Quick assembled type sloping roof based on assembled type composite wall structural system and construction method of quick assembled type sloping roof

A compound wall and prefabricated technology, which is applied in building structure, roof, construction, etc., can solve the problems of long construction period, high energy and raw material consumption, complex formwork, etc., and achieve precise labor use, less labor use, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

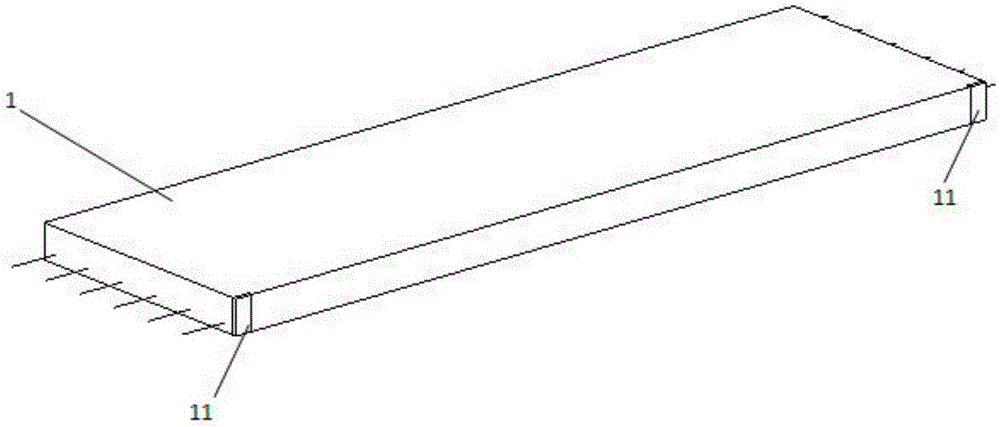

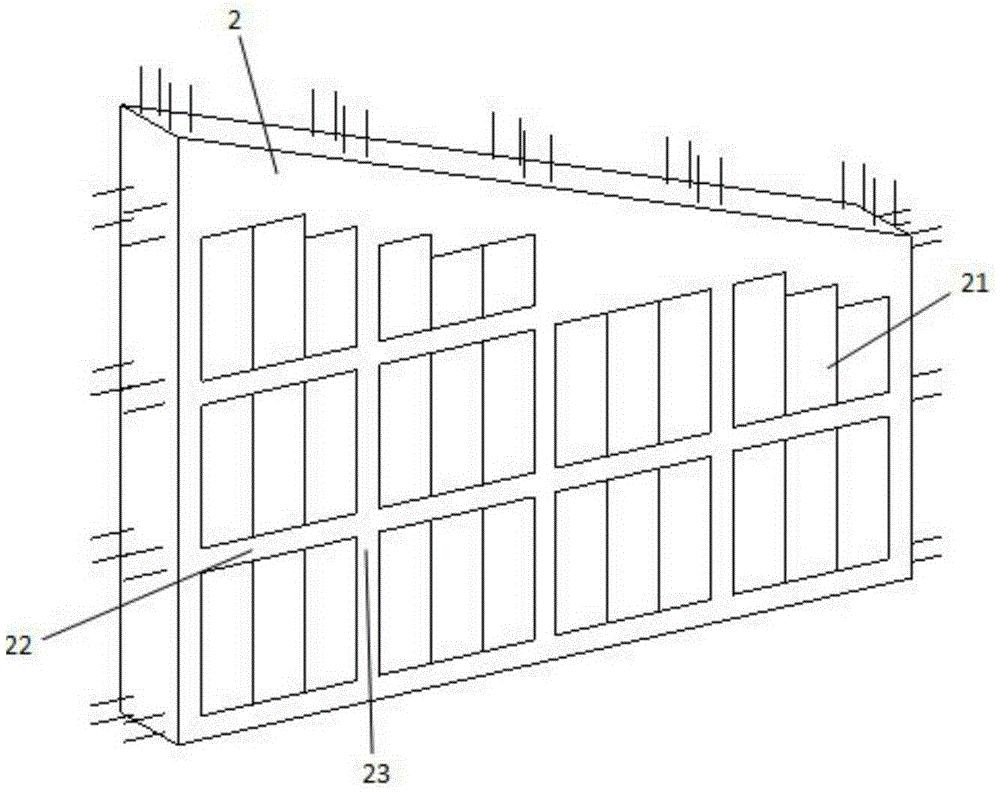

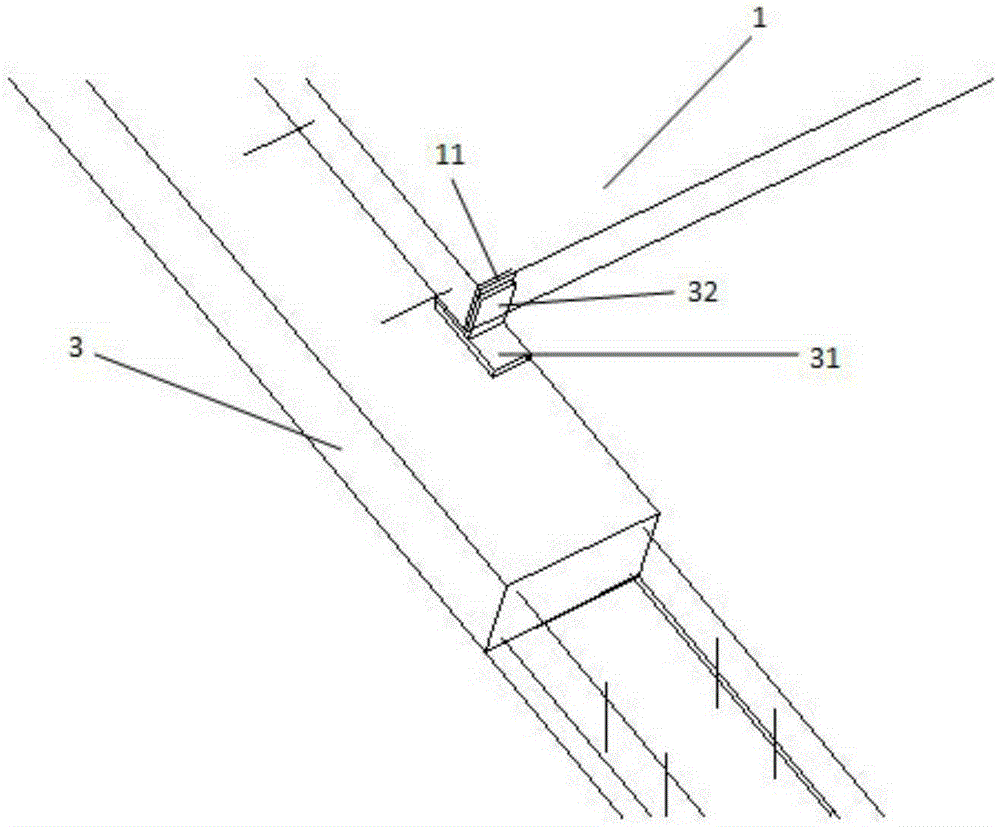

[0025] Such as figure 1 and figure 2 As shown, a rapidly assembled sloping roof based on the prefabricated composite wall structure system of the present invention is composed of main components including a prefabricated sloping roof panel 1 and a prefabricated composite ridge wall panel 2 assembled on site. Among them, the lower surface of the prefabricated sloping roof panel 1 is pre-embedded with a number of angle steels 11, the upper part of the prefabricated composite ridge wall panel 2 has a hidden beam 3, and the top surface of the hidden beam 3 is pre-embedded with a welding plate 31, and on the welding plate 31 The angle steel 2 32 corresponding to the angle steel 11 is welded, and the connection between the concealed beam 3 and the prefabricated sloping roof panel 1 is realized through the welding of the angle steel 11 and the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com