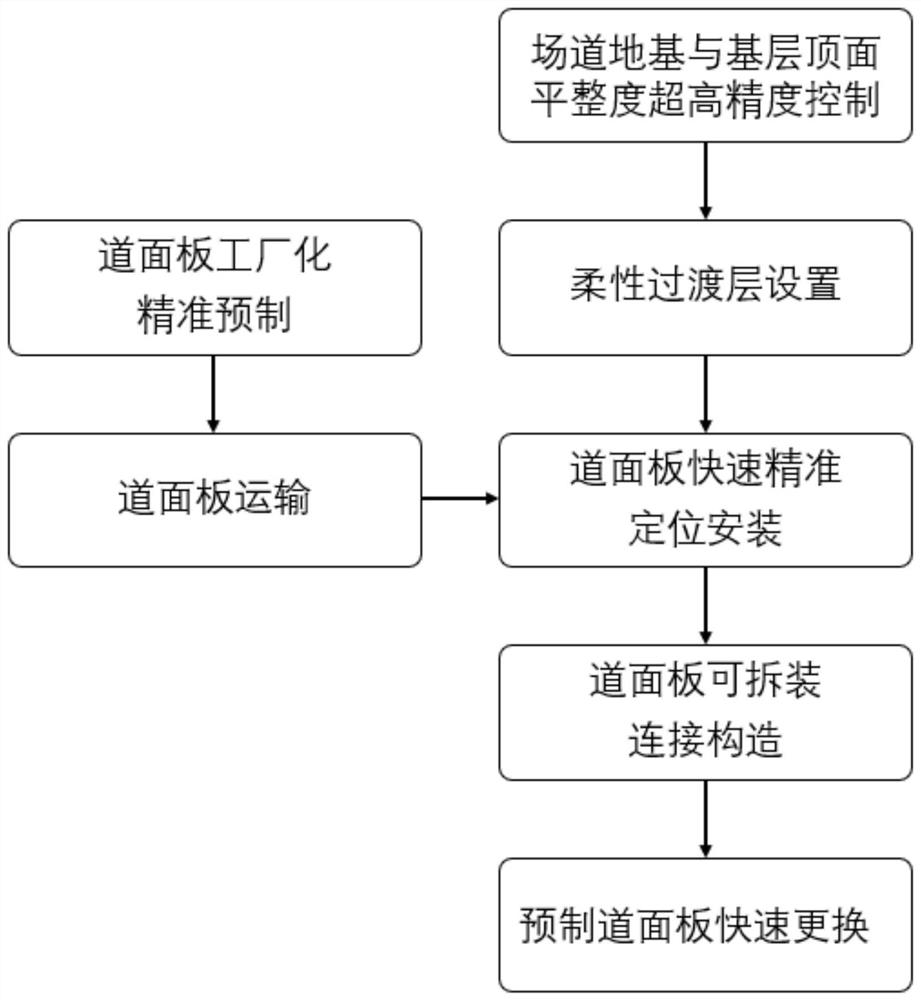

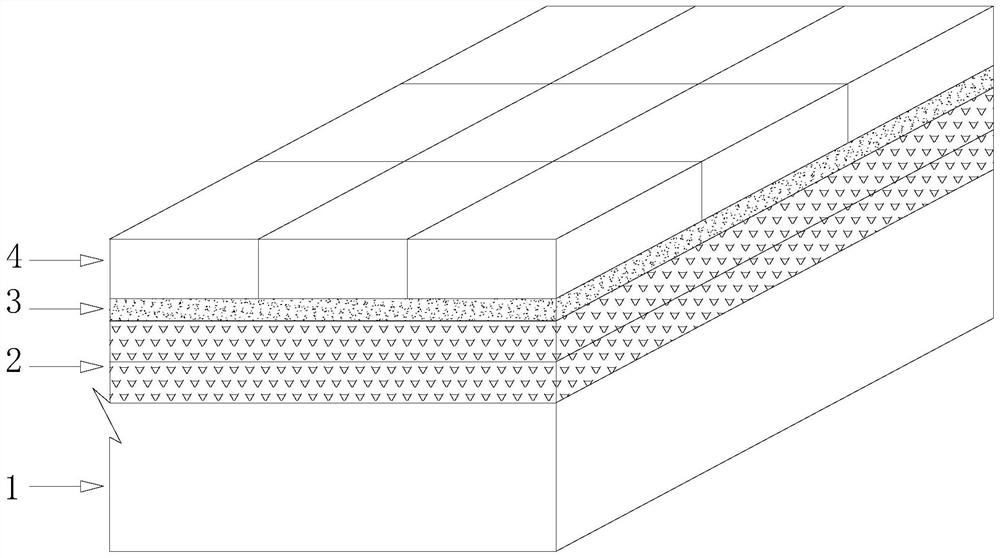

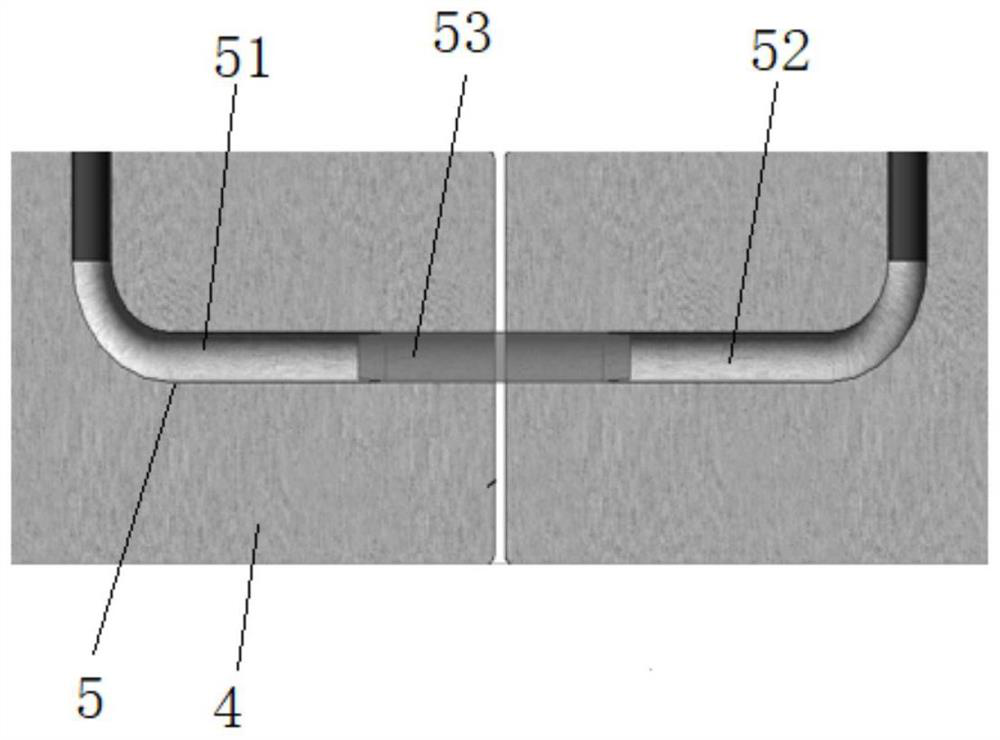

[0046] combine Figure 1 to Figure 4 , a new airport prefabricated pavement system, including a track foundation 1 and a base layer 2 arranged on the track foundation, a flexible transition layer 3 and an assembled prefabricated track panel 4 are arranged on the base layer 2 . Accurate airport pavement is achieved through the precision control method for the flatness of the foundation and the top surface of the base layer, the construction control method for the flexible transition layer, the precise positioning and installation method for the prefabricated pavement panel, the detachable connection structure of the pavement panel, and the rapid replacement method for the prefabricated pavement panel. Quick installation and replacement maintenance.

Embodiment 2

[0048]The new airport prefabricated pavement system, through the precision control method of the ground and the top surface of the base layer, the construction control method of the flexible transition layer, the precise positioning and installation method of the prefabricated road panel, the detachable connection structure of the road panel and the rapid replacement of the prefabricated road panel method to realize accurate and rapid installation, replacement and maintenance of airport pavement.

[0049] The methods for controlling the flatness accuracy of the foundation and the top surface of the base course include the following:

[0050] Step A1: Control the accuracy of the foundation, the bottom of the base layer, and the base layer from bottom to top, and improve the accuracy of the flatness layer by layer, thereby reducing the impact of the unevenness of each layer on the compaction operation of the upper layer;

[0051] Step A2, using a digital automatic control system...

Embodiment 3

[0056] The new airport prefabricated pavement system, through the precision control method of the ground and the top surface of the base layer, the construction control method of the flexible transition layer, the precise positioning and installation method of the prefabricated road panel, the detachable connection structure of the road panel and the rapid replacement of the prefabricated road panel method to realize accurate and rapid installation, replacement and maintenance of airport pavement.

[0057] The construction control methods of the flexible transitional layer include the following:

[0058] Step B1, using a flexible coiled material to lay above the base layer, and setting up and down two layers of flexible coiled material, and laying the upper and lower coiled material transition layers with staggered joints;

[0059] Step B2, when laying the flexible coil, use professional roll-laying equipment for positioning and laying to further control the surface flatness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com