Deck type color plate molding press

A technology for molding machines and color plates, which is applied to presses, metal processing equipment, feeding devices, etc., can solve the problems of difficult selection of color plate equipment, increased labor usage, and high breakage rate of color plates, and achieves The effect of saving mechanical shifts and labor costs, reducing the breakage rate, and reducing the labor utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

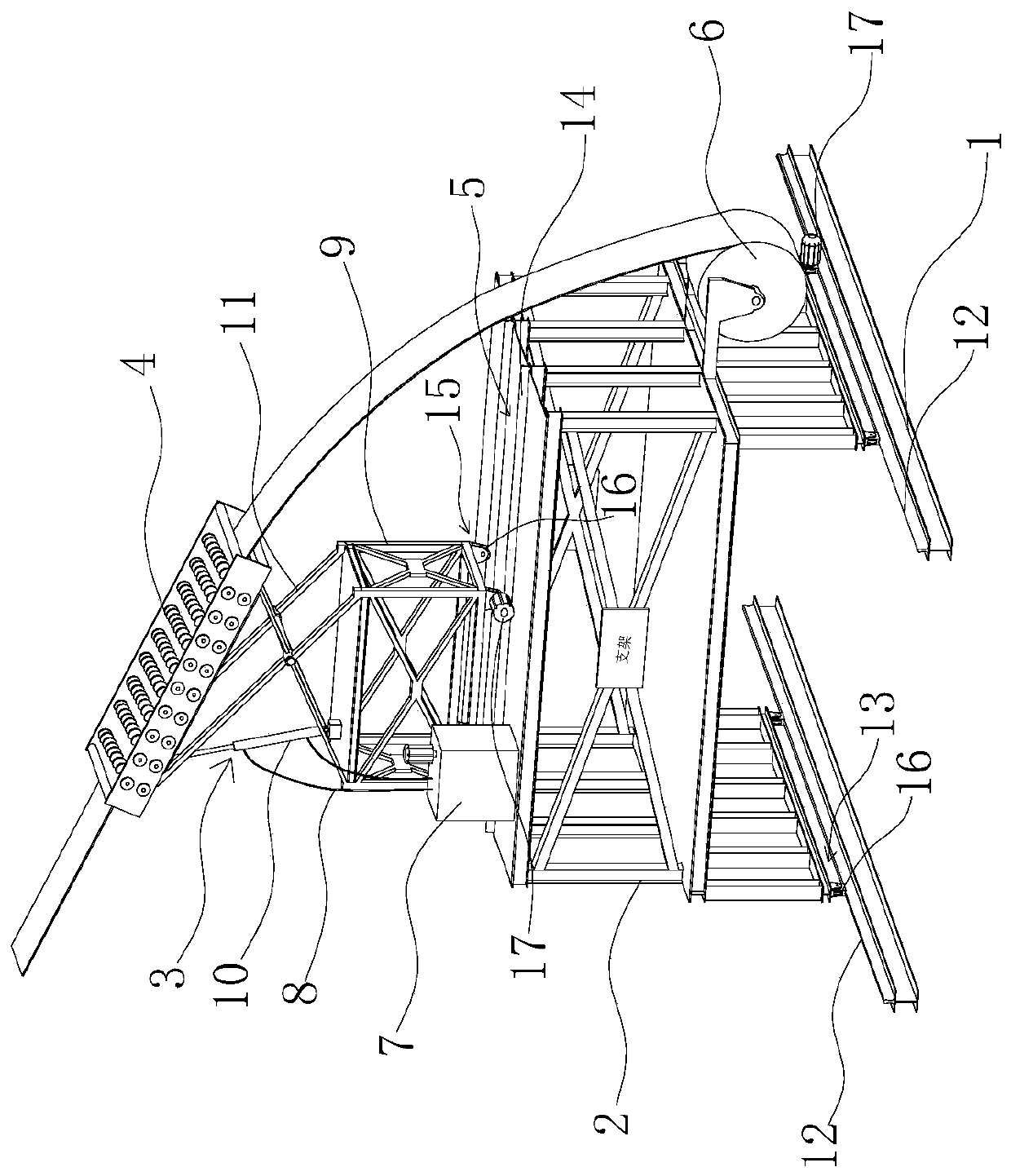

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0017] like figure 1 As shown, an upper-support type color plate molding machine includes: a longitudinal rail group 1, a first frame 2, a rocker mechanism 3 and a plate pressing machine 4, the first frame 2 is arranged on the longitudinal rail group 1, and the second A frame 2 is movably connected with the longitudinal rail group 1, the first frame 2 is equipped with a horizontal rail group 5, a color steel coil hanger 6 and a hydraulic station 7, and a second frame 9 is installed on the horizontal rail group 5, The horizontal rail group 5 is movably connected with the second frame 9, the rocker mechanism 3 has a jacking hydraulic cylinder 10, the hydraulic station 7 has a hydraulic oil pipe 8, and the hydraulic oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com